Professional Documents

Culture Documents

NZS 3101-06 RC-BM-001

Uploaded by

renzo1221Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NZS 3101-06 RC-BM-001

Uploaded by

renzo1221Copyright:

Available Formats

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

EXAMPLE NZS 3101-06 RC-BM-001

Flexural and Shear Beam Design

PROBLEM DESCRIPTION

The purpose of this example is to verify slab flexural design in SAFE. The load

level is adjusted for the case corresponding to the following conditions:

The stress-block extends below the flange but remains within the balanced

condition permitted by NZS 3101-06.

The average shear stress in the beam is below the maximum shear stress

allowed by NZS 3101-06, requiring design shear reinforcement.

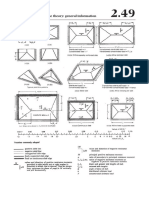

A simple-span, 6-m-long, 300-mm-wide, and 500-mm-deep T beam with a

flange 100 mm thick and 600 mm wide is modeled using SAFE. The beam is

shown in Figure 1. The computational model uses a finite element mesh of frame

elements, automatically generated by SAFE. The maximum element size has

been specified to be 200 mm. The beam is supported by columns without

rotational stiffnesses and with very large vertical stiffness (1 1020 kN/m).

The beam is loaded with symmetric third-point loading One dead load case

(DL50) and one live load case (LL130) with only symmetric third-point loads of

magnitudes 50, and 130 kN, respectively, are defined in the model. One load

combinations (COMB130) is defined with the NZS 3101-06 load combination

factors of 1.2 for dead loads and 1.5 for live loads. The model is analyzed for

both of these load cases and the load combinations.

The beam moment and shear force are computed analytically. The total factored

moment and shear force are compared with the SAFE results. These moment and

shear force are identical. After completing the analysis, design is performed

using the NZS 3101-06 code in SAFE and also by hand computation. Table 1

shows the comparison of the design longitudinal reinforcements. Table 2 shows

the comparison of the design shear reinforcements.

EXAMPLE NZS 3101-06 RC-BM-001 - 1

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

600 mm

75 mm 100 mm

500 mm

75 mm

300 mm

Beam Section

2000 mm 2000 mm 2000 mm

Shear Force

Bending Moment

Figure 1 The Model Beam for Flexural and Shear Design

EXAMPLE NZS 3101-06 RC-BM-001 - 2

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

GEOMETRY, PROPERTIES AND LOADING

Clear span, l = 6000 mm

Overall depth, h = 500 mm

Flange Thickness, ds = 100 mm

Width of web, bw = 300 mm

Width of flange, bf = 600 mm

Depth of tensile reinf., dc = 75 mm

Effective depth, d = 425 mm

Depth of comp. reinf., d' = 75 mm

Concrete strength, f' c = 30 MPa

Yield strength of steel, fy = 460 MPa

Concrete unit weight, wc = 0 kN/m3

Modulus of elasticity, Ec = 25x105 MPa

Modulus of elasticity, Es = 2x108 MPa

Poisson’s ratio, v = 0.2

Dead load, Pd = 50 kN

Live load, Pl = 130 kN

TECHNICAL FEATURES OF SAFE TESTED

Calculation of flexural and shear reinforcement

Application of minimum flexural and shear reinforcement

RESULTS COMPARISON

Table 1 shows the comparison of the SAFE total factored moments in the design

strip with the moments obtained by the analytical method. They match exactly

for this problem. Table 1 also shows the comparison of design reinforcements.

Table 1 Comparison of Moments and Flexural Reinforcements

Reinforcement Area (sq-cm)

Moment

Method (kN-m) As+

SAFE 510 35.046

Calculated 510 35.046

A s ,min = 535.82 sq-m

EXAMPLE NZS 3101-06 RC-BM-001 - 3

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

Table 2 Comparison of Shear Reinforcements

Av

Reinforcement Area,

s

(sq-cm/m)

Shear Force (kN) SAFE Calculated

255 14.962 14.89

COMPUTER FILE: NZS 3101-06 RC-BM-001.FDB

CONCLUSION

The SAFE results show an acceptable close comparison with the independent

results.

