Professional Documents

Culture Documents

Ketamine Hydrochloride

Uploaded by

amin138irOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ketamine Hydrochloride

Uploaded by

amin138irCopyright:

Available Formats

For personal use only. Not to be reproduced without permission of the publisher (copyright@ppme.eu).

EJHP Science • Volume 14 • 2008 • Issue 1 • P. 14-18

© 2008 Pharma Publishing and Media Europe. All rights reserved 1781-7595 €20

www.ehjp.eu

Development of ready-to-use ketamine hydrochloride

syringes for safe use in post-operative pain

M Cyril Stucki, PharmD1; Sandrine Fleury-Souverain, PhD2; Anna-Maria Sautter, PhD3; Farshid Sadeghipour, PhD4;

Pascal Bonnabry, PhD5

ABSTRACT

Study objectives: To increase safety in use of ketamine. This would be achieved by introducing a ready-to-use (RTU)

intravenous syringe of ketamine hydrochloride, which would be prepared under aseptic conditions in the hospital phar-

macy, for post-operative pain.

Methods: The chemical stability of ketamine hydrochloride solution (1 mg/mL) in 0.9% sodium chloride was determined

at 4°C, 25°C and 40°C by means of a stability-indicating capillary electrophoresis method. Changes in pH and the pres-

ence of non-visible particulate matter were measured throughout the study. Sterility testing was performed to check the

integrity of the syringes.

Results: The loss in potency was less than 8% after 12 months at the three temperatures, and no degradation products

were detected. The pH values did not change appreciably and the syringe contents remained sterile throughout the

study. Each syringe fulfilled all US Pharmacopeia criteria in terms of non-visible particles.

Conclusion: RTU syringes of ketamine hydrochloride with a shelf life of one year can be manufactured and supplied by

the hospital pharmacy for use in post-operative pain. This product will help reduce the risk of dilution errors and lead to

significant economic advantages.

KEYWORDS

Ketamine, drug stability, central intravenous additive service (CIVAS), RTU, analgesia, post-operative pain

INTRODUCTION appear detached from their surroundings, and their eyes

Ketamine is a general anaesthetic for human and vet- remain open. The brand name of the hydrochloride salt

erinary use. It is often termed a dissociative anaesthetic is Ketalar. Pharmacologically, this drug is very similar to

because unlike with the conventional ones, patients other dissociative anaesthetics, such as phencyclidine.

However, ketamine suppresses respiration much less

than most other available anaesthetics, and is therefore

Contact for correspondence: M Cyril Stucki, PharmD

still used in human medicine as a first-choice anaesthetic

Pharmacy Department

for patients with an unknown medical history, e.g. traffic

University Hospitals of Geneva

24 Rue Micheli du Crest accident victims, in paediatrics and in other types of minor

CH-1211 Geneva 14, Switzerland surgery.

Tel: +41 22 382 39 74

Fax: +41 22 382 39 40 Ketamine, like phencyclidine, acts primarily as a non-

cyril.stucki@hcuge.ch competitive antagonist of the NMDA receptor, which

www.hcuge.ch/Pharmacie opens in response to binding of the neurotransmitter gluta-

mate. The NMDA receptor mediates the analgesic effects

1

Pharmacy Department, University Hospitals of Geneva, of ketamine at low doses, which mainly take place in the

Switzerland hippocampal formation and in the prefrontal cortex. Keta-

2

Head of Quality Control, Pharmacy Department, University mine can be used in small doses as an analgesic, particu-

Hospitals of Geneva, Switzerland larly for the treatment of pain associated with movement,

3

Clinical Pharmacy, Pharmacy Department, University Hospitals

neuropathic pain, and to relieve acute pain. When used in

of Geneva, Switzerland

4

Head of Production, Pharmacy Department, University

small doses, the psychotropic side effects, e.g. hallucina-

Hospitals of Geneva, Switzerland tions, are less apparent and more easily managed than

5

Head of Pharmacy, Pharmacy Department, University Hospitals those of benzodiazepines.

of Geneva, Switzerland

When used in sub-anaesthetic doses, ketamine causes

Received: 13 April 2007; revised manuscript received: 2 May analgesia without loss of consciousness and can thus be

2008; accepted: 6 May 2008 used for the treatment of pain [1-4]. This type of analgesia is

14 • EJHP Science • Volume 14 • 2008/1 • www.ejhp.eu

RTU ketamine syringes for safe use in post-operative pain

M Cyril Stucki et al

European Journal of Hospital Pharmacy Science

used in recovery rooms and is usually reserved for patients Ketamine hydrochloride Ph Eur: (Fagron GmbH Co,

who are resistant or allergic to opioids. Until recently, at Germany), batch number 0505A432, expiry date: 09 2009.

the University Hospitals of Geneva (HUG) [5], ketamine Procaine hydrochloride Ph Eur: (Hänseler, Herisau,

syringes were prepared extemporaneously by anaes- Switzerland), batch number 2001070326, expiry date: 04

thetists or nursing staff. The preparation of a syringe of 2007.

ketamine consists of a 10-fold dilution of Ketalar from the Sodium chloride 0.9% solution: (Bischel, Switzerland).

normal doses used in anaesthesia, i.e. 10 or 50 mg/mL, Tris (trishydroxymethylaminomethane) for pH buffer: (Fluka

to a recommended analgesic dose of 1 mg/mL. Prepara- AG, Switzerland).

tions under such conditions can introduce dilution errors Phosphorous acid concentrated: (Fluka AG, Switzerland).

