Professional Documents

Culture Documents

HVACR Tech Bulletin 194 Cleaning Fluorescent Leak Detection Dye Spills Designed Template

Uploaded by

ClaraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HVACR Tech Bulletin 194 Cleaning Fluorescent Leak Detection Dye Spills Designed Template

Uploaded by

ClaraCopyright:

Available Formats

CLEANING FLUORESCENT

LEAK DETECTION DYE SPILLS

TECHNICAL BULLETIN #194

Most fIuorescent dye spills occur when a service port of a pressurized AC&R system charged with dye is

accessed, resulting in a forcible spray of dye. Incomplete connection to the service port and/or injecting

fIuorescent dyes into systems with damaged or out-of-specification service ports may also result in dye spills.

HINTS AND TIPS

The best cure is prevention. Work neatly and do Always wear disposable latex gloves when

your best to avoid dye spills or sprays in the first place. working with fluorescent dyes. Discard gloves

immediately after each use.

Always cover the service port connection with

a rag when connecting or disconnecting dye Dye stains on hands can be easily removed with

injection devices. This way any dye spray will be kept any waterless hand cleaner. One helpful tip when

to the access fittings where it can be easily managed. using these cleaners is to first apply them to hands or

skin, rub them in vigorously, then wipe off the residue

React quickly. The quicker that the mess is cleaned with a paper towel or rag. Do not rinse with water after

up, the smaller it will be. Older stains can be very difficult the first application; wiping off first removes dye better

to remove, especially on porous, painted, or plastic and prevents spreading. Following up with additional

materials. waterless cleaner or soap, both with a water rinse will

complete the job. Any remaining skin staining should

Only use rags to absorb cleaners used in the dye wear off and fade after a day or two.

clean ups. They work much better than paper towels.

SOLVENT CLEANERS

Several types of readily available solvent cleaners will work well on removing fluorescent dye spills from

most surfaces however several factors will contribute to their effectiveness, including the spill size, type of

material stained, and length of time before cleaned. Solvent cleaners yielding the best results are:

GOOD BETTER BEST

Goof-Off

WD-40 (spray can) Non-chlorinated

Mineral spirits

Isopropyl alcohol automotive brake

(paint thinner)

(spray can) cleaner (spray can)

Penetrating oil

(spray can)

HVAC/R

12/17 A17352

PRINTED IN USA

Innovating for Today Imagining for Tomorrow

You might also like

- 24.2 The Core Assumptions of MindfulnessDocument9 pages24.2 The Core Assumptions of Mindfulnessale alvarezNo ratings yet

- Paint Problem and Final Detailing Duffy - AutoBody - ch28Document28 pagesPaint Problem and Final Detailing Duffy - AutoBody - ch28soasystemNo ratings yet

- Cemco T80Document140 pagesCemco T80Eduardo Ariel Bernal100% (3)

- L A R G e - S C A L e M e T H A M P H e T A M I N e M A N U F A C T U R eDocument21 pagesL A R G e - S C A L e M e T H A M P H e T A M I N e M A N U F A C T U R eDaria Schka100% (1)

- Wood Finishing GuideDocument25 pagesWood Finishing Guideadnhas100% (3)

- List of Government Circuit Bungalow Nuwara EliyaDocument4 pagesList of Government Circuit Bungalow Nuwara EliyaAsitha Kulasekera78% (9)

- Dry and Wet Cleaning AgentsDocument14 pagesDry and Wet Cleaning AgentsLeah ViloriaNo ratings yet

- Cleaning Equipments and AgentsDocument69 pagesCleaning Equipments and AgentsShubham GuptaNo ratings yet

- StainingWood PDFDocument11 pagesStainingWood PDFtheresa0derek0frost100% (2)

- Manual Visible Dye Penetrant PDFDocument16 pagesManual Visible Dye Penetrant PDFAndik SetyawanNo ratings yet

- Printing Ink Final Project LavinaDocument36 pagesPrinting Ink Final Project LavinaLavina GurbaniNo ratings yet

- Varnishing FurnituresDocument4 pagesVarnishing FurnituresPbts CorpNo ratings yet

