Professional Documents

Culture Documents

Shutdown Valves

Uploaded by

nazury2k0 ratings0% found this document useful (0 votes)

547 views2 pagesShutdown valves (SDV) are used in oil and gas production systems to safely isolate different systems and minimize hazards. SDVs must have tight shut-off, be fire-resistant, close quickly from full open to full close within seconds, minimize fluid passing during closure, cause minimal turbulence, fail-safe to the closed position, be manually reset on-site, have clear position indicators, and periodically undergo partial stroke testing to maintain reliability. SDVs are also equipped with features like position switches, accumulators, and secondary solenoid valves to further increase safety.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentShutdown valves (SDV) are used in oil and gas production systems to safely isolate different systems and minimize hazards. SDVs must have tight shut-off, be fire-resistant, close quickly from full open to full close within seconds, minimize fluid passing during closure, cause minimal turbulence, fail-safe to the closed position, be manually reset on-site, have clear position indicators, and periodically undergo partial stroke testing to maintain reliability. SDVs are also equipped with features like position switches, accumulators, and secondary solenoid valves to further increase safety.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

547 views2 pagesShutdown Valves

Uploaded by

nazury2kShutdown valves (SDV) are used in oil and gas production systems to safely isolate different systems and minimize hazards. SDVs must have tight shut-off, be fire-resistant, close quickly from full open to full close within seconds, minimize fluid passing during closure, cause minimal turbulence, fail-safe to the closed position, be manually reset on-site, have clear position indicators, and periodically undergo partial stroke testing to maintain reliability. SDVs are also equipped with features like position switches, accumulators, and secondary solenoid valves to further increase safety.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

http://webwormcpt.blogspot.com/2007_10_01_archive.

html

Shutdown Valves (SDV) are common apply in oil and gas production system for safe and

proper isolation purpose to minimize escalation of hazardous from one system to another

system. General shutdown valve is controlled by a high integrity Emergency Shutdown

System (ESDS).

A shutdown valve shall equipped with the following features :

i) Tie Shut Off (TSO)

- Zero/minimum leakage shall be expected for a device act as shutdown valve. Generally a

Shutdown valve seat leakage shall pass the seat leakage testing per API 508 and/or ISO

5208.

ii) Firesafe

- shutdown valve is expected to work promptly even though it expose to external fire attacks.

thus, shutdown valve body shall be fire rated according to API 607 for soft seated valve or

API 6FA for API 6A & API 6D valves or BS 6755 Part 2.

iii) Fast action (From Full Open - Full Close)

- A shutdown valve shall act fast to minimize the escalation of hazards. Generally a quarter

ball valve is the excellent device in quick action. As rule of thumb, shutdown valve shall be

capable of begin it closing action within 10 seconds of activation, and time taken from Full

open to Full Close is within 1-2 seconds per inch of shutdown valve size. However, this shall

be compliant to overall safety philosophy. Proper selection and sizing of actuator to ensure

above requirements are fulfilled.

iv) Minimum passing (during closing of shutdown valve)

- The feature is required to minimize the potential of overpressure of Low pressure system

and spurious trip. A shutdown valve with equal% characteristic (most ball valve will have this

feature. However, this shall be confirmed with valve supplier) is preferred type. With equal%

characteristic, it can operate with 10% valve closure give 20% flow reduction, 20% closure

give 50% closure...the closure of valve is fast and minimize inventory passing.

v) Minimum disturbance / turbulence to process fluid

- This feature is to minimize unnecessary energy lost. Reduced Bore (RB) ball valve having

hole in the middle would minimize flow direction change and turbulence. Full Bore (FB) ball

valve virtually like a pipe- significantly minimize energy lost.

vi) Fail-safe

- A shutdown valve actuator shall pneumatic/hydraulic fail-safe spring-return type. Generally a

shutdown valve failed to close (FC). Electrical driven type shall not be used.

vii) Manual field reset

- A shutdown valve shall be reset manual at field. The operator shall ensure the system is

clear and safe and reset on site. No remote reset is allowed.

