Professional Documents

Culture Documents

ISMB

Uploaded by

tiwarivivek2Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ISMB

Uploaded by

tiwarivivek2Copyright:

Available Formats

Paper by Dr.

Mohan Gupta - for possible publication in January 2006 issue of Steel in Construction

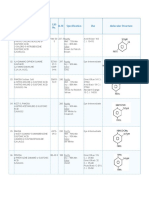

Table 3: Additional Sectional Properties of Indian Standard Tapered Flange Medium Weight Beam and Channel Sections

Web Flange Root Toe Flange Moment Section modulus Depth Local Torsional Warping

Mass Area Depth Width between Buckling

Thk. Thk. Radius Radius Slope of Inertia Plastic Constant Constant

Designation Root Fillets ratios

M A h bf tw tf R r Iz Iy Zpz Zpy d It Iw

Flange Web

kg/m cm2 mm mm mm mm mm mm cm4 cm4 cm3 cm3 mm x 104 mm4 x 109 mm6

MB 100 11.5 14.60 100 75 4.0 7.2 9.0 4.5 8° 257.5 40.8 58.65 18.3 65.0 5.2 16.2 2.95 0.88

MB 125 13.0 16.60 125 75 4.4 7.6 9.0 4.5 8° 449.0 43.7 81.85 19.6 89.2 4.9 20.3 3.52 1.51

MB 150 14.9 19.00 150 80 4.8 7.6 9.0 4.5 8° 726.4 52.6 110.48 22.4 113.9 5.3 23.7 4.00 2.67

MB 175 19.3 24.62 175 90 5.5 8.6 10.0 5.0 8° 1272.0 85.0 166.08 32.2 134.5 5.2 24.5 6.56 5.88

MB 200 25.4 32.33 200 100 5.7 10.8 11.0 5.5 8° 2235.4 150.0 253.86 50.0 152.7 4.6 26.8 12.49 13.42

MB 225 31.2 39.72 225 110 6.5 11.8 12.0 6.0 8° 3441.8 218.3 348.27 66.4 173.3 4.7 26.7 18.32 24.81

MB 250 37.3 47.55 250 125 6.9 12.5 13.0 6.5 8° 5131.6 334.5 465.71 89.8 194.1 5.0 28.1 25.02 47.17

MB 300 44.2 56.26 300 140 7.5 12.4 14.0 7.0 8° 8603.6 453.9 651.74 110.7 241.5 5.6 32.2 29.99 93.86

MB 350 52.4 66.71 350 140 8.1 14.2 14.0 7.0 8° 13630.3 537.7 889.57 129.7 288.0 4.9 35.6 42.38 151.58

MB 400 61.6 78.46 400 140 8.9 16.0 14.0 7.0 8° 20458.4 622.1 1176.18 149.4 334.4 4.4 37.6 58.75 229.33

MB 450 72.4 92.27 450 150 9.4 17.4 15.0 7.5 8° 30390.8 834.0 1533.36 186.8 379.2 4.3 40.3 79.83 390.19

MB 500 86.9 110.74 500 180 10.2 17.2 17.0 8.5 8° 45218.3 1369.8 2074.67 259.5 424.1 5.2 41.6 101.57 798.24

MB 550 103.7 132.11 550 190 11.2 19.3 18.0 9.0 8° 64893.6 1833.8 2711.98 327.6 467.5 4.9 41.7 147.59 1291.19

MB 600 122.6 156.21 600 210 12.0 20.8 20.0 10.0 8° 91813.0 2651.0 3510.63 429.0 509.7 5.0 42.5 204.81 2223.34

°

MC 75 6.8 8.67 75 40 4.4 7.3 8.5 4.5 6 76.0 12.6 24.17 8.69 41.4 5.5 9.4 1.43 0.113

MC 100 9.2 11.70 100 50 4.7 7.5 9 4.5 6° 186.7 25.9 43.83 14.30 64.0 6.7 13.6 2.05 0.447

MC 125 12.7 16.19 125 65 5 8.1 9.5 5 6° 416.4 59.9 77.15 25.56 85.4 8.0 17.1 3.38 1.698

MC 150 16.4 20.88 150 75 5.4 9 10 5 6° 779.4 102.3 119.82 37.88 106.7 8.3 19.8 5.27 4.256

MC 175 19.1 24.38 175 75 5.7 10.2 10.5 5.5 6° 1223.3 121.0 161.65 44.40 128.4 7.4 22.5 7.26 6.717

MC 200 22.1 28.21 200 75 6.1 11.4 11 5.5 6° 1819.3 140.4 211.26 51.07 150.2 6.6 24.6 9.80 10.036

