Professional Documents

Culture Documents

G3412

Uploaded by

Harish RangerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

G3412

Uploaded by

Harish RangerCopyright:

Available Formats

® Gas

Industrial G3412

Engine

235-675 hp

SPECIFICATIONS

V-12, 4-Stroke-Cycle Gas

Bore—in (mm) . . . . . . . . . . . . . . . . . . . . . . . . . 5.4 (137)

Stroke—in (mm). . . . . . . . . . . . . . . . . . . . . . . . 6.0 (152)

Displacement—cu in (L). . . . . . . . . . . . . . . . 1,649 (27)

Compression ratio

HCR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10:1

LCR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.5:1

Jacket Water System

Capacity without radiator — gal (L). . . . . . . 20 (75)

Gas Pressure Requirements — psi (bar)

TA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 (1.4)

NA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5 (.1)

Lube Oil Capacity—gal (L) . . . . . . . . . . . . . . . 50 (189)

Shown with optional Aspiration. . . . . . . . . . . . Naturally Aspirated (NA) or

equipment .............................Turbocharged-Aftercooled (TA)

FEATURES

■ DIESEL STRENGTH BUILT IN ■ GAS ENGINES

All Caterpillar® Gas Engines are built on diesel Represent the latest technology in engine

frames which means greater service life. design and efficiency. Engines are offered in

Caterpillar® Gas Engines inherit more from their both naturally aspirated (NA) and turbocharged/

diesel counterparts then just strength. They are aftercooled (TA) configurations with both high

backed by the same support system recognized and low compression ratios.

as one of the most sophisticated and • High energy ignition systems for consistent

dependable in the world. firing with many fuels.

• State-of-the-art combustion technology for

■ APPLICATION FLEXIBILITY improved fuel consumption.

Constant torque over a large operating speed • Modern componentry, designed and

range and ability to burn a wide spectrum of rigorously tested to provide excellent

gaseous fuels. performance, reliability, and durability.

CONTINUOUS RATINGS (bhp)

Aspiration 1800 rpm* 1400 rpm

TA-90 HCR 675 525

TA-130 HCR 600 465

TA-90 LCR 625 495

TA-130 LCR 565 450

NA HCR 365 315

* Catalyst Ratings – approximately 10% less bhp than

continuous ratings. Contact your Caterpillar dealer.

®

G3412 GAS INDUSTRIAL ENGINE

STANDARD EQUIPMENT OPTIONAL EQUIPMENT

Air cleaners Paint, Caterpillar Air cleaners and Protection devices

two stage, with rain yellow accessories oil pressure and

cap and service Pumps Bases and foundations coolant temperature

indicator auxiliary water, gear Controls and governors contactors

Breather, crankcase driven, centrifugal Cooling systems, Power takeoffs

Carburetor, natural gas non-self-priming heat exchangers Starting systems

Cooler, lubricating oil (TA only) aftercooler groups

Elbow, exhaust, dry jacket water, gear expansion tank

Filter, lubricating oil, driven CSA ignition (Class 1,

bypass (TA only) Regulator, gas Div 2, Gp D)

