Professional Documents

Culture Documents

Light Weight Concrete

Uploaded by

MazharYasin0 ratings0% found this document useful (0 votes)

24 views23 pagesLight Weight Concrete

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLight Weight Concrete

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views23 pagesLight Weight Concrete

Uploaded by

MazharYasinLight Weight Concrete

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 23

ADVANCE CONCRETE TECHNOLOGY-I

LIGHT WEIGHT CONCRETE

Presenter: Engr. Rameez Khalid

Roll No. MSCE-01191014

Presented to: Prof. Dr. Muhammad Afzal Javed

A UNIVERSITY OF

= LAHORE

LIGHTWEIGHT CONCRETE

Introduction

The use of lightweight aggregate concrete (LWAC) can be traced to as early as 3000 BC, when the

famous towns of Mohenjo-Daro and Harappa were built during the Indus Valley civilization, In

arlier use of LWAC occurred about two thousand

Europ ars ago when the Romans built the

Pantheon, the aqueducts, and the Colosseum in Rome. It is interesting to note that pumice is still

used (a former Roman temple) today as an aggregate for structural conerete in certain countries

such as Germany, Italy, Iceland, and Japan. In some places, like Malaysia, palm oil shells are used

for making lightweight aggregate concrete.

In 1918, Stephen J. Hayde patented the lightweight aggregate “Haydite,” the first one made by the expansion of shale,

Which came into production in the US. Synthetic aggregates of this type have been universally accepted, making

satisfactory reinforced or prestressed concrete.

Because of the practical advantages which it possesses, LWAC has, in recent years, become an important structural

material and the demand for it is increasing. A savings inthe weight of the superstructure means that foundations can be

‘reduced in bulk, and time and expenses saved in erection and handling of components, so that smaller Titing equipment

‘can be employed or larger precast units ean be handled, The low density results in high thermal insulation of buildings

and, in some instances, the thickness of roofs and walls can be reduced. Where there is reduction in weight, # higher

degree of thermal insulation will be achieved. Other early applications are the ships built with the LWAC at the end of

World War I, 1917. One of the famous ships was named Selma. After so many years of service in harsh climates, it is

still in satisfactory condition. This speaks of the durability of lightweight aggregate concrete, In addition to the

‘materials, the techniques adopted by the ship builders to construct the ship is equally important, It was so well

‘constructed that some of the factors have become specifications for ship making.

Physical & Chemical Properties

Density

Strength

Shrinkage and clestcity

Resistance to acids

(Chloride ingress (Penetration of chloride ion)

Carbonation

Freeze and Thaw Resistance

Fire Resistance

Today, lightweight aggregates are available in a wide range of densities, strengths, and

sizes. The raw materials used for producing lightweight aggregates (LWA) are natural

minerals like clays, shales, and slates, as well as industrial by-products like fly ash, bed

ash, blast furnace slag, ete. Synthetic organic aggregates, like polystyrene beads, are also

used for making insulation conerete.

This makes it possible to design concrete with a very wide spectrum, a concrete of very

low density for insulation and, at the same time, a high strength conerete, more than 80

MPa 15 cm cube compressive strength, for structural purposes.

In spite of the increasing use and demand, there is still a lack of adequate explanations to

understand the mechanisms responsible for the strength and durability properties of

LWAC,

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Hip, Valley, & Jack Rafters: Chapter ObjectivesDocument26 pagesHip, Valley, & Jack Rafters: Chapter ObjectivesdamindaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- MathWorks 11 WorkbookDocument374 pagesMathWorks 11 WorkbookKeston LukeNo ratings yet

- CA - Commissioning - Guide - New - California - CostDocument84 pagesCA - Commissioning - Guide - New - California - Costlong minn2No ratings yet

- Construction and Building MaterialsDocument9 pagesConstruction and Building MaterialsMazharYasinNo ratings yet

- SBR LatexDocument2 pagesSBR LatexMazharYasinNo ratings yet

- Construction Project StakeholdersDocument19 pagesConstruction Project StakeholdersMazharYasinNo ratings yet

