Professional Documents

Culture Documents

Filtration Cartridge Duplex Unit - TDW 610-50-40

Uploaded by

Tg TarroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Filtration Cartridge Duplex Unit - TDW 610-50-40

Uploaded by

Tg TarroCopyright:

Available Formats

Duplex Unit A Baker Hugher equipment selection

Dual Vessel Filter Unit (TDW)

The Parker Twin Filter Duplex Cartridge

Filter Unit is the most commonly

used cartridge filter unit in the

oilfield industry. This offshore proof,

skid mounted filter unit offers a cost-

effective way to clean most common

oilfield fluids and fluid-waste streams.

The Duplex is equipped with all

necessary valves and safety features.

The unit enables simultaneous

filtration with one vessel, while the

spent cartridges of the other vessel

are changed out. Certified hoisting

slings and forklift pockets enable the

equipment to be lifted quickly and easily

with minimum risk at damaging.

Contact Information Benefits •

•

Waste water

Diesel / fuel / oil

• Up to 60 cartridges per vessel. • Sea-, river-, well water intake

Twin Filter BV

• Easy to operate lever and swing- • Polishing brines

A Parker Hannifin Company

away vessel lid. • Gels, amines & glycols

Zuiddijk 398

• Designed for offshore duty. • Process water

1505 HE Zaandam

• Swing-bolts and nuts for quick • Pre-filtration RO

The Netherlands

opening. • Stimulation fluids

phone +31 756 555 000 • Safety railing, ladder and service

fax +31 756 555 015 platform.

• Self sealing, service friendly cover

Filter unit range

twinfilter.info@parker.com

gasket. • Cartridge unit

www.parker.com/processfiltration • All 4 inch valves easy to operate. • Bag unit

www.twinfilter.com • Certified hoisting slings lifting lugs • Cartridge/bag combination unit

and forklift pockets. • Parallel configuration

• Safety valve set at 7 bar (101.5 psi). • Low temperature execution

• Offshore DNV 2.7-1 / EN12079 frame. • Integrated C-pump

• TDW 510 and 710 cartridge, bag

Applications and combination unit

• Different specifications (high pres

• Completion fluids sure, high flow etc.) on request.

• Work over fluids

• Gravel pack fluids

ENGINEERING YOUR SUCCESS.

1

Duplex Cartridge and/or Bag Unit

SPECIFICATIONS

Design Specifications

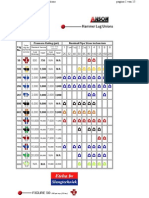

Cartridge L W H Weight Cartridge/bag

Model Pipe size Cartridge / bag length

/bag no. (empty) diameter

Duplex Cartridge 7.38 ft 3.94 ft 7.22 ft 3086 lb 4" 2.5" 40"

Unit 60 (2,25 m) (1,2 m) (2,20 m) (1400 kg) (101,6 mm) (63,5 mm) (1016 mm)

Duplex Combina- 7.38 ft 3.94 ft 7.22 ft 3306 lb 4" 2.5" 7" 40" L2

50/4

tion Unit (2,25 m) (1,2 m) (2,20 m) (1500 kg) (101,6 mm) (63,5 mm) (178 mm) (1016 mm) (175 mm / 750 mm)

7.38 ft 3.94 ft 7.22 ft 3086 lb 4" 7" L2

Duplex Bag Unit 4

(2,25 m) (1,2 m) (2,20 m) (1400 kg) (101,6 mm) (178 mm) (175 mm / 750 mm)

Design Specifications

No. of Vessel

Model Vessel lid Instruments Pressure relief valve Lifting

vessels diameter

Duplex Cartridge Unit

Hoisting slings

24" Lever operated In/outlet pressure 1" brass, set point

Duplex Combination Unit 2 (certified) and

(610 mm) swing away gauge @ 7 bar (101.5 psi)

forklift pockets

Duplex Bag Unit

Materials of Construction

Design code Material wetted Vessels built

Model Material Frame Lid seal

frame parts according

Duplex Cartridge Unit

Carbon steel

DNV 2.7-1 /

Duplex Combination Unit (powder coated) SS316L NBR PED

EN/2079

(RAL 5015)

Duplex Bag Unit

Maximum Operating Conditions Connections

Inlet/

Max. Max. Cartridge

Max. Drain/ Main outlet

Model operating working Model connec-

recom. flow Vent Valves connec-

pressure temp. tion

tion

20 bbl/min Duplex Cartridge Unit 2OF

Duplex Cartridge Unit Butterfly

200 m3/hr 1"ball

valves Union fig.

