Professional Documents

Culture Documents

Job Safety Analysis Worksheet: HSE-JSA/XII/17

Uploaded by

Bayu HidayatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis Worksheet: HSE-JSA/XII/17

Uploaded by

Bayu HidayatCopyright:

Available Formats

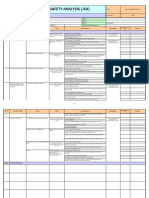

JOB TITLE OR OPERATION LOCATION DATE NO DOC.

JOB SAFETY ANALYSIS

WORKSHEET

Lifting Gear Inspection HSE-JSA/XII/17

COMPLETE BY EMPLOYEE/ OPERATOR REVIEWED AND APPROVED BY

Signature :

Name : 1 Sign Name :

Position : 2 Sign Position :

Signature :

3 Sign Name :

Sign :

4 Sign Position :

Signature :

COMPANY/ ORGANIZATION WORK SECTION / DEPARTMENT Name :

ABC Position :

REQUIRE RECOMMENDED PERSONAL PROTECTIVE EQUIPMENT/ SAFE WORK PERMITS

Yes, PPE & Safe Work Permits are recommended,

PPE : Helmet cover all Flame Retardant Safety Body Harness

safety glass/ google Hand Glove

masker safety shoes

BASIC JOB STEP, IN SEQUENCE POTENTIAL HAZARDS RECOMMENDED PREVENTIVE MEASURES

No. A. Job Planing / Preparation

Loud & clear during submit all job

1 Conducted Pre job safety meeting Unclear voice, Miscommunication,

plan & risk assesment

Personal injury Prepare all

Equipment failure, pared cable,

2 Prepare all tool & equipment needed neceseary tools / equipment as per

required on the job

Review minimum PPE requirement,

consider:

Defective of PPE, Improper PPE for

3 Asses PPE requirements Safety halmet, glasses,

the job,

handgloves,shoes, coverall,

additonal PPE i.e body harness,

B. Job Carry Out

Removing Paint using brushing and Wire brusing and dust rust, Use hand glove, face shield,

4

chemical removing paint Iritations/ Chemical Exposure. googles, mask, from injured.

Wearing proper & correct PPE (body

Visual dan Dimensional Checks Unit Fall from a high position, Pinch harness) during perform a job,

5

and Sling point. Hand & body placement in right

position,

Hand & body placement in right

position, Ensure there are MSDS/

electricity, Chemical Exposure,

6 MPI / PTI Test certificate of chemical list and the

Pinch point

crew understand about content of

MSDS (risk, potential hazard, etc).

C. Job Completion

Bad house keeping, Ensure all tools and equipments are

7 Housekeeping

Loosing tools and equipments return the proper place

Page 1 of 1

You might also like

- Lifting and Removing Using Unloading, Loading and Placing 0F Cable ReelsDocument3 pagesLifting and Removing Using Unloading, Loading and Placing 0F Cable ReelsAMINNo ratings yet

- Cutting ActivitiesDocument3 pagesCutting ActivitiesWalid KhelfaNo ratings yet

- TEIPL-JSA-058 Carpentry Wood WorkDocument3 pagesTEIPL-JSA-058 Carpentry Wood Workba ratnaparkheNo ratings yet

- Jha For RoadworksDocument15 pagesJha For RoadworksHenry RajahNo ratings yet

- KaphDocument7 pagesKaphFrater MagusNo ratings yet

- JHA Manual HandlingDocument5 pagesJHA Manual HandlingFatin Zulkifli100% (1)

- Must Know+Polish+Slang+Words+&+PhrasesDocument103 pagesMust Know+Polish+Slang+Words+&+PhrasesArkadiusz StrzeszewskiNo ratings yet

- TheAncientWisdom AnnieBesantDocument153 pagesTheAncientWisdom AnnieBesantJose Fernandez Romero100% (2)

- Kiran S (1) - Kedlaya - The William Lowell Putnam Mathematical Competition 1985-2000Document351 pagesKiran S (1) - Kedlaya - The William Lowell Putnam Mathematical Competition 1985-2000ellioatNo ratings yet

- JHA General Maintenance Activity PDFDocument5 pagesJHA General Maintenance Activity PDFdede SinbadNo ratings yet