[6] and/or increase the risk of infection [7-9].

Preparation of syringes for the stability study

In the past three years, three incidents have occurred in our An injection solution was prepared that contained 0.9%

hospital because of ketamine dilution errors. In December sodium chloride in water and 1 mg/mL of ketamine hydro-

2003, an anaesthetist forgot a dilution step, resulting in chloride. The solution was sterilised by filtration (Millipore

the administration of 60 mg of ketamine instead of the 20 Millipack Gamma Gold 0.22 µm) and 10 mL was trans-

7 mg prescribed. During the injection, the patient entered ferred into 10 mL polypropylene syringes under a hori-

a state of deep drowsiness, causing the anaesthetist to zontal laminar-airflow hood in a GMP class B clean room.

realise the mistake and stop the procedure. Fortunately, The syringes were closed using tamper-evident caps and

the patient did not suffer any medical problems as a result stored at either 4 ± 2°C, 25 ± 2°C or 40 ± 2°C. The solu-

of this error. In July 2005, a patient operated on for sig- tions were analysed at eight different time points: immedi-

moidectomy was administered morphine, paracetamol ately after preparation (day 0), after day 2 and day 7, and

and ketorolac (all intravenously) for analgesia, but contin- after one, three, five, seven and 12 months.

ued to experience pain. Ketamine was then prescribed to

improve the analgesia: the 42-kg patient was given 45 mg Capillary electrophoresis (CE) analysis

of ketamine. Such a dose is appropriate for anaesthesia CE instrumentation and conditions

and was administered instead of the analgesic dosage, Our method was adapted from those of Cherkaoui and

i.e. 4.5 mg. This caused immediate respiratory failure, Veuthey [10]. The CE system was an HP3D-CE appara-

myosis and an 84% saturation. Resuscitative measures tus (Agilent, Waldbronn, Germany) equipped with a diode

were quickly applied and the patient fortunately recovered array detector. A CE Chemstation (Agilent Technologies)

without notable consequences other than a prolonged was used for CE control, data acquisition and handling.

stay in the recovery room. A third incident involving a simi- Separations were performed in a fused silica capillary (BGB

lar dilution error took place more recently. Analytik AG, Böckten, Switzerland) with an inner diameter

of 50 µm and a total length of 48.5 cm (distance to UV

The aim of this study was to develop a RTU ketamine detector: 40 cm). Experiments were carried out in cationic

syringe for use in post-operative pain, with a long shelf- mode, i.e. anode at the inlet and cathode at the outlet, by

life and prepared under aseptic and good manufacturing applying a constant voltage of 30 kV with an initial ramp-

practice (GMP) conditions to improve the safe administra- ing of 1 kV/s. The capillary was maintained at 25°C, sam-

tion of this drug. The analytical method selected for this ples were injected by pressure (50 mbar for 10 s), and

work was a capillary electrophoresis coupled to UV detec- UV detection was recorded at 200 nm. The background

tion (CE-UV) method. The choice of this technique was electrolyte solution was a 50 mM tris-phosphate buffer set

mainly based on its low organic solvent consumption, low at pH 2.5. Before initial use, the capillary was sequentially

capillary cost, the high efficiency and the faster method washed with methanol, 1 M HCl, water and background

development compared with liquid chromatography. electrolyte (BGE) for five minutes each. Between analyses,

Moreover, CE-UV is particularly suitable for the analysis of the capillary was flushed with BGE for two minutes.

small basic compounds with chromophore groups, such

as ketamine. Validation of the CE method

The capillary electrophoresis method was validated

MATERIAL AND METHODS according to French Society of Pharmaceutical Science

Material and chemical products: and Technology guidelines [11] before applying it to the

Polypropylene syringes: KlerpackTM BD/3325382 Ref stability study of the RTU ketamine hydrochloride solution.

KSY15010 Shield Medicare tamper-evident caps: TEC Standard (std) and reconstituted formulation (rf) solutions

1000 B (B.Braun, Melsungen, Germany). at five different ketamine hydrochloride concentrations

EJHP Science • Volume 14 • 2008/1 • www.ejhp.eu • 15

RTU ketamine syringes for safe use in post-operative pain

M Cyril Stucki et al

European Journal of Hospital Pharmacy Science

(60, 80, 100, 120, and 140 µg/mL) were prepared daily ing from 60-140 µg/mL and a procaine concentration of

and used to test for linearity and accuracy. In addition, six 100 µg/mL. The 1 mg/mL ketamine hydrochloride assay

replicate solutions, each one of 100 µg/mL (correspond- solution (syringe) was diluted in distilled water to obtain

ing to the 10-fold dilution of 100% ketamine hydrochlo- a final concentration of 100 µg/mL. As with the calibra-

ride present in the formulation), were prepared daily and tion samples, procaine hydrochloride was added to the

used to determine the precision of the dilution method. assay solution as an internal standard (final concentration

Validation results are summarised in Table 1. Slopes and of IS = 100 µg/mL).

intercepts were not significantly different between rf and

std samples (t tests), and intercepts were not significantly Sterility testing

different from 0 (t test). All statistical tests were positive, The tests were performed using a method developed

thus verifying the linearity and accuracy of the method. and validated by the quality control laboratory in the HUG

Furthermore, the tests yielded good determination coef- pharmacy department [12]. This test is based on the use

ficients (r²), and adequate recovery and precision values of standard disposable syringes and classic 0.22 µm

(Table 1). Therefore, the method was accepted for deter- membrane filters (fit for aseptic purposes) to retain hypo-

mining ketamine hydrochloride concentrations in RTU thetical microbes on the membrane. Then a liquid CASO

intravenous polypropylene syringes. (casein-peptone soymeal-peptone) broth is introduced to

the same syringe by the same filter but through the out-

Stability-indicating method side filter tip to allow microbe re-suspension and growth.