EXAMPLE NZS 3101-06 RC-BM-001 - 4

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

HAND CALCULATION

Flexural Design

The following quantities are computed for the load combination:

b = 0.85

1 0.85 for f c 55MPa

1 0.85 for f c 30,

c

cb d = 240.56 mm

c f y Es

amax = 0.751cb= 153.36 mm

f c

Ac 535.82

4 fy

As ,min max sq-mm

1.4 c 136.96

A

fy

= 535.82 sq-mm

COMB130

N* = (1.2Nd + 1.5Nt) = 255 kN

N *l

M* = 510 kN-m

3

The depth of the compression block is given by:

2 M*

ad d 2

= 105.322 mm (a > Ds)

1 f c'bb f

The compressive force developed in the concrete alone is given by:

Cf is given by:

C f 1 f c b f bw h f = 765 kN

EXAMPLE NZS 3101-06 RC-BM-001 - 5

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

Cf

Therefore, As1 = and the portion of M* that is resisted by the flange is given

fy

by:

d

M *f C f d s b = 243.84375 kN-m

2

Cf

As1 = = 1663.043 sq-mm

fy

Therefore, the balance of the moment, M*, to be carried by the web is:

M*w = M* − M*f = 510 243.84375 = 266.15625 kN-m

The web is a rectangular section with dimensions bw and d, for which the depth of

the compression block is recalculated as:

2 M w*

a1 d d 2 = 110.7354 mm amax

1 f cbbw

If a1 amax (NZS 9.3.8.1), the area of tension reinforcement is then given by:

M w*

As2 = = 1841.577 sq-mm

a1

b f y d

2

As = As1 + As2 = 3504.62 sq-mm

Shear Design

The basic shear strength for rectangular section is computed as,

As

b = 0.07 10 f c = 0.3834

bw d

f c 50 MPa, and

0.08 f c = 0.438 MPa b 0.2 f c = 1.095 MPa

c = kd ka b = 0.438 where (kd =1.0, ka=1.0)

The average shear stress is limited to a maximum limit of,

vmax = min 0.2 f c , 8 MPa = min{6, 8} = 6 MPa

EXAMPLE NZS 3101-06 RC-BM-001 - 6

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

The shear reinforcement is computed as follows:

If * s v c 2 or h ≤ max(300 mm, 0.5bw)

Av

=0 (NZS 9.3.9.4.13)

s

If s v c 2 < * sc,

Av 1 bw

= f c (NZS 9.3.9.4.15)

s 16 f yt

If sc < * smax, (NZS 9.3.9.4.2)

Av

v * s vc

s s f yt d

If * > max, a failure condition is declared.

For the load combination, the N* and V* are calculated as follows:

N* = 1.2Nd + 1.5N1

V* = N*

*

V

*

=

bw d

(COMB130)

Nd = 50 kips

Nl = 130 kips

V* = 255 kN

*

V

= = 2.0 MPa (sc < smax)

* *

bw d

Av

v* s vc bw

= 1.489 sq-mm/mm = 1489 sq-mm/m

s s f yt

EXAMPLE NZS 3101-06 RC-BM-001 - 7

You might also like

- NZS 3101-2006 Example 001Document8 pagesNZS 3101-2006 Example 001RMM100% (1)

- 2017 - OPUS Quant Advanced PDFDocument205 pages2017 - OPUS Quant Advanced PDFIngeniero Alfonzo Díaz Guzmán100% (1)

- Icc-Es Esr-1917Document15 pagesIcc-Es Esr-1917kmccrapmailNo ratings yet

- Anchorbolt R1Document12 pagesAnchorbolt R1Matheus HenrichNo ratings yet

- Anchor 201 - Evaluation of Factors That Affect Bond StressDocument27 pagesAnchor 201 - Evaluation of Factors That Affect Bond StressPatrice AudetNo ratings yet