viii) Clear physical indicator

- Shutdown valve shall be equipped with visible external valve position indicators to provide

clear positioning and status of a shutdown valve.

ix) Position switches

Position switches shall be provided on shutdown valve to provide clear positioning and status

of a shutdown valve to control room.

x) Partial Stroke Testing of Shutdown Valve

A shutdown valve in critical service e.g. Pipeline outgoing and incoming shutdown valve

(ESDV) will required periodically partial stroke testing in order to maintain / increase it

reliability, availability & SIL level.

xi) Accumulator

Some shutdown valve may be equipped with accumulator to facilitate valve stroking and /or

reopen in the event maloperation.

xii) Second Solenoid valve

Shutdown valve in critical service may be equipped with second solenoid valve to increase

reliability and availability.

You might also like

- API 598, EN 12266-1 Leakage RatesDocument2 pagesAPI 598, EN 12266-1 Leakage RatesjshadwanNo ratings yet

- Hydraulic Power Unit Cum Control Panel: Sheet No. 1 of 1Document1 pageHydraulic Power Unit Cum Control Panel: Sheet No. 1 of 1rakeshsundaramurthyNo ratings yet

- Magnetic Flow Meter 1 - 6f9aDocument16 pagesMagnetic Flow Meter 1 - 6f9aSilvaACANo ratings yet

- Safety Analysis Function Evaluation Chart: TBBM Tanjung Uban ProjectDocument3 pagesSafety Analysis Function Evaluation Chart: TBBM Tanjung Uban ProjectAriz Joelee ArthaNo ratings yet

- Buckling Pin Pressure Relief Technology PDFDocument12 pagesBuckling Pin Pressure Relief Technology PDFfkboulosNo ratings yet

- Vortex WellDocument7 pagesVortex WellPirun SirimangkaloNo ratings yet

- Parker Industrial Hose Catalog 4800Document258 pagesParker Industrial Hose Catalog 4800MROstop.comNo ratings yet

- Scotch Yoke or Rack-and-Pinion Quarter-Turn Actuator?Document2 pagesScotch Yoke or Rack-and-Pinion Quarter-Turn Actuator?Assured AutomationNo ratings yet

- Statoil TR0042 Version 4Document14 pagesStatoil TR0042 Version 4BlainNo ratings yet

- DC 950045 001Document1 pageDC 950045 001Abu Anas M.SalaheldinNo ratings yet

- Fisher 2500 249 Pneumatic Controllers Transmitters en 127050Document16 pagesFisher 2500 249 Pneumatic Controllers Transmitters en 127050GOKUL PRASADNo ratings yet

- New SSIV InstallationDocument12 pagesNew SSIV InstallationDidiNo ratings yet

- Applications Guideline-Flashing (Water)Document2 pagesApplications Guideline-Flashing (Water)strahor7492No ratings yet

- Safety ManualDocument88 pagesSafety ManualSelsayed428No ratings yet

- PVRVDocument4 pagesPVRVbkkbrazil100% (1)

- Pyroban Wallchart 2019Document1 pagePyroban Wallchart 2019abdelhalimNo ratings yet

- Section 34 - Sight GlassDocument27 pagesSection 34 - Sight GlasshammamiNo ratings yet

- Manual Valves - Flow CoefficientsDocument4 pagesManual Valves - Flow Coefficientspal_stephenNo ratings yet

- HippsDocument31 pagesHippsAjaykumar TiwariNo ratings yet

- Conservation Vent Specifications and Principles of OperationDocument8 pagesConservation Vent Specifications and Principles of OperationRuban PaulNo ratings yet

- TSV and PSV PDFDocument5 pagesTSV and PSV PDFMetoo ChyNo ratings yet

- Spec For Shutdown ValvesDocument24 pagesSpec For Shutdown ValvesYogesh Kumar Bhatnagar100% (1)

- Mokveld Test Unit VTU-1Document1 pageMokveld Test Unit VTU-1eng_moh04No ratings yet