- JSA Communication Tower Painting Foundation Repairs at WR - 501 WR - 617) - 6-20-21Document23 pagesJSA Communication Tower Painting Foundation Repairs at WR - 501 WR - 617) - 6-20-21Shaikh Abu bakarNo ratings yet

- JSA-001 Earth Works & Civil WorksDocument5 pagesJSA-001 Earth Works & Civil WorksMoaatazz Nouisri50% (2)

- JSA Hot WorkDocument3 pagesJSA Hot WorkNasir Mehmood Aryani100% (1)

- (Bruce H. Walker) Optical Design For Visual SystemDocument166 pages(Bruce H. Walker) Optical Design For Visual SystemDewata100% (3)

- Safety Behavior Observation Checklist: Observe Quietly. Mark Each Observation ItemDocument1 pageSafety Behavior Observation Checklist: Observe Quietly. Mark Each Observation Itemkhrayzie bhone100% (3)

- Jsa PolypipeDocument2 pagesJsa PolypipeHow Chin Engineering Sdn BhdNo ratings yet

- Positif Jsa HMCFDDocument4 pagesPositif Jsa HMCFDBryant TorresNo ratings yet

- Semi 4 Ex Sol 3Document4 pagesSemi 4 Ex Sol 3Devendra ChauhanNo ratings yet

- High Pressur Hydro Testing JSA 03Document5 pagesHigh Pressur Hydro Testing JSA 03Saiyad RiyazaliNo ratings yet

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Paket Petronas Ame + Usg AbdomenDocument3 pagesPaket Petronas Ame + Usg AbdomenBayu HidayatNo ratings yet

- API Specification 7-2 2nd Edition Addendum 1 20200320Document8 pagesAPI Specification 7-2 2nd Edition Addendum 1 20200320Bayu HidayatNo ratings yet

- Job Safety Analysis: Department: (Bagian/fungsi)Document9 pagesJob Safety Analysis: Department: (Bagian/fungsi)Yosua SitumorangNo ratings yet

- BBS ChecklistDocument3 pagesBBS ChecklistTarun KakkarNo ratings yet

- JSA Teflon - U BoltDocument3 pagesJSA Teflon - U BoltHow Chin Engineering Sdn BhdNo ratings yet

- Solar Pavement - A New Emerging TechnologyDocument13 pagesSolar Pavement - A New Emerging TechnologyMauricio Pertuz ParraNo ratings yet

- Semantics and GrammarDocument12 pagesSemantics and GrammarYara TarekNo ratings yet

- Job Safety Analysis: 10.06.2017 Page 1 of 7Document7 pagesJob Safety Analysis: 10.06.2017 Page 1 of 7Raghava RichhuNo ratings yet

- Lifting Work PermitDocument1 pageLifting Work PermitRadha BuildtechNo ratings yet

- Job Safety Analysis: Pembuatan Dinding PenahanDocument7 pagesJob Safety Analysis: Pembuatan Dinding PenahanAnnisa AgustinaNo ratings yet

- API Specification 7-2 2nd Edition Errata 2 20191205Document2 pagesAPI Specification 7-2 2nd Edition Errata 2 20191205Bayu HidayatNo ratings yet

- Jsa Dismantling The Wooden Framework-NewDocument3 pagesJsa Dismantling The Wooden Framework-NewHow Chin Engineering Sdn BhdNo ratings yet

- JSA Safety Valve CertivicationDocument12 pagesJSA Safety Valve CertivicationelvandiNo ratings yet

- HIRA WaterproofingDocument16 pagesHIRA WaterproofingPRIYESH . K. PRIYANNo ratings yet

- JSA Install RepeaterDocument2 pagesJSA Install Repeatertelteguh01No ratings yet

- Phalaborwa - ZBS Upgrade ProjectDocument2 pagesPhalaborwa - ZBS Upgrade Projectcontrax8No ratings yet

- SOP For Compressors 009Document2 pagesSOP For Compressors 009Clifford ThackwrayNo ratings yet

- JSA Install ScaffoldingDocument2 pagesJSA Install Scaffoldingtelteguh01No ratings yet

- Job Safety Analysis (Jsa) FormDocument1 pageJob Safety Analysis (Jsa) FormsigitNo ratings yet

- Phalaborwa - ZBS Upgrade ProjectDocument2 pagesPhalaborwa - ZBS Upgrade Projectcontrax8100% (1)

