Professional Documents

Culture Documents

Manual Instruction Watt Water - Part9

Uploaded by

Irvan VatoniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Instruction Watt Water - Part9

Uploaded by

Irvan VatoniCopyright:

Available Formats

Pop-Up Screens

Under certain circumstances a pop-up screen may be displayed.

These look like a window that partially blocks out the screen behind

it. The conditions that display pop-up screens are:

Low Inlet Pressure

Pretreatment Interlock

Overload Conditions

Trying to calibrate if the temperature and/or conductivity is not stable.

Service And Maintenance

The CI-1000 Reverse Osmosis Controller is designed for ease of

maintenance and minimum service. Since the highest quality of

electronic semiconductor components are used in this design, it

is not likely that circuit malfunctions or failures will occur. It is our

recommendation that service be limited to identifying malfunctions at

the board level and that component level troubleshooting be referred

to the factory.

Field failures that most frequently occur are:

- Improper or broken wiring connections

- Incorrect wiring of the motor starter

- Improper grounding

- Cable run is too long

- Water in connectors

- Dirty probes

- Defective probes

Troubleshooting

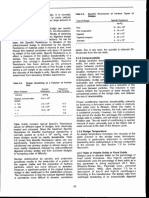

Description of Problem Possible Cause or Solution

System shuts down on low-pressure but pressure is okay. 1. Check the pressure switch set point

2. Possible short in wiring to pressure switch

3. Defective pressure switch

4. Orifice in pressure switch may be plugged

Pressing the Start/Stop button does not turn the system on. 1. Verify that the key switch is on

2. Verify that the circular connector on the bottom of the controller is attached

3. Check the fuse in the power inlet

Conductivity monitor does not display the proper reading. 1. Calibrate the controller

2. Check the wiring to the conductivity probe

3. Clean the conductivity probe

4. Replace the conductivity probe

Erratic conductivity display 1. Conductivity probe wiring may be too close to high voltage lines.

2. Check for moisture in the connection between the probe and the lead wire.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- DD 24 DD 22Document2 pagesDD 24 DD 22evega97No ratings yet

- 4.5 Cargo DischargingDocument2 pages4.5 Cargo DischargingHasan Cosalev100% (1)

- Takniki Darpan - Issue 18Document40 pagesTakniki Darpan - Issue 18ronyjohnsonNo ratings yet

- Cutler-Hammer: Learning Module 26: DevicenetDocument41 pagesCutler-Hammer: Learning Module 26: Devicenetksenthil77No ratings yet

- Fire and Gas Alarm SystemDocument6 pagesFire and Gas Alarm SystemsswahyudiNo ratings yet

- Technical English 1 Workbook With KeyDocument80 pagesTechnical English 1 Workbook With Keyurno.one80% (15)

- Dewatering Municipal Wastewater Sludges - Part43Document1 pageDewatering Municipal Wastewater Sludges - Part43Irvan VatoniNo ratings yet

- Dewatering Municipal Wastewater Sludges - Part45Document1 pageDewatering Municipal Wastewater Sludges - Part45Irvan VatoniNo ratings yet

- Dewatering Municipal Wastewater Sludges - Part34Document1 pageDewatering Municipal Wastewater Sludges - Part34Irvan VatoniNo ratings yet

- Dewatering Municipal Wastewater Sludges - Part44Document1 pageDewatering Municipal Wastewater Sludges - Part44Irvan VatoniNo ratings yet

- Dewatering Municipal Wastewater Sludges - Part39Document1 pageDewatering Municipal Wastewater Sludges - Part39Irvan VatoniNo ratings yet

- Dewatering Municipal Wastewater Sludges - Part33Document1 pageDewatering Municipal Wastewater Sludges - Part33Irvan VatoniNo ratings yet

- Dewatering Municipal Wastewater Sludges - Part38Document1 pageDewatering Municipal Wastewater Sludges - Part38Irvan VatoniNo ratings yet

- Dewatering Municipal Wastewater Sludges - Part37Document1 pageDewatering Municipal Wastewater Sludges - Part37Irvan VatoniNo ratings yet

- Dewatering Municipal Wastewater Sludges - Part32Document1 pageDewatering Municipal Wastewater Sludges - Part32Irvan VatoniNo ratings yet

- Dewatering Municipal Wastewater Sludges - Part40Document1 pageDewatering Municipal Wastewater Sludges - Part40Irvan VatoniNo ratings yet

- Manual Instruction Watt Water - Part16Document1 pageManual Instruction Watt Water - Part16Irvan VatoniNo ratings yet

- Dewatering Municipal Wastewater Sludges - Part36Document1 pageDewatering Municipal Wastewater Sludges - Part36Irvan VatoniNo ratings yet

- Manual Instruction Watt Water - Part15 PDFDocument1 pageManual Instruction Watt Water - Part15 PDFIrvan VatoniNo ratings yet

- Manual Instruction Watt Water - Part4 PDFDocument1 pageManual Instruction Watt Water - Part4 PDFIrvan VatoniNo ratings yet