Flywheel housing, pressure Dual timing magneto

SAE No. 0 SAE standard rotation Exhaust fittings

Governor, Service meter Fuel systems

Woodward PSG Supports, engine Gauges & instrument

Ignition system Thermostats and panels

Altronic III housing Mufflers

Lifting eyes Torsional vibration

Manifold, exhaust, damper

watercooled

PHYSICAL FACTORS

Length Height Width Weight

in mm in mm in mm lb kg

TA 80.7 2049 68.3 1734 63.1 1603 4720 2143

STD NA 76.3 1938 64.2 1631 49.8 1265 4420 2007

®

G3412 GAS INDUSTRIAL ENGINE

FUEL CONSUMPTION

HCR TA-90 HCR TA-130

bkW bkW

149 298 448 597 149 298 448 597

13000 18.3 13000 18.3

12000 16.9 12000 16.9

Btu/bhp-hr

MJ/bkW-hr

Btu/bhp-hr

MJ/bkW-hr

11000 15.5 11000 1400 rpm 15.5

1400 rpm

10000 14.1 10000 14.1

9000 1800 rpm 12.7 9000 1800 rpm 12.7

8000 11.3 8000 11.3

7000 9.9 7000 9.9

200 400 600 800 200 400 600 800

bhp bhp

LCR TA-90 LCR TA-130

bkW bkW

149 298 448 597 149 298 448 597

13000 18.3 13000 18.3

12000 16.9 12000 16.9

Btu/bhp-hr

MJ/bkW-hr

Btu/bhp-hr

MJ/bkW-hr

11000 15.5 11000 1400 rpm 15.5

1400 rpm

10000 14.1 10000 14.1

9000 1800 rpm 12.7 9000 1800 rpm 12.7

8000 11.3 8000 11.3

7000 9.9 7000 9.9

200 400 600 800 200 400 600 800

bhp bhp

3412 NA

bkW

149 298 448 597

13000 18.3

12000 16.9

1400 rpm

Btu/bhp-hr

MJ/bkW-hr

11000 15.5

10000 14.1

1800 rpm

9000 12.7

8000 11.3

7000 9.9

200 400 600 800

bhp

®

G3412 GAS INDUSTRIAL ENGINE

GAS INDUSTRIAL ENGINE

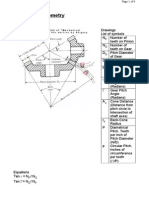

01 Centerline of Crankshaft 104 Jacket Water Outlet 401 Air Inlet

02 Centerline of Engine 125 Aftercooler Water Inlet 402 Exhaust

03 Rear Face of Cylinder Block 126 Aftercooler Water Outlet 411 Air Bleed Cooling System

103 Jacket Water Inlet 201 Fuel Inlet

TA configuration shown. See General Dimension Note: General configuration not to be used for

Drawing 7W0103 for additional detail. installation.

RATING CONDITIONS AND DEFINITIONS

Ratings are based on SAE J1349 standard Turbocharged-aftercooled ratings apply to

conditions of 29.61 in Hg (100 kPa) and 77° F 5,000 ft (1525 m) and 77° F (25° C).

(25° C). These ratings also apply at ISO3046, Naturally aspirated engines apply to 500 ft (150 m)

DIN6271, BS5514 standard conditions of and 77° F (25° C). For applications which exceed

29.61 in Hg (100 kPa) 81° F (27° C); and API 7B-11C these limits contact your Caterpillar dealer.

standard conditions of 29.38 in Hg (99 kPa) and

90 refers to aftercooler water inlet temperature

85° F (29° C) also apply.

in 90° F (32° C).

Ratings are based on dry natural gas having an

130 refers to aftercooler water inlet temperature

LHV (low heat valve) of 905 btu/cu ft

in 130° F (54° C).

(35.54 MJ/N m3). Variations in altitude,

temperature, and gas composition from standard Additional ratings may be available for specific

conditions may require a reduction in engine customer requirements. Consult your Caterpillar

horsepower. representative for details.

Materials and specifications are subject to change without notice. The International System of Units (SI) is used in this publication.

LEHQ5415 (9-95) © 1995 Caterpillar Inc. Printed in U.S.A.

Supersedes LEHQ3201 All rights reserved.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ADAMS Lecture 1 Introduction To ADAMSDocument19 pagesADAMS Lecture 1 Introduction To ADAMSAneesh KalraNo ratings yet

- Printable Fastener Tools PDFDocument28 pagesPrintable Fastener Tools PDFAgustin PeraltaNo ratings yet

- Hlep / Vsax: High Performance Cryogenic Reciprocating PumpsDocument4 pagesHlep / Vsax: High Performance Cryogenic Reciprocating Pumpsbarun1977No ratings yet

- Second Law of Thermodynamics 1Document16 pagesSecond Law of Thermodynamics 1Lone KnightNo ratings yet