- Chipping: Job Safety AnalysisDocument2 pagesChipping: Job Safety Analysisridhoni putraNo ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.004Document7 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.004Yosua SitumorangNo ratings yet

- JHA - Lifting of Air Receiver Tank AR 1 ADocument4 pagesJHA - Lifting of Air Receiver Tank AR 1 AAizuddinNo ratings yet

- Daqing Petroleum Iraq Branch Job Safety Analysis 工作安全分析: HSE-MS/Doc. No.22Document2 pagesDaqing Petroleum Iraq Branch Job Safety Analysis 工作安全分析: HSE-MS/Doc. No.22khurramNo ratings yet

- JHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Document2 pagesJHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Armando AballeNo ratings yet

- SWP - Riyad ProjectDocument6 pagesSWP - Riyad ProjectRais BurondkarNo ratings yet

- SWMS No 11 Duct CuttingDocument5 pagesSWMS No 11 Duct CuttingMokka SamaiyalNo ratings yet

- SWMS No 6 Threaded Rod InstallingDocument6 pagesSWMS No 6 Threaded Rod InstallingMokka SamaiyalNo ratings yet

- JHA Conveyor Belt ChangingDocument9 pagesJHA Conveyor Belt ChangingMohammad Sharique PathanNo ratings yet

- Langkah Pekerjaan: Job StepDocument4 pagesLangkah Pekerjaan: Job StepelvandiNo ratings yet

- JSA 173 - CRT RIG UP - Updated 21.10.2019Document11 pagesJSA 173 - CRT RIG UP - Updated 21.10.2019tafhim rashidNo ratings yet

- Jsa TubularDocument2 pagesJsa TubularRonniNo ratings yet

- JSA Hot WorkDocument1 pageJSA Hot WorkAli Ramadhan AksodiNo ratings yet

- High Pressur Hydro Testing JSA 03Document6 pagesHigh Pressur Hydro Testing JSA 03Nikunja mohantyNo ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.013Document5 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.013Yosua SitumorangNo ratings yet

- Termination CableDocument29 pagesTermination CableMuhamad HasbiNo ratings yet

- Pulling, Dress and GlandDocument2 pagesPulling, Dress and GlandAbdul Hakam Mohamed YusofNo ratings yet

- Jsa Fueling Barge From The DockDocument2 pagesJsa Fueling Barge From The DockIlya BordonosovNo ratings yet

- Job Safety Analysis: Printed in USA Saf 55 (Front) Nov 95Document2 pagesJob Safety Analysis: Printed in USA Saf 55 (Front) Nov 95AdilMunirNo ratings yet

- JSA Elevator MaintenancDocument6 pagesJSA Elevator MaintenancHSE fahadNo ratings yet

- Survy WorkDocument4 pagesSurvy Workاسامه محمد راضي جعفرNo ratings yet

- JSA-AUST-HAL-PE-037 PS Rev - ACIDDocument7 pagesJSA-AUST-HAL-PE-037 PS Rev - ACIDIulian Costin IonNo ratings yet

- Panipat Refinery & Petrochemical Complex Job Safety AnalysisDocument6 pagesPanipat Refinery & Petrochemical Complex Job Safety AnalysisSaiyad RiyazaliNo ratings yet

- Job Hazard Analysis (JHA) Worksheet: Jerp # 3 Aromatic UnitDocument5 pagesJob Hazard Analysis (JHA) Worksheet: Jerp # 3 Aromatic UnitTeodoro EsquilloNo ratings yet

- JOB Observation Checklist Safe UnsafeDocument3 pagesJOB Observation Checklist Safe UnsafeHelp Tubestar CrewNo ratings yet

- Ban Company Job Hazard Analysis (Jha) WorksheetDocument2 pagesBan Company Job Hazard Analysis (Jha) WorksheetMarwan NazzalNo ratings yet

- R.C.C and P.C.C Work JsaDocument1 pageR.C.C and P.C.C Work JsaAKBAR ALINo ratings yet

- RA of Manual ChippingDocument2 pagesRA of Manual ChippingMohamedSaidNo ratings yet

- Splicing, Termination and POWER Cable TestDocument3 pagesSplicing, Termination and POWER Cable TestEthos SeptiansyahNo ratings yet

- HIRAC - AC Cooler Blower (Daily Inspection)Document2 pagesHIRAC - AC Cooler Blower (Daily Inspection)Randy PedrozaNo ratings yet