To rule out possible interference of degradation products One syringe at each of the three storage temperatures, i.e.

during the ketamine hydrochloride determination, 1 mL of 4 ± 2ºC, 25 ± 2ºC and 40 ± 2ºC, was tested for sterility

a 1 M sodium hydroxide solution and 1 mL of a 1 M hydro- on days 0, 2 and 7, and after one, three, five, seven and

chloric acid solution were added to 1 mL of the ketamine 12 months.

hydrochloride mother solution (1 mg/mL). The solutions

were heated at 100ºC in a water bath for two hours. In Endotoxin (LAL) detection

order to check the absence of decomposition products The tests were performed using the method in the US Phar-

eluting under the analyte peak, the peak height/area ratio macopeia for endotoxin detection. One syringe at each of

was compared at two different detection wavelengths the three storage temperatures was tested for endotoxin

(200 and 220 nm) with a pure ketamine hydrochloride at eight different time intervals (see Sterility testing).

standard.

pH determination

Sample preparation during the stability study The pH of the solutions stored at the three different tem-

Stock solutions containing 1 mg/mL of ketamine hydro- peratures was measured at each time interval with a

chloride and 1 mg/mL of procaine hydrochloride (internal glass electrode pH meter (Metrohm model 691, Herisau,

standard (IS)) were prepared in distilled water. Standard Switzerland). Before each measurement, the pH meter

samples were prepared by diluting the stock solutions in was calibrated at pH 4.01 and 7.00.

distilled water to obtain a ketamine concentration rang-

Non-visible particulate matter

A HIAC Royco counter (SKAN, Allschwil, Switzerland) with

Table 1: Validation results for ketamine hydrochloride a HRLD-50 sensor module (serial number 95080045) was

analysed by capillary electrophoresis coupled

to UV detection used for the particle count determination. Three runs were

carried out, and particle counts were performed at each

Ketamine time interval on 10 mL samples obtained from syringes at

hydrochloride

the three storage temperatures.

Determination coefficients for std and 0.997/0.998

rf (r2) RESULTS

Mean recovery and confidence 99.40 ± 0.69% Only the ketamine hydrochloride peak was seen on the

interval* electropherograms of the acid and base degraded samples.

Intra-day precision (CV) 0.60% The ratio values of the analyte peak after base decomposi-

tion of a fresh ketamine hydrochloride standard solution

Day-to-day precision (CV) 1.97%

were 0.98 and 1.01 at 200 and 220 nm, respectively. For

Key: std: standard, rf: reconstituted formulation, r2: determination

acid decomposition, ratio values were 0.98 and 1.01 at

coefficients, CV: coefficient of variation, *(N = 15, t(0.05; N-1) = 2.145)

200 and 220 nm, respectively. These results confirm the

16 • EJHP Science • Volume 14 • 2008/1 • www.ejhp.eu

RTU ketamine syringes for safe use in post-operative pain

M Cyril Stucki et al

European Journal of Hospital Pharmacy Science

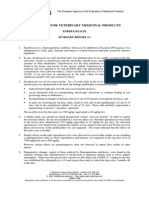

purity of the analyte peak. Figure 1 depicts a typical elec- water loss through the syringe walls was visually verified,

tropherogram of RTU ketamine hydrochloride solution in by controlling the volume of each tested sample. However,

0.9% NaCl after 12 months at 25°C. The solutions were no gravimetric test was carried out.

considered stable if the drug levels remained higher than

90% of the original concentration at the time of prepara- DISCUSSION

tion. The results confirmed the stability of these solutions The objective in developing a RTU ketamine syringe was

as the ketamine concentration remained above 95% after to ensure the best possible safety for the patient. There

12 months at 4°C, 25°C and 40°C (Figure 2). The pH varied are two main reasons why RTU ketamine syringes contrib-

slightly during the study for all three temperature regimes ute to the safety of the preparation of ketamine for admin-

by, on average, 0.5 pH units at 4°C, 0.5 pH units at 25°C istration in post-operative pain.

and 0.4 pH units at 40°C. However, these changes had no

effect on the assay results. Similar variations have already First, this method ensures proper aseptic conditions during

been observed during stability studies of several active the preparation of syringes, thereby reducing the risk of

ingredients in ampoules, and are therefore not expected microbiological contamination. This contrasts with previ-

to be related to leakage from the syringes. The sterility ous occasions when ketamine syringes were prepared in

tests and endotoxin tests were found to be negative in all hospital wards or operating rooms, increasing the risk of

cases. Furthermore, the syringes fulfilled all US Pharmaco- contamination. A recent study (unpublished data) examin-

peia criteria in terms of non-visible particles in all cases: the ing microbiological contamination in preparations prepared

admixture remained clear without visible particulate matter by anaesthetists showed that 0.5% of drugs prepared

throughout the study period. The absence of significant in the anaesthesiology unit of our hospital were con-

taminated by microbes, illustrating that asepsis is some-

Figure 1: Typical electropherogram of ketamine HCl in times compromised. This can occur either during aseptic

NaCl 0.9% at 25°C after 12 months production and/or during storage, because of a loss of

syringe integrity. Microbial contamination is a risk inherent

Ketamine

mAU

to aseptic production, which must be minimised by strict

Procaine (IS)

70 application of GMPs. These include regular environmental

60 controls, initial and continuing education of operators and

50 process validation through media-fill simulations as shown

40 in a recent study [13]. In our study, syringe integrity was

30 demonstrated by the negative results of the sterility tests.

