Professional Documents

Culture Documents

FBC Boiler and Auxiliary Equipment

Uploaded by

yogacruiseOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FBC Boiler and Auxiliary Equipment

Uploaded by

yogacruiseCopyright:

Available Formats

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

7.2.2 STOKER BOILER AND AUXILIARY EQUIPMENT

STEAM GENERATOR AND AUXILIARY EQUIPMENT

1. MAJOR DATA

1.1 Type (of : Stoker Coal)

Brand Name & Licensor CFBC

1.2 Manufacturer/Designer TBA

Or Equals

1.3 Number 1 _______________________

1.4 Steam generating capacity at boiler

maximum load (main steam flow) (T/H) 55_______________________

1.5 Design pressure (Drum) (kg/cm²g) 45________________________

o

1.6 Design temperature at (°C) 475 ±10 C_______________

Super heater outlet

1.7 Boiler heat release rate at MCR:

Main steam flow (T/H) 50.5______________________

Heat available in the furnace above

the ambient air temperature (Kcal/H) 23499680_________________

Heat absorbing water wall surface

exposed to fluidizing solid (m2) 337_____________________

Furnace water wall heat

absorption rate (Kcal/H/m2) 69732_____________________

Heat absorbing surface in furnace

other than water wall (m2) 23_______________________

Heat absorption rate in furnace

other than water wall (Kcal/H/m2 ) 1021725________________

1.8 Total weight (Ton) approx.

Steam generator complete except

steel structure (Boiler Pressure Part) (Ton) 160 _________________________

Drum (Ton) 21___________________________

Boiler supporting steel Structure (Ton) 47___________________________

1.9 Holding water capacity

Cold condition at normal level (m3) 47.5________________________

Max load operation at normal level (m3) Water: 45,7 .

Schedule 7.2.2 - 1 PLTU KENDARI

(1 x 10 MW)

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

Steam: 9,21 .

Hydrostatic test (m3) 47,3_______________________

1.10 Maximum size and weight for

shipping (max.m) __---___________________

Name of parts Press Part Boiler

Size (max. m) L: 12 .

H: 4 .

W: 4 .

Weight (max. ton) ___30____________________

1.11 Maximum weight for shipping

Name of parts Non Pressure Part Boiler

Weight (Tons) approx.___ 15 _____

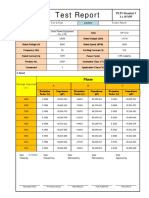

BOILER PERFORMANCE DATA (COAL)

FUEL AVERAGE COAL

No.

LOAD BMCR 100%TGL

100%TGL 75%TGL

75%TGL 50%TGL

1-0 FLOW

1-1 Main Steam Flow t/h 55 50,5 38,8 25,0

1-2 SH 1st Spray Flow t/h 0,95 0,92 0,86 0,67

1-3 SH 2nd Spray Flow t/h 0,95 0,92 0,86 0,67

1-4 SH Total Spray Flow t/h 1,9 1,84 1,72 1,34

1-5 % SH Total Spray Flow than Main Steam % 3,45 3,7 4,4 5,1

Flow

1-6 Blow Down Flow t/h 1,65 1,52 1,16 0,75

1-7 S/B Steam Flow (From PRI. SH Outlet) t/h 1,1 1,1 1,1 1,1

1-8 Aux. Steam Flow (From PRI. SH Outlet) t/h - - - -

1-9 Feedwater Through ECO t/h 56,65 50,75 40,65 27,62

1-10 Feedwater At Terminal Point t/h 67,98 57,75 46,91 31,48

1-11 Fuel Flow kg/h 13570 12335 9613 6097

1-12 Comb. Air kg/h 173015 154338 115753 77169

1-13 Comb. Gas kg/h 209348 186750 152315 106283

1-14 Sec. Air flow (FDF Out x 2) kg/h 50092 44683 36445 25430

1-15 (% Of Windbox In Air) % - - - -

Schedule 7.2.2 - 2 PLTU KENDARI

(1 x 10 MW)

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

FUEL AVERAGE COAL

No.