Duplex Combination Unit 2OF valve

101,5 psi 158°F 18 bbl/min (BSP-F)

4" (SS 100 M/F

Duplex Combination Unit disc)

(7 bar) (70°C) 172 m3/hr Duplex Bag Unit -

12 bbl/min

Duplex Bag Unit

115 m3/hr

Article description

TDW

Vessel diameter No. of cartridges Length No. of bags

Special options

(leave empty if not applicable) (leave empty if not applicable) (leave empty if not applicable)

Code mm Code No. Code Inch mm Code No. Code Description

610 610 50 50 40 40 1016 4B 4 HP High Pressure

Others on request Others on request Others on request Others on request HF High Flow

M Maxguard cartridges

MB Magnum cartridges

LT Low Temperature

Others on request

Specifications are subject to change without notification. © 2013 Parker-Hannifin Corporation

For User Responsibility Statement, see www.parker.com/safety Twin Filter BV.

All Rights Reserved

DS_OG_TDW

You might also like

- Chapter 08 HomeworkDocument40 pagesChapter 08 HomeworkFatboy9146% (24)

- SH Shaker-Brandt Mini CobraDocument92 pagesSH Shaker-Brandt Mini CobraKapil Tiwari100% (1)

- Guideline For Examining Failed Parts (1000, 7000) : Applied Failure AnalysisDocument70 pagesGuideline For Examining Failed Parts (1000, 7000) : Applied Failure AnalysisKusuma Jaya100% (1)

- Hammer Union PresentationDocument17 pagesHammer Union PresentationDaniel100% (1)

- The Mechanics of TractorDocument166 pagesThe Mechanics of TractorAbhijeet joseph50% (2)

- MDTotco General Catalog SM VerDocument44 pagesMDTotco General Catalog SM VerErIck Cabañas100% (10)

- D-GASSERS Orizontal + Vertical PDFDocument2 pagesD-GASSERS Orizontal + Vertical PDFciucalata880% (1)

- Piping and Instrument Diagram (P&id) Standard Symbols Detailed DocumentationDocument15 pagesPiping and Instrument Diagram (P&id) Standard Symbols Detailed Documentationautomationforum92% (103)

- 750 HP Ideco Sbs h44 Drilling RigDocument22 pages750 HP Ideco Sbs h44 Drilling Riga. lekadirNo ratings yet

- Tr6 Electronic Distributorless Ignition Kit Part1Document9 pagesTr6 Electronic Distributorless Ignition Kit Part1Kunta Si Kun KunNo ratings yet

- Evo-Trieve® EB0 Retrievable Straddle - HalliburtonDocument2 pagesEvo-Trieve® EB0 Retrievable Straddle - HalliburtonYovaraj KarunakaranNo ratings yet

- Heat Detector - Fusible Loop SystemDocument1 pageHeat Detector - Fusible Loop SystemTg TarroNo ratings yet

- Heat Detector - Fusible Loop SystemDocument1 pageHeat Detector - Fusible Loop SystemTg TarroNo ratings yet

- 30/40 Models SpecificationsDocument333 pages30/40 Models SpecificationsDouglas Duarte100% (2)

- Casing Data SheetDocument19 pagesCasing Data Sheetdursosono50% (2)

- Triplex Pump Part 2Document20 pagesTriplex Pump Part 2Rodolfo Castro50% (4)

- Tech Manual: Tech-5.12 10M Ec Combi Large SHRDocument260 pagesTech Manual: Tech-5.12 10M Ec Combi Large SHROvRrj AhmedNo ratings yet

