Professional Documents

Culture Documents

SafetyPerceptionSurvey-A Case Study

Uploaded by

Pillai SreejithOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SafetyPerceptionSurvey-A Case Study

Uploaded by

Pillai SreejithCopyright:

Available Formats

Pillai Sreejith

Safety Perception Survey – A Refinery

Case Study

Introduction

A grass-root refinery (certified ISO 9002, ISO 14001, OHSAS 18001) decided to carry out

Safety Perception Survey (SPS) of their employees, totaling to around 1723. SPS, world

over is conducted as part of Culture Change Management (CCM). SPS results will be used

to effectively design the CCM programme. The trends / indicators revealed by SPS

analysis will be used as foundation blocks, on which the CCM programme is built upon.

Why SPS?

Generally, few employees voice strong opinions and managements have no way of

knowing how widespread and important the raised issues are. Keeping this in mind, the

general objective of SPS was to complete a thorough evaluation of the safety perception

of the client’s employees. To summarize, the objective was to:

• To evaluate the safety perception and safety culture of employees with

reference to occupational health & safety issues

• To assess employee involvement level in the existing safety programme

• To assess the employee perception regarding the existing safety management

system

All over the world, SPS is being seen as a measure of the “organizational health and

safety culture”. It is also generally agreed that culture of the organization plays a lead

role in why employees behave the way they do. For proactive organizations who are on

the constant lookout for safety development (beyond international safety certification

(OHSAS 18001, ISRS, British Safety Sword of Honour, etc.), SPS is logically the next step.

SPS also helps managements to understand whether their safety programmes are

effective, their safety policies are functional as expected by the management- a kind of

reality check! Oil Industry Safety Directorate (OISD), India also recommends SPS.

Moreover, the proactive client management also believes that the safety perception of

the employees is of paramount importance as it is a lead indicator of the safety

performance of an organization.

Scope and Approach of Safety Perception Survey

The process by which this perception study was conducted is consistent with the general

state of safety management and the best professional judgment of the survey team.

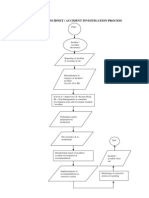

Figure in the next page

depicts the key steps in the survey process. SPS was conducted by 4 surveyors

(experienced risk management engineers) for nearly 8 days.

The survey team had used customized questionnaires, which were evolved in

consultation with the executives from Fire & Safety department of the client.

There were four main components in the approach to this evaluation:

Safety Management Systems

Human Factors

Safety Culture

Safety Perception Survey – A Refinery Case Study

Pillai Sreejith

Employee Participation

The survey was intended to address the following:

Management and Line Organization Commitment to Safety

Personal Involvement in Safety

Training, Competence and Awareness of Responsibilities

Perception towards Accidents / Incidents and their reporting system

Efforts were made towards sampling major facets of safety management, but it is

important to recognize that this method is intended to uncover major system

deficiencies and the evaluation may not have identified all potential strengths and

weaknesses.

Key Steps in the Safety Perception Survey Process:

Pre Survey Activities Onsite Survey Activities

Post Survey Activities

Defining the scope and Survey Kick off meeting with the Development of customized

methodology of the survey HODs of various Departments to software to capture the data

explain the objective and gathered during the survey

methodology

Discussion with client to identify

the key elements, categories of Grouping of Survey team – Focus Scientific Analysis of the structured

employees and the sampling on various departments data

percentage

Personal Interaction with the Interpretation of data and

Evolution of Questionnaire for

employees across all the categories documentation of findings as Draft

various categories of the

to gather information detailed in the Report – For comments from client

employees

questionnaire

Pre Survey meeting with client to Daily briefing of the personal Close out meeting to brief client

finalize the questionnaire interactions Top management on survey

findings

Final Report incorporating

suggestions / comments

SPS Elements:

After extensive deliberations (internal and with the client), 17 elements were included in

the SPS questionnaire, under 4 broad categories:

SAFETY LEADERSHIP

SAFETY MANAGEMENT

SAFETY CULTURE

SAFETY PROMOTION

Safety Perception Survey – A Refinery Case Study

Pillai Sreejith

Employee Categorization:

The refinery employees were grouped based on their cadre / nature of operations so that

the developed SPS questionnaire were relevant in consultation with the client

management. This grouping helped the survey team to develop specific questionnaire

for each of the categories.