20

10

Second, RTU ketamine syringes prevent dilution errors

0

during ketamine preparation, which was our primary moti-

0.5 1 1.5 2 2.5 3 3.5 4 Time (min)

vation for designing these syringes. The global error rate

for drug preparation in anaesthesia is 5% [14]. It has there-

fore been essential to improve patient safety by reducing

errors in ketamine preparation. Our experience has shown

Figure 2: Stability of ketamine HCl 1 mg in 1 mL

of a 0.9% sodium chloride solution in

that no incidents have been declared after the use of nearly

polypropylene syringes for a period of 30,000 RTU syringes (containing atropine, phenylephrine,

12 months at 4°C, 25°C and 40°C ephedrine, insulin, isoprenaline or vancomycin) over the

Ketamine concentration (%)

past three years in our hospital. Furthermore, since RTU

120

ketamine syringes are prepared by the hospital pharmacy

110 staff, this allows for the production of standardised labels

100

and packaging. A standardised coloured labelling scheme

(in agreement with international standards) and a stand-

90

ardised packaging of sealed boxes can both increase the

80

4°C

safe use and quality of this drug.

70 25°C

40°C

60

To the best of our knowledge, all previously published sta-

bility studies involving ketamine hydrochloride in syringes

50

0 50 100 150 200

Days

250 300 350 400 have been carried out only for periods of up to one

month [15], which is too short to ensure suitable batch

EJHP Science • Volume 14 • 2008/1 • www.ejhp.eu • 17

RTU ketamine syringes for safe use in post-operative pain

M Cyril Stucki et al

European Journal of Hospital Pharmacy Science

production and appropriate storage. If ketamine solutions because a potential overdose can strongly depress vital

are only stable for this short time period, syringes in both organs, which would require expensive procedures, such

ward stocks and at the bedside can quickly expire, which as resuscitation measures, in an intensive care unit. From

means that numerous batches would be necessary, this viewpoint, the savings are indirect. Third, unused RTU

increasing the chances of contamination. For these rea- syringes in their original unopened carton boxes can be

sons, we carried out a long-term study, and the results returned to stock and made available for other patients.

showed that the ketamine hydrochloride solution remains This reduces costs because of waste.

stable after 12 months, even under accelerated degrada-

tion conditions (40°C). CONCLUSION

Ready-to-use ketamine syringes supplied by the hospi-

From an economic standpoint, RTU ketamine syringes are tal pharmacy and stored in the anaesthesiology unit were

profitable for three main reasons. First, it costs Euros 7 found to be stable at room temperature and in accelerated

to prepare a 1 mg/mL ketamine syringe using 1mL from degradation conditions for at least twelve months, with no

a 10 mg/mL Ketalar ampoule, i.e. Euros 6 for the Keta- significant loss in potency. Their long shelf-life allows for

lar ampoule, most of which is discarded, and Euros 2 for an optimised use of production batches. Furthermore, the

the syringe, cap, needle and some NaCl 0.9% solution for availability of pre-filled syringes reduces the risks of errors

dilution. In contrast, a RTU ketamine syringe only costs and/or microbiological contamination. The preparation of

Euros 3 to prepare. For 2,000 RTU ketamine syringes RTU syringes of ketamine can also provide a means to

produced in a year, the savings would amount to Euros decrease the overall cost of health care, and save time for

8,000. Second, because RTU ketamine syringes increase hospital staff.

safety and decrease the chance of error, their use can

decrease the average duration of a patient’s hospital Disclosure

stay. This can especially hold true for drugs like ketamine, Nothing to disclose.

REFERENCES

1. Bell RF, Dahl JB, Moore RA, Kalso E. Perioperative keta- related to contaminated substances. J Hosp Infect.

mine for acute postoperative pain.Cochrane Database 2007;65(1):15-23. Epub 2006 Dec 4.

Syst Rev. 2006 Jan 25;(1):CD004603. 10. Cherkaoui S, Veuthey J-L. Use of negatively charged

2. Roewer N, Thiel H. Atlas de poche d’anesthésie. Paris: cyclodextrins for the simultaneous enantiosepara-

Flammarion; 2003. tion of selected anesthetic drugs by capillary electro-

3. Schorderet M. Pharmacologie: des concepts fonda- phoresis-mass spectrometry. J Pharm Biomed Anal.

mentaux aux applications thérapeutiques. 3rd ed. Paris, 2002;27(3-4):615-26.

Genève: Frison-Roche, Slatkine, 1998. 11. Caporal-Gautier J, Nivet JM, Algranti P, et al. Guide to

4. Annetta MG, Iemma D, Garisto C, et al. Ketamine: analytical validation. Report of an SFSTP commission. I.

new indications for an old drug. Curr Drug Targets. Methodology. STP Pharma pratiques. 1992;2(4):205-26.