LOAD BMCR 100%TGL

100%TGL 75%TGL

75%TGL 50%TGL

1-16 (% Of SEC.AH In Gas Flow) % 23,9 23,9 23,9 23,9

1-17 PRI. Air flow (PAF OUT x 2) kg/h 122923 109655 89435 62407

1-18 PRI. Air flow (AH IN) kg/h 173015 154341 125881 87837

1-19 PRI. Air flow (Temp.Air) oC 205 205 205 205

1-20 (% Of PAF Out Flow) % 71 71 71 71

1-21 Gas Flow (AH In) kg/h 209398 18999 152315 106283

1-22 (% Of Comb. Gas Flow) % 120 120 120 120

1-23 Gas Flow ( EP In) kg/h 209398 18999 152315 106283

1-24 Gas Flow (IDF in x 2) kg/h 209398 18999 152315 106283

1-25 Air /Fuel Ratio - 18,97 18,97 18,97 18,97

2 STEAM & WATER TEMPERATURE

0

2-1 Sec. SH (RAD.SH) Outlet C 474,7 474,7 474,7 474,7

0

2-2 Inlet C 375 375 375 375

0

2-3 PRI. SH Outlet C 375 375 375 375

0

2-4 Inlet C 375 375 375 375

0

2-5 Drum C 225 225 225 225

0

2-6 Econ Outlet C 225 225 225 225

0

2-7 Inlet C 120 120 120 120

2-8 GAS TEMPERATURE

0

2-9 FEGT (RAD. SH Inlet) C 1093 1093 1093 1093

0

2-10 PRI. SH Inlet C 1084 1084 1084 1084

0

2-11 PRI. SH Outlet C 799 799 799 799

0

2-12 Econ Outlet C 263 263 263 263

0

2-13 AH Outlet (UNCOR) C 263 263 263 263

2-14 FOR BOILER EFF % 88 87 85 82

0

2-15 PRI. AH Outlet C 193 193 193 193

0

2-16 PRECIPITATOR INLET C 190 190 190 190

0

2-17 PRECIPITATOR OUTLET C 180 180 180 180

0

2-18 IDF Outlet C 175 175 175 175

0

2-19 Stack Outlet C 160 160 160 160

AIR TEMPERATURE

0

2-20 FDF Inlet C 33 33 33 33

0

2-21 Outlet C 36 36 36 36

0

2-22 Sec. AH Outlet C 150 150 150 150

0

2-23 Venturi Inlet C 125 125 125 125

3 PRESSURE

3-1 TSV Inlet (Terminal) bar(a) 42 42 42 42

3-2 Sec. SH (CONV SH) Outlet bar(a) 43 43 43 43

3-3 Inlet bar(a) 43,5 43,5 43,5 43,5

3-4 PRI.SH Outlet bar(a) 44,97 44,97 44,97 44,97

3-5 Inlet bar(a) 45 45 45 45

3-6 Drum bar(a) 46 46 46 46

3-7 Econ Outlet bar(a) 47,5 47,5 47,5 47,5

3-8 Inlet bar(a) 48,5 48,5 48,5 48,5

3-9 F/W Terminal bar(a) 50,5 50,5 50,5 50,5

Schedule 7.2.2 - 3 PLTU KENDARI

(1 x 10 MW)

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

FUEL AVERAGE COAL

No.

LOAD BMCR 100%TGL

100%TGL 75%TGL

75%TGL 50%TGL

3-10 S/B Steam To Control Valve bar(a) 16 16 16 16

3-11 S/B Steam Leaving Control Valve bar(a) 14 14 14 14

PRESSURE DROP

3-12 SH Outlet to TSV bar 2 2 2 2

3-13 SEC. SH (CONV..SH) bar 1 1 1 1

3-14 PRI. SH to SEC.SH bar 1,5 1,5 1,5 1,5

3-15 PRI. SH bar 0,5 0,5 0,5 0,5

3-16 Drum to PRI .SH bar 2,5 2,5 2,5 2,5

3-17 Econ to Drum (ex Head) bar 2,5 2,5 2,5 2,5

3-18 Econ (ex Head) bar 0,9 0,9 0,9 0,9

3-19 Total Boiler (Eco in to SH Out) bar 5,3 5,3 5,3 5,3

3-20 Terminal To Econ bar 2,9 2,9 2,9 2,9

3-21 Head ( At Drum) bar 46 46 46 46

3-22 Head ( at Terminal) bar 50,5 50,5 50,5 50,5

4-0 SEC. AIR PRESSURE/LOSSES

4-1 Through Suction Duct mmWC 35,5 30,8 22,86 12,7

4-2 Through Sec.AH mmWC 38,1 38,1 38,1 38,1

4-3 Through Ducts Up to W/B mmWC 35,5 30,8 22,86 12,7

4-4 Total Loss Through System mmWC 301 295,8 228,7 278,6

4-5 Static Head in W/B mmWC 399 389 389 376

FLUE GAS DRAFT LOSS/PRESSURE

4-6 Furnace Static Head mmWC 35,5 34,9 34,1 32,9

4-7 Through TER.SH and PRI. SH mmWC 50,8 50,8 50,8 50,8

4-8 Through Econ mmWC 38,1 38,1 38,1 38,1

4-9 Through PRI.AH mmWC 38,1 38,1 38,1 38,1

4-10 Through Ducts up to PRECIPITATOR Inlet mmWC 38,1 37,4 36,5 35,2

4-11 Through PRECIPITATOR mmWC 127 127 127 127

4-12 Through Ducts up to IDF Inlet mmWC 30,8 29,9 29,2 28,2

4-13 Through Ducts up to Stack Inlet mmWC 25,4 24,9 2,3 23,5

4-14 Through Stack mmWC 27,9 27,5 26,7 25,8

4-15 Total Loss Through System mmWC 411,9 408,7 404,8 399,5

5-0 MISCELLANEOUS

5-1 Ex. Air Ratio (ECO Out ) % 12,86 12,86 12,86 12,86

5-2 Q Heat Output MW 8,061 7,192 5,572 3,467

LOSS

5-3 Dry Gas Loss % 6,85 6,85 6,85 6,85

5-4 Moisture In Fuel % 35 35 35 35

5-5 Hydrogen In Fuel % 9,01 9,01 9,01 9,01

5-6 Moisture in Air % 0,367 0,367 0,367 0,367

5-7 Carbon Loss % Later Later Later Later

5-8 Radiation Loss % 9,16 9,16 9,16 9,16

5-9 Unaccounted Loss % 3,22 3,22 3,22 3,22

5-10 Total loss % 34,68 34,68 34,68 34,68

5-11 Boiler EFF (HHV) % 94,6 94,6 93,5 91,4

5-12 Boiler EFF (LHV) % 88 88 87 85

Schedule 7.2.2 - 4 PLTU KENDARI

(1 x 10 MW)

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

FUEL AVERAGE COAL

No.