- "Dear Students, Due Dates For Fall-2018 Semester Fee Are Mentioned BelowDocument1 page"Dear Students, Due Dates For Fall-2018 Semester Fee Are Mentioned BelowAlauddin Ahmad KHAN KHANNo ratings yet

- HOT WEATHER CONCRETING TIPSDocument6 pagesHOT WEATHER CONCRETING TIPSMazharYasinNo ratings yet

- GGBFSDocument2 pagesGGBFSMazharYasinNo ratings yet

- Const.P. 2 2011Document42 pagesConst.P. 2 2011MazharYasinNo ratings yet

- Cement: The Binding Building MaterialDocument12 pagesCement: The Binding Building MaterialMazharYasinNo ratings yet

- Drawing Lecture-1Document28 pagesDrawing Lecture-1MazharYasinNo ratings yet

- Burned Clay Pozzolana-Used PDFDocument9 pagesBurned Clay Pozzolana-Used PDFMazharYasinNo ratings yet

- CM 425 - Properties of Fresh Concrete PDFDocument14 pagesCM 425 - Properties of Fresh Concrete PDFTran Huynh NamNo ratings yet

- Uol HRD EdifDocument1 pageUol HRD EdifMazharYasinNo ratings yet

- Citation 222245843Document1 pageCitation 222245843MazharYasinNo ratings yet

- Citation 222245843Document36 pagesCitation 222245843MazharYasinNo ratings yet

- Untitled MapDocument1 pageUntitled MapMazharYasinNo ratings yet

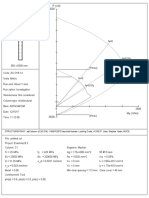

- Structurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceDocument1 pageStructurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceMazharYasinNo ratings yet

- 3Document4 pages3MazharYasinNo ratings yet

- Slab DesignDocument78 pagesSlab DesignMazharYasinNo ratings yet

- Public Notice CE 2019 EnglishDocument4 pagesPublic Notice CE 2019 EnglishMazharYasinNo ratings yet

- Experiment No. 10: To Determine The Effect of Rate of Loading On The Compressive Strength of P.C.C Cube and CylinderDocument3 pagesExperiment No. 10: To Determine The Effect of Rate of Loading On The Compressive Strength of P.C.C Cube and CylinderMazharYasinNo ratings yet

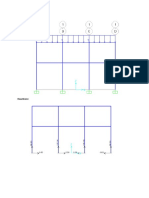

- PlanDocument1 pagePlanMazharYasinNo ratings yet

- Structurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceDocument1 pageStructurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceMazharYasinNo ratings yet

- Public Notice CE 2019 English PDFDocument1 pagePublic Notice CE 2019 English PDFMazharYasinNo ratings yet

- Brick BondsDocument4 pagesBrick BondsMazharYasinNo ratings yet

- ReactionsDocument2 pagesReactionsMazharYasinNo ratings yet

- Table: Assembled Joint Masses Joint Masssource U1 U2 U3 R1 R2 R3 CenterxDocument80 pagesTable: Assembled Joint Masses Joint Masssource U1 U2 U3 R1 R2 R3 CenterxMazharYasinNo ratings yet

- Structurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceDocument1 pageStructurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceMazharYasinNo ratings yet

- SP ColumnDocument2 pagesSP ColumnMazharYasinNo ratings yet

- Excavator: EquipmentDocument8 pagesExcavator: EquipmentBijaya PandeyNo ratings yet

- IBS Scoresheet Calculator for Precast Construction ProjectDocument1 pageIBS Scoresheet Calculator for Precast Construction ProjectAsraf MuidinNo ratings yet

- Lenton Coupler UES ReportDocument30 pagesLenton Coupler UES ReportBrian HowellNo ratings yet

- Risk Tip 6 Sample Project File IndexDocument4 pagesRisk Tip 6 Sample Project File IndexVijay PrasadNo ratings yet