- SEAL SELECTION GUIDEDocument2 pagesSEAL SELECTION GUIDEZAMFERLENONo ratings yet

- Induction Drilling Motor Instruction ManualDocument33 pagesInduction Drilling Motor Instruction ManualAhmed MNo ratings yet

- University of Palestine Fluid Statics Chapter SummaryDocument97 pagesUniversity of Palestine Fluid Statics Chapter SummaryABDFERNo ratings yet

- Operations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0Document18 pagesOperations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0dowel hernandezNo ratings yet

- 20brochure PDFDocument27 pages20brochure PDFparet999No ratings yet

- Coiled Tubing Surface EquipmentDocument75 pagesCoiled Tubing Surface EquipmentMIRCEA1305100% (2)

- Necchi Manuel de Service Bu-Bf Nova-Mira PDFDocument93 pagesNecchi Manuel de Service Bu-Bf Nova-Mira PDFSissyNo ratings yet

- DL Bop BrochureDocument4 pagesDL Bop BrochurekrishnsgkNo ratings yet

- Drilling Junk Sub: Operation & Maintenance ManualDocument8 pagesDrilling Junk Sub: Operation & Maintenance ManualShag ShaggyNo ratings yet

- 5-0001 Wire Line Guide BJDocument1 page5-0001 Wire Line Guide BJJacekNo ratings yet

- AQ Coring System PDFDocument72 pagesAQ Coring System PDFEloy GeraldoNo ratings yet

- 290-00 - PHPA Polymer Concentration KitDocument5 pages290-00 - PHPA Polymer Concentration KitJessica Matos TacuriNo ratings yet

- Cartridge and Bag Filter UnitDocument6 pagesCartridge and Bag Filter UnitDoni KurniawanNo ratings yet

- Cameron F FC BookletDocument4 pagesCameron F FC Booklettxlucky80No ratings yet

- Chapter 3 Injector Specs and SystemsDocument83 pagesChapter 3 Injector Specs and SystemsEl Mundo De YosedNo ratings yet

- RETSCO Mud Hopper mixing centrifugal pumpsDocument2 pagesRETSCO Mud Hopper mixing centrifugal pumpsGregory StewartNo ratings yet

- SPM Dart Valve Manual PDFDocument32 pagesSPM Dart Valve Manual PDFYM Edwin Gil Beltran100% (1)

- Maintain and operate gate valvesDocument32 pagesMaintain and operate gate valvesNeilton Junior100% (1)

- Tech Manual: Tech-5.12 10K Es54 Dual QcmaDocument24 pagesTech Manual: Tech-5.12 10K Es54 Dual QcmaRiski KurniawanNo ratings yet

- Mud Hopper: User ManualDocument13 pagesMud Hopper: User ManualAli Ali50% (2)

- Hamerlug Unions (Anson)Document15 pagesHamerlug Unions (Anson)Leonardo ViannaNo ratings yet

- 5.DD9701971846 - Lub Assy 4.06 E12 LW 10K H2SDocument2 pages5.DD9701971846 - Lub Assy 4.06 E12 LW 10K H2SAbhinav KumarNo ratings yet

- Vendor B - Technical ProposalDocument136 pagesVendor B - Technical ProposalBilal Mehdi100% (1)

- Technical Description MPPUDocument10 pagesTechnical Description MPPUNinaNo ratings yet

- Anti Surge Controller Protects CompressorsDocument5 pagesAnti Surge Controller Protects CompressorsInter Tung100% (1)

- DSQ4 10M SidedoorDocument15 pagesDSQ4 10M SidedoorДудла СтаніславNo ratings yet

- Drilling EquipmentDocument18 pagesDrilling EquipmentGhinet Teodor-ioanNo ratings yet

- Parker Drilling Rig 258Document2 pagesParker Drilling Rig 258Nathan Thillai100% (2)

- Procedure For Well TestingDocument4 pagesProcedure For Well TestingTg TarroNo ratings yet