- MechatronicsDocument61 pagesMechatronicsSajitha ManuNo ratings yet

- NZS 3101-06 RC-SL-001Document5 pagesNZS 3101-06 RC-SL-001renzo1221100% (1)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Steel Ch4 - Beams MoviesDocument80 pagesSteel Ch4 - Beams Moviesomar45No ratings yet

- CE 581 Reinforced Concrete StructuresDocument82 pagesCE 581 Reinforced Concrete StructuresCelil OrakNo ratings yet

- Reinforcement For Slabs On GroundDocument7 pagesReinforcement For Slabs On GroundfordesignNo ratings yet

- Seismic Behavior and Design of Composite Steel Plate Shear Walls PDFDocument73 pagesSeismic Behavior and Design of Composite Steel Plate Shear Walls PDFmanpreetkhanujaNo ratings yet

- Steel Ch3 - Columns MovieDocument60 pagesSteel Ch3 - Columns Movieomar45No ratings yet

- Connections Between Failure Modes Observed in Shake Table Testing of Models in Building Contest and Earthquake Damage To Actual BuildingsDocument19 pagesConnections Between Failure Modes Observed in Shake Table Testing of Models in Building Contest and Earthquake Damage To Actual BuildingsSuresh BabuNo ratings yet

- 2 Lateral-Load-Transfer Session-2 2perDocument56 pages2 Lateral-Load-Transfer Session-2 2perLuis CortesNo ratings yet

- Inverted-T Bent Cap Calculations V1Document20 pagesInverted-T Bent Cap Calculations V1satyaNo ratings yet

- Hilti HIT System - Rebar ApplicationDocument34 pagesHilti HIT System - Rebar ApplicationTerence CheeNo ratings yet

- Gusset Plate Stability Using Variable Stress TrajectoriesDocument6 pagesGusset Plate Stability Using Variable Stress TrajectoriestmaNo ratings yet

- Performance Assessment and Design of Multistoreyed Reinforced Concrete Special Moment Resisting FramesDocument8 pagesPerformance Assessment and Design of Multistoreyed Reinforced Concrete Special Moment Resisting FramesRahul SharmaNo ratings yet

- Dapped-End Strengthening of Precast PSC Double Tee Beams With FRP Composites PDFDocument157 pagesDapped-End Strengthening of Precast PSC Double Tee Beams With FRP Composites PDFHyunkyoun JinNo ratings yet

- NZS 3101-06 RC-PN-001 PDFDocument6 pagesNZS 3101-06 RC-PN-001 PDFHaytham ZaghloulNo ratings yet

- Column Shortening-Compensation in Tall Buildings - PresentationsDocument28 pagesColumn Shortening-Compensation in Tall Buildings - Presentationsgulilero_yoNo ratings yet

- XTRACT - Fall2012 ManualDocument15 pagesXTRACT - Fall2012 ManualEdgarFloresGonzalesNo ratings yet

- Discussion - Steel Column Base Plate Design PDFDocument4 pagesDiscussion - Steel Column Base Plate Design PDFOtto A. CobeñaNo ratings yet

- Methodolgy A Nonlinear Analysis Method For Performance Based Seismic Design (1) - NewDocument8 pagesMethodolgy A Nonlinear Analysis Method For Performance Based Seismic Design (1) - Newsalmantop1No ratings yet

- Ensuring Seismic Safety Trough Properly Specified AnchoringDocument59 pagesEnsuring Seismic Safety Trough Properly Specified AnchoringStelian ConstantinescuNo ratings yet

- Steel - Ch1 - IntroductionDocument55 pagesSteel - Ch1 - Introductionomar45100% (1)

- Stud Welding of Shear Conector PDFDocument13 pagesStud Welding of Shear Conector PDFramdacNo ratings yet

- Effects of Column Creep and Shrinkage in Tall StructuresDocument3 pagesEffects of Column Creep and Shrinkage in Tall StructuresMagellan ChiritescuNo ratings yet

- Double Tee Ridge BeamDocument3 pagesDouble Tee Ridge BeamhuyxpkissNo ratings yet