- Dawit Ketema To TsgayeDocument52 pagesDawit Ketema To TsgayeDawit Ketema100% (1)

- Drainage Structures PDFDocument16 pagesDrainage Structures PDFShierene Mae LabisNo ratings yet

- Soil Drainage/Sewerage: Measurement of Construction Works V BQS601Document36 pagesSoil Drainage/Sewerage: Measurement of Construction Works V BQS601Syamimi AmirahNo ratings yet

- Detail & Abstract Estimate NewDocument6 pagesDetail & Abstract Estimate NewSAE/SO Damudya MahbubNo ratings yet

- Integrating A Procurement Management Process IntoDocument22 pagesIntegrating A Procurement Management Process Intofrancis pacaigueNo ratings yet

- Aercel SP20Document2 pagesAercel SP20Yassin Abd El AalNo ratings yet

- Core Classics Series Model, 150th Scale, CAT Models Canada, Diecast Masters, High Quality - CATmodels CanadaDocument1 pageCore Classics Series Model, 150th Scale, CAT Models Canada, Diecast Masters, High Quality - CATmodels Canadaturcottep3No ratings yet

- The Manufacturing Progress Report For HRSG Non-Pressure Part & DCSDocument17 pagesThe Manufacturing Progress Report For HRSG Non-Pressure Part & DCSAgustinus SitioNo ratings yet

- 450e Backhoe Loader Lyr00001-Up (Machine) Powered by c4.4 Engine (Sebp6402 - 18) - Por Número de PiezaDocument3 pages450e Backhoe Loader Lyr00001-Up (Machine) Powered by c4.4 Engine (Sebp6402 - 18) - Por Número de PiezaJaime Santisteban CáceresNo ratings yet

- Hoisting Equipments - Construction & Building Materials Questions and Answers - SanfoundryDocument3 pagesHoisting Equipments - Construction & Building Materials Questions and Answers - SanfoundrySumedha SawniNo ratings yet

- Astm E2121 03 Residential Mitigation Protocols2Document13 pagesAstm E2121 03 Residential Mitigation Protocols2asdfNo ratings yet

- Fast installation system for flat roofsDocument6 pagesFast installation system for flat roofsSakthi GaneshNo ratings yet

- Gmail - MOM - Breez Core Team 10.07.2021Document6 pagesGmail - MOM - Breez Core Team 10.07.2021Navneet KumarNo ratings yet

- Manifold El-Check: Effective: December 2018 K-85-0519 Rev ABDocument2 pagesManifold El-Check: Effective: December 2018 K-85-0519 Rev ABFRANCISCO2003360602No ratings yet

- eProcurement System Government of Uttar Pradesh Construction ProjectDocument4 pageseProcurement System Government of Uttar Pradesh Construction ProjectDeepak Sonkar100% (1)

- Model: P2B-SC-30M: SpecificationDocument1 pageModel: P2B-SC-30M: SpecificationR NandakumarNo ratings yet

- Part A - Hvac Technical Specifications 1. Hot Water GeneratorDocument25 pagesPart A - Hvac Technical Specifications 1. Hot Water GeneratorAnand_HvacNo ratings yet

- Technical Specification of Brick Laying MaterialsDocument13 pagesTechnical Specification of Brick Laying MaterialsMoe Zaw OoNo ratings yet

- I-City New CairoDocument64 pagesI-City New CairoAhmedNo ratings yet

- Circle Constructions and Tangents Maths Chapter 19 Class XDocument13 pagesCircle Constructions and Tangents Maths Chapter 19 Class XSANDEEP SINGHNo ratings yet

- Plans, Sections and ElevationsDocument16 pagesPlans, Sections and ElevationsDilshad Jaf100% (1)

- Building Control Regulations 2003 Arrangement of RegulationsDocument99 pagesBuilding Control Regulations 2003 Arrangement of RegulationsSamuelSzeNo ratings yet

- FDB222 A6v10061936Document20 pagesFDB222 A6v10061936Sze WalterNo ratings yet