Professional Documents

Culture Documents

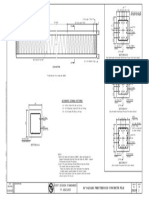

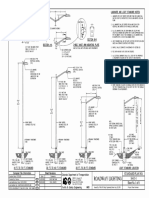

Pole Top Plate: Service Support Type SP (O) - Overhead Service Service Support Type SF & SP

Uploaded by

Dina ShresthaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pole Top Plate: Service Support Type SP (O) - Overhead Service Service Support Type SF & SP

Uploaded by

Dina ShresthaCopyright:

Available Formats

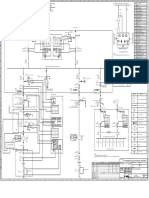

SUPPORT TYPE STEEL POLE (SP) AND STEEL FRAME (SF) Top of •"

White insulation 2" to 6" 20' measured from 2 •" TYP.

weatherhead radius

1.Provide steel pole and steel frame supports as per TxDOT Departmental Material Specification or color code 6" 4" (typ.) grade. Circumtances

of neutral to be 2" to 6",

(DMS)11080 "Electrical Services." Mount all equipment and conduit on 12 gauge galvanized may require the

conductor's 4" typical

steel or stainless steel channel strut, 1 • in. or 1 † in. wide by 1 in. up to 3 ƒ in. electrical service

below the top NOTE:

deep Unistrut, Kindorf, B-line or equal. Bolt or weld all channel and hardware to vertical insulation with support to be taller

5" TYP.

of pole.

No warranty of any

TxDOT assumes no responsibility for the conversion

members as approved. Do not stack channel. File smooth and paint field cut ends of all channel white tape where than the 20" shown, All rough

RMC C

L

with zinc-rich paint before installing. conductor exits check with utility edges shall

weatherhead. before installing. be ground

White insulation

2.Provide poles for overhead service with an eyebolt or similar fitting for attachment of the smooth

or color code 6"

Red insulation

of this standard to other formats or for incorrect results or damages resulting from its use.

service drop to the pole in conformance with the electric utility provider's specifications. of neutral

or color code 6" Point of

attachment conductor's Drain hole

length of Line 1

3.Provide and install galvanized ƒ in. x 18 in. x 4 in. (dia. x length x hook length) anchor insulation with

or Line 2 of service drop for galv.

bolts for underground service supports. Provide and install galvanized ƒ in. x 56 in. x 4 in. •" •"

to be below white tape where 2 - places

conductor's

anchor bolts for overhead service supports. Ensure anchor bolts have 3 in of thread, with conductor exits

insulation with weatherhead. TYP.

3 ‚ in. to 3 • in. of the exposed anchor bolt projecting above finished foundation. Provide weatherhead.

red tape where ‰" ‰"

The use of this standard is governed by the "Texas Engineering Practice Act".

and install leveling nuts for all anchor bolts. Conduit support

conductor exits ‰"

spacing, 3'max Red insulation

the weatherhead.

4.Bond one of the anchor bolts to the rebar cage with 6 AWG bare stranded copper conductor. Use from the ends, or color code 6"

Conductor slack

listed mechanical connectors rated for embedment in concrete. See Inset B. and 5' in between length of Line 1 POLE TOP PLATE

length, 12" min.,

Service unless otherwise or Line 2

18" max.

5.Furnish and install rigid metallic ells in all steel pole and steel frame foundations for all Enclosure called for by the conductor's

conduits entering the service from underground. utility. insulation with 24" Diameter

Meter Inset A

red tape where drill shaft 8"

6.Use class C concrete for foundations. Ensure reinforcing steel is Grade 60 with 3" of conductor exits

Safety Service

1 ‚" 1 ‚"

unobstructed concrete cover. Channel the weatherhead.

Switch Enclosure

Conduit

60" TYP.

bracket or Conductor slack

7.Drill and tap steel poles and frames for • in. X 13 UNC tank ground fitting. For steel pole service other arrangement length, 12" min.,

supports, provide and install tank ground fitting 4 in. to 6 in. below electrical service enclosure. approved by 18" max.

Provide properly sized hole through the bottom of the enclosure for the service grounding electrode Inset B Inset A 5 •" 8"

the Engineer.

conductor. Ensure electrical service grounding electrode conductor is as short and straight as possible (Kindorf, Meter

from the enclosure to the tank ground fitting. For steel frame service supports, provide and install Unistrut,

kind is made by TxDOT for any purpose whatsoever.

tank ground fitting on steel frame post. Install service grounding electrode conductor in a non-metallic B-line or

2"

conduit or tubing from the enclosure to the steel frame post. Connect electrical service grounding equal.) 5 •"

electrode conductor to the tank ground fitting. See steel frame and steel pole details and Inset A for

Min.