MC 225 25.9 33.01 225 80 6.4 12.4 12 6 6° 2694.6 187.2 277.93 63.64 170.9 6.5 26.7 13.25 26.589

MC 250 30.4 38.67 250 80 7.1 14.1 12 6 6° 3816.8 219.1 356.72 73.90 192.5 5.7 27.1 18.78 23.999

MC 300 35.8 45.64 300 90 7.6 13.6 13 6.5 6° 6362.6 310.8 496.77 91.21 240.7 6.6 31.7 21.37 51.601

MC 350 42.1 53.66 350 100 8.1 13.5 14 7 6° 10008.0 430.6 672.20 110.70 288.1 7.4 35.6 25.58 101.382

MC 400 49.4 62.93 400 100 8.6 15.3 15 7.5 6° 15082.8 504.8 891.03 127.69 332.8 6.5 38.7 35.44 152.584

Page 7 of 7

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Perfect Prayer by by Jon Courson - Matthew 6 9-13 The Lords PrayerDocument6 pagesThe Perfect Prayer by by Jon Courson - Matthew 6 9-13 The Lords PrayerRobert Beaupre100% (1)

- Air ConditioningDocument54 pagesAir Conditioningtiwarivivek2100% (1)

- 6 Strategies For Effective Financial Management Trends in K12 SchoolsDocument16 pages6 Strategies For Effective Financial Management Trends in K12 SchoolsRainiel Victor M. CrisologoNo ratings yet

- Mil HDBK 1390 PDFDocument31 pagesMil HDBK 1390 PDFsleepanon4362No ratings yet

- Detailed list of chemical dyes and intermediates with propertiesDocument12 pagesDetailed list of chemical dyes and intermediates with propertiestiwarivivek2No ratings yet

- What Music Really Means To ChildrenDocument5 pagesWhat Music Really Means To ChildrenMara Sofia ValenteNo ratings yet

- Open Access (Power Trading) PresentationDocument38 pagesOpen Access (Power Trading) Presentationtiwarivivek2100% (1)

- To Sir With LoveDocument2 pagesTo Sir With LoveRamita Udayashankar100% (2)

- Exim Policy 2009-14 HighlightsDocument8 pagesExim Policy 2009-14 HighlightsSvvs ReddyNo ratings yet

- HRMDocument104 pagesHRMsreedevi_sree58No ratings yet

- Exim Policy 2009-14 HighlightsDocument8 pagesExim Policy 2009-14 HighlightsSvvs ReddyNo ratings yet

- Stainless Steel Pressure RatingsDocument7 pagesStainless Steel Pressure RatingsNauman KhanNo ratings yet

- Purchase PresentationDocument6 pagesPurchase Presentationtiwarivivek2No ratings yet

- Stainless Steel Pressure RatingsDocument7 pagesStainless Steel Pressure RatingsNauman KhanNo ratings yet

- Improving Personality Through HandwritingDocument2 pagesImproving Personality Through Handwritingankita dablaNo ratings yet

- Improving Personality Through HandwritingDocument2 pagesImproving Personality Through Handwritingankita dablaNo ratings yet

- CMAI - Paul Blanchard - Nylon ABS Review 5.12Document42 pagesCMAI - Paul Blanchard - Nylon ABS Review 5.12tiwarivivek2No ratings yet

- Civil - BhelDocument5 pagesCivil - Bheltiwarivivek2No ratings yet

- Prayer BuddyDocument42 pagesPrayer BuddyJoribelle AranteNo ratings yet

- ARCH1350 Solutions 6705Document16 pagesARCH1350 Solutions 6705Glecy AdrianoNo ratings yet