- Manual Instruction Watt Water - Part6 PDFDocument1 pageManual Instruction Watt Water - Part6 PDFIrvan VatoniNo ratings yet

- Manual Instruction Watt Water - Part7Document1 pageManual Instruction Watt Water - Part7Irvan VatoniNo ratings yet

- Motor troubleshooting chartDocument1 pageMotor troubleshooting chartIrvan VatoniNo ratings yet

- Manual Instruction Watt Water - Part13Document1 pageManual Instruction Watt Water - Part13Irvan VatoniNo ratings yet

- Manual Instruction Watt Water - Part2Document1 pageManual Instruction Watt Water - Part2Irvan VatoniNo ratings yet

- Manual Instruction Watt Water - Part3Document1 pageManual Instruction Watt Water - Part3Irvan VatoniNo ratings yet

- Manual Instruction Watt Water - Part11Document1 pageManual Instruction Watt Water - Part11Irvan VatoniNo ratings yet

- Manual Instruction Watt Water - Part10 PDFDocument1 pageManual Instruction Watt Water - Part10 PDFIrvan VatoniNo ratings yet

- Manual Instruction Watt Water - Part8Document1 pageManual Instruction Watt Water - Part8Irvan VatoniNo ratings yet

- Manual Instruction Watt Water - Part14Document1 pageManual Instruction Watt Water - Part14Irvan VatoniNo ratings yet

- Manual Instruction Watt Water - Part5Document1 pageManual Instruction Watt Water - Part5Irvan VatoniNo ratings yet

- Manual Instruction Watt Water - Part1Document1 pageManual Instruction Watt Water - Part1Irvan VatoniNo ratings yet

- B550 PG VelocitaDocument99 pagesB550 PG VelocitaEduardo RigueraNo ratings yet

- ManualOmronE5CWL, ControladorDocument1 pageManualOmronE5CWL, ControladorJose CruzNo ratings yet

- Katalog DEG PerkinsDocument2 pagesKatalog DEG Perkinsramadani bimaNo ratings yet

- Mahindra Max 28items CSD PerDocument1 pageMahindra Max 28items CSD Perboobalan_shriNo ratings yet

- 3.4.1.7 Lab - Research A Hardware UpgradeDocument2 pages3.4.1.7 Lab - Research A Hardware UpgradeLinnaNo ratings yet

- CR420Document56 pagesCR420Gikcoklat AmuntaiNo ratings yet

- Modul 3. Timer & Counter 1. TujuanDocument6 pagesModul 3. Timer & Counter 1. TujuanYohana Crisma LimbongNo ratings yet

- Experiment No. 7 SensorsDocument8 pagesExperiment No. 7 SensorsJonelNo ratings yet

- Pressure ReliefDocument1 pagePressure ReliefIskandar HasibuanNo ratings yet

- How Often Replace Sump PumpDocument3 pagesHow Often Replace Sump Pumphaleigh33No ratings yet

- Senator CS Series With MAM 870 Controller Instruction Manual v02 2018 04 27Document64 pagesSenator CS Series With MAM 870 Controller Instruction Manual v02 2018 04 27steel biteNo ratings yet

- Specifications: Horn LocationDocument14 pagesSpecifications: Horn LocationCarlos VelázquezNo ratings yet

- Manual de FrenoDocument145 pagesManual de Frenofabian bazanNo ratings yet

- Led LightDocument32 pagesLed LightHugo Hernandez GustherNo ratings yet

- AT206-130907rev01 ENDocument4 pagesAT206-130907rev01 ENPablo Gaspar D'Agostini AmengualNo ratings yet

- Manual Osciloscopio IsotechDocument114 pagesManual Osciloscopio IsotechVgomez GomezNo ratings yet

- Air Hydraulic Jack User'S Manual Model 820B: 20ton CapacityDocument6 pagesAir Hydraulic Jack User'S Manual Model 820B: 20ton CapacityAlain DefoeNo ratings yet

- WEG Brake Motor Installation Operation and Maintenance Manual 50021973 Manual EnglishDocument2 pagesWEG Brake Motor Installation Operation and Maintenance Manual 50021973 Manual EnglishadalcomjesusNo ratings yet

- 2006-2011 Yaris Aftermarket Fog Light Switch WiringDocument3 pages2006-2011 Yaris Aftermarket Fog Light Switch WiringPaolo Jan C. LimNo ratings yet

- Windjammer Pro Selection Guide FinalDocument6 pagesWindjammer Pro Selection Guide FinalAlex CastilloNo ratings yet

- Literature Review of Automatic Night LampDocument5 pagesLiterature Review of Automatic Night Lampafmzvadopepwrb100% (1)

- Inventory Tool Tyre Period 2Document16 pagesInventory Tool Tyre Period 2Andri RinjaniNo ratings yet

- ENG-STAG-4 (PS-01) - ConnectionDocument1 pageENG-STAG-4 (PS-01) - ConnectionGerman SalasNo ratings yet

- Operator'S Manual Backhoe: ModelDocument46 pagesOperator'S Manual Backhoe: ModelGayitri KanabiranNo ratings yet