- Theoretical overview of surge analysesDocument14 pagesTheoretical overview of surge analysesdNo ratings yet

- ActuationDocument12 pagesActuationZeeshan KhanNo ratings yet

- EGE15B5Document56 pagesEGE15B5Jhonny Rafael Blanco CauraNo ratings yet

- Fisher EW Series (EWD/EWS/EWT) Sliding - Stem Control Valves Through NPS 12x8Document36 pagesFisher EW Series (EWD/EWS/EWT) Sliding - Stem Control Valves Through NPS 12x8Marcelo Alves Dos SantosNo ratings yet

- Literature Pressure GaugesDocument5 pagesLiterature Pressure GaugesHardik AcharyaNo ratings yet

- Pneumatic Actuated Ball Valve PE4320Document2 pagesPneumatic Actuated Ball Valve PE4320Fa ChNo ratings yet

- RP G103 2007Document82 pagesRP G103 2007Robert SmallwoodNo ratings yet

- Elastopipe A Flexible Piping SystemDocument2 pagesElastopipe A Flexible Piping SystemRuano StumpfNo ratings yet

- Nuflo Mc-III Exp DatasheetDocument4 pagesNuflo Mc-III Exp DatasheetJerrydawangNo ratings yet

- High Integrity Pressure Protection System SIL VerificationDocument22 pagesHigh Integrity Pressure Protection System SIL Verificationjose vasquezNo ratings yet

- Habonim SIL CertificationDocument7 pagesHabonim SIL Certificationjamil vora0% (1)

- Coriolis Flow Meter FSI Workshop 15.0Document22 pagesCoriolis Flow Meter FSI Workshop 15.0Reza NazariNo ratings yet

- Trelleborg Piping SPEC. REV CDocument1 pageTrelleborg Piping SPEC. REV CSIVANo ratings yet

- OLGA 7-NotesDocument10 pagesOLGA 7-NotesraminabkNo ratings yet

- AADvance Controller System BuildDocument161 pagesAADvance Controller System BuildFer EscalonaNo ratings yet

- Catalog Foxboro Pneumatic Instruments 03-11Document88 pagesCatalog Foxboro Pneumatic Instruments 03-11Chu Tùng100% (1)

- Safety - System ESD PSDDocument9 pagesSafety - System ESD PSDMakiber100% (1)

- CRP Sampling Literature PDFDocument8 pagesCRP Sampling Literature PDFgullenariNo ratings yet

- ActuationDocument12 pagesActuationSrimp sasaNo ratings yet

- BEL - 6D Through Conduit GateDocument2 pagesBEL - 6D Through Conduit Gateasoka.pwNo ratings yet

- Model Selection de Codification ChartDocument7 pagesModel Selection de Codification ChartGopinath GunasekaranNo ratings yet

- Compressed Natural Gas Facility: Ranges, Alarms, Trips, and SetpointDocument2 pagesCompressed Natural Gas Facility: Ranges, Alarms, Trips, and SetpointArnel MorenoNo ratings yet

- NR 15 - Unhealthy Activities and Operations PDFDocument96 pagesNR 15 - Unhealthy Activities and Operations PDFpNo ratings yet

- 60.30-069 - 1994specification For Differential PressureDocument5 pages60.30-069 - 1994specification For Differential PressurepradeepNo ratings yet

- GBA Flare Systems BrochureDocument15 pagesGBA Flare Systems BrochurejpvissottoNo ratings yet

- P-100 - Process Systems Ed3, 2010Document42 pagesP-100 - Process Systems Ed3, 2010Dragoslav Dzolic100% (1)

- ROX000318781 - AF Functional Description For Roxar 2600 MPFMDocument34 pagesROX000318781 - AF Functional Description For Roxar 2600 MPFMOmar Al SousliNo ratings yet

- SIL-assignment Example Using Risk Graph MatrixDocument4 pagesSIL-assignment Example Using Risk Graph MatrixTFattahNo ratings yet