2005;6(7):789-94. 12. Ing H, Saadi JF, Dahran S, et al. Le contrôle de la stérilité

5. Griffiths W. Formulating IV drugs for neonatal intensive d’une solution peut-il être simple et peu couteux? Can

care. Hosp Pharm Eur. 2003;10:78-80. sterility testing of a solution be easy or inexpensive? Le

6. Taxis K, Barber N. Ethnographic study of incidence and Pharmacien Hospitalier. 2003;38:154-8.

severity of intravenous drug errors. BMJ. 2003; 326: 13. De Giorgi I, Sadeghipour F, Favet J, Bonnabry P. Steril-

684-8. ity validity period of vials after multiple sampling under

7. Beaney AM, Goode J. A risk assessment of the ward- vertical laminar airflow hood. J Oncol Pharm Pract.

based preparation of parenteral medicines. Hospital 2005;11(2):57-62.

Pharmacist 2003;10:306-8. 14. Garnerin P, Pellet-Meier B, Chopard P, et al. Measur-

8. Van Grafhorst JP, Foudraine NA, Nooteboom RF, et al. ing human-error probabilities in drug preparation: a pilot

Unexpected high risk contamination with Staphylococci simulation study. Eur J Clin Pharmacol. 2007;63(8):

species attributed to standard preparation of syringes 769-76.

for continuous intravenous drug administration in a 15. Gupta VD. Stability of ketamine hydrochloride injection

simulation model in intensive care units. Crit Care Med. after reconstitution in water for injection and storage in

2002;30:833-6. 1-mL tuberculin polypropylene syringes for pediatric use.

9. Vonberg RP, Gastmeier P. Hospital-acquired infections Int J Pharm Compound. 2002;6(4):316-7.

18 • EJHP Science • Volume 14 • 2008/1 • www.ejhp.eu

You might also like

- 2,5-Dimethoxybenzaldehyde From 4-Methoxy PhenolDocument7 pages2,5-Dimethoxybenzaldehyde From 4-Methoxy PhenolSignora SauerNo ratings yet

- The Oxidation of Alcohols and Ethers Using Calcium HypochloriteDocument3 pagesThe Oxidation of Alcohols and Ethers Using Calcium HypochloriteVictor VikeneNo ratings yet

- Short Communication - A Novel Synthesis of 3 4-Methylenedioxyphenyl-2-Propanone MDP2P From HelionalDocument3 pagesShort Communication - A Novel Synthesis of 3 4-Methylenedioxyphenyl-2-Propanone MDP2P From HelionalMikel L.No ratings yet

- Illicit Drug Labs Pose Serious Health RisksDocument9 pagesIllicit Drug Labs Pose Serious Health RisksAlexander Melo AnguloNo ratings yet

- Identification of 4-Methoxy-a-PVP Metabolites Using Hepatocytes and HRMSDocument15 pagesIdentification of 4-Methoxy-a-PVP Metabolites Using Hepatocytes and HRMStediNo ratings yet

- Synthesis of Tramadol LabDocument3 pagesSynthesis of Tramadol Labchedhed50% (2)

- Cleaning Validation SOPDocument8 pagesCleaning Validation SOPamin138ir100% (3)

- DSM Chemical Resistance TablesDocument32 pagesDSM Chemical Resistance TablesJacp2No ratings yet

- Guggenheim PDFDocument11 pagesGuggenheim PDFAll about NBJNo ratings yet

- Tem-290 Process Validation Protocol Template SampleDocument5 pagesTem-290 Process Validation Protocol Template SampleJonatan Dominguez Perez100% (2)

- Opioid Conversion ChartDocument4 pagesOpioid Conversion ChartVanessa NicoleNo ratings yet

- New Reagent ChartDocument1 pageNew Reagent ChartCindy EnglishNo ratings yet

- Erythroxylum Novogranatense - Wikipedia, The Free EncyclopediaDocument2 pagesErythroxylum Novogranatense - Wikipedia, The Free EncyclopediaindiesceneNo ratings yet

- Determination of Alkaloid Structures I. Isolation Characterization and Physical MethodsDocument6 pagesDetermination of Alkaloid Structures I. Isolation Characterization and Physical Methodsgeovani2No ratings yet

- Etizolam Article1 Who 2016Document22 pagesEtizolam Article1 Who 2016Stiven DestNo ratings yet

- Pseudoephedrine: 1. Synonyms CFR: Nist #Document18 pagesPseudoephedrine: 1. Synonyms CFR: Nist #Yuyun Saputri NingsihNo ratings yet

- Opium 160604163652Document14 pagesOpium 160604163652roberto cabungcagNo ratings yet

- METHAMPHETAMINE and Illicit Drugs, Precursors 9106 and Adulterants On Wipes by Liquid-Liquid ExtractionDocument30 pagesMETHAMPHETAMINE and Illicit Drugs, Precursors 9106 and Adulterants On Wipes by Liquid-Liquid ExtractionMatthew MulderNo ratings yet

- ChiralityDocument6 pagesChiralityAchmad Basori100% (1)

- GHB Checklist, Version 2.0Document2 pagesGHB Checklist, Version 2.0jac_blakeNo ratings yet

- Glassware CleaningDocument3 pagesGlassware CleaningSiti Nurazlin FariddunNo ratings yet

- Cultivation and Propagation Methods for Medicinal PlantsDocument8 pagesCultivation and Propagation Methods for Medicinal PlantsRita BhattaNo ratings yet