Inset B

18"

more information. Size service entrance conduit and branch circuit conduit as shown in the plans. For

underground conduit runs from the electrical service, extend RMC from the service enclosure to an RMC 2"

Min.

18"

elbow, and then connect the schedule type and size of conduit shown in the plans. Provide and install Class "C"

grounding bushings where RMC terminates in the enclosure. Grounding bushings are not required when RMC concrete RMC PVC

24" dia. X 60"

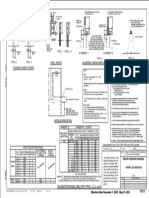

BASE PLATE DETAIL

is fitted into a sealing hub or threaded boss.

24 Dia. x 60" foundation 4-#5

PVC RMC

8.If Steel pole or frame is painted, bond each separate painted piece with a bonding jumper attached to depth foundation reinforcing bars

a tapped hole. 4-#5 reinforcing and #2 spiral at 6" ‰"

bars and #2 spiral pitch (typ.)

Š"

9.Provide ‚" - 20 machine screws for bonding. Do not use sheet metal screws. Remove all non- (typ.) at 6" pitch ƒ"

conductive material at contact points. Terminate bonding jumpers with listed devices. Install

minimum size 6 AWG stranded copper bonding jumpers. Make up all threaded bonding connections WITH SAFETY SWITCH WITHOUT SAFETY SWITCH ‚"

wrench tight.

SERVICE SUPPORT TYPE SP (O) - OVERHEAD SERVICE BOTTOM OF POLE

10.Avoid contact of the service drop and service entrance conductors with the metal pole to

prevent abrasion of the insulated conductors. See Note 4

SERVICE SUPPORT TYPE SF & SP

DISCLAIMER:

Drill, top, and thread

11.Shop drawings are not required for service support structure unless specifically stated •" X 13 UNC. Install

elsewhere or directed by the Engineer. tank ground fitting,

connect electrical

Varies

service grounding

electrode conductor.

See Note 7. 5" thick

3'-6"

•" expansion

72" concrete

joint material

above pad (class C

Rebar

grade Center of meter Anchor concrete and

max. SAFETY socket 60" typical Bolt 6" X 6" #6

SWITCH above grade. wire mesh)

(Verify with utility)

METER

FRONT VIEW

INSET A INSET B Dimension varies,

Threaded install only as

boss wide as required

Varies Service to accommodate

RMC Enclosure equipment

Steel post Safety

Thread

SERVICE switch

Channel Strut

Top

ENCLOSURE (when TOP VIEW

for mounting

required)

equipment.

Anchor Bolt Length

Number of struts Inset A

SERVICE SUPPORT TY SF (O) & SF (U)

60" (typ.)

as needed to SERVICE

(See Note 3)

METER 3'

securely mount ENCLOSURE max.

equipment Traffic

3/4" dia. Operations

Inset B

Inset A Division

2" Standard

20"

Inset B

min.

Min.

Min.

5"

18"

18"

Inset A ELECTRICAL DETAILS

RMC to

SERVICE SUPPORT

2" utility

Inset B RMC PVC

24" dia. x 48"

24" dia. x 36" depth

TYPES SF & SP

foundation

4"

4-#5 reinforcing foundation 4-#5

reinforcing bars Hook

bars and #2 spiral

and #2 spiral Length ED(7)-14

at 6" pitch (typ.) WITHOUT SAFETY SWITCH

WITH SAFETY SWITCH FILE: ed7-14.dgn DN: TxDOT CK: TxDOT DW: TxDOT CK: TxDOT

(typ.) at 6" pitch

FRONT VIEW HOOKED ANCHOR DETAIL C TxDOT October 2014 CONT SECT JOB HIGHWAY

WITH SAFETY SWITCH

REVISIONS

DATE:

FILE:

SERVICE SUPPORT TYPE SF(U) - UNDERGROUND SERVICE SERVICE SUPPORT TYPE SP(U) - UNDERGROUND SERVICE DIST COUNTY SHEET NO.