- 00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentDocument4 pages00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentFaizal AbdullahNo ratings yet

- FC Gate Valve TrimDocument1 pageFC Gate Valve TrimPetrotrim ServicesNo ratings yet

- Emergency shutdown valve function and typesDocument4 pagesEmergency shutdown valve function and typesKyrie Abaya100% (1)

- What Is An ESD PDFDocument6 pagesWhat Is An ESD PDFSaid FerdjallahNo ratings yet

- Chemical & Process Technology - 12 Features Required For Shutdown Valve (SDV)Document5 pagesChemical & Process Technology - 12 Features Required For Shutdown Valve (SDV)Karl GlorstadNo ratings yet

- Using FCI-70-2 or API-598 - Valve Engineering - Eng-TipsDocument4 pagesUsing FCI-70-2 or API-598 - Valve Engineering - Eng-TipsMAHESH CHANDNo ratings yet

- Instruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaDocument14 pagesInstruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaAlexandre EmmerickNo ratings yet

- M B Lal NoteDocument3 pagesM B Lal Noteutut yfhgNo ratings yet

- Cross Reference of ASTM Material SpecificationsDocument3 pagesCross Reference of ASTM Material Specificationsnazury2kNo ratings yet

- Difference Between PSL1 and PSL2Document1 pageDifference Between PSL1 and PSL2samkarthik47100% (1)

- ENARDO Flame Arrestor Technology ExplainedDocument14 pagesENARDO Flame Arrestor Technology ExplainedVishnu TejaNo ratings yet

- IP Vs NEMADocument2 pagesIP Vs NEMAnazury2kNo ratings yet

- Ultrasonic Flow-MeterDocument16 pagesUltrasonic Flow-MeterSugun Kumar PedapudiNo ratings yet

- Vortex CoolersDocument2 pagesVortex Coolersnazury2kNo ratings yet

- NAMUR NE43 - Analog Output SignalDocument2 pagesNAMUR NE43 - Analog Output Signalnazury2k100% (1)

- Oil and Gas AuditDocument7 pagesOil and Gas AuditShamsur Rahman Russell100% (1)

- CT DetailsDocument12 pagesCT DetailssilakramNo ratings yet

- Equal Angles 1Document1 pageEqual Angles 1nazury2kNo ratings yet

- RTJ DimensionsDocument6 pagesRTJ Dimensionsnazury2kNo ratings yet

- Terrorism Is Not A Muslim MonopolyDocument2 pagesTerrorism Is Not A Muslim Monopolynazury2kNo ratings yet

- Volvo Control Valve PortsDocument8 pagesVolvo Control Valve PortsAnas Omar100% (1)

- Excavator Cat 322c Diagram HydDocument2 pagesExcavator Cat 322c Diagram HydJhon VillamizarNo ratings yet

- Valve Types and RefineryDocument35 pagesValve Types and RefineryVo Hai HungNo ratings yet

- Diagram Alir Proses Pra-Rancangan Pabrik Ethylbenzene Dari Benzene Dan Ethylene Proses Mobil-Badger Dengan Kapasitas Produksi 200.000 Ton/TahunDocument1 pageDiagram Alir Proses Pra-Rancangan Pabrik Ethylbenzene Dari Benzene Dan Ethylene Proses Mobil-Badger Dengan Kapasitas Produksi 200.000 Ton/TahunirvanNo ratings yet

- EMKADE EDi Inventory-2016Document31 pagesEMKADE EDi Inventory-2016Renato BarbozaNo ratings yet

- Preaction System With Model DV-5 Deluge Valve Double Interlock - Electric/Electric Actuation 1-1/2 Thru 8 Inch (DN40 Thru DN200)Document14 pagesPreaction System With Model DV-5 Deluge Valve Double Interlock - Electric/Electric Actuation 1-1/2 Thru 8 Inch (DN40 Thru DN200)PhuNguyenHoangNo ratings yet