- Tramadol HydrochlorideDocument2 pagesTramadol HydrochlorideNurFauziahKasimNo ratings yet

- Omcl0204 - 0181 - Synthesis of MescalineDocument10 pagesOmcl0204 - 0181 - Synthesis of MescalineOleksandr StorcheusNo ratings yet

- Marjolein Gabriëlle Klous - Pharmaceutical Development of Diacetylmorphine Preparations For Prescription To Opioid Dependent PatientsDocument205 pagesMarjolein Gabriëlle Klous - Pharmaceutical Development of Diacetylmorphine Preparations For Prescription To Opioid Dependent PatientsPoloGreenNo ratings yet

- Overview of Hazards and Safe Handling of Piranha SolutionsDocument4 pagesOverview of Hazards and Safe Handling of Piranha Solutionsklausegert viilNo ratings yet

- References for LSD SynthesisDocument2 pagesReferences for LSD SynthesismjauuuuuNo ratings yet

- Focused Microwave-Assisted Extraction of COCA PDFDocument8 pagesFocused Microwave-Assisted Extraction of COCA PDF19simon85No ratings yet

- Mixing and Formulation of Low Dose Drugs UnderlyinDocument17 pagesMixing and Formulation of Low Dose Drugs UnderlyincbcalderonNo ratings yet

- Opium and Its DerivativesDocument40 pagesOpium and Its DerivativesAswin KennedyNo ratings yet

- Methamphetamine: History, Cooking Methods, and DecontaminationDocument52 pagesMethamphetamine: History, Cooking Methods, and DecontaminationMarcus RamosNo ratings yet

- A REVIEW Selection of Dissolution MediaDocument21 pagesA REVIEW Selection of Dissolution MediavunnamnareshNo ratings yet

- Sassafras Oils As Precursors For The Production of Synthetic Drugs: Profiling Via MEKC-UVD - By: C. Huhn, M. Pütz, R. Dahlenburg, U. PyellDocument11 pagesSassafras Oils As Precursors For The Production of Synthetic Drugs: Profiling Via MEKC-UVD - By: C. Huhn, M. Pütz, R. Dahlenburg, U. PyellyunusNo ratings yet

- MethaqualoneDocument9 pagesMethaqualoneSRNo ratings yet

- Sintese Do 2c-bDocument13 pagesSintese Do 2c-bRF BragaNo ratings yet

- Codeine From WikipediaDocument12 pagesCodeine From WikipediaMuhammad Miftahul HudaNo ratings yet

- The Merk IndexDocument182 pagesThe Merk IndexReply choice100% (1)

- Project ON Tablet ManufacturingDocument19 pagesProject ON Tablet ManufacturingakashtrivedeNo ratings yet

- Study report on the medicinal plant Ephedra foliataDocument16 pagesStudy report on the medicinal plant Ephedra foliatavishwanathz47No ratings yet

- Synthesis of P2P From 3-Phenyl-1-ChloropropaneDocument1 pageSynthesis of P2P From 3-Phenyl-1-ChloropropaneFlorianLiest100% (1)

- Drug Charc & Impurity ProfileDocument19 pagesDrug Charc & Impurity ProfileSagar Patel0% (1)

- Morphine Synthesis and Biosynthesis-An UpdateDocument21 pagesMorphine Synthesis and Biosynthesis-An UpdatejaNo ratings yet

- The Characterization of α-PyrrolidinopentiophenoneDocument6 pagesThe Characterization of α-PyrrolidinopentiophenonetysonNo ratings yet

- Muriatic Acid MSDSDocument8 pagesMuriatic Acid MSDSKim MalangNo ratings yet

- Methadone - DrugBankDocument13 pagesMethadone - DrugBankravaNo ratings yet

- Alexandra Doddridge, Michael Collins and Helen SalourosDocument26 pagesAlexandra Doddridge, Michael Collins and Helen SalourosDoc MartenzNo ratings yet

- Classification of AlkaloidsDocument8 pagesClassification of Alkaloidssandy4u08No ratings yet

- 4.7 Ethylphenidate CritReviewDocument19 pages4.7 Ethylphenidate CritReviewkevinNo ratings yet

- The Gardeners CompanionDocument27 pagesThe Gardeners CompanionJason RileyNo ratings yet

- The Total Synthesis of Lysergic AcidDocument28 pagesThe Total Synthesis of Lysergic AcidFabio CavalcanteNo ratings yet

- An Efficient Method For The Synthesis of 1,5-Benzodiazepine Derivatives Under Microwave Irradiation Without SolventDocument4 pagesAn Efficient Method For The Synthesis of 1,5-Benzodiazepine Derivatives Under Microwave Irradiation Without SolventHaouassi LakhdarNo ratings yet

- An Efficient, Optimized Synthesis of Fentanyl and Related AnalogsDocument8 pagesAn Efficient, Optimized Synthesis of Fentanyl and Related AnalogsJay MasonNo ratings yet

- Opioid Peptides: Biology, Chemistry, and Genetics: The Peptides: Analysis, Synthesis, Biology, Vol. 6From EverandOpioid Peptides: Biology, Chemistry, and Genetics: The Peptides: Analysis, Synthesis, Biology, Vol. 6No ratings yet

- Dose-Response Study of Dimethyltryptamine Effects in HumansDocument13 pagesDose-Response Study of Dimethyltryptamine Effects in HumansPedro S Reis100% (1)