71G

You might also like

- Metering Skid: Station Outlet 350 250 Psig 600 MMSCFDDocument1 pageMetering Skid: Station Outlet 350 250 Psig 600 MMSCFDshakuntla5bankerNo ratings yet

- Metering Skid: Station Outlet 350 250 Psig 600 MMSCFDDocument1 pageMetering Skid: Station Outlet 350 250 Psig 600 MMSCFDshakuntla5bankerNo ratings yet

- Typical Plan: SpanDocument11 pagesTypical Plan: SpanJoem0989No ratings yet

- RCC Ceiling Installation GuideDocument29 pagesRCC Ceiling Installation GuideandalibNo ratings yet

- Power Problems O : G Uad Sele Off TotDocument12 pagesPower Problems O : G Uad Sele Off TotThe Stony Brook PressNo ratings yet

- Fdot Design Standards: 20624 1 24" Square Prestressed Concrete PileDocument1 pageFdot Design Standards: 20624 1 24" Square Prestressed Concrete Pilearkiriz23No ratings yet

- Building Plan of M.parhiDocument1 pageBuilding Plan of M.parhiPurusottam PanigrahiNo ratings yet

- Install Chain Link Fence Along Bridge Parapet RailDocument1 pageInstall Chain Link Fence Along Bridge Parapet Railjaelani sidikNo ratings yet

- Robinson Pagadian - Bended Roof 9Document1 pageRobinson Pagadian - Bended Roof 9Cesar DuriasNo ratings yet

- Series 320Document6 pagesSeries 320Prathamesh GangalNo ratings yet

- Grade Beam Plan and Section DetailsDocument1 pageGrade Beam Plan and Section DetailsSumaya TabassumNo ratings yet

- 0214 PID 002 3 ModelDocument1 page0214 PID 002 3 ModelMuhammad Al FaatehNo ratings yet

- Skema Jalur PendinginDocument2 pagesSkema Jalur Pendinginwahana maintenanceNo ratings yet

- Section Along Ma - Orosa 2Document1 pageSection Along Ma - Orosa 2Pablo PaboritoNo ratings yet

- Abb MCCB PDFDocument98 pagesAbb MCCB PDFwiznueNo ratings yet

- First Floor Opt - 3Document1 pageFirst Floor Opt - 3venkatalakshmi natarasanNo ratings yet

- ManifoldsDocument1 pageManifoldsIshan RanganathNo ratings yet

- Abitat ORM: Project Description: Proposed Appartment at ThanjavurDocument1 pageAbitat ORM: Project Description: Proposed Appartment at Thanjavurvenkatalakshmi natarasanNo ratings yet

- Section B-B: - Working DrawingDocument1 pageSection B-B: - Working DrawingARCHITECTURAL WORLDNo ratings yet

- Shougang Hierro Peru S.A.A.: Plano No. Plano NoDocument1 pageShougang Hierro Peru S.A.A.: Plano No. Plano NoFrank Jerry Aylas TejedaNo ratings yet

- General Notes:: Type "D" BearingsDocument1 pageGeneral Notes:: Type "D" BearingsMiguel Angel Montaña PeñaNo ratings yet

- C.3-141-Temporary Fence H.5MDocument1 pageC.3-141-Temporary Fence H.5MYudi CasanovaNo ratings yet

- Wa0000.Document3 pagesWa0000.nmarozhe_225151671No ratings yet

- A (44) SeriesDocument4 pagesA (44) SeriesSsenyonjo EricNo ratings yet

- 11010P1-DG6206001 0 PDFDocument1 page11010P1-DG6206001 0 PDFNidhin T BNo ratings yet

- Val2 Art HLS SHD SST 40 2 Cov 002 ADocument24 pagesVal2 Art HLS SHD SST 40 2 Cov 002 AAnh KyNo ratings yet

- PRINYANKADocument1 pagePRINYANKAApna gharNo ratings yet

- Basics of WeldingDocument49 pagesBasics of WeldingAmit Agarwal100% (2)

- Off R1Document1 pageOff R1Josphat benzNo ratings yet

- 367-STR1-004Document1 page367-STR1-004sibag49612No ratings yet

- Shougang Hierro Peru S.A.A.: Plano No. Plano NoDocument1 pageShougang Hierro Peru S.A.A.: Plano No. Plano NoFrank Jerry Aylas TejedaNo ratings yet

- PSK1-E0000-0000-DDI - Single Line Diagram-Rev-ADocument1 pagePSK1-E0000-0000-DDI - Single Line Diagram-Rev-AAsep SaepudinNo ratings yet

- Shougang Hierro Peru S.A.A.: Plano No. Plano NoDocument1 pageShougang Hierro Peru S.A.A.: Plano No. Plano NoFrank Jerry Aylas TejedaNo ratings yet