- How To Remove Ink From Clothes - 11 Steps - Wikihow PDFDocument8 pagesHow To Remove Ink From Clothes - 11 Steps - Wikihow PDFmilan_lahiruNo ratings yet

- Part 7. Inks VarnishesDocument9 pagesPart 7. Inks VarnishesSukshamNo ratings yet

- Chemical Used in HousekeepingDocument51 pagesChemical Used in HousekeepingRaakesh Kanodia92% (12)

- Method Statement For Installation of Chilled Water Pump & Condenser Water PumpDocument14 pagesMethod Statement For Installation of Chilled Water Pump & Condenser Water Pump721917114 47No ratings yet

- Inkjet Printer Inkjet Printer Maintenance Guide Maintenance GuideDocument2 pagesInkjet Printer Inkjet Printer Maintenance Guide Maintenance GuideSerge MaciaNo ratings yet

- Detachur PDFDocument8 pagesDetachur PDFMayank DhariwalNo ratings yet

- Presentation On Non Descriptive TestingDocument36 pagesPresentation On Non Descriptive TestingBhargav BishuNo ratings yet

- Ink PDFDocument4 pagesInk PDFNeslyn BocioNo ratings yet

- ABA PaintBuyersGuide 2015 WebDocument8 pagesABA PaintBuyersGuide 2015 WebDavidzapperNo ratings yet

- A450 - EN - Rev.1 Car Dashboard Polish SpecsDocument1 pageA450 - EN - Rev.1 Car Dashboard Polish SpecsWeldon KipyegonNo ratings yet

- Engine CleaningDocument12 pagesEngine Cleaningbudimen99No ratings yet

- Floor TipsDocument7 pagesFloor TipsnamjachinguNo ratings yet

- DIY Cleaning Fluids: VariantsDocument7 pagesDIY Cleaning Fluids: VariantsMichael PridayNo ratings yet

- Touch Up Paint Spray Can Kit InstructionsDocument5 pagesTouch Up Paint Spray Can Kit InstructionsVictorNo ratings yet

- Touch Up Paint Spray Can Kit InstructionsDocument5 pagesTouch Up Paint Spray Can Kit Instructionsعلي العثربيNo ratings yet

- Inkjet Printer Inkjet Printer Maintenance Guide Maintenance GuideDocument3 pagesInkjet Printer Inkjet Printer Maintenance Guide Maintenance GuideSoro FohonaNo ratings yet

- Application of Cleaning AgentsDocument29 pagesApplication of Cleaning AgentsRogielyn AscañoNo ratings yet

- LLP Catalogue PDFDocument27 pagesLLP Catalogue PDFManish GoyalNo ratings yet

- Thinner FormulationDocument2 pagesThinner FormulationnanoNo ratings yet

- Fabric Care ProductsDocument9 pagesFabric Care ProductsSrinivasNo ratings yet

- Driving CBLMDocument6 pagesDriving CBLMDEJIE FELIZARTA - UNIFIED ENG'G WMPCNo ratings yet

- How To Print WB and Discharge InksDocument2 pagesHow To Print WB and Discharge InksBen HarrisonNo ratings yet

- TDS Artisan Chalkwash V1Document2 pagesTDS Artisan Chalkwash V1Mihail BurlacNo ratings yet

- Whirlpool La56ooxt Users Manual 307454Document16 pagesWhirlpool La56ooxt Users Manual 307454CristianNo ratings yet

- HSE Advisory - Chemicals For Cleaning Sanitisation and DisinfectionDocument8 pagesHSE Advisory - Chemicals For Cleaning Sanitisation and DisinfectionBoopathi ChinnaduraiNo ratings yet

- FEYNLABDocument3 pagesFEYNLABJohn ChatzidisNo ratings yet

- What Are The Differences Between Developers, and Which Should I Use For Penetrant InspectionsDocument4 pagesWhat Are The Differences Between Developers, and Which Should I Use For Penetrant InspectionsAlanka PrasadNo ratings yet

- New Microsoft Word DocumentDocument29 pagesNew Microsoft Word DocumentWasi HaiderNo ratings yet