- A GENERAL PHYSICS I 12 Q2M2 Teacher PDFDocument17 pagesA GENERAL PHYSICS I 12 Q2M2 Teacher PDFRETCHIE JOY PISANANo ratings yet

- 250 HMI 475 SpecsDocument3 pages250 HMI 475 SpecsProyectil De Proyecto100% (1)

- Balanced Eliptical Motion Shale Shaker (BEM-600)Document6 pagesBalanced Eliptical Motion Shale Shaker (BEM-600)LoganBohannonNo ratings yet

- PidDocument101 pagesPidBagus AtmajaNo ratings yet

- Paper Machine Handbook 10580EN - TCM - 12-125114 PDFDocument214 pagesPaper Machine Handbook 10580EN - TCM - 12-125114 PDFJeffry KarundengNo ratings yet

- IMO T11 Tank DetailsDocument4 pagesIMO T11 Tank DetailsTg TarroNo ratings yet

- Annular GK Hydril 12 Inch X 3000 Psi Parts ManualDocument1 pageAnnular GK Hydril 12 Inch X 3000 Psi Parts ManualBéchir Yacoubi0% (1)

- BOP BoltsDocument5 pagesBOP BoltsHadirah DunglahNo ratings yet

- A1 001 Wireline Unit PTO SwapBody 24ftDocument2 pagesA1 001 Wireline Unit PTO SwapBody 24ftRio de MarioNo ratings yet

- Honghua Hydraulic Power Unit Parts ListDocument29 pagesHonghua Hydraulic Power Unit Parts Listcmrig74No ratings yet

- Westco Product Catalog 2019Document16 pagesWestco Product Catalog 2019DiegoCaicedo1982100% (2)

- D352004107 MKT 001 PDFDocument20 pagesD352004107 MKT 001 PDFEloy Lardet LafiNo ratings yet

- IRI-044 IRI Parts Manual Non-Controlled Rev - 2 - 0 10-09-2015 - 9901910937 - 01 - 6375912 - 01Document68 pagesIRI-044 IRI Parts Manual Non-Controlled Rev - 2 - 0 10-09-2015 - 9901910937 - 01 - 6375912 - 01Tanyawat Sahsakmontri100% (2)

- CAD Control Systems - Oil and Gas BrochureCurrentDocument28 pagesCAD Control Systems - Oil and Gas BrochureCurrentajayNo ratings yet

- Cameron - DL-Annular BopDocument1 pageCameron - DL-Annular BopAnonymous 48jYxR1CNo ratings yet

- BOP Dimensions 13stackDocument3 pagesBOP Dimensions 13stackSasan AbbasiNo ratings yet

- 5 Series E-Lite Control ModuleDocument1 page5 Series E-Lite Control ModuleDuy ThaiNo ratings yet

- Yemen 1 - 1000 HP Land RigDocument4 pagesYemen 1 - 1000 HP Land Rigoilrigsales100% (1)

- TDS 9 SpecificationsDocument3 pagesTDS 9 SpecificationsKhaled El-FaramawyNo ratings yet

- Test Pump WindlassDocument40 pagesTest Pump WindlassMd.farman Ali AhmedNo ratings yet

- Unitized Mud Systems: Closed LoopDocument16 pagesUnitized Mud Systems: Closed Loopmr_heeraNo ratings yet

- MGS Capacity CalculatorDocument13 pagesMGS Capacity CalculatorRodolfo MendezNo ratings yet

- 2 Bridge PlugsDocument9 pages2 Bridge PlugsaaaNo ratings yet

- M60dsu4 0445XB Man 001Document13 pagesM60dsu4 0445XB Man 001Riski KurniawanNo ratings yet

- Agitators Manual 6556451 01 PDFDocument135 pagesAgitators Manual 6556451 01 PDFDani RiveraNo ratings yet

- TM 80 Daily and Weekly Inspection and Maintenance TasksDocument25 pagesTM 80 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoNo ratings yet

- 3in BOP Inner & Outer SealsDocument1 page3in BOP Inner & Outer SealsusamakhattakNo ratings yet

- API Casing Float Collar and ShoeDocument2 pagesAPI Casing Float Collar and Shoeisrar haiderNo ratings yet

- Hydrocyclones: D-Sa N Der D-SilterDocument10 pagesHydrocyclones: D-Sa N Der D-Siltersaa6383No ratings yet

- Detailed Working Instruction: South Azadegan Oil Field Epd Project AZNS-163/ 7" Liner Lap Inflow TestDocument9 pagesDetailed Working Instruction: South Azadegan Oil Field Epd Project AZNS-163/ 7" Liner Lap Inflow TestMehdi NorouziNo ratings yet

- Series 150 Overshots Supplement: Instruction Manual 1150ADocument25 pagesSeries 150 Overshots Supplement: Instruction Manual 1150AForos IscNo ratings yet

- Mud Pumps 1Document2 pagesMud Pumps 1John RongNo ratings yet

- Paper - Coupling Norsok Co2 Corrosion Prediction Model With Pipelines Thermal Hydraulic Models To Simulate Co2 Corrosion Along Pipelines PDFDocument11 pagesPaper - Coupling Norsok Co2 Corrosion Prediction Model With Pipelines Thermal Hydraulic Models To Simulate Co2 Corrosion Along Pipelines PDFnaveen_86No ratings yet

- Extension of NORSOK CO Corrosion Prediction Model For Elbow GeometryDocument14 pagesExtension of NORSOK CO Corrosion Prediction Model For Elbow GeometryTg TarroNo ratings yet

- RIGZONE - How Does Coiled Tubing WorkDocument2 pagesRIGZONE - How Does Coiled Tubing WorkTg TarroNo ratings yet

- Guidance Note: Heritage Railway AssociationDocument10 pagesGuidance Note: Heritage Railway AssociationTg TarroNo ratings yet

- ABC Quick Check: The Purpose of This Test To Obtain Your Feedback On The ABC SeminarDocument5 pagesABC Quick Check: The Purpose of This Test To Obtain Your Feedback On The ABC SeminarTg TarroNo ratings yet

- B TH 2011 AbdullaDocument106 pagesB TH 2011 Abdullathanhvinh710No ratings yet

- Piping & Instrumentation Diagram P&IdDocument41 pagesPiping & Instrumentation Diagram P&IdTg TarroNo ratings yet

- en - Assets - Mastersizer 3000 Basic Guide English Man0475 07 en 00 - tcm50 11650 PDFDocument104 pagesen - Assets - Mastersizer 3000 Basic Guide English Man0475 07 en 00 - tcm50 11650 PDFCarlos Alberto Salazar Duque100% (2)

- Wearable Dialysis Device Horizon ReportDocument17 pagesWearable Dialysis Device Horizon ReportRay Adriane Teves MayorNo ratings yet

- 6 Years Old Invoice (Online Class)Document2 pages6 Years Old Invoice (Online Class)Tg TarroNo ratings yet

- How To Ensure H2S Safety On Offshore Rigs - Drilling ContractorDocument10 pagesHow To Ensure H2S Safety On Offshore Rigs - Drilling ContractorTg TarroNo ratings yet

- Job Vacancy - Geotechnical EngineerDocument2 pagesJob Vacancy - Geotechnical EngineerTg TarroNo ratings yet

- 1.0 FourPhase Sand TrapDocument2 pages1.0 FourPhase Sand TrapTg TarroNo ratings yet

- Sand-Vac, Well-Vac, Tele-Vac Well Cleanout Systems: Remove Solids and Liquids From Ultralow-Pressure WellboresDocument2 pagesSand-Vac, Well-Vac, Tele-Vac Well Cleanout Systems: Remove Solids and Liquids From Ultralow-Pressure WellboresTg TarroNo ratings yet

- SPM UsageandMaintenanceGuideDocument71 pagesSPM UsageandMaintenanceGuideVladyslavNo ratings yet

- Hydrogen Sulphide: Offshore Coshh EssentialsDocument3 pagesHydrogen Sulphide: Offshore Coshh EssentialsBoro DjakaridjaNo ratings yet

- Confined Space ExplainedDocument2 pagesConfined Space ExplainedGrady HopkinsNo ratings yet

- SPE Optimization of Well Performance by Use of A Semi Permanent Dynamic Desander Ted Brueren Statoil1Document30 pagesSPE Optimization of Well Performance by Use of A Semi Permanent Dynamic Desander Ted Brueren Statoil1Tg TarroNo ratings yet

- 1.0 FourPhase Sand TrapDocument2 pages1.0 FourPhase Sand TrapTg TarroNo ratings yet

- Safety and Health Topics - Hydrogen Sulfide - Standards - Occupational Safety and Health AdministrationDocument3 pagesSafety and Health Topics - Hydrogen Sulfide - Standards - Occupational Safety and Health AdministrationTg TarroNo ratings yet

- Gas Book - V5 - 0413 - LR - EN PDFDocument116 pagesGas Book - V5 - 0413 - LR - EN PDFArioston JúniorNo ratings yet

- Guidance Note: Heritage Railway AssociationDocument10 pagesGuidance Note: Heritage Railway AssociationTg TarroNo ratings yet

- 9869 Omega SealsDocument12 pages9869 Omega SealsStephenNo ratings yet

- IP Ratings Chart V3 PDFDocument1 pageIP Ratings Chart V3 PDFsuprakashpaul93No ratings yet

- Datasheet (Métrico) - 2BH1900Document2 pagesDatasheet (Métrico) - 2BH1900Rafael BalakNo ratings yet

- ColumnsDocument66 pagesColumnsArchana GSNo ratings yet

- Diagnositc Trouble Codes and Possible CausesDocument6 pagesDiagnositc Trouble Codes and Possible CausesJuan Carlos Sequeira Robles100% (1)

- Screw Air Compressors: SCR Belt DriveDocument2 pagesScrew Air Compressors: SCR Belt DriveDelwin Jose HernandezNo ratings yet

- Serial Number RangeDocument304 pagesSerial Number RangeBracamonte Varon100% (1)

- 6 Rolled BeamsDocument3 pages6 Rolled BeamsBCXC LLAMNo ratings yet

- GSE EnVision ProcessFund Sim IDocument2 pagesGSE EnVision ProcessFund Sim IFungky KingNo ratings yet

- Limit Switches: FeaturesDocument2 pagesLimit Switches: FeaturesNoUserNameNo ratings yet

- CZ Sincro DG83Document14 pagesCZ Sincro DG83JoNo ratings yet

- H8.0FT, H8.0FT9, H9.0FT (B299) : 4053648 ©2012 Hyster Company 10/2012Document560 pagesH8.0FT, H8.0FT9, H9.0FT (B299) : 4053648 ©2012 Hyster Company 10/2012pruhavNo ratings yet

- Ashok LeylandDocument1 pageAshok LeylandDileep Mannath100% (1)

- 3500 MSB80 ENS1 0110 02 - General Material SpecificationDocument304 pages3500 MSB80 ENS1 0110 02 - General Material SpecificationJoão Luiz CortatNo ratings yet

- Contoh 2 WATER COOLED SCREW CHILLERDocument3 pagesContoh 2 WATER COOLED SCREW CHILLERsitiNo ratings yet

- Sarjana Site Visit Schedule-CPPDocument13 pagesSarjana Site Visit Schedule-CPPSanjay GuptaNo ratings yet

- Annexure - A Process Flow Diagram (ECOTEX)Document2 pagesAnnexure - A Process Flow Diagram (ECOTEX)Dipjyoti SenNo ratings yet

- ZZ5371VDMB32100Document1 pageZZ5371VDMB32100Andy WangNo ratings yet

- Manual Transmission and DifferentialDocument1 pageManual Transmission and DifferentialJeff PascoeNo ratings yet

- Calorifier ManualDocument6 pagesCalorifier ManualKanak MevadaNo ratings yet