Category 1 Category 2 Category 3 Category 4

(Top Management) (Senior and middle

Management)

Directors General Manager Field Operators Contractor

Executive Director Dy. General Manager Maintenance Employees

Chief Manager Technicians

Senior Manager

Manager

Deputy Manager

Senior Engineer

Engineer

SPS Questionnaire Development:

After agreeing on the main and sub elements of the questionnaire, the survey team drafted the

questionnaire, one for each category. Various sub elements for each of the 17 elements were

developed based on survey team’s expertise & client’s operations. Although questionnaires were

designed separately for each of the categories, the sub elements were kept same to have overall

parity. The SPS also recorded the employee comments / suggestions in the questionnaire as

suggested by the client. The following employee details were also recorded in the employee

questionnaire to help during the process of data analysis:

• Designation / Cadre:

• Number of years of experience:

• Department:

• Date & Time of Survey:

Selection of sub-elements for SPS elements can be best understood by the following example:

SPS Element: Emergency Management

Sub-Elements:

• Effectiveness

• Awareness

• Emergency Communication

• Updation of Emergency Management Plan

• Confidence in emergency preparedness

• Mock drill participation

Safety Perception Survey – A Refinery Case Study

Pillai Sreejith

Category No of questions

Category 1 54

Category 2 93

Category 3 86

Category 4 69

SPS Sampling:

The survey team decided on the SPS sampling percentage in consultation with the refinery

management.

Employee Total Number of Sampling Number of

Category employees Percentage employees

surveyed

1 6 67 4

2 593 15 89

3 1108 10 110

4 - - 16

Total Number of employees Surveyed 219

Note: In category 4, employees from 7 contractors (civil, electrical, mechanical) were interviewed.

SPS Coverage:

As part of SPS, employees from the following refinery departments were surveyed.

• Fire & Safety

• Projects

• R&D

• LPG Plant

• DHDS

• Crude I, II Plants

• OHS Centre

• Technical Services

• Maintenance (Electrical, mechanical, instrumentation)

• Tank farm

SPS Auditors’ Profile:

The survey team consisted of experienced safety professionals who have executed a variety of safety

and risk management projects for reputed industries in the oil and gas sector.

SPS Analysis & Report:

Safety Perception Survey – A Refinery Case Study

Pillai Sreejith

Survey team made all possible efforts to ensure that evaluation was impartial and objective. However,

because findings do reflect perceptions, they may not be indicative of “reality”, and there may be

apparent conflicts between the factual evidence gained as part of safety management system

evaluation and the anecdotal evidence gathered from interviews with employees.

The survey team decided on the various comparisons. Based on the graphs generated, various

interpretations were drawn so that the refinery management can take action. The refinery

management was supposed to draw up an action plan based on the SPS report.

The employee comments (extracted from SPS questionnaire) were grouped under various SPS

elements and was attached along with the SPS report.

Acceptable Safety Perception Level (ASPL):

ASPL, a term coined by the survey team, is the acceptable level of safety perception set at 80 (a thick

black bar represents ASPL in the graphs). ASPL is not a benchmark and ideally the score should be

100. The score above or below does not indicate that either the element meets or does not meets

standards. It is a line that is assumed to facilitate and draw inferences across groups.

Contact:

For details, please write to: pillai_sreejith@hotmail.com.