- Neoclassicism: Romanticism Realism ImpressionismDocument16 pagesNeoclassicism: Romanticism Realism ImpressionismErika EludoNo ratings yet

- Librarianship and Professional Ethics: Understanding Standards for Library ProfessionalsDocument12 pagesLibrarianship and Professional Ethics: Understanding Standards for Library ProfessionalsHALLNo ratings yet

- Sustainability of A Beach Resort A Case Study-1Document6 pagesSustainability of A Beach Resort A Case Study-1abhinavsathishkumarNo ratings yet

- Homework WatergateDocument8 pagesHomework Watergateaapsujtif100% (1)

- What's The Line Between Middle Class, Upper Middle Class, and Upper Class in Britain - QuoraDocument11 pagesWhat's The Line Between Middle Class, Upper Middle Class, and Upper Class in Britain - QuoraFaizan ButtNo ratings yet

- WORKSHOP ON ACCOUNTING OF IJARAHDocument12 pagesWORKSHOP ON ACCOUNTING OF IJARAHAkif ShaikhNo ratings yet

- SOLUS Is An Autonomous System That Enables Hyper-Personalized Engagement With Individual Customers at ScaleDocument3 pagesSOLUS Is An Autonomous System That Enables Hyper-Personalized Engagement With Individual Customers at ScaleShikhaNo ratings yet

- Fractional GradingDocument7 pagesFractional Gradingapi-355619062No ratings yet

- Leading a Community Through Integrity and CourageDocument2 pagesLeading a Community Through Integrity and CourageGretchen VenturaNo ratings yet

- Atmospheres of Space The Development of Alvar Aalto S Free Flow Section As A Climate DeviceDocument18 pagesAtmospheres of Space The Development of Alvar Aalto S Free Flow Section As A Climate DeviceSebastian BaumannNo ratings yet

- Network Monitoring With Zabbix - HowtoForge - Linux Howtos and TutorialsDocument12 pagesNetwork Monitoring With Zabbix - HowtoForge - Linux Howtos and TutorialsShawn BoltonNo ratings yet

- Summary Basis For Regulatory Action TemplateDocument23 pagesSummary Basis For Regulatory Action TemplateAviseka AcharyaNo ratings yet

- UNDERSTANDING-WPS OfficeDocument51 pagesUNDERSTANDING-WPS OfficeCristina Lance100% (1)

- Analysing Context CluesDocument2 pagesAnalysing Context CluesSwathiNo ratings yet

- Speed of Sound and its Relationship with TemperatureDocument2 pagesSpeed of Sound and its Relationship with TemperatureBENNY CALLONo ratings yet

- Unit Test, Part 2: Literature With A Purpose: Total Score: - of 40 PointsDocument3 pagesUnit Test, Part 2: Literature With A Purpose: Total Score: - of 40 PointsAriana Stephanya Anguiano VelazquezNo ratings yet

- Carb-Based-Dll No. 2 - 4th Qtr.Document5 pagesCarb-Based-Dll No. 2 - 4th Qtr.Kathrene Santos RiveraNo ratings yet

- Shear Explains Shear Cracks 45 DegDocument15 pagesShear Explains Shear Cracks 45 DegHieu Huy NguyenNo ratings yet

- 4th Singapore Open Pencak Silat Championship 2018-1Document20 pages4th Singapore Open Pencak Silat Championship 2018-1kandi ari zonaNo ratings yet

- ASSIGNMENTDocument5 pagesASSIGNMENTPanchdev KumarNo ratings yet

- 5 - Econ - Advanced Economic Theory (Eng)Document1 page5 - Econ - Advanced Economic Theory (Eng)David JackNo ratings yet

- ISE I Conversation Task - Rules and RegulationsDocument3 pagesISE I Conversation Task - Rules and RegulationsElena B. HerreroNo ratings yet

- 2 - RUBRIC PHY110 (For Student)Document3 pages2 - RUBRIC PHY110 (For Student)Puteri AaliyyaNo ratings yet