Professional Documents

Culture Documents

Knife Steel

Uploaded by

Dobber1978Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Knife Steel

Uploaded by

Dobber1978Copyright:

Available Formats

I have been very happy with my Puma folder.

I bought it 25 years ago and after much use a

piece broke off inside the handle and it wouldn't lock open, I returned it for service and they

sent me a new knife no charge!! they stand behind their lifetime warantee.

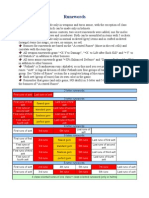

Here is some info in knife steels

154CM

This is an American made stainless steel that was originally developed to make turbine blades in jet engines. It is

very similar to ATS-34. It's very corrosion resistant and has good toughness and edge quality.

440C

This is a stainless steel that is used on many factory manufactured knife blades. It is very tough and extremely stain

resistant. It holds an edge well and is fairly easy to sharpen. It is generally hardened to between 56 and 59 Rc., and

makes a great all around blade. 440C is far superior to most other 400 series steels. 440A and 440B are not as good.

ATS-34

This is a stainless steel that comes from Japan and is very similar to The U.S.'s 154CM. It became very popular with

knife makers in the 1990's as a higher quality alternative to 440C. The steel is not as rust resistant as 440C, but holds

a better edge. The carbon content is 1.04% . It works best when hardened to between 59 Rc to 61 Rc.

AUS-8

This steel has a low carbon to chromium ratio. It is very resistant to corrosion, and is very tough, but does not hold

an edge as well as many other steel variations with higher carbon content.

BG-42

This material is a stainless steel. It has a better edge holding ability than 44C and ATS-34, and is tougher than ATS-

34. Works best when hardened to 61 - 63 Rc.

D2

This material is a very high carbon steel (1.5%) that has superb edge holding ability and unmatched wear resistance,

but lacks toughness. It is not as corrosion resistant as 440C or ATS-34, and is not considered a stainless steel

because it only has 12% chrome. Stainless blades have 13% or more.

Damascus

Damascus is made of a variety of steels that are layered together. The finishing process involves an acid etch that

exposes the surface lines. The end result is a tough blade with good edge quality. It is quite expensive and used

mostly for its artistic nature.

H1

H1's claim to fame is its corrosion resistance. Blades made of the material sacrifice edge quality for this corrosion

resistance and toughness.

M2

This is an extremely tough, tool grade steel. It is used mostly for industrial cutting tasks. The steel has superb

strength and is extremely wear resistant, but is highly susceptible to corrosion.

S30V

This is a premium grade steel that was designed in the U.S. for knife making. It has very good edge holding ability

and is very corrosion resistant.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Theory and Practice of Armored Warfare in Spain Part.1Document6 pagesThe Theory and Practice of Armored Warfare in Spain Part.1SamdogeNo ratings yet

- Arnis - Anyo Isa - Form OneDocument1 pageArnis - Anyo Isa - Form OneJerry Don Smith, Jr.No ratings yet

- Alliant Powder CatalogDocument43 pagesAlliant Powder Cataloganthony2069No ratings yet

- Skill List v. 1.0.1 Fire Emblem Midnight SunDocument14 pagesSkill List v. 1.0.1 Fire Emblem Midnight SunAlfred KamonNo ratings yet

- The Space Wolves Players Handbook 04 2016 PDFDocument173 pagesThe Space Wolves Players Handbook 04 2016 PDFSándor SzabóNo ratings yet

- List of Support Spirits - Super Smash Bros. Ultimate (SSBU)Document1 pageList of Support Spirits - Super Smash Bros. Ultimate (SSBU)Cypke71No ratings yet

- Tori-Tori No Mi Model Pheonix GM BinderDocument1 pageTori-Tori No Mi Model Pheonix GM BinderSauceboy 538No ratings yet

- Agarwal Sons: House of Fasteners, Hand Tools and General HardwareDocument3 pagesAgarwal Sons: House of Fasteners, Hand Tools and General Hardwaresmallik3No ratings yet

- The Global Reset Survival GuideDocument174 pagesThe Global Reset Survival Guiderhp8968380% (15)

- War Fighting TacticsDocument306 pagesWar Fighting TacticsUnited States Militia100% (13)

- October Daye JumpChain 1.2Document23 pagesOctober Daye JumpChain 1.2tvo770No ratings yet

- WW2 Roleplay Character SheetDocument2 pagesWW2 Roleplay Character SheetTeam of MODNo ratings yet

- Crown ORBAT for Dystopian WarsDocument15 pagesCrown ORBAT for Dystopian WarsGuillaume Ferlin100% (1)

- TACP-1010 RW CAS TacticsDocument93 pagesTACP-1010 RW CAS TacticsCharles Cousineau100% (3)

- Mengil Manhide's Company of Dark Elves: PROFILES - 2nd EditionDocument15 pagesMengil Manhide's Company of Dark Elves: PROFILES - 2nd EditionZakys Backinblack100% (1)

- METRICS Thread DimensionsDocument19 pagesMETRICS Thread DimensionsSurajPachhadeNo ratings yet

- Rune WordsDocument3 pagesRune Wordschaosky26No ratings yet

- Reinstalling a Martini-Henry BreechblockDocument6 pagesReinstalling a Martini-Henry BreechblocktwinscrewcanoeNo ratings yet

- Old School 5E D&D Character Sheet (Form) - 1Document2 pagesOld School 5E D&D Character Sheet (Form) - 1bigkev73No ratings yet

- Crime Statistics PDFDocument3 pagesCrime Statistics PDFRecordTrac - City of OaklandNo ratings yet

- 2023 Sterling KatalogDocument124 pages2023 Sterling KatalogBerkeNo ratings yet

- Master-at-Arms NAVEDTRA 14137BDocument322 pagesMaster-at-Arms NAVEDTRA 14137B120v60hz100% (2)

- Half Elf Valor BardDocument2 pagesHalf Elf Valor Bardcamilo duqueNo ratings yet

- Pendragon - 6th Edition IntroDocument21 pagesPendragon - 6th Edition IntroYohann100% (1)

- Edge of The Empire Talent TreesDocument34 pagesEdge of The Empire Talent TreesEd RekishiNo ratings yet

- (Amber DRPG) John Biles Partial PowersDocument135 pages(Amber DRPG) John Biles Partial PowersWill HarperNo ratings yet

- Selitos Moonshadow - Druid of RashemenDocument4 pagesSelitos Moonshadow - Druid of RashemenAthalaric GumaNo ratings yet

- Plan 9 From Outer SpaceDocument16 pagesPlan 9 From Outer SpaceMIDNITECAMPZNo ratings yet

- Usage InstructionsDocument18 pagesUsage InstructionsGames RedDragon100% (1)

- D&D 5e - Races of TamrielDocument6 pagesD&D 5e - Races of TamrielJacobNo ratings yet