- Argus-Biomass-Markets - 4 Oct 2023Document19 pagesArgus-Biomass-Markets - 4 Oct 2023Bayu HidayatNo ratings yet

- MSDS Tanah ElektrolitDocument5 pagesMSDS Tanah ElektrolitBayu HidayatNo ratings yet

- Argus-Biomass-Markets - 29 Sep 2023Document15 pagesArgus-Biomass-Markets - 29 Sep 2023Bayu HidayatNo ratings yet

- Operation Daily Quarantine Report: 31 Januari 2021Document1 pageOperation Daily Quarantine Report: 31 Januari 2021Bayu HidayatNo ratings yet

- Operation Daily Quarantine Report: 29 Januari 2021Document1 pageOperation Daily Quarantine Report: 29 Januari 2021Bayu HidayatNo ratings yet

- Operation Daily Quarantine Report: 28 Januari 2021Document1 pageOperation Daily Quarantine Report: 28 Januari 2021Bayu HidayatNo ratings yet

- Palasgians, Pre Ancient Greeks..Document14 pagesPalasgians, Pre Ancient Greeks..aemilorNo ratings yet

- Najo Modular Interface Quick StartDocument71 pagesNajo Modular Interface Quick StartAaron SmithNo ratings yet

- Human Resource DepartmentDocument6 pagesHuman Resource DepartmentHardik BabelNo ratings yet

- Sapphire SAP CRMDocument23 pagesSapphire SAP CRMvinay_vadrevuNo ratings yet

- VSSDocument5 pagesVSSAiman HakimNo ratings yet

- Chapter 1Document11 pagesChapter 1Crist John PastorNo ratings yet

- How To Configure IP Address For Ethernet Port PrintersDocument6 pagesHow To Configure IP Address For Ethernet Port PrintersIsis DiazNo ratings yet

- Catatan Statisktik FIXDocument59 pagesCatatan Statisktik FIXAndrian WicaksonoNo ratings yet

- Molinos Eolicos VestasDocument41 pagesMolinos Eolicos VestasOscar Männlich100% (1)

- Inductive Reasoning For LearningDocument7 pagesInductive Reasoning For LearningKashaf SheikhNo ratings yet

- Record & Field Mapping For Fusion ReportsDocument6 pagesRecord & Field Mapping For Fusion ReportsRajiNo ratings yet

- Chem 1 SyllabusDocument10 pagesChem 1 SyllabusJaycee TualaNo ratings yet

- Heli FlexDocument5 pagesHeli Flexdmepdo100% (2)

- LSP Writeshop Guide 2014Document84 pagesLSP Writeshop Guide 2014Michelle de los Santos100% (2)

- AIS Chapter 11 CasesDocument6 pagesAIS Chapter 11 CasesHarold Dela FuenteNo ratings yet

- يَا نَبِي سَلَام عَلَيْكَDocument1 pageيَا نَبِي سَلَام عَلَيْكَAcengMNasruddinNo ratings yet

- Von Neumann Stability Analysis of Reduced Navier-Stokes Equations in Vorticity-Stream Function FormulationDocument8 pagesVon Neumann Stability Analysis of Reduced Navier-Stokes Equations in Vorticity-Stream Function FormulationAshish mishraNo ratings yet

- Transcribed Speech Roberto Mangabeira Unger at Social FrontiersDocument4 pagesTranscribed Speech Roberto Mangabeira Unger at Social Frontiersmarli_kaboomNo ratings yet

- GMO's and LabelingDocument30 pagesGMO's and LabelingNational Press FoundationNo ratings yet

- The Threat of Ethical Accountants An Application of Foucault's Concept of Ethics To Accounting Education and Some Thoughts On Ethically Educating For The Other 1999 Critical PerspectivesDocument34 pagesThe Threat of Ethical Accountants An Application of Foucault's Concept of Ethics To Accounting Education and Some Thoughts On Ethically Educating For The Other 1999 Critical PerspectivesiportobelloNo ratings yet

- Outline: Optimum Spray Cooling in Continuous Slab Casting Process Under Productivity ImprovementDocument5 pagesOutline: Optimum Spray Cooling in Continuous Slab Casting Process Under Productivity ImprovementKiatkajohn WorapradyaNo ratings yet

- Attitude Change Social PsychologyDocument16 pagesAttitude Change Social PsychologyJaebeom's Best FriendNo ratings yet