P.G. Sreejith

pillai_sreejith@hotmail.com

Safety Perception Survey – A Refinery Case Study

You might also like

- culture of safety A Complete Guide - 2019 EditionFrom Everandculture of safety A Complete Guide - 2019 EditionRating: 5 out of 5 stars5/5 (1)

- Safety Culture SurveyDocument7 pagesSafety Culture SurveyardhianhkNo ratings yet

- Transforming A Safety Culture: Presented By: Chad Johnston Senior Director Enterprise & Public SafetyDocument25 pagesTransforming A Safety Culture: Presented By: Chad Johnston Senior Director Enterprise & Public SafetyarsayaNo ratings yet

- DSS Safety Perception Survey SPS US-11 8 2017Document4 pagesDSS Safety Perception Survey SPS US-11 8 2017Isaías Bastos Enoque100% (1)

- Assessing Your Safety Culture in Seven Simple StepsDocument5 pagesAssessing Your Safety Culture in Seven Simple StepsSuhardi RahamatNo ratings yet

- Chapter 5 Accident Investigation and ReportingDocument55 pagesChapter 5 Accident Investigation and ReportingAinur Sya IrahNo ratings yet

- The Importance of Near Miss Reporting - What You Need To KnowDocument6 pagesThe Importance of Near Miss Reporting - What You Need To KnowaneethavilsNo ratings yet

- Safety Science: David Oswald, Fred Sherratt, Simon SmithDocument11 pagesSafety Science: David Oswald, Fred Sherratt, Simon SmithFatih D. PrasetioNo ratings yet

- Ohsas 18001 VS Iso 45001Document5 pagesOhsas 18001 VS Iso 45001MDNV RAONo ratings yet

- Case Study 1 - Health and Safety Policy - Final Draft - August 2018Document76 pagesCase Study 1 - Health and Safety Policy - Final Draft - August 2018lonnyNo ratings yet

- Machine Guarding - Barry BlodgettDocument66 pagesMachine Guarding - Barry BlodgettmanimeczNo ratings yet

- Five Steps To Sustainable Safety Culture Excellence PDFDocument1 pageFive Steps To Sustainable Safety Culture Excellence PDFSuhardi RahamatNo ratings yet

- Budgeting For Safety PDFDocument34 pagesBudgeting For Safety PDFHari KoneruNo ratings yet

- Confined Space Rescue PlanDocument4 pagesConfined Space Rescue PlanFranscois Van RooyenNo ratings yet

- Safety Resume Without Certificate PDFDocument4 pagesSafety Resume Without Certificate PDFSAFETY RNo ratings yet

- First Aid Program OSHA Compliant From GDIDocument14 pagesFirst Aid Program OSHA Compliant From GDIGrant Davis100% (2)

- Safety Culture Assessment Tool OverviewDocument10 pagesSafety Culture Assessment Tool OverviewBurdang PinoyNo ratings yet

- Data-Centric Safety: Challenges, Approaches, and Incident InvestigationFrom EverandData-Centric Safety: Challenges, Approaches, and Incident InvestigationNo ratings yet

- Integr Ted Business Re S: at SourceDocument14 pagesIntegr Ted Business Re S: at SourcecyclopsoctopusNo ratings yet

- Safety Leadership Survey key factorsDocument4 pagesSafety Leadership Survey key factorslooking99No ratings yet

- Oregon OSHA's guide to controlling hazardous energyDocument36 pagesOregon OSHA's guide to controlling hazardous energyYoga PradanaNo ratings yet

- Safety Culture Survey ReportDocument43 pagesSafety Culture Survey ReportClaireNo ratings yet

- IS0 9001 - 2008 OHSAS 18001 and ISO 14001 Requirements SummaryDocument9 pagesIS0 9001 - 2008 OHSAS 18001 and ISO 14001 Requirements Summaryジェイ センニュリンNo ratings yet

- OHSAS 18001 and 18002 OverviewDocument10 pagesOHSAS 18001 and 18002 OverviewArshad MahmoodNo ratings yet

- Riddor: Health and Safety Advice For StonemasonsDocument12 pagesRiddor: Health and Safety Advice For StonemasonsMohammed IlliasuddinNo ratings yet

- Assess Safety CultureDocument2 pagesAssess Safety CulturedeeNo ratings yet

- Workplace Safety SurveyDocument2 pagesWorkplace Safety SurveyBuddy KertunNo ratings yet

- Safe Operating Procedures GuideDocument12 pagesSafe Operating Procedures GuideRahul100% (1)