- Mama Structure-Structure 3Document1 pageMama Structure-Structure 3Saugat ThapaNo ratings yet

- TM570Document1 pageTM570nim coNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Shougang Hierro Peru S.A.A.: Plano No. Plano NoDocument1 pageShougang Hierro Peru S.A.A.: Plano No. Plano NoFrank Jerry Aylas TejedaNo ratings yet

- 01.MBT-RCC OHT-5 Lakh-DK-Model PDFDocument1 page01.MBT-RCC OHT-5 Lakh-DK-Model PDFArun NesamNo ratings yet

- Crevit User Manual 3377843Document1 pageCrevit User Manual 3377843DavidNo ratings yet

- Cable Voltage Drop CalculationDocument2 pagesCable Voltage Drop CalculationVaibhav ThoratNo ratings yet

- M4 or M6 M4 or M6: Rev. CNN CNN Description Date Check in 01 - 13/08/2013 Shaun Barron 02 - 10/12/2013 Shaun BarronDocument1 pageM4 or M6 M4 or M6: Rev. CNN CNN Description Date Check in 01 - 13/08/2013 Shaun Barron 02 - 10/12/2013 Shaun BarronAndy ReynoldsNo ratings yet

- 04.roof Bottom - Colour-Rev1Document1 page04.roof Bottom - Colour-Rev1sudhakarthekingNo ratings yet

- Drawing Symbols and SpecsDocument1 pageDrawing Symbols and SpecsHarried EscalonaNo ratings yet

- Thermadyne-Catalog CigweldDocument292 pagesThermadyne-Catalog CigweldUmmi Rahmatul IstiqomahNo ratings yet

- B1.2 B2.1 B3 B2.2 B1.3 B1.1: Saddle Arrangement in Intermediate YardDocument1 pageB1.2 B2.1 B3 B2.2 B1.3 B1.1: Saddle Arrangement in Intermediate YarddeniNo ratings yet

- Indus Hospital Floor Plans - 08.06.2020Document13 pagesIndus Hospital Floor Plans - 08.06.2020Ritika AnandNo ratings yet

- Type 1 Structural DrawingDocument23 pagesType 1 Structural Drawingmyoaung.clickNo ratings yet

- 3 Mps Building Dingras ElectricalDocument7 pages3 Mps Building Dingras ElectricalJuan MarcosNo ratings yet

- Ethane Filter (Et1 000 20)Document12 pagesEthane Filter (Et1 000 20)Mohammad TV'sNo ratings yet

- Jis B2316 PDFDocument1 pageJis B2316 PDFOluwachidiNo ratings yet

- Residence Belongs To Prasad: Wall Electrical DrawingDocument1 pageResidence Belongs To Prasad: Wall Electrical DrawingGangapatnam Teja Gangapatnam TejaNo ratings yet

- Ficha Tecnica Autohormigonera Dieci L3500Document2 pagesFicha Tecnica Autohormigonera Dieci L3500REINALDO ANTONIO NAVARRO BLANCONo ratings yet

- Detail of O.H. Water Tank Stair Detail Detail of U.G. Water TankDocument1 pageDetail of O.H. Water Tank Stair Detail Detail of U.G. Water TankaenanrocksNo ratings yet

- General Notes:: 00ENB20BB003 Treated Co Storage TankDocument1 pageGeneral Notes:: 00ENB20BB003 Treated Co Storage Tankmustafa1989ocNo ratings yet

- Innovance H2U Data SheetDocument2 pagesInnovance H2U Data SheetAmr samir ShahinNo ratings yet

- Construction notes and typical details for structural drawingsDocument1 pageConstruction notes and typical details for structural drawingsHailley DensonNo ratings yet

- Proposed 4way D54 Proposed 2way D56: Issue Date DescriptionDocument3 pagesProposed 4way D54 Proposed 2way D56: Issue Date DescriptionADIL BASHIRNo ratings yet

- Shougang Hierro Peru S.A.A.: Plano No. Plano NoDocument1 pageShougang Hierro Peru S.A.A.: Plano No. Plano NoFrank Jerry Aylas TejedaNo ratings yet

- February Monthly Collection, Grade 5From EverandFebruary Monthly Collection, Grade 5Rating: 3 out of 5 stars3/5 (1)

- Roadway Lighting Adot S-613-1Document6 pagesRoadway Lighting Adot S-613-1Dina ShresthaNo ratings yet

- ITS STD Drawings April 2019Document68 pagesITS STD Drawings April 2019Dina ShresthaNo ratings yet