- Enhanced Codeine and Morphine Production in SuspendedDocument5 pagesEnhanced Codeine and Morphine Production in SuspendedPádraig Ó ĊonġaileNo ratings yet

- Alexandra Doddridge, Michael Collins and Helen SalourosDocument26 pagesAlexandra Doddridge, Michael Collins and Helen SalourosDoc MartenzNo ratings yet

- An Advanced Laboratory Manual of Organic Chemistry 1923 - Heidelberger PDFDocument103 pagesAn Advanced Laboratory Manual of Organic Chemistry 1923 - Heidelberger PDFRodrigo Negrelli GuzzoNo ratings yet

- LSD Synthesis GuideDocument12 pagesLSD Synthesis GuideKyle Ryan100% (1)

- Dimethylamine PDFDocument2 pagesDimethylamine PDFangelofgloryNo ratings yet

- Production of Ecstasy in The NetherlandsDocument26 pagesProduction of Ecstasy in The Netherlandsthor888888No ratings yet

- Buy Adderall 30 MG Online in UsDocument9 pagesBuy Adderall 30 MG Online in UsAdderall UsNo ratings yet

- Ketamine's Medical Uses and EffectsDocument23 pagesKetamine's Medical Uses and EffectsDimas Gatra DiantoroNo ratings yet

- Torulaspora Delbrueckii and Conversion To Ephedrine byDocument4 pagesTorulaspora Delbrueckii and Conversion To Ephedrine bysalvia1025100% (1)

- Synthetic Cannabinoids - Epidemiology, Pharmacodynamics, and Clinical Implications Nihms-2014Document61 pagesSynthetic Cannabinoids - Epidemiology, Pharmacodynamics, and Clinical Implications Nihms-2014smk0602No ratings yet

- Flupentixol Injection From Injectable Drugs Guide Book - Alistair GrayDocument3 pagesFlupentixol Injection From Injectable Drugs Guide Book - Alistair Grayamin138irNo ratings yet

- Certificate of Quality: Cayman Pharma S.R.O. Ul. Práce 657, 277 11 NERATOVICE Czech Republic Tel. +420 315 665 360Document3 pagesCertificate of Quality: Cayman Pharma S.R.O. Ul. Práce 657, 277 11 NERATOVICE Czech Republic Tel. +420 315 665 360amin138irNo ratings yet

- Plga Microspheres and Nanospheres As Drug CarriersDocument29 pagesPlga Microspheres and Nanospheres As Drug Carriersamin138irNo ratings yet

- Tecfidera (Dimethyl Fumarate) MonographDocument7 pagesTecfidera (Dimethyl Fumarate) Monographamin138irNo ratings yet

- 2.2. Graham CookDocument9 pages2.2. Graham Cookamin138irNo ratings yet

- Virus Therapy in CancerDocument10 pagesVirus Therapy in Canceramin138irNo ratings yet

- Voriconazole API Specifications - IHSDocument1 pageVoriconazole API Specifications - IHSamin138irNo ratings yet

- Procos New Generic List - 2014 - V5 - September 2014Document1 pageProcos New Generic List - 2014 - V5 - September 2014amin138irNo ratings yet

- USP Medicines Compendium publishes Eflornithine Topical Cream monographDocument3 pagesUSP Medicines Compendium publishes Eflornithine Topical Cream monographamin138irNo ratings yet

- Etravirine - Potent Antiviral Activity in HIV-1 With NNRTI ResistanceDocument2 pagesEtravirine - Potent Antiviral Activity in HIV-1 With NNRTI Resistanceamin138irNo ratings yet

- Indian Pharma Global ConnectionDocument35 pagesIndian Pharma Global Connectionamin138irNo ratings yet

- Pharmacotherapy of Chronic Hepatitis B With EntecavirDocument5 pagesPharmacotherapy of Chronic Hepatitis B With Entecaviramin138irNo ratings yet

- Total Synthesis of Taxol. The Chinese ConectionDocument6 pagesTotal Synthesis of Taxol. The Chinese Conectionamin138irNo ratings yet

- Freeze-Drying Proteins Emerging ConcernsDocument13 pagesFreeze-Drying Proteins Emerging Concernsamin138irNo ratings yet

- J. Org. Chem. 1998, 63, 3471-3473Document3 pagesJ. Org. Chem. 1998, 63, 3471-3473Suman BalyaniNo ratings yet

- Clinical Pharmacokinetics and Pharmacodynamics of EtravirineDocument15 pagesClinical Pharmacokinetics and Pharmacodynamics of Etravirineamin138irNo ratings yet

- Cholesterol-Dependent Cytolysins, A Family of VersatileDocument11 pagesCholesterol-Dependent Cytolysins, A Family of Versatileamin138irNo ratings yet

- Etravirine Drug ProfileDocument13 pagesEtravirine Drug Profileamin138irNo ratings yet

- Brand NameDocument2 pagesBrand Nameamin138irNo ratings yet

- Emea 1Document3 pagesEmea 1amin138irNo ratings yet

- The Use of Bacterial ToxinsDocument7 pagesThe Use of Bacterial Toxinsamin138irNo ratings yet

- Biotechnological Approaches For The Production of Anticancer TaxolDocument24 pagesBiotechnological Approaches For The Production of Anticancer Taxolamin138irNo ratings yet

- 3021 enDocument3 pages3021 enamin138irNo ratings yet

- Pegylated Shikonin-Loaded LiposomesDocument14 pagesPegylated Shikonin-Loaded Liposomesamin138irNo ratings yet