- Greenwich Health & Safety Induction OverviewDocument27 pagesGreenwich Health & Safety Induction OverviewMin ingNo ratings yet

- CPWR Confined Spaces 1 PDFDocument2 pagesCPWR Confined Spaces 1 PDFIgnacio RomeroNo ratings yet

- Sample Electrical Safety Training ProgrammeDocument2 pagesSample Electrical Safety Training ProgrammePillai Sreejith100% (2)

- HSE Alert 105-21 Welder Finger InjuryDocument2 pagesHSE Alert 105-21 Welder Finger InjuryAlecs NedeaNo ratings yet

- General Safety Incident Reporting ProcessDocument1 pageGeneral Safety Incident Reporting ProcessFredrick OganoNo ratings yet

- Machine Guarding Safety ChecklistDocument2 pagesMachine Guarding Safety ChecklistSirley Sanmartín RestrepoNo ratings yet

- Machine SafeguardingDocument72 pagesMachine SafeguardingEvert W. VanderBergNo ratings yet

- Behaviour-Based Safety in Organizations: Saving Life Before The Accident, 2/eDocument2 pagesBehaviour-Based Safety in Organizations: Saving Life Before The Accident, 2/ePampanagouda YadavNo ratings yet

- Safety Climate Assessment ToolkitDocument60 pagesSafety Climate Assessment Toolkitnjenns100% (1)

- 11 Emergency Preparedness PlanDocument6 pages11 Emergency Preparedness PlanMAHESH SHAWNo ratings yet

- Hot Work Program PDFDocument49 pagesHot Work Program PDFAnonymous wtK1AZBiNo ratings yet

- Grievance Register and TemplatesDocument6 pagesGrievance Register and TemplatesAditya Kumar SharmaNo ratings yet

- Chemical Management PlanDocument64 pagesChemical Management PlanyahyaNo ratings yet

- Safety Leadership AssessmentDocument96 pagesSafety Leadership AssessmentitapiazNo ratings yet

- Safety Requirements Behavior Based Safety For Power Plants PDFDocument34 pagesSafety Requirements Behavior Based Safety For Power Plants PDFmaneesh_03100% (1)

- BBS JBE IntroDocument246 pagesBBS JBE IntroInfrastructure Development ServiceNo ratings yet

- Workplace Violence Prevention June2016Document3 pagesWorkplace Violence Prevention June2016eliasox123No ratings yet

- Safety Management - PDFDocument43 pagesSafety Management - PDFMansi PatelNo ratings yet

- JUST Safety Audit ReportDocument3 pagesJUST Safety Audit ReportMohammad LiftawiNo ratings yet

- HSE InductionDocument20 pagesHSE InductionShailendraNo ratings yet

- Global Electrical SafetyDocument34 pagesGlobal Electrical SafetyPillai Sreejith100% (16)

- Causes & DefinitionsDocument11 pagesCauses & DefinitionsSayed DarwishNo ratings yet

- 4.4.3.3 Data and Trend AnalysisDocument6 pages4.4.3.3 Data and Trend AnalysisIndermohan MehtaNo ratings yet

- 501 2012 6 28 27 39 561Document26 pages501 2012 6 28 27 39 561MITHILESH KUMARNo ratings yet

- Behavior Based SafetyDocument27 pagesBehavior Based SafetySuresh KumarNo ratings yet

- QEHS ManualDocument100 pagesQEHS ManualRob WillestoneNo ratings yet

- Workplace Health and Safety Assessment FormDocument9 pagesWorkplace Health and Safety Assessment Forms9n9No ratings yet

- Positive Isolaton: Prepared By: Bikash Keshari KhilarDocument16 pagesPositive Isolaton: Prepared By: Bikash Keshari KhilarBikash KhilarNo ratings yet

- Root Cause AnalysisDocument2 pagesRoot Cause Analysis360 International LimitedNo ratings yet

- 03 49006 Risk Tolerability ALARP v02Document15 pages03 49006 Risk Tolerability ALARP v02MohammadFaisalAmjadNo ratings yet