- C StrucDesign Morgan Jun151 PDFDocument3 pagesC StrucDesign Morgan Jun151 PDFkyleNo ratings yet

- ICBO CIA-7000 Anchor SystemDocument16 pagesICBO CIA-7000 Anchor SystemDon RockwellNo ratings yet

- Doubly Reinforced Beams: Chapter 4 (Continuation)Document4 pagesDoubly Reinforced Beams: Chapter 4 (Continuation)Yo FangirlsNo ratings yet

- Design of Advanced Reinforced Concrete MembersDocument226 pagesDesign of Advanced Reinforced Concrete MembersĐỗ Nguyên KhôiNo ratings yet

- Required Thickness Rigid PlateDocument13 pagesRequired Thickness Rigid PlateMad WonderNo ratings yet

- 9.7 Vibration in Concrete Structures: PCI Design Handbook/Sixth Edition First Printing/CD-ROM EditionDocument9 pages9.7 Vibration in Concrete Structures: PCI Design Handbook/Sixth Edition First Printing/CD-ROM Editionomar42170No ratings yet

- CE697R DiaphragmsF12Document74 pagesCE697R DiaphragmsF12^passwordNo ratings yet

- Stability Design of Steel Buildings, ATT00143Document9 pagesStability Design of Steel Buildings, ATT00143yy20100No ratings yet

- Foundations and Anchor BoltsDocument6 pagesFoundations and Anchor BoltsRam BabuNo ratings yet

- Concrete Column Design Based On ACI 318-19: Input Data & Design SummaryDocument3 pagesConcrete Column Design Based On ACI 318-19: Input Data & Design SummaryKaren Esther Acuña VelasquezNo ratings yet

- TM 5 809 12 Slab On GradeDocument54 pagesTM 5 809 12 Slab On GradeGreg RabulanNo ratings yet

- Steel Tips - Composite Beam Design With Metal Deck PDFDocument9 pagesSteel Tips - Composite Beam Design With Metal Deck PDFmateus456No ratings yet

- Design of Vertical Bracing Connections For High Seismic DriftDocument12 pagesDesign of Vertical Bracing Connections For High Seismic DriftvNo ratings yet

- Wind Tunnel Testing For Tall BuildingsDocument7 pagesWind Tunnel Testing For Tall BuildingsSilver Olguín CamachoNo ratings yet

- ADAPT TN290 Vibration AnalysisDocument20 pagesADAPT TN290 Vibration AnalysisMai KawayapanikNo ratings yet

- Roberts 1991Document18 pagesRoberts 1991guojie zhouNo ratings yet

- Shear Strength of Reinforced Concrete Deep BeamsDocument4 pagesShear Strength of Reinforced Concrete Deep Beamsnevinkoshy100% (1)

- Time History Analysis With Recorded AccelerogramsDocument35 pagesTime History Analysis With Recorded Accelerogramsmariutza_lucia100% (1)

- CIGRE b2-305Document8 pagesCIGRE b2-305Jorge Pinto RochaNo ratings yet

- Dev LengthDocument5 pagesDev LengthdghtghfgjhhjjhnNo ratings yet

- Steel Interchange: Cold Weather Welding Plate Girder StiffenersDocument2 pagesSteel Interchange: Cold Weather Welding Plate Girder Stiffenershector diazNo ratings yet

- NZS 3404-1997 Example 003 PDFDocument6 pagesNZS 3404-1997 Example 003 PDFIhab El AghouryNo ratings yet

- BOLTGRP13Document31 pagesBOLTGRP13taddeoNo ratings yet

- Xie Liping 200906 PHD ThesisDocument374 pagesXie Liping 200906 PHD ThesisrammirisNo ratings yet

- Research On Steel Plate Shear Wall Past, Present, FutureDocument50 pagesResearch On Steel Plate Shear Wall Past, Present, FutureAlexander Vega VásquezNo ratings yet