- 6,855,331 WRAIR 96-12A Vook Sustained Release Hydrophobic Bioactive PLGA MicrospheresDocument1 page6,855,331 WRAIR 96-12A Vook Sustained Release Hydrophobic Bioactive PLGA Microspheresamin138irNo ratings yet

- The Ascf Endorses High Peptide ColostrumDocument3 pagesThe Ascf Endorses High Peptide Colostrumamin138irNo ratings yet

- MSDS for Alprostadil InjectionDocument8 pagesMSDS for Alprostadil Injectionamin138ir100% (1)

- Taxol MexicanoDocument4 pagesTaxol Mexicanoamin138irNo ratings yet

- Fractionated Coconut Oil: Material Safety Data SheetDocument3 pagesFractionated Coconut Oil: Material Safety Data Sheetamin138irNo ratings yet

- The Nuclear Reactions Involved in The Synthesis of New ElementsDocument3 pagesThe Nuclear Reactions Involved in The Synthesis of New ElementsChristian Isip67% (3)

- Esm Bank Soal Sma 2 (English)Document25 pagesEsm Bank Soal Sma 2 (English)mayang segaraNo ratings yet

- Theory of Solutions BasicsDocument34 pagesTheory of Solutions BasicsSiddharth DhurandharNo ratings yet

- Toluene: Safety Data SheetDocument10 pagesToluene: Safety Data SheetLiaHerlianaNo ratings yet

- Introduction To Medical TechnologyDocument22 pagesIntroduction To Medical TechnologyKaycee Gretz LorescaNo ratings yet

- JR Elite& AIIMS S60 NEET WET - 14 (14-11-23) SyllabusDocument1 pageJR Elite& AIIMS S60 NEET WET - 14 (14-11-23) SyllabussindhukarnikapNo ratings yet

- Molecular ModelingDocument22 pagesMolecular ModelingHely PatelNo ratings yet

- SyllabusDocument4 pagesSyllabusAlysson Vany ClochetteNo ratings yet

- Research Paper VinegarDocument4 pagesResearch Paper Vinegarrwinpqgkf100% (1)

- The Cassini Ion and Neutral Mass Spectrometer (Inms) InvestigationDocument119 pagesThe Cassini Ion and Neutral Mass Spectrometer (Inms) InvestigationDima FontaineNo ratings yet

- Review of Radiation Sterilization Technologies For Medical Devices - 170113Document18 pagesReview of Radiation Sterilization Technologies For Medical Devices - 170113Kunashiny RamashNo ratings yet

- Optical Balance Procedure For The Unbalanced Diode Error On The G1362A Refractive Index DetectorDocument4 pagesOptical Balance Procedure For The Unbalanced Diode Error On The G1362A Refractive Index DetectorAhmad IbrahemNo ratings yet

- F2 = 30 kNm)2/4) 70 × 109 N/m2Document11 pagesF2 = 30 kNm)2/4) 70 × 109 N/m2Don ValentinoNo ratings yet

- KITZ DJ Series Ductile Iron Butterfly Valves E-231-06 PDFDocument16 pagesKITZ DJ Series Ductile Iron Butterfly Valves E-231-06 PDFYulita Ika PawestriNo ratings yet

- Atomic Structure and Chemical Bonding Chapter 2 QuestionsDocument19 pagesAtomic Structure and Chemical Bonding Chapter 2 QuestionsAhmed ZiadNo ratings yet

- GHS COMPLIANT LABELDocument2 pagesGHS COMPLIANT LABELsemeneh haile100% (1)

- Comet Assay: From Wikipedia, The Free EncyclopediaDocument11 pagesComet Assay: From Wikipedia, The Free EncyclopediasuryasivNo ratings yet

- Ginger CandyDocument8 pagesGinger CandyRizka Arifani Kromodimedjo100% (2)

- Inclusion Compounds & Cyclodextrins: Presented By: Kunal Goyal Pt.B.D. Sharma Univ. Health Sci. RohtakDocument23 pagesInclusion Compounds & Cyclodextrins: Presented By: Kunal Goyal Pt.B.D. Sharma Univ. Health Sci. Rohtakgkunal991No ratings yet

- Allison Transmission-1K 2K Mechanic's Tips 4th GenDocument60 pagesAllison Transmission-1K 2K Mechanic's Tips 4th GenCarlos Cornejo80% (5)

- Ujian RemediDocument1 pageUjian RemediJokoSuswonoNo ratings yet

- Atomic StructureDocument2 pagesAtomic Structureapi-350245383No ratings yet

- API CatalogueDocument20 pagesAPI CatalogueMadirley Pimenta100% (1)

- AMB AMC Machine DescriptionDocument87 pagesAMB AMC Machine DescriptionEduard Nurmetov0% (1)

- Class 12 Biology ProjectDocument14 pagesClass 12 Biology ProjectDhruv Shah100% (3)

- Determination of Specific Gravity or Relative Density of Substances (Formal Report)Document3 pagesDetermination of Specific Gravity or Relative Density of Substances (Formal Report)Zac AshtonNo ratings yet

- Purificazione e Studio Cinetico - Lattato Deidrogenasi (LDH) Da Fegato Di ConiglioDocument10 pagesPurificazione e Studio Cinetico - Lattato Deidrogenasi (LDH) Da Fegato Di ConiglioS_CucinottaNo ratings yet