- Assingment 2Document1 pageAssingment 2Aliaa TarekNo ratings yet

- Design of Drag-Link Mechanisms With Optimum Transmission AngleDocument5 pagesDesign of Drag-Link Mechanisms With Optimum Transmission AngleNigussie AdemNo ratings yet

- Service News: Installation of Stage 2 Long MK Ii Onzr4 Priority: Iv Gac: 48 Ecb Aif 1357/C1 Date: 17/07/2004Document30 pagesService News: Installation of Stage 2 Long MK Ii Onzr4 Priority: Iv Gac: 48 Ecb Aif 1357/C1 Date: 17/07/2004Muhammad HardiusNo ratings yet

- Trusses ExamplesDocument13 pagesTrusses ExamplesShaikh Yaseen MehmoodNo ratings yet

- Production and Industrial EngineeringDocument27 pagesProduction and Industrial EngineeringShivangi MishraNo ratings yet

- 2-Theory of SedimentationDocument11 pages2-Theory of SedimentationSheeraz AhmedNo ratings yet

- Piper Arrow checklist guide for pilotsDocument3 pagesPiper Arrow checklist guide for pilotsmichael.s.lacy7874No ratings yet

- Smokevent Calculation..Document2 pagesSmokevent Calculation..Karthy GanesanNo ratings yet

- Ade 12 Physics Exercise 6 Page 135 144Document48 pagesAde 12 Physics Exercise 6 Page 135 144Hope AlforqueNo ratings yet

- MT 2010Document8 pagesMT 2010kokonunezNo ratings yet

- New ChangeDocument68 pagesNew ChangeAnoop Kamla PandeyNo ratings yet

- D8T HidraulicoDocument13 pagesD8T Hidraulicoesmeralda100% (1)

- Hand Operated Can CrusherDocument60 pagesHand Operated Can CrusherParen Trivedi100% (2)

- Principle of PhysicsDocument446 pagesPrinciple of PhysicsWendirad Beshada86% (7)

- Adsorption Gas Treatment Plant - Design Information: Spec. NumberDocument5 pagesAdsorption Gas Treatment Plant - Design Information: Spec. NumberabhmarsNo ratings yet

- S Emi Rotary Hand Wing Pumps: A Plication PDocument2 pagesS Emi Rotary Hand Wing Pumps: A Plication PMarketing CTNNo ratings yet

- Heavy lifting skidding system specificationsDocument1 pageHeavy lifting skidding system specificationsm4l4ysiaNo ratings yet

- Sanjana 04 Acoustics ReportDocument5 pagesSanjana 04 Acoustics ReportSanjana BhandiwadNo ratings yet

- Bevel ExplanationDocument4 pagesBevel ExplanationVarun VaidyaNo ratings yet

- Andromeda V1.2 Assembly GuideDocument19 pagesAndromeda V1.2 Assembly Guidenajoko6753No ratings yet

- Tut3 - Bending Moment and Shear Force Diagrams - MemoDocument12 pagesTut3 - Bending Moment and Shear Force Diagrams - MemoDazzle Njabs MbungeleNo ratings yet

- 6100 6200 Tractors Europe Edition IntroductionDocument16 pages6100 6200 Tractors Europe Edition Introductionceli gimNo ratings yet

- Product Information: Diesel Extra LD 15W40Document2 pagesProduct Information: Diesel Extra LD 15W40movie hunterNo ratings yet

- STB S19 00 Datenblatt - Scalpac - EN - v01 PDFDocument2 pagesSTB S19 00 Datenblatt - Scalpac - EN - v01 PDFAnastasia PošaracNo ratings yet

- Heat Transfer - K. A. GavhaneDocument175 pagesHeat Transfer - K. A. GavhaneHussainNo ratings yet

- High-speed FANUC M-420iA industrial robotDocument2 pagesHigh-speed FANUC M-420iA industrial robotMarek GryskoNo ratings yet