- Limit State Response of Composite Columns and Beam-Columns Part I, Roberto Leon PDFDocument18 pagesLimit State Response of Composite Columns and Beam-Columns Part I, Roberto Leon PDFHeriberto Bórquez UrquidyNo ratings yet

- Csa A23.3-04 RC-BM-001Document7 pagesCsa A23.3-04 RC-BM-001Khuất Trần ThanhNo ratings yet

- Software Verification: Example Hong Kong Cp-04 Rc-Bm-001Document7 pagesSoftware Verification: Example Hong Kong Cp-04 Rc-Bm-001renzo1221No ratings yet

- CIS SAFE د ماجد البنا مقارنة الحل اليدوي والحل في برنامج 2Document7 pagesCIS SAFE د ماجد البنا مقارنة الحل اليدوي والحل في برنامج 2bassam1911992No ratings yet

- AS 3600-2009 Ex001Document8 pagesAS 3600-2009 Ex001Antonius AjalahNo ratings yet

- Aci 318-14 RC-BM-001Document7 pagesAci 318-14 RC-BM-001Bunkun15No ratings yet

- VB4-24 - Footing DesignDocument16 pagesVB4-24 - Footing Designrenzo1221No ratings yet

- Analytical ThinkingDocument1 pageAnalytical Thinkingrenzo1221No ratings yet

- Rectangular Beam Design - 2010 NSCPDocument2 pagesRectangular Beam Design - 2010 NSCPrenzo1221No ratings yet

- Checklist For Concrete Shear Wall (ACI 318-14)Document5 pagesChecklist For Concrete Shear Wall (ACI 318-14)renzo1221No ratings yet

- Software Verification: Example Hong Kong Cp-04 Rc-Bm-001Document7 pagesSoftware Verification: Example Hong Kong Cp-04 Rc-Bm-001renzo1221No ratings yet

- WT 4x A0 X 1Z, I X 1e.g W T 4 X 1 4 X 1 2 WT 4 X 10, I XG Tfiff 4 X Z.G X - B - G x5 WT 3 X 14,5 X 1 0Document3 pagesWT 4x A0 X 1Z, I X 1e.g W T 4 X 1 4 X 1 2 WT 4 X 10, I XG Tfiff 4 X Z.G X - B - G x5 WT 3 X 14,5 X 1 0renzo1221No ratings yet

- Contracts 2019Document37 pagesContracts 2019renzo1221No ratings yet

- 2-Way Yield Line TheoryDocument1 page2-Way Yield Line Theoryrenzo1221No ratings yet

- App5 - EC2 Design PDFDocument70 pagesApp5 - EC2 Design PDFrenzo1221No ratings yet

- Handout (Final) 071517 - Carlos M. Villaraza PDFDocument3 pagesHandout (Final) 071517 - Carlos M. Villaraza PDFrenzo1221No ratings yet

- Hong Kong CoP-04 RC-PN-001 PDFDocument5 pagesHong Kong CoP-04 RC-PN-001 PDFrenzo1221No ratings yet

- Software Verification: Example 12Document6 pagesSoftware Verification: Example 12renzo1221No ratings yet

- Piled Raft Foundations For Tall BuildingsDocument8 pagesPiled Raft Foundations For Tall Buildingsrenzo1221No ratings yet

- Road Tunnel Projects in ASEAN RegionDocument52 pagesRoad Tunnel Projects in ASEAN Regionrenzo1221No ratings yet

- Railway Development in Metro Manila: Engr. Deo Leo N. Manalo, PHDDocument29 pagesRailway Development in Metro Manila: Engr. Deo Leo N. Manalo, PHDrenzo1221No ratings yet

- GGHHHDocument3 pagesGGHHHjovica37No ratings yet

- Umass Lowell Computer Science 91.503: Graduate AlgorithmsDocument46 pagesUmass Lowell Computer Science 91.503: Graduate AlgorithmsShivam AtriNo ratings yet

- Stiffness Analysis of FramesDocument37 pagesStiffness Analysis of FramesCarolina VacaNo ratings yet