LOAD BMCR 100%TGL

100%TGL 75%TGL

75%TGL 50%TGL

HEAT RELEASE

5-13 Volume ( Gross in Base) MW/m3 0,0378 0,0337 0,026 0,016

1.12 Data for steam generator at all high Pressure

Feed water heater bypass operation __________________________

Generator output (MW) 1 x 10_____________________

Steam generation (T/H) 1 x 50,5___________________

Main steam temperature at turbine inlet (°C) 475______________________

Boiler metal temperature at the most

highest parts and its name (area) (°C) 814______________________

Feedwater temperature at the

economizer inlet (°C) 120_______________________

Spray water flow (T/H) 1,38______________________

1.13 Bonafide performance data

a. Steam generator efficiency at rated %

with the average coal 50%TMCR 75%TMCR 100%TMCR

Heat losses of steam generator:

Total (%) __6,85__ __6,85__ ___6,85__

Heat loss due to heat in dry flue gas (%) __3,1___ __2,5___ ___1,8___

Heat loss due to moisture in the fuel (%) __6,97___ __6,97__ __6,97__

Heat loss due to moisture from

burning hydrogen (%) __0,367___ __0,367__ _0,367_

Heat loss due to moisture in the

combustion air (%) __0____ ____0____ ___0____

Heat loss due heat to the formation

of carbon monoxide (%) ___0____ ___0____ ___0____

Heat loss due to cacination (%) ___0____ ___0____ ___0____

Heat credit to desulfurization (%) ________ ________ ________

Heat loss due to sensible heat of ash(%) ___3,89___ _3,89___ _3,89__

Heat loss due to radiation and

convection (%) ___9,16__ ___9,16__ __9,16__

Heat loss due to un-counting losses (%) ____-____ ___-_____ ___-_____

b. Emission at boiler maximum with the Worst Coal:

NOx (mg/m3) 850_______________________

NOx with Fuel Oil (HSD) (mg/m3) 0__________________________

SOx (mg/m3) 750_______________________

PARTICLE (mg/m3) 150_______________________

c. Steam generating capacity:

Boiler max. (kg/H) 55________________________

d. Steam pressure at turbine inlet:

VWO (105 % TMCR)__42__kg/cm2g±__2__ kg/cm2

Schedule 7.2.2 - 5 PLTU KENDARI

(1 x 10 MW)

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

BMCR (108 % TMCR)__42__kg/cm2g±__2__ kg/cm2

100% rated __42__kg/cm2g±__2__ kg/cm2

75% rated __42__kg/cm2g±__2__ kg/cm2

50% rated __42__kg/cm2g±__5__ kg/cm2

Minimum load (30% rated) __42__kg/cm2g±__5__ kg/cm2

e. Steam temperature at turbine inlet:

VWO (105 % TMCR) °C± 475 ±5 °C

BMCR (108 % TMCR) °C± 475 ±5 °C

100% rated °C± 475 ±5 °C

75% rated °C± 475 ±5 °C

50% rated °C± 475 ±5 °C

f. Auxiliary power consumption;

For the plant heat rate calculation, the

Total power consumption of following

Equipment shall be guaranteed at each

Test load: °C ± 475 ±5 °C

1.14 Steam generator and auxiliary equipment

50% 75% 100%

Auxiliary power consumption for steam generator kW __Later_ ______ ________

2. DETAIL DATA

2.1 Furnace and boiler

a. Tubes:

Furnace :

Water wall heating surface (exposed) (m2) 350______________________

Other heating surface (exposed) (m2) __________________________

Dimension Width (m) 5,23_______________________

Length (m) 3,79_______________________

Height (m) 11,87_______________________

Volume (m3) 235______________________

Refractory lining thickness:

Base for strength (mm) Later______________________

Wear allowance (mm) Later______________________

Furnace Total:

Total Height (m) 12,06______________________

Total Volume (m3) 239_____________________

Total weight of furnace with Later______________________

full water and highest level of solid (kg) Later______________________

Furnace wall tubes vertical and roof :

Material SA 192___________________

Diameter (mm) 76,2____________________

Schedule 7.2.2 - 6 PLTU KENDARI

(1 x 10 MW)

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

Thickness (mm) 4_________________________

Furnace wall horizontal/inclined (except roof) :

Material SA 192___________________

Diameter (mm) 76,2____________________

Thickness (mm) 4_________________________

Furnace tubes except wall tube:

Material SA 192___________________

Diameter (mm) 76,2____________________

Thickness (mm) 4_________________________

Furnace tubes lined with refractory:

Material SA 192___________________

Diameter (mm) 76,2____________________

Thickness (mm) 4________________________

Detail of refractory lining Later____________________

Measure against erosion on any transient zone

around the boundary between exposed tube and

the refractory lining in the furnace Later____________________

Boiler tubes:

Material SA 192___________________

Diameter (mm) 50,8____________________

Thickness (mm) 3,5______________________

Detail of refractory lining Later____________________

b. Headers

Furnace:

Material SA 106 ___________________

Diameter (mm) 318,5_____________________

Thickness (mm) 25,4______________________

Measure against erosion Later______________________

Boiler :

Material SA 106 ___________________

Diameter (mm) 318,5_____________________

Thickness (mm) 25,4______________________

Measure against erosion due to

Solid in flue gas Later______________________

2.2 Drum (Steam drum) and internals

Design pressure (kg/cm2.g) 48

Internal diameter (mm) 1400

Thickness (mm) 60

Length (mm) 8100

Material SA 515-70

Schedule 7.2.2 - 7 PLTU KENDARI

(1 x 10 MW)

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

Manhole size (mm) 500 x 500

Number of thermocouples for metal temperature 2

Type of steam purifier Cyclone / Dimester

Nozzle connection for tube and pulpes :

Size Number Pitch Longitudinal

(mm)

Name of connection

a. Feedwater inlet 125 inch 1 600

b. Safety valve 3 inch 1 600

c. Superheater connecting links 4 inch 1 600

d. Roof Tubes 76,2 mm

e. Level Gauge ¾ inch 1

f. Level Transmitter ½ icnh 1

2.3 Economizer

Type (include supporting method/tube type) Bare tube_________________

Heating surface (m2) 400______________________

Tube

Type of tube Bore tube or Extended Fine tube

Distance between tube and tube (mm) 100______________________

Diameter (mm) 50,8_____OD_____________

Required thickness (mm) 3,5______________________

Minimum thickness __________________________

Material SA 192____________________

Length (mm) 5030_____________________

Traverse pitch 100_______________________

Traverse row number __________________________

In flow row number 1148______________________

Distance between walls:

Length (m) 4380______________________

Width (m) 1955_____________________

Flue gas velocity

(each section at boiler max.) (m/s) 20_______________________

Header:

Number 2________________________

Diameter (mm) 218________OD __________

Thickness (mm) 12,7_______________________

Length (mm) 2766_______________________

Material SA 106_____________________

Manhole number and size (mm) 550 x 500 .