- Desuperheater Catalog of DAEJU CONTROL CO., LTD.Document28 pagesDesuperheater Catalog of DAEJU CONTROL CO., LTD.Ki Ho ChungNo ratings yet

- 82848211-TREX-05106 Equipmenl Alerl ReviewDocument10 pages82848211-TREX-05106 Equipmenl Alerl ReviewHKHKBOOKSNo ratings yet

- Consolidated Relief Valves SRVDocument498 pagesConsolidated Relief Valves SRVHitesh PanchalNo ratings yet

- Valve Inspection ChecklistDocument1 pageValve Inspection ChecklistMohamed Afsal100% (11)

- 6.cylinder Head and ValvetrainDocument14 pages6.cylinder Head and ValvetrainKuba SwkNo ratings yet

- 330C Excavator Hydraulic System: Cya1-Up Haa1-Up Mca1-Up Jab1-Up Kdd1-Up Gag1-Up Gkx1-Up Dky1-UpDocument2 pages330C Excavator Hydraulic System: Cya1-Up Haa1-Up Mca1-Up Jab1-Up Kdd1-Up Gag1-Up Gkx1-Up Dky1-UpJose QuispeNo ratings yet

- TP Catalogue 2012 LowendDocument86 pagesTP Catalogue 2012 Lowendbobsam66No ratings yet

- DSA 2011 01967 - Spare Parts ListDocument2 pagesDSA 2011 01967 - Spare Parts ListMehedi HasanNo ratings yet

- VZPR enDocument14 pagesVZPR enoanzarNo ratings yet

- MRP Catalog - North - July 2022Document96 pagesMRP Catalog - North - July 2022amjadNo ratings yet

- Hindware Bathroom Fittings PricelistDocument31 pagesHindware Bathroom Fittings PricelistlkovijayNo ratings yet

- High pressure steam system notes and detailsDocument1 pageHigh pressure steam system notes and detailszhangNo ratings yet

- Daily ScheduleDocument40 pagesDaily SchedulesajanchaudhariNo ratings yet

- Section04 Relief ValvesDocument30 pagesSection04 Relief ValvesMarcin EldorNo ratings yet

- Foundation Course On DRS: (District Regulating Station)Document22 pagesFoundation Course On DRS: (District Regulating Station)ToniNo ratings yet

- Frg/2Mb Frg/2Mbc Frg/2Mcc Rg/2Mcc Frg/2Mcs Rg/2McsDocument19 pagesFrg/2Mb Frg/2Mbc Frg/2Mcc Rg/2Mcc Frg/2Mcs Rg/2McsJorge SaavedraNo ratings yet

- Hidraulica - TaicinDocument4 pagesHidraulica - TaicinJhoompieer VFNo ratings yet

- Hydraulics 12: CatalogueDocument107 pagesHydraulics 12: CatalogueПетр ШкильNo ratings yet

- Material Valve, Fittting, Pump Room - PT MicoDocument9 pagesMaterial Valve, Fittting, Pump Room - PT MicoPurnama HelmiNo ratings yet

- Klinger Marine Bronze Valves: Globe & SDNR Valves - ThreadedDocument64 pagesKlinger Marine Bronze Valves: Globe & SDNR Valves - ThreadedPipolo PippoNo ratings yet

- ONGC - Approved Vendor ListDocument4 pagesONGC - Approved Vendor ListAnonymous gr5Pr9AVNo ratings yet

- Gate Valve Butterfly Valve and Check Valve EditDocument4 pagesGate Valve Butterfly Valve and Check Valve EditDhimas IriantoNo ratings yet

- Fitting Catalog 2013: Maret 2013 - 112Document39 pagesFitting Catalog 2013: Maret 2013 - 112SujokoTeeNo ratings yet

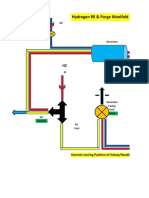

- Hydrogen Fill & Purge Manifold: GeneratorDocument12 pagesHydrogen Fill & Purge Manifold: GeneratorSAROJNo ratings yet