- Zhang2021 Article TransportPhenomenonFlowFieldAnDocument11 pagesZhang2021 Article TransportPhenomenonFlowFieldAnJoão Victor OsórioNo ratings yet

- False-Position Method of Solving A Nonlinear Equation: Exact RootDocument6 pagesFalse-Position Method of Solving A Nonlinear Equation: Exact Rootmacynthia26No ratings yet

- Lateral-Torsional Buckling: KiepahdusDocument120 pagesLateral-Torsional Buckling: KiepahdusOrhan YanyatmazNo ratings yet

- Engineering Syllabus of First Year EE, ECE, PWE, AEIE, EEE, IC, Apparel 2007Document37 pagesEngineering Syllabus of First Year EE, ECE, PWE, AEIE, EEE, IC, Apparel 2007Anish LahiriNo ratings yet

- Centrifugal Pump Test RigDocument4 pagesCentrifugal Pump Test RigSameer Tamboli100% (1)

- 3 IntroductionDocument5 pages3 IntroductionKhamvanh PhengnaoneNo ratings yet

- Experiences of ISFOC On Concentration Photovoltaic: Francisca RubioDocument49 pagesExperiences of ISFOC On Concentration Photovoltaic: Francisca RubioHikary AcevesNo ratings yet

- Unijin Pressure Gauge p258Document2 pagesUnijin Pressure Gauge p258Nguyễn Đăng PhúcNo ratings yet

- Lab Session 3Document7 pagesLab Session 3m.sheraz malikNo ratings yet

- AppNote 07 FPSO and Offshore PlatformsDocument4 pagesAppNote 07 FPSO and Offshore PlatformsRao MadepalliNo ratings yet

- (NagpurStudents - Org) Advanced PhysicsDocument4 pages(NagpurStudents - Org) Advanced PhysicsVaibhav NardangeNo ratings yet

- Material Balance: Lecture By: Ir. Dewi Tristantini Mt. Phd. University of IndonesiaDocument29 pagesMaterial Balance: Lecture By: Ir. Dewi Tristantini Mt. Phd. University of IndonesiaEdward Gustaf100% (3)

- RT Finalpresenatation08 161118104713Document56 pagesRT Finalpresenatation08 161118104713sajay2010No ratings yet

- 413 Impurities Testing in MedicalDocument2 pages413 Impurities Testing in MedicalIsmail MathakiyaNo ratings yet

- A New Method of Grounding Grid DesignDocument5 pagesA New Method of Grounding Grid DesignOrgil-erdene YadamsurenNo ratings yet

- Calculus For Business and Social SciencesDocument5 pagesCalculus For Business and Social SciencesMarchol PingkiNo ratings yet

- ECB Non Turf Cricket Wicket PDFDocument23 pagesECB Non Turf Cricket Wicket PDFJames OttaNo ratings yet

- Phy ATP (5054) Class 10Document57 pagesPhy ATP (5054) Class 10Maryam SiddiqiNo ratings yet

- Electrical and Electronic Measurements and InstrumentationDocument12 pagesElectrical and Electronic Measurements and InstrumentationKarthik VNo ratings yet

- Stepper Motors VsServo MotorsDocument2 pagesStepper Motors VsServo MotorsEhab MohamedNo ratings yet

- 1 - Pdfsam - 51 - Pdfsam - Jane Bennett Vibrant Matter A Political Ecology of Things 2010 PDFDocument25 pages1 - Pdfsam - 51 - Pdfsam - Jane Bennett Vibrant Matter A Political Ecology of Things 2010 PDFAnna PrzytomskaNo ratings yet

- TB Welding-English PDFDocument20 pagesTB Welding-English PDFdanghpNo ratings yet

- CV 101Document4 pagesCV 101frco1504No ratings yet

- Kim Lighting B30 Series Bollard Brochure 1985Document20 pagesKim Lighting B30 Series Bollard Brochure 1985Alan MastersNo ratings yet

- Quality Assurance Plan For Civil4mDocument3 pagesQuality Assurance Plan For Civil4mMohammed Abdul BaseerNo ratings yet