- Process Safety Master Class I Sreejith Pillai 2018Document22 pagesProcess Safety Master Class I Sreejith Pillai 2018Pillai Sreejith100% (1)

- Managing OE Operationalization ChallengesDocument2 pagesManaging OE Operationalization ChallengesPillai Sreejith100% (1)

- Offshore Technical Safety FAQDocument12 pagesOffshore Technical Safety FAQPillai Sreejith100% (15)

- Bow Ties and Offshore Safety StudiesDocument3 pagesBow Ties and Offshore Safety StudiesPillai Sreejith100% (7)

- Asset Integrity FAQ 2Document4 pagesAsset Integrity FAQ 2Pillai SreejithNo ratings yet

- Explosion Riks-Battery RoomsDocument6 pagesExplosion Riks-Battery RoomsPillai Sreejith100% (12)

- HAZOP Pre ConcessionsDocument1 pageHAZOP Pre ConcessionsPillai Sreejith100% (1)

- Technical Integrity Guidance NoteDocument4 pagesTechnical Integrity Guidance NotePillai Sreejith100% (1)

- Asset Integrity Performance Management FAQDocument5 pagesAsset Integrity Performance Management FAQPillai Sreejith100% (1)

- Offshore Safety Performance ManagementDocument7 pagesOffshore Safety Performance ManagementPillai Sreejith100% (9)

- Offshore QRA ChecklistDocument2 pagesOffshore QRA ChecklistPillai Sreejith100% (5)

- Insights Into ESSADocument7 pagesInsights Into ESSAPillai Sreejith100% (2)

- Work at Height SurveyDocument5 pagesWork at Height SurveyPillai Sreejith100% (3)

- Sample Electrical Safety Training ProgrammeDocument2 pagesSample Electrical Safety Training ProgrammePillai Sreejith100% (2)

- Piper Alpha DiscussionDocument8 pagesPiper Alpha DiscussionPillai Sreejith100% (7)

- Electrical Thermal ImagingDocument6 pagesElectrical Thermal ImagingPillai Sreejith90% (10)

- Offshore Safety Case TrainingDocument114 pagesOffshore Safety Case TrainingPillai Sreejith100% (131)

- 25 Major Power Plant LossesDocument28 pages25 Major Power Plant LossesPillai Sreejith100% (31)

- Piper Alpha Case StudyDocument21 pagesPiper Alpha Case StudyPillai Sreejith100% (38)

- Mumbai Offshore Platform FireDocument18 pagesMumbai Offshore Platform FirePillai Sreejith100% (18)

- Syndicate Excercise Hazardous Area ClassificationDocument6 pagesSyndicate Excercise Hazardous Area ClassificationPillai Sreejith100% (3)

- BP Texas ExplosionDocument24 pagesBP Texas ExplosionPillai Sreejith92% (12)

- QUIZ-Hazardous Area ClassificationDocument2 pagesQUIZ-Hazardous Area ClassificationPillai Sreejith100% (4)

- Electrical Engineer EmployabilityDocument30 pagesElectrical Engineer EmployabilityPillai Sreejith96% (27)

- Risk Management-A Balancing ActDocument19 pagesRisk Management-A Balancing ActPillai Sreejith100% (13)

- Lightning Risk NoteDocument7 pagesLightning Risk NotePillai Sreejith100% (5)

- Safety Audit Observations & RecommmendationsDocument41 pagesSafety Audit Observations & RecommmendationsPillai Sreejith100% (36)

- Personal Lightning SafetyDocument25 pagesPersonal Lightning SafetyPillai Sreejith100% (7)

- Major 50 Fires & ExplosionsDocument53 pagesMajor 50 Fires & ExplosionsPillai Sreejith100% (11)

- Calibration Essentials Ebook PDFDocument64 pagesCalibration Essentials Ebook PDFsolbahia100% (1)

- Chapter-5 103338Document11 pagesChapter-5 103338WONDYE DESTANo ratings yet

- Principles of Language Testing Rita GreenDocument32 pagesPrinciples of Language Testing Rita GreenKhairun Nisa100% (1)

- Corporate New Ventures at Procter & Gamble: International Business TheoryDocument63 pagesCorporate New Ventures at Procter & Gamble: International Business TheoryVerVe LimNo ratings yet

- Textbook EvaluationDocument31 pagesTextbook EvaluationRahhal Ajbilou69% (13)

- L6 CTSE STO023 EPA AG Issue 2.1 - New Amended Version of Apprentice Handbook (6) (Part Version - Extracts Only)Document7 pagesL6 CTSE STO023 EPA AG Issue 2.1 - New Amended Version of Apprentice Handbook (6) (Part Version - Extracts Only)Laura CuestaNo ratings yet

- Course Schedule 2020 - NIOSHCertDocument3 pagesCourse Schedule 2020 - NIOSHCertJamsari SulaimanNo ratings yet

- Final Skills Checklist for Civic Welfare TrainingDocument1 pageFinal Skills Checklist for Civic Welfare TrainingMark B. BarrogaNo ratings yet

- Australia Awards Scholarship Referee ReportDocument3 pagesAustralia Awards Scholarship Referee ReportryandroidNo ratings yet

- Rubric For Portfolio Evaluation (Updated)Document1 pageRubric For Portfolio Evaluation (Updated)Daniella Daniella67% (3)

- Chapter 3Document15 pagesChapter 3norielNo ratings yet

- Quality in Health Care PDFDocument102 pagesQuality in Health Care PDFjeetNo ratings yet

- Grade Boundaries International As and A Level June 220818 115120Document4 pagesGrade Boundaries International As and A Level June 220818 115120AshijNo ratings yet

- A Conceptual Model of Service QualityDocument11 pagesA Conceptual Model of Service QualityAbhinav SaxenaNo ratings yet

- Business ManagementDocument68 pagesBusiness Managementhlafsd0% (1)

- Ongoing Professional Practice Evaluation (Oppe) : Administrative Policies and ProceduresDocument5 pagesOngoing Professional Practice Evaluation (Oppe) : Administrative Policies and ProceduresTary BaruNo ratings yet

- Cordillera A+ College research course syllabusDocument6 pagesCordillera A+ College research course syllabusAveryl LadipNo ratings yet

- HMS Business PracticeDocument19 pagesHMS Business Practiceadvantage025No ratings yet

- 7 BusinessDissertationsDocument1,772 pages7 BusinessDissertationsshreeshail_mp60090% (1)

- Global Workforce Performance Management - ShivajiMaitra - S11MMMMM00755 - IHRMDocument22 pagesGlobal Workforce Performance Management - ShivajiMaitra - S11MMMMM00755 - IHRMShivaji Maitra100% (1)

- Grading Essay Test: Joanna Gran DumalagDocument16 pagesGrading Essay Test: Joanna Gran DumalagChristian Dahnuel DaroyaNo ratings yet

- Assessing Student Learning EffectivelyDocument3 pagesAssessing Student Learning EffectivelyDhon ValeNo ratings yet

- Critical Success Factors in Six Sigma ImplementationDocument5 pagesCritical Success Factors in Six Sigma ImplementationMarco Antonio MacielNo ratings yet

- Evaluation WPS OfficeDocument3 pagesEvaluation WPS OfficeMery IsabellaNo ratings yet

- APAC - Guidance For Organic CertificationDocument21 pagesAPAC - Guidance For Organic CertificationMauleni BudiartiNo ratings yet

- Maintenance Planner Day2 DetailsDocument7 pagesMaintenance Planner Day2 Detailsahmed mahmoudNo ratings yet

- Philippines school reading test resultsDocument2 pagesPhilippines school reading test resultsCamille Castrence CaranayNo ratings yet

- Continuing Nursing EducationDocument24 pagesContinuing Nursing EducationSathish Rajamani100% (3)

- ABM - Organization and Management CG - 4 PDFDocument5 pagesABM - Organization and Management CG - 4 PDFHaj Heloise75% (20)

- Washington State Performance GuideDocument45 pagesWashington State Performance GuideedrialdeNo ratings yet