- Prep My CarDocument9 pagesPrep My CarLollipopNo ratings yet

- Guide Bonnet Lip RemovalDocument7 pagesGuide Bonnet Lip RemovalAlexandru-Mihai NitaNo ratings yet

- Sahara Clear Masonry Sealer 2-2 DescriptionDocument3 pagesSahara Clear Masonry Sealer 2-2 DescriptionNathaniel Gutierez MangubatNo ratings yet

- Name: Indrani Mondal ROLL NO: 11101420021 Year: 3 Year SubjectDocument4 pagesName: Indrani Mondal ROLL NO: 11101420021 Year: 3 Year SubjectIndraniNo ratings yet

- Aviation Catalog 2016 PDFDocument17 pagesAviation Catalog 2016 PDFMurat aktaşNo ratings yet

- Farbent Gum Ed1 Enen FTDocument2 pagesFarbent Gum Ed1 Enen FTMANUEL LOPEZ MOLINANo ratings yet

- Cleaning of Radiometer OpticsDocument2 pagesCleaning of Radiometer OpticsPeter LichterveldNo ratings yet

- FSM Build Great Models 2 PDFDocument2 pagesFSM Build Great Models 2 PDFAdriano BelucoNo ratings yet

- TDS MIB Paint RemoverDocument1 pageTDS MIB Paint RemoverstkmNo ratings yet

- Andom Rbital Nstructions: Diagram A, Imaginary SquareDocument2 pagesAndom Rbital Nstructions: Diagram A, Imaginary SquareYcn YousefiNo ratings yet

- All Purpose Paint Remover - Dipping Grade: PRODUCT CODE: RRA 200-SeriesDocument2 pagesAll Purpose Paint Remover - Dipping Grade: PRODUCT CODE: RRA 200-SeriesPieter FourieNo ratings yet

- BSP Bottle Trap Data Sheet WK0402Document3 pagesBSP Bottle Trap Data Sheet WK0402Armağan DemirelNo ratings yet

- VapproVCI 620BrochureR1Document2 pagesVapproVCI 620BrochureR1AbdulrehmanNo ratings yet

- Using A Basic Spray Chrome KitDocument10 pagesUsing A Basic Spray Chrome Kitshaun shepherdNo ratings yet

- Projection SMART Board™ Interactive Whiteboard: Keeping The Writing Surface Clean On Your FrontDocument2 pagesProjection SMART Board™ Interactive Whiteboard: Keeping The Writing Surface Clean On Your FrontWaldon HendricksNo ratings yet

- Cleaning and Maintaining Trespa Meteon: GeneralDocument3 pagesCleaning and Maintaining Trespa Meteon: GeneralCarla SilvaNo ratings yet

- INF A4 Verarbeitungshinweise CC en 20190527Document5 pagesINF A4 Verarbeitungshinweise CC en 20190527emadNo ratings yet

- Dinol Sellsheet Protecting 77 B GBDocument2 pagesDinol Sellsheet Protecting 77 B GBDewton EspíndolaNo ratings yet

- Washing Guidelines / Materials of Construction: Orienter Caps Tray and Locking PlateDocument4 pagesWashing Guidelines / Materials of Construction: Orienter Caps Tray and Locking PlateMariaNo ratings yet

- Stain RemovalDocument9 pagesStain RemovalDeepak KumarNo ratings yet

- Topik 4 Penjagaan FabrikDocument22 pagesTopik 4 Penjagaan FabrikWan SazarenaNo ratings yet

- HAG TdsDocument2 pagesHAG TdsjaurenaNo ratings yet

- Convenient and Versatile Degreasing Wipes Impregnated With Lotoxane® FastDocument2 pagesConvenient and Versatile Degreasing Wipes Impregnated With Lotoxane® FastEurotech Tra TranNo ratings yet

- Analisys and application of dry cleaning materials on unvarnished pain surfacesFrom EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNo ratings yet

- Varioklav Steam Sterilizer 75 S - 135 S Technical SpecificationsDocument10 pagesVarioklav Steam Sterilizer 75 S - 135 S Technical Specificationssagor sagorNo ratings yet

- Frequency Inverter: User's ManualDocument117 pagesFrequency Inverter: User's ManualCristiano SilvaNo ratings yet

- Electric Field Summary NotesDocument11 pagesElectric Field Summary NotesVoyce Xavier PehNo ratings yet

- Complement Fixation Test: Process Testing For Antigen Semi-Quantitative Testing References External LinksDocument2 pagesComplement Fixation Test: Process Testing For Antigen Semi-Quantitative Testing References External LinksYASMINANo ratings yet

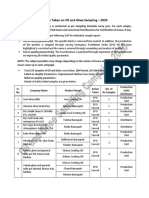

- Action Taken On Oil and Ghee Sampling - 2020Document2 pagesAction Taken On Oil and Ghee Sampling - 2020Khalil BhattiNo ratings yet

- DR K.M.NAIR - GEOSCIENTIST EXEMPLARDocument4 pagesDR K.M.NAIR - GEOSCIENTIST EXEMPLARDrThrivikramji KythNo ratings yet

- Lecture 8 - ThermodynamicsDocument65 pagesLecture 8 - ThermodynamicsHasmaye PintoNo ratings yet

- Acuson P10Document2 pagesAcuson P10anon-259218No ratings yet

- Section 80CCD (1B) Deduction - About NPS Scheme & Tax BenefitsDocument7 pagesSection 80CCD (1B) Deduction - About NPS Scheme & Tax BenefitsP B ChaudharyNo ratings yet

- Radproduction Chapter 2-9Document276 pagesRadproduction Chapter 2-9Christian DioNo ratings yet

- ClistDocument14 pagesClistGuerraNo ratings yet

- The Impact Behaviour of Composite MaterialsDocument6 pagesThe Impact Behaviour of Composite MaterialsVíctor Fer100% (1)

- IB Final ShellDocument25 pagesIB Final ShellsnehakopadeNo ratings yet

- Plumbing Breakup M 01Document29 pagesPlumbing Breakup M 01Nicholas SmithNo ratings yet

- Missoula County Fairgrounds Phase 2Document10 pagesMissoula County Fairgrounds Phase 2Olivia IversonNo ratings yet

- New Book "101 Costly HR Mistakes... and How To Fix Them" by Vanessa Nelson Released To Help Employers Avoid Costly HR Mistakes and Save MillionsDocument2 pagesNew Book "101 Costly HR Mistakes... and How To Fix Them" by Vanessa Nelson Released To Help Employers Avoid Costly HR Mistakes and Save MillionsPR.comNo ratings yet

- Experiment Number 16 Formal ReportDocument4 pagesExperiment Number 16 Formal Reportapi-524547303No ratings yet

- Impression TakingDocument12 pagesImpression TakingMaha SelawiNo ratings yet

- MPERSDocument1 pageMPERSKen ChiaNo ratings yet

- WeaknessesDocument4 pagesWeaknessesshyamiliNo ratings yet

- Hydrolysis and Fermentation of Sweetpotatoes For Production of Fermentable Sugars and EthanolDocument11 pagesHydrolysis and Fermentation of Sweetpotatoes For Production of Fermentable Sugars and Ethanolkelly betancurNo ratings yet

- 2-Product Spec PDFDocument10 pages2-Product Spec PDFMhooMOoChaappHteenNo ratings yet

- Dabur Vs PatanjaliDocument4 pagesDabur Vs PatanjalirangarajanNo ratings yet

- Intentions and Results ASFA and Incarcerated ParentsDocument10 pagesIntentions and Results ASFA and Incarcerated Parentsaflee123No ratings yet

- A Review On Bioactive Compounds of Beet Beta Vulgaris L Subsp Vulgaris With Special Emphasis On Their Beneficial Effects On Gut Microbiota and Gastrointestinal HealthDocument13 pagesA Review On Bioactive Compounds of Beet Beta Vulgaris L Subsp Vulgaris With Special Emphasis On Their Beneficial Effects On Gut Microbiota and Gastrointestinal HealthWinda KhosasiNo ratings yet