- Qualitative Questions Transportation Depth Vf18Document28 pagesQualitative Questions Transportation Depth Vf18Dina ShresthaNo ratings yet

- ELECTRICAL SERVICE INSTALLATION NOTESDocument1 pageELECTRICAL SERVICE INSTALLATION NOTESDina ShresthaNo ratings yet

- Pole Top Plate: Service Support Type SP (O) - Overhead Service Service Support Type SF & SPDocument1 pagePole Top Plate: Service Support Type SP (O) - Overhead Service Service Support Type SF & SPDina ShresthaNo ratings yet

- Large Guide: Section 4Document36 pagesLarge Guide: Section 4AHmeD AbdelrahmanNo ratings yet

- Granite Concrete (GC) & Other Concrete (Oc) Notes Timber Pole (TP) Service Support NotesDocument1 pageGranite Concrete (GC) & Other Concrete (Oc) Notes Timber Pole (TP) Service Support NotesDina ShresthaNo ratings yet

- 08 Stopping Sight DistanceDocument39 pages08 Stopping Sight Distancegetachew ambayeNo ratings yet

- Saturation Flow AssignmentDocument3 pagesSaturation Flow AssignmentDina ShresthaNo ratings yet

- Relative Influences of Individual, Social Environmental and PhysicalDocument7 pagesRelative Influences of Individual, Social Environmental and PhysicalDina ShresthaNo ratings yet

- Franklin RD - Google MapsDocument1 pageFranklin RD - Google MapsDina ShresthaNo ratings yet

- Acadcal2010 11Document1 pageAcadcal2010 11Rohit TyagiNo ratings yet

- KB Rebar BrochureDocument4 pagesKB Rebar BrochureJun Xian Wai100% (1)

- Chapter 4.1 Basic Call Procedure (ED01 - 53 - EN)Document53 pagesChapter 4.1 Basic Call Procedure (ED01 - 53 - EN)quaderbtech06No ratings yet

- Physical and Rheological Properties of Modified Sulfur Asphalt BinderDocument8 pagesPhysical and Rheological Properties of Modified Sulfur Asphalt Binderramesh naikNo ratings yet

- Engineering QuotesDocument10 pagesEngineering QuotesGendakenNo ratings yet

- PARTSDocument10 pagesPARTSTestrooteNo ratings yet

- Rectify Binary Plate Efficiency BubblesDocument4 pagesRectify Binary Plate Efficiency BubblesCsaba AndrásNo ratings yet

- Appendix B - Design Examples: B.1 Multi-Span Precast Concrete Girder Made Continuous With Composite DeckDocument35 pagesAppendix B - Design Examples: B.1 Multi-Span Precast Concrete Girder Made Continuous With Composite DeckMICHAEL TADESSENo ratings yet

- Boiler MaintenanceDocument144 pagesBoiler Maintenanceaziz100% (2)

- A JIT Lot Splitting Model For Supply Chain Management Enhancing Buyer Supplier Linkage 2003 International Journal of Production EconomicsDocument10 pagesA JIT Lot Splitting Model For Supply Chain Management Enhancing Buyer Supplier Linkage 2003 International Journal of Production EconomicsDaniel Renaldo SimanjuntakNo ratings yet

- Saes N 004Document5 pagesSaes N 004Mo'tasem SerdanehNo ratings yet

- The NT Insider: Writing Filters Is Hard WorkDocument32 pagesThe NT Insider: Writing Filters Is Hard WorkOveja NegraNo ratings yet

- Schedule of Floor Finishes: Code Description Area (SQM) FF101 FF102Document5 pagesSchedule of Floor Finishes: Code Description Area (SQM) FF101 FF102Camille ArielNo ratings yet

- Development and Evaluation - KocabaDocument263 pagesDevelopment and Evaluation - KocabaWRLSNo ratings yet

- Process Level ChartDocument2 pagesProcess Level ChartzaidinNo ratings yet

- DiGas 4000 Light E 08.02Document2 pagesDiGas 4000 Light E 08.02manit1963No ratings yet

- Universal CNC Turning Center Maxxturn 65 G2Document13 pagesUniversal CNC Turning Center Maxxturn 65 G2Vũ LêNo ratings yet

- D3755-14 Standard Test Method For Dielectric BreakdowDocument6 pagesD3755-14 Standard Test Method For Dielectric Breakdowjose flores100% (1)

- Torque Specifications: Service Specifications - Ra60F Manual TransmissionDocument1 pageTorque Specifications: Service Specifications - Ra60F Manual TransmissionPedro Javier Castro SanchezNo ratings yet

- List of