Recirculation line of economizer No .

2.4 Superheater and attemperator

Type of superheater (Perdant/Horizontal) Pendant type______________

Schedule 7.2.2 - 8 PLTU KENDARI

(1 x 10 MW)

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

Heating surface (m2) Primary Secondary

Convection 430 150

Tube: Primary Secondary

Distance between tube and tube (mm) 90 85

Design temperature (°C) 375 485

Diameter (mmOD) 38,1 38,1

Thickness (mm) 3,5 3,5

Material SA 213-11 SA 213-22

Length (mm) Later Later

Traverse pitch (mm) 40 40

In flow row number 8x2 8x2

Flue gas velocity at boiler max. (m/s) 30 25

Distance between walls:

Length (m) 5,1 5,1

Width (m) 3,8 3,8

Header:

Number 1 1

Diameter (mm) 318,5 318,5

Thickness (mm) 21,44 21,44

Material SA 106 SA 106

Size of outlet connection Later Later

Nozzles (mm in nominal) 200 200

Design metal temperature 400 500

Number of thermocouples for metal

temperature 2 2

Maximum temperature (°C) 375 485

Attemperator:

Type Spray steam Spray steam

Number 1

Location Secondary superheater

Material SUS 304

Control method Later

2.5 Casing, Brick Works, Refractory, Insulation and Lagging:

(for the areas have not been described in other data sheets)

The Bidder shall make copies of the form and continue filling it if necessary to complete the

data sheets in his scope

Inner casing:

Name/Location a)Front b)Side_ c)Rear d)Roof e)____ f)____

Material SA 36

Thickness 3,2

Outer casing:

Name/Location a)Front b)Side_ c)Rear d)Roof e)____ f)____

Material Alluminium

Thickness 0,8

Schedule 7.2.2 - 9 PLTU KENDARI

(1 x 10 MW)

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

Brick works:

Name/Location a)Front b)Rear c)____ d)____ e)____ f)____

Material C 16 ______ ______ ______ ______

Thickness Later ______ ______ ______ ______

Refractory:

Name/Location a)Front b)Rear c)____ d)____ e)____ f)____

Material SK 36 ______ ______ ______ ______

Thickness Later ______ ______ ______ ______

Insulation:

Name/Location a)Front b)Rear c)____ d)____ e)____ f)____

Material Silica ______ ______ ______ ______

Thickness ______ ______ ______ ______ ______ ______

Lagging:

Name/Location a)Upper drum

Material SA 36

Thickness 3,2

2.6 Gas Air Heater

Type Tubular

Number 1

Inner dimension of flue gas side:

Length (mm) 2200

Width (mm) 1600

Height (mm) 3048

Each section Primary Secondary Air

Cold section:

Tube material STK 400 STK 400

Tube diameter 76,3 76,3

Tube thickness 2,8 2,8

Tube length 5360 2148

Horizontal pitch 110 110

Horizontal row number 17 17

Vertical pitch 80 80

Vertical row number 20 20

Hot section:

Tube material SA 53 SA 53

Tube diameter (mm) 76,3 76,3

Tube thickness (mm) 2,8 2,8

Tube length approx (m) 5360 2148

Horizontal pitch 110 110

Horizontal row number 17 17

Vertical pitch 80 80

Schedule 7.2.2 - 10 PLTU KENDARI

(1 x 10 MW)

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

Vertical row number 20 20

Tube plate

Cold section:

Material SA 36 SA 36

Thickness (mm) 12 12

Hot section:

Material SA 36 SA 36

Thickness (mm) 12 12

Insulation:

Material Silica #80

Thickness (mm) 50 50

Lagging:

Type Bare type

Material SA 36 SA 36

Thickness (mm) 4,5 4,5

Air velocity at boiler max. (m/s) 20 20

Flue gas velocity at boiler MCR (m/s) 25 25

Total weight of gas air heater (kg) Later

2.7 Coal firing system

2.7.1 Coal feed system

a. Coal inlet gate valve:

Type Chain feeder

Operation & control Automatic inverter (speed control)

Number 4set

Material Mfg standard

b. Spreader stoker

Number of stoker 4 set

Manufacturer Jianglian

Size of grate 5,5 x 3,68 m

Type of stoker Travelling grate

Spreader stoker equipment

Performance data :

c. Actual maximum capacity of

Schedule 7.2.2 - 11 PLTU KENDARI

(1 x 10 MW)

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

Stoker (kg coal per hour) 13600

at specified

fineness (kg coal per hour) ____________________________________

Max. temperature of preheated

air that can be used in stoker

(ºC) 150

Turn down of each pulverizer without

supplementary firing i.e. range of

flame stability of pulverizer, fans

burners (%) 30

Power consumed by each at

continous rated on (kw) Later_______

steam generator

d. Coal bunker:

Type & shape Steel made

Material SA 36

Thickness (mm) 6

Number 2 per each boiler

Capacity (Ton) 150

Net Volume (m3) 200

Net weight of storage (Ton) 142,56

Total volume (m3) for _6__ hour operating at boiler maximum

Total weight of storage (Ton) 150

Major dimension:

Width (or Diameter) (m) Later

Length (m) Later

Height (m) Later

Lining material SA 36/SUS 304

Inlet size 800 x 800

Outlet size 315 x 250

Installation Front Boiler

Support method Steel made

Emergency coal discharge

chute ____________________________________

Material ____________________________________

Size

Capacity (T/H) ____________________________________

Level monitoring

- Type ____________________________________

- Manufacturer Jianglian mfg

- Number 2 set for each

e. Coal outlet gate valve:

Type Bar Damper

Operation & control ____________________________________

Schedule 7.2.2 - 12 PLTU KENDARI

(1 x 10 MW)

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

Number 4 set for each

Material SUS 304

Size 315 x 250

Installation Hopper coal bunker

f. Coal feeder:

Type & manufacturer China & Jianglian

Operation & control Later

Number 4 set for each

Size

Capacity (T/H) 3,5 for each feeder

Turn down ____________________________________

Accuracy (%) ± _________________________________

Cleaning method ____________________________________

Materials contacting with Coal ____________________________________

2.8 Fuel (HSD) Oil firing system:

Oil Pressure (kg/cm2)

Viscosity: ________________________________

2.9 Sootblower

Location Furnace SHT Eco Air Heater

Type a)______ b)Long Retr c)Trav. d)Trav

Manufacturer ________ JLL JLL JLL

Number ________ 1 1 2

Steam flow (Peak) (kg/H) ________ 1,38 1,38 1,38

Steam pressure (kg/cm2g) ________ 14,5 14,5 14,5

Steam temperature (°C) ________ 900 650 650

Control method ________ Automatic

Blowing time (min/each) ________ 2 2 2

Order ________ _________ __________ _________

Warm up flow time (air) ________ _________ __________ _________

Warm up flow valve size ________ _________ __________ _________

Warm up steam flow (kg/H)

_________ ________ __________

2.10 Blow down tank

Type Continuous blow down system

Number 1 set

Tank capacity (m3) 0,960

Design pressure (kg/cm2g) 8

Design temperature (°C) 160

Peak flow down flow (kg/H) 5000

Break down (to describe item numbers)

of peak blow down Later

Schedule 7.2.2 - 13 PLTU KENDARI

(1 x 10 MW)

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

2.11 Air and flue gas duct

2.11.1 Dust

Primary air duct:

Location Before & After FDF & SFDF

Design pressure (mm H2O) 300

Material SA 36

Thickness (mm) 3,2

Flue Gas Duct:

Location After Gas Boiler outlet up to chimney inlet

Design pressure (mm H2O) 250

Material SA 36

Thickness (mm) 3,2

2.11.2 Hoppers:

Soot and ash hopper:

Location Under grate, drum, A/H

Design pressure (mm H2O) 300

Material SA 36/SUS 304

Thickness (mm) 6

Storage capacity for (Hour) Later

2.12 Boiler Make-up Water Pump

Type Motor direct couple multi stage

Manufacturer China

Number 2 for each boiler

Material Mfg standard

Size or Serial No. Later

Capacity (T/H) 60

Pressure (kg/cm2) 55

Revolution (RPM) Later

2.13 Power piping system

Safety valves: Drum Superheater

Reheater

Type __________ ________ ________

Material __________ ________ ________

Size __________ ________ ________

Number __________ ________ ________

Set pressure __________ ________ ________

Schedule 7.2.2 - 14 PLTU KENDARI

(1 x 10 MW)

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

Main steam pipe: From superheater outlet to steam turbine

inlet

Route ________________________________

Material SA 106

Diameter (mm) 200

Thickness (mm) 19

Total length approx (mm) Later

Design pressure (kg/cm2) 50

Feedwater pipe:

Route From FWP to BFW

Material Mfg standard

Diameter (mm) 125

Thickness (mm) 7,2

Total length approx (mm) Later

Design pressure (kg/cm2) 55

2.14 Steam Generator Supporting Steel,

Hanger Beams Plat Form, Stairs, Ladders

and Walkways

Steam generator supporting steel structure:

Type Bottom steel structure supported

Manufacturer Mfg standard

Total weight 18,4 ton

Size of steel structure Boiler area GASH area

Height (mm) _______________ ________________

Width (mm) _______________ ________________

Depth (mm) _______________ ________________

Schedule 7.2.2 - 15 PLTU KENDARI

(1 x 10 MW)

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

Name of Bidder:

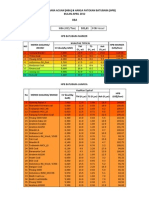

21. PARTIC

PARTICULATE EXTRACTION

Item Description Unit Data

Particulate Extraction

1. Manufacturer/Country of origin Jianglian/China

2. Type Bag filter

3. Number 1 (one) For each boiler

BMCR

Performance Data at BMCR

4. Gas mass flow kg/s 3490

5. Volumetric gas now Nm3/s -

O

6. Gas temperature at inlet C 190

7. Static gas pressure at inlet (gauge) mm WC 38,1

3

8. Dust concentration at inlet mg/Nm >150

3

9. Dust concentration at outlet (AT O2 6%) mg/Nm <100

10. Gas velocity at outlet m/s -

11. Power consumption kW Mfg std

12. Draft loss mm WC 100

13. Ash hopper capacity M3/hr Mfg std

14. Collection efficiency (with all fields in % 99

Schedule 7.2.2 - 16 PLTU KENDARI

(1 x 10 MW)

BOOK IV

PART 5 FORMS AND SCHEDULES

Schedule 7 Technical Data

Schedule 7.2.2 Stoker Boiler and Auxiliary Equipment

Bidder’s Data Sheet PT HUTAMA KARYA (Persero)

(Bidder’s Name)

operation)

15. Collection efficiency (with any one field out of % -

operation)

Schedule 7.2.2 - 17 PLTU KENDARI

(1 x 10 MW)

You might also like

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- APH Brochure PDFDocument10 pagesAPH Brochure PDFdillipsh123No ratings yet

- Syed Ammal Engineering College Power Plant Engineering Question BankDocument16 pagesSyed Ammal Engineering College Power Plant Engineering Question BankNizam MANo ratings yet

- Kusile Training Teil 2 File-064 - Soot Blowers - 20170116Document50 pagesKusile Training Teil 2 File-064 - Soot Blowers - 20170116Msimanga Arnold BudalNo ratings yet

- Convert emissions from lb/MM BTU to ppmvd basisDocument2 pagesConvert emissions from lb/MM BTU to ppmvd basiskunju1234No ratings yet

- Uninterrupted and Reliable Operation For CFB BOILERDocument59 pagesUninterrupted and Reliable Operation For CFB BOILERRizqi PriatnaNo ratings yet

- Ennore Thermal Power StationDocument14 pagesEnnore Thermal Power StationRajesh Kumar100% (2)

- Bab 3Document18 pagesBab 3trisnadewiNo ratings yet

- Boiler Types and ClassificationsDocument26 pagesBoiler Types and ClassificationshardikNo ratings yet

- Track beam and sootblower componentsDocument12 pagesTrack beam and sootblower componentsHaidar YafieNo ratings yet

- TPP Steel PlantDocument25 pagesTPP Steel PlantPRASANTHNo ratings yet

- Description Unit Unit - I: Turbine Heat Rate CalculationDocument7 pagesDescription Unit Unit - I: Turbine Heat Rate CalculationRameez FaroukNo ratings yet

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDocument12 pagesEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshNo ratings yet

- UTW CJSC Steam TurbinesDocument36 pagesUTW CJSC Steam TurbinesvamsiklNo ratings yet

- Training ReportPDF PDFDocument42 pagesTraining ReportPDF PDFAman RajNo ratings yet

- Vacuum - Condenser Presentasi 2Document17 pagesVacuum - Condenser Presentasi 2Neon PhoerbaNo ratings yet

- Pnacj953 PDFDocument395 pagesPnacj953 PDFSwaroop KumarNo ratings yet

- CFB Thermal HeatDocument9 pagesCFB Thermal HeatbamzNo ratings yet

- Supercritical PlantDocument71 pagesSupercritical PlantNitish KumarNo ratings yet

- CPP Pocket ManualDocument180 pagesCPP Pocket ManualdevagiriNo ratings yet

- Industrial Waste Fuel Options and Steam Generator Design ConsiderationsDocument21 pagesIndustrial Waste Fuel Options and Steam Generator Design ConsiderationsSathish PaulNo ratings yet

- Power Plant Cycles-AnimationDocument22 pagesPower Plant Cycles-AnimationLyndsey CooperNo ratings yet

- Air Monitoring Combustion Air Power BoilersDocument189 pagesAir Monitoring Combustion Air Power BoilersAnonymous zdCUbW8HfNo ratings yet

- Hydrazine DosingDocument2 pagesHydrazine DosingAnonymous 3HTgMDO100% (1)

- BHEL Readies Design For 800 MW Plant With Ultra Supercritical ParametersDocument1 pageBHEL Readies Design For 800 MW Plant With Ultra Supercritical Parameterslaloo01No ratings yet

- Ash ReinjectionDocument22 pagesAsh Reinjectiongaol_bird009No ratings yet

- B&W FBC Boiler Opeating Experience With U BeamsDocument9 pagesB&W FBC Boiler Opeating Experience With U BeamsNath BoyapatiNo ratings yet

- Vindh 9 CAVT ReportDocument20 pagesVindh 9 CAVT ReportSamNo ratings yet

- Boiler fouling and slagging prevention with intelligent sootblowingDocument8 pagesBoiler fouling and slagging prevention with intelligent sootblowingSuganya LokeshNo ratings yet

- Steam: Its Generation and Use, 40th EditionDocument316 pagesSteam: Its Generation and Use, 40th EditionIqbaldimaNo ratings yet

- Test for Half of Condenser Operation冷凝器半面运行试验Document2 pagesTest for Half of Condenser Operation冷凝器半面运行试验erwin5sambas5aryanaNo ratings yet

- Quality - Concept of CombustionDocument3 pagesQuality - Concept of CombustionNoviandryNo ratings yet

- 锅炉一次风机及其系统调试措施Boiler PAF Commissioning ProcedureDocument34 pages锅炉一次风机及其系统调试措施Boiler PAF Commissioning ProcedurekvsagarNo ratings yet

- T10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0Document13 pagesT10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0Thắng NguyễnNo ratings yet

- What is a Superheater and how does it workDocument2 pagesWhat is a Superheater and how does it workPangestu Try WibowoNo ratings yet

- Plant Component Chart For Condition Assessment Services: Unique or Patented B&W ServicesDocument2 pagesPlant Component Chart For Condition Assessment Services: Unique or Patented B&W ServicesGautam GhoshalNo ratings yet

- Lesson 2 Rev Introduction To Power PlantDocument53 pagesLesson 2 Rev Introduction To Power Plantfelix asadeNo ratings yet

- Data Pengukuran BFPT ADocument3 pagesData Pengukuran BFPT AazisyuswandiNo ratings yet

- Overview of NTPC PDFDocument40 pagesOverview of NTPC PDFRahul KediaNo ratings yet

- Super Critical Salient FeaturesDocument16 pagesSuper Critical Salient Featureshanumehrotra100% (1)

- 72 Europac BrochureDocument2 pages72 Europac BrochureAntyox Stark100% (1)

- Project ReportDocument89 pagesProject ReportgoyalzNo ratings yet

- Amit Agarwal Training ReportDocument59 pagesAmit Agarwal Training ReportAmit AgarwalNo ratings yet

- Thermal Efficiency of Turbine in A Thermal Power PlantDocument6 pagesThermal Efficiency of Turbine in A Thermal Power PlantRavishankarNo ratings yet

- Biomass Power Plants in ChinaDocument2 pagesBiomass Power Plants in ChinaBülent Aksu0% (1)

- Daily Report ListrikDocument48 pagesDaily Report ListrikKomang Khrisna Satya NarayanaNo ratings yet

- Module 8 - Energy Performance Assessment of BoilersDocument24 pagesModule 8 - Energy Performance Assessment of BoilersAnonymous a19X9GHZNo ratings yet

- Bi-Drum Vs Single Drum - Research Paper 2Document6 pagesBi-Drum Vs Single Drum - Research Paper 2Parth Merchant100% (1)

- Super Critical Boiler Materials - Metallurgical Aspects: R N Mehrotra, GM Energy TechnologyDocument41 pagesSuper Critical Boiler Materials - Metallurgical Aspects: R N Mehrotra, GM Energy TechnologyVIBHAV100% (1)

- Gne Presentation 201009Document20 pagesGne Presentation 201009Hardik HardNo ratings yet

- Report #1: Alternating-Current Project: Steam-Electric Power PlantDocument41 pagesReport #1: Alternating-Current Project: Steam-Electric Power PlantKian TecsonNo ratings yet

- Performance Evaluation of Air Preheater at off Design ConditionDocument32 pagesPerformance Evaluation of Air Preheater at off Design ConditionSuresh DewanganNo ratings yet

- Condensate Extraction Pump: GeneralDocument5 pagesCondensate Extraction Pump: GeneralAnonymous DKv8vpNo ratings yet

- Boiler EfficiencyDocument24 pagesBoiler EfficiencyAmit ChauhanNo ratings yet

- APGENCO FlyashDocument37 pagesAPGENCO Flyashlokesh0144No ratings yet

- Turbine TestDocument43 pagesTurbine TestNiraj WanjariNo ratings yet

- Pulverized Coal TechnologyDocument7 pagesPulverized Coal TechnologyRi KoNo ratings yet

- Tata Chemicals Limited Mithapur 1 x 200 TPH CFBC Boiler Logic SystemDocument26 pagesTata Chemicals Limited Mithapur 1 x 200 TPH CFBC Boiler Logic Systemraveekas6148No ratings yet

- 19 Boiler ESP System Commissioning Procedure-Töàtéëtö TÖñs Ÿt +T+ƑF Âf Ò Ä Û+Document31 pages19 Boiler ESP System Commissioning Procedure-Töàtéëtö TÖñs Ÿt +T+ƑF Âf Ò Ä Û+kvsagarNo ratings yet

- From Pinch Methodology to Pinch-Exergy Integration of Flexible SystemsFrom EverandFrom Pinch Methodology to Pinch-Exergy Integration of Flexible SystemsNo ratings yet

- Hipot Testing Dielectric Strength Test EepDocument14 pagesHipot Testing Dielectric Strength Test EepyogacruiseNo ratings yet

- Vibration Guidelines C132530Document1 pageVibration Guidelines C132530yogacruiseNo ratings yet

- Tan Delta-FDocument1 pageTan Delta-FyogacruiseNo ratings yet

- EDG TestDocument6 pagesEDG Testyogacruise100% (1)

- Boiler Feed Pump KSBDocument9 pagesBoiler Feed Pump KSByogacruiseNo ratings yet

- Steam BlowingDocument6 pagesSteam BlowingS V NAGESHNo ratings yet

- Honeywell Chart Recorder QuestionDocument1 pageHoneywell Chart Recorder QuestionyogacruiseNo ratings yet

- Calculation Sheet of Bus Protection Unit 3 FinalDocument17 pagesCalculation Sheet of Bus Protection Unit 3 Finalyogacruise100% (1)

- Budget For FEED of An Onshore Oil FieldDocument1 pageBudget For FEED of An Onshore Oil FieldyogacruiseNo ratings yet

- Tan Delta-FDocument1 pageTan Delta-FyogacruiseNo ratings yet

- Protection Relay of Generator TestDocument6 pagesProtection Relay of Generator Testyogacruise100% (2)

- Stiffness Coefficients For Nozzles in API 650 Tanks - 2Document8 pagesStiffness Coefficients For Nozzles in API 650 Tanks - 2yogacruise100% (2)

- Harga Batubara Acuan April 2012Document6 pagesHarga Batubara Acuan April 2012satuiku100% (1)

- XA Manual-V1.2Document72 pagesXA Manual-V1.2Mohamed Elsayed100% (1)

- Ge DGCM Field Rtu CatalogDocument12 pagesGe DGCM Field Rtu CatalogyogacruiseNo ratings yet

- Manhole On Weld SeamDocument1 pageManhole On Weld SeamyogacruiseNo ratings yet

- Magnetrol Level Flow Tech HandbookDocument44 pagesMagnetrol Level Flow Tech HandbookDelfinshNo ratings yet

- Zirconium IdentificationDocument2 pagesZirconium IdentificationyogacruiseNo ratings yet

- SS 310 Temperature Limit AlternativesDocument3 pagesSS 310 Temperature Limit AlternativesyogacruiseNo ratings yet

- Non Metallic Expansion JointDocument2 pagesNon Metallic Expansion JointyogacruiseNo ratings yet

- Refractory Repair Procedure GuideDocument3 pagesRefractory Repair Procedure Guideyogacruise50% (2)

- 3 Heating Load Calculation: 3.1 Heat Transmission LossDocument14 pages3 Heating Load Calculation: 3.1 Heat Transmission LossyogacruiseNo ratings yet

- What Code To Design Chlorine TankDocument3 pagesWhat Code To Design Chlorine TankyogacruiseNo ratings yet

- Pure Argon For Non Carbon SteelDocument3 pagesPure Argon For Non Carbon SteelyogacruiseNo ratings yet

- If The Misalignment Between The Head and Shell in A Pressure Vessel Exceeds The ASME Requirement1Document8 pagesIf The Misalignment Between The Head and Shell in A Pressure Vessel Exceeds The ASME Requirement1yogacruiseNo ratings yet

- Chimney RateDocument6 pagesChimney RateyogacruiseNo ratings yet

- WUXI HUAGUANG BOILER CO., LTD. (无锡华光锅炉股份有限公司) : Wang Fu Jun Zhao Xiao Li Zhang Wei Min Wang Fu Jun Tang Xing LiangDocument4 pagesWUXI HUAGUANG BOILER CO., LTD. (无锡华光锅炉股份有限公司) : Wang Fu Jun Zhao Xiao Li Zhang Wei Min Wang Fu Jun Tang Xing LiangyogacruiseNo ratings yet

- Expansion Bellows Leak RepairDocument1 pageExpansion Bellows Leak RepairyogacruiseNo ratings yet

- Instrument Cable LayoutDocument2 pagesInstrument Cable LayoutyogacruiseNo ratings yet

- Surge Gas Pilene Cross CountryDocument2 pagesSurge Gas Pilene Cross CountryyogacruiseNo ratings yet

- I.C. Engines & Reciprocating MachinesDocument106 pagesI.C. Engines & Reciprocating MachinesTesfa TemesgenNo ratings yet

- Boletin Caterpillar CuDocument3 pagesBoletin Caterpillar CuDavid PomaNo ratings yet

- Heat Transfer: Lecture 22: External Flow Forced ConvectionDocument10 pagesHeat Transfer: Lecture 22: External Flow Forced ConvectionDavico MartinezNo ratings yet

- Compressibility of Natural GasDocument20 pagesCompressibility of Natural GasIman AkbariNo ratings yet

- Piping Design Philosophy: Essar Oil Limited Vadinar Refinery ExpansionDocument20 pagesPiping Design Philosophy: Essar Oil Limited Vadinar Refinery ExpansionSami ThirunavukkarasuNo ratings yet

- Tüvis: TÜVIS-Prüfgrundlagen: AD 2000 Code, Volume 1, Register A Replaces Page - VersionDocument2 pagesTüvis: TÜVIS-Prüfgrundlagen: AD 2000 Code, Volume 1, Register A Replaces Page - VersionGentelmanOnlyNo ratings yet

- An66f PDFDocument104 pagesAn66f PDFMarco PerezNo ratings yet

- Particle Physics NotesDocument378 pagesParticle Physics Notesewanmc189No ratings yet

- Master List of Approved Suppliers For Three Phase Electric Loco ComponentsDocument99 pagesMaster List of Approved Suppliers For Three Phase Electric Loco ComponentssumitshyamalNo ratings yet

- KYOCERA km2540 SERVICE MANUALDocument364 pagesKYOCERA km2540 SERVICE MANUALshaj100% (1)

- GEAR PUMPS: COMPACT AND HIGH-PERFORMANCE LIQUID TRANSFERDocument5 pagesGEAR PUMPS: COMPACT AND HIGH-PERFORMANCE LIQUID TRANSFERGeorge Cobra100% (1)

- @perkins: 400 Series 404C-22GDocument2 pages@perkins: 400 Series 404C-22GNibrasNo ratings yet

- Camphor BallsDocument8 pagesCamphor BallsGurunath EpiliNo ratings yet

- 4TEC3F60B1000ADocument21 pages4TEC3F60B1000ABlackdragon86No ratings yet

- Ashrae Psychrometric Chart No.1 PDFDocument2 pagesAshrae Psychrometric Chart No.1 PDFshamsNo ratings yet

- WEG w22 Three Phase Electric MotorDocument44 pagesWEG w22 Three Phase Electric MotorMATIAS GODOYNo ratings yet

- Building With Hemp and LimeDocument25 pagesBuilding With Hemp and Lime23krneki100% (3)

- HP LP Bypass System (Turbine)Document9 pagesHP LP Bypass System (Turbine)Debasish Dewan67% (3)

- The Heating of Liquids in TanksDocument25 pagesThe Heating of Liquids in Tanksaleksandar_djordjic100% (1)

- A Comparison of A Dynamic and Static Optimization of An ASP Flooding Process For EORDocument20 pagesA Comparison of A Dynamic and Static Optimization of An ASP Flooding Process For EORAasNo ratings yet

- The Jere Beasley Report, Jan. 2009Document52 pagesThe Jere Beasley Report, Jan. 2009Beasley AllenNo ratings yet

- Marine Equivalent Oil Chart for Raysun Oil CoDocument1 pageMarine Equivalent Oil Chart for Raysun Oil Coparag7676100% (3)

- INVERTER FREEZER CHEAT SHEET EpcDocument3 pagesINVERTER FREEZER CHEAT SHEET EpcHeco Hek Hek CanapiNo ratings yet

- Solidification: Universiti Tunku Abdul Rahman (Utar)Document26 pagesSolidification: Universiti Tunku Abdul Rahman (Utar)Sim Hong YiNo ratings yet

- LESCO - Web Bill-February 2023Document2 pagesLESCO - Web Bill-February 2023MudassirNo ratings yet

- Paper No: 2002 OMAE - Volume 111, Materials EngineeringDocument6 pagesPaper No: 2002 OMAE - Volume 111, Materials EngineeringAnonymous 9PIxHy13No ratings yet

- 20 - ACV - Alfa F-FV - Carte Tehnica - CI - 05.01.01 - Ro PDFDocument21 pages20 - ACV - Alfa F-FV - Carte Tehnica - CI - 05.01.01 - Ro PDFCraciun DanielNo ratings yet

- Compressor Anti SurgeDocument4 pagesCompressor Anti SurgeAboaliNo ratings yet

- Use and Maintenance Instructions - Ql0208-Rev.2-2017 - enDocument70 pagesUse and Maintenance Instructions - Ql0208-Rev.2-2017 - enmauriciojjNo ratings yet

- H1 Axial Piston Tandem Pumps: Size 045/053Document56 pagesH1 Axial Piston Tandem Pumps: Size 045/053Luis Arturo Arenales MaytaNo ratings yet