Professional Documents

Culture Documents

Shank Dia. Before Thread Rolling Ø8: Machining Drawing Critical Component

Uploaded by

GauravOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shank Dia. Before Thread Rolling Ø8: Machining Drawing Critical Component

Uploaded by

GauravCopyright:

Available Formats

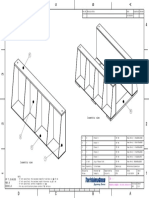

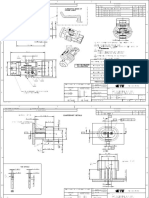

D C B A PROTO-0015-1

4 4

Shank Dia. Before

Thread Rolling

Ø8

M8x1.25P

3 3

14

10 17

27

2 2

Note: Per valve qty- 4No's

EARLIER DRG. NO. 12-32-15-250-3D CRITICAL COMPONENT MACHINING DRAWING

DRAWN M. S. B 05.01.2017 THIS DRAWING IS PROPRIETARY ARTICLE AND IS LOANED IN CONFIDENCE SUBJECT TO RETURN UPON

DEMAND. REPRODUCTION THEREOF OR MANUFACTUREOF PARTS THEREFROM IS NOT PERMISSIBLE CLASS --

WITHOUT THE WRITTEN PERMISSION OF MICROFINISH VALVES PVT LTD. HUBLI-INDIA

CHECKED P. S. P 03.02.2017

Doc No: R/5.4/6 R01

GENERAL MACHINING TOLERANCES for linear dimension: PRODUCT BALL VALVE FL

APPROVED S. A. N 03.02.2017 Over 6 Over 30 Over 120 Over 400 Over 1000 Over 2000

0.5 upto 6 upto 30 upto 120 upto 400 upto 1000 upto 2000 upto 4000 MATERIAL REFER BOM

NOTES:-

1) All dimension are in mm `0.1 `0.2 `0.3 `0.5 `0.8 ` 1.2 `2.0

PART NO. 3

2) Remove all sharp corners and edges by 0.5 raddi / 0.5x45° GENERAL MACHINING TOLERANCES for angular dimension:

3) Critical dimension with its surface finish &

LENGTH UPTO 10 Over 10 upto 50 Over 50 upto 120 Over 120 upto 400 Over 400 upto 1000 WEIGHT

GD&T marked as ◐

1 4) Dimension's showed in (_) only for reference

5) For any Clarification or Suggestion please contact R&D

ANGLE `1° `0° 30' `0° 20' `0° 10' `0° 5'

DRG. NO. :

Machining to 6.3 µ m to 3.2 µm Ra

Fine machining to 1.6 µm to 0.8 µm Ra

TITLE R0501110409XX

Grinding to 0.8 µm to 0.4 µm Ra

Lap to 0.2 µm to 0.1 µm Ra STUD : M8x1.25Px27L (B-10, C-14)

CRYO. BE-250 REV. NO: 0 SHEET 01 OF 01

SCALE:

N.T.S

REV. DCN.NO REGION BRIEF RECORD SIGN/DATE

210C-NC

D C B A

You might also like

- Assembly Drawing (Amplifier PCB Assembly, 055-227-10)Document1 pageAssembly Drawing (Amplifier PCB Assembly, 055-227-10)thiep tranNo ratings yet

- Piping Isometric - 8Document1 pagePiping Isometric - 8CosminMarianNo ratings yet

- Apple Iphone 4s n94 MLB v3 SCH PDFDocument33 pagesApple Iphone 4s n94 MLB v3 SCH PDFwadeNo ratings yet

- Piping Isometric - 4Document1 pagePiping Isometric - 4CosminMarianNo ratings yet

- HDL 61cuDocument1 pageHDL 61curiza jakaNo ratings yet

- DWG SPCTool-A Sheet 1Document1 pageDWG SPCTool-A Sheet 1AdeImanudinNo ratings yet

- VMP113BP-2-1#1 SUCTION (203-K-002 1st Stage)Document1 pageVMP113BP-2-1#1 SUCTION (203-K-002 1st Stage)Aryo Arief Adhitomo SaifudinNo ratings yet

- GE ED: ToolboxDocument1 pageGE ED: ToolboxstefanNo ratings yet

- VB-000075 Rev ADocument1 pageVB-000075 Rev AelmoNo ratings yet

- Iphone 6 PLUS Schematics - 1197859924Document54 pagesIphone 6 PLUS Schematics - 1197859924María ShirleyNo ratings yet

- Arihant Industries: Side View Front ViewDocument1 pageArihant Industries: Side View Front Viewthe vaultNo ratings yet

- Moving coil actuator specifications sheetDocument2 pagesMoving coil actuator specifications sheetivan torresNo ratings yet

- Key Plan: Engineering Consultants GroupDocument1 pageKey Plan: Engineering Consultants GroupRashidNo ratings yet

- 0STXOSDocument1 page0STXOSDinesh YkatilNo ratings yet

- 电话:18602029640 微信:wywen1: iphone6 4.7 iphone6 5.5 iphone6 4.7Document55 pages电话:18602029640 微信:wywen1: iphone6 4.7 iphone6 5.5 iphone6 4.7Derrick AgbodziNo ratings yet

- CN345 - 2.5mm Jack PlugDocument1 pageCN345 - 2.5mm Jack PlugAymen CheffiNo ratings yet

- CN345 - 2.5mm Jack PlugDocument1 pageCN345 - 2.5mm Jack PlugAymen CheffiNo ratings yet

- GT3-1 Default SetupDocument1 pageGT3-1 Default SetupBruno D.No ratings yet

- Avento 1: Installation Instructions IECDocument3 pagesAvento 1: Installation Instructions IECHALCON DE LOS ANDESNo ratings yet

- Revisions C: REVISED PER ECO-11-005150 RK HMR New Creo Drawing BV GBDocument1 pageRevisions C: REVISED PER ECO-11-005150 RK HMR New Creo Drawing BV GBhulaneNo ratings yet

- Imp Ring Fire Pum No 3Document1 pageImp Ring Fire Pum No 3Ade ImanudinNo ratings yet

- SW1210!04!00059 - Geodesic Dome DrawingsDocument6 pagesSW1210!04!00059 - Geodesic Dome DrawingsApdb GalabnodNo ratings yet

- 500-30-008 Corner Cap Die Cast New Version - 05-11-2020Document1 page500-30-008 Corner Cap Die Cast New Version - 05-11-2020Mirza MešanovićNo ratings yet

- Extract Page 4Document1 pageExtract Page 4Damiano DaidoneNo ratings yet

- RTL9210-VB-CG Demo V203 PDFDocument5 pagesRTL9210-VB-CG Demo V203 PDFCenusa MihaiNo ratings yet

- Piping Isometric - 5Document1 pagePiping Isometric - 5CosminMarianNo ratings yet

- Option 2Document2 pagesOption 2Chien Dang VanNo ratings yet

- VR2D 245-4000 + 1xCD 101 - C25036ECDC09 - C PDFDocument6 pagesVR2D 245-4000 + 1xCD 101 - C25036ECDC09 - C PDFAhmed Nasr (By NAZRi)No ratings yet

- Lever 1Document1 pageLever 1balasubramani krishnamurthiNo ratings yet

- 2 PrhlegconrDocument1 page2 Prhlegconrsameer panigrahiNo ratings yet

- Iphone 6 Full schematic+IC BoardDocument86 pagesIphone 6 Full schematic+IC BoardSIDNEY TABOADANo ratings yet

- Tie Rod 4tpi 16MM SF Tird 393Document1 pageTie Rod 4tpi 16MM SF Tird 393m_prvcnNo ratings yet

- 25LPO10Document1 page25LPO10karthikNo ratings yet

- Piping Isometric - 10Document1 pagePiping Isometric - 10CosminMarianNo ratings yet

- 240x64 LCD Module with RA6963 ControllerDocument11 pages240x64 LCD Module with RA6963 ControllerMitchell DanielsNo ratings yet

- Tohatsu MFS20D MFS30D SMDocument413 pagesTohatsu MFS20D MFS30D SMpowerserviceNo ratings yet

- Touch Screen SpecificationDocument1 pageTouch Screen SpecificationDJ_CROWNNo ratings yet

- Bill of MaterialDocument1 pageBill of Materialriza jakaNo ratings yet

- AnsambluDocument1 pageAnsambluFlorin BuruNo ratings yet

- Top View: 300 1000 1000 150 300 0.25 0.5 1.0 1.0 2.5 1.5 Nominal Size 0.1 Fabrication MachiningDocument2 pagesTop View: 300 1000 1000 150 300 0.25 0.5 1.0 1.0 2.5 1.5 Nominal Size 0.1 Fabrication MachiningPunky IrlanditoNo ratings yet

- Tunnel-2 Lining Geometry (Without Invert) Typical Tunnel-2 Lining Section (Without Invert)Document1 pageTunnel-2 Lining Geometry (Without Invert) Typical Tunnel-2 Lining Section (Without Invert)Hemant YesajiNo ratings yet

- Imp Ring Fire Pump No 1Document1 pageImp Ring Fire Pump No 1Ade ImanudinNo ratings yet

- M2910369 ZG 01-03 HingeDocument1 pageM2910369 ZG 01-03 HingeSarfaraj ShaikhNo ratings yet

- NG50501 Knee Clamp AssemblyDocument1 pageNG50501 Knee Clamp AssemblyAlejandro González TorresNo ratings yet

- TS 3000 door closer series specificationsDocument2 pagesTS 3000 door closer series specificationsguzde38383No ratings yet

- D2 D3 D4 D5: Revisions CDocument2 pagesD2 D3 D4 D5: Revisions CSemih YelkenNo ratings yet

- Acme-002 - Baker Stub Acme Form Thread - Rev DDocument1 pageAcme-002 - Baker Stub Acme Form Thread - Rev Dsumansri459No ratings yet

- Cable M12-Picospox 0.5MDocument1 pageCable M12-Picospox 0.5MBoxerpower GasNo ratings yet

- Panel ATS 400A technical drawingDocument4 pagesPanel ATS 400A technical drawingardi yansaNo ratings yet

- D-Me-Ms-152r0 Side Wheel of Spillway Service GateDocument1 pageD-Me-Ms-152r0 Side Wheel of Spillway Service Gateolalekan fatai RotimiNo ratings yet

- GAD For Strainer - StampedDocument2 pagesGAD For Strainer - StampedAnıl ÖztürkNo ratings yet

- tc-000099Document1 pagetc-000099magiNo ratings yet

- Ball Base 12.0 20.0: Letourneau Technologies™Document1 pageBall Base 12.0 20.0: Letourneau Technologies™Mikel1020No ratings yet

- Detail A Detail B: Stinger, FLD AssyDocument2 pagesDetail A Detail B: Stinger, FLD Assybends1408No ratings yet

- Proto 3: Nano SensorDocument12 pagesProto 3: Nano SensorkadiravannNo ratings yet

- Imp Ring Fire Pump No. 2,3,4Document1 pageImp Ring Fire Pump No. 2,3,4Ade ImanudinNo ratings yet

- Va536 3Document1 pageVa536 3陆军No ratings yet

- NG 910CV11 04 00 (Rev00)Document4 pagesNG 910CV11 04 00 (Rev00)Saeed MahmoudabadiNo ratings yet

- Approved by Project: Client: - Check by H/R Designed by H/R Drawing by R/H RevDocument1 pageApproved by Project: Client: - Check by H/R Designed by H/R Drawing by R/H RevBudi CahyonoNo ratings yet

- Full 3-4 10unc 115 B7 BlackodisingDocument1 pageFull 3-4 10unc 115 B7 BlackodisingGauravNo ratings yet

- Full 3-4 10unc 130 B7 BlackodisingDocument1 pageFull 3-4 10unc 130 B7 BlackodisingGauravNo ratings yet

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - RollingDocument1 pageSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - RollingGauravNo ratings yet

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - GrindingDocument1 pageSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - GrindingGauravNo ratings yet

- SW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - BlankingDocument1 pageSW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - BlankingGauravNo ratings yet

- SW Full M12X1.75PX60 B7 ZN Al SM0000000001 - RollingDocument1 pageSW Full M12X1.75PX60 B7 ZN Al SM0000000001 - RollingGauravNo ratings yet

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - BlankingDocument1 pageSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - BlankingGauravNo ratings yet

- 3X45° Bar Stud Machining DrawingDocument1 page3X45° Bar Stud Machining DrawingGauravNo ratings yet

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - GrindingDocument1 pageSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - GrindingGauravNo ratings yet

- SW Full M12X1.75PX60 B7 ZN Al SM0000000001 - Blanking PDFDocument1 pageSW Full M12X1.75PX60 B7 ZN Al SM0000000001 - Blanking PDFGauravNo ratings yet

- SW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - GrindingDocument1 pageSW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - GrindingGauravNo ratings yet

- SW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - RollingDocument1 pageSW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - RollingGauravNo ratings yet

- SW Full M12X1.75PX60 B7 ZN Al SM0000000001 - GrindingDocument1 pageSW Full M12X1.75PX60 B7 ZN Al SM0000000001 - GrindingGauravNo ratings yet

- SW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - MarkingDocument1 pageSW Full M16X2PX90 A193 B7 ZN Al SM0000000003 - MarkingGauravNo ratings yet

- SW Full M12X1.75PX60 B7 ZN Al SM0000000001 - MarkingDocument1 pageSW Full M12X1.75PX60 B7 ZN Al SM0000000001 - MarkingGauravNo ratings yet

- M16X2PX52L B8Document1 pageM16X2PX52L B8GauravNo ratings yet

- M16X2PX52L 4140 B7 BlackodisingDocument1 pageM16X2PX52L 4140 B7 BlackodisingGauravNo ratings yet

- KGC Full 3-4 10unc 110 MM A193 B7 Black Kgcfti34010110b7a193 - BlankingDocument1 pageKGC Full 3-4 10unc 110 MM A193 B7 Black Kgcfti34010110b7a193 - BlankingGauravNo ratings yet

- Eee Full m12x1.75px65 b7 ZN Blue Hwst12065bf0Document1 pageEee Full m12x1.75px65 b7 ZN Blue Hwst12065bf0GauravNo ratings yet

- BEC 013 Automotie ElectronicsDocument70 pagesBEC 013 Automotie Electronicsjimshith jimmuNo ratings yet

- Gargi EnterprisesDocument10 pagesGargi EnterprisesGauravNo ratings yet

- M20X2.5PX60L 4140 B7 BlackodisingDocument1 pageM20X2.5PX60L 4140 B7 BlackodisingGauravNo ratings yet

- Full M12X1.75PX60 B7 ZN Al - BlankingDocument1 pageFull M12X1.75PX60 B7 ZN Al - BlankingGauravNo ratings yet

- Full M20X2.5PX210L A193 B8M CL-1Document1 pageFull M20X2.5PX210L A193 B8M CL-1GauravNo ratings yet

- MPCPL BSR M10X1.5PX50 4140 B7 Blackodising M10-50-SB7 PDFDocument1 pageMPCPL BSR M10X1.5PX50 4140 B7 Blackodising M10-50-SB7 PDFGauravNo ratings yet

- Eee Full m12x1.75px65 b7 ZN Blue Hwst12065bf0Document1 pageEee Full m12x1.75px65 b7 ZN Blue Hwst12065bf0GauravNo ratings yet

- Mic Full m12x1.75px45l b7 Blackodising Mi0000000011Document1 pageMic Full m12x1.75px45l b7 Blackodising Mi0000000011GauravNo ratings yet

- Mic Full m12x1.75px45l b7 Blackodising Mi0000000011Document1 pageMic Full m12x1.75px45l b7 Blackodising Mi0000000011GauravNo ratings yet

- MPCPL BSR M10X1.5PX45 4140 B7 Blackodising M10-45-SB7Document1 pageMPCPL BSR M10X1.5PX45 4140 B7 Blackodising M10-45-SB7GauravNo ratings yet

- MPCPL BSR M12X1.75PX45 4140 B7 Blackodising M12-45-SB7Document1 pageMPCPL BSR M12X1.75PX45 4140 B7 Blackodising M12-45-SB7GauravNo ratings yet

- IscarDocument158 pagesIscarDOBJAN100% (1)

- ThreadsDocument50 pagesThreadsSagar JathanNo ratings yet

- FANUC Series 0M-D Machining Center ManualDocument406 pagesFANUC Series 0M-D Machining Center Manualcesar_abdd100% (1)

- Machining: Machining Is Any of Various Processes in Which A Piece of RawDocument7 pagesMachining: Machining Is Any of Various Processes in Which A Piece of RawAshwin KumarNo ratings yet

- Description and Taxonomy of The Manufacturing Processes PDFDocument5 pagesDescription and Taxonomy of The Manufacturing Processes PDFBhupesh GuptaNo ratings yet

- NIKO Ball ScrewsDocument33 pagesNIKO Ball ScrewsAndrey RossiNo ratings yet

- NcStudio V8 Engraving CNC System Users' Manual-R5.1Document118 pagesNcStudio V8 Engraving CNC System Users' Manual-R5.1Yudhi HermawanNo ratings yet

- Digital Readouts Linear Encoders: For Manually Operated Machine ToolsDocument36 pagesDigital Readouts Linear Encoders: For Manually Operated Machine ToolsAdairNo ratings yet

- Modern Manufacturing Methods: Unit IDocument17 pagesModern Manufacturing Methods: Unit IharinathNo ratings yet

- Drill Stem Components GuideDocument28 pagesDrill Stem Components Guidechonubobby100% (1)

- Jig and FixturesDocument25 pagesJig and FixturesFadhli LieNo ratings yet

- Fabrication Erection and Installation Procedure For PipingDocument36 pagesFabrication Erection and Installation Procedure For PipingThiên Khánh67% (3)

- 10 1 1 1071 7012 PDFDocument7 pages10 1 1 1071 7012 PDFKombet 69No ratings yet

- Mitsubishi ManualsDocument4 pagesMitsubishi ManualsRevolusiSoekarnoNo ratings yet

- Geometric Errors Compensation of CNC Machine ToolDocument6 pagesGeometric Errors Compensation of CNC Machine ToolnenadNo ratings yet

- 2020 Ductile Mode Cutting of Brittle MaterialsDocument303 pages2020 Ductile Mode Cutting of Brittle MaterialsSasidhar Reddy MuramNo ratings yet

- ISO Turning Inserts GuideDocument36 pagesISO Turning Inserts GuideferNo ratings yet

- Top Reason Inventor HSM CAMDocument2 pagesTop Reason Inventor HSM CAMCha YessicaNo ratings yet

- 1Document64 pages1Leonardo GallegoNo ratings yet

- Reamers: Number of Cutting EdgeDocument5 pagesReamers: Number of Cutting EdgeSunilkumar ReddyNo ratings yet

- Machine Screws: DIN 965 & ISO 7045 TorxDocument1 pageMachine Screws: DIN 965 & ISO 7045 TorxDerekNo ratings yet

- Industrial Production Engineering Project IdeasDocument4 pagesIndustrial Production Engineering Project IdeasRahul Shrivas67% (3)

- METAL | MAATSURA | SUCCESS STORY CNCDocument5 pagesMETAL | MAATSURA | SUCCESS STORY CNCSander DuqueNo ratings yet

- Design and Fabrication of Multipurpose Wood Machining Device PDFDocument12 pagesDesign and Fabrication of Multipurpose Wood Machining Device PDFamsa yazeNo ratings yet

- Catia Syllabus-2017 - 18 AitDocument3 pagesCatia Syllabus-2017 - 18 Aitarun chandranNo ratings yet

- Catalogo 14 PDFDocument258 pagesCatalogo 14 PDFJuan Manuel VizosoNo ratings yet

- Mechanism of Chip Formation in Machining Process.: Presented byDocument19 pagesMechanism of Chip Formation in Machining Process.: Presented byShraddha SangoleNo ratings yet

- Project Report YamahaDocument23 pagesProject Report YamahaAman KumarNo ratings yet

- Nominal Diameter Minimum Diameter Imaginary Diameter Maximum DiameterDocument8 pagesNominal Diameter Minimum Diameter Imaginary Diameter Maximum DiameterHansyyy CarantoNo ratings yet

- Lukas KatalogDocument31 pagesLukas KatalogJosko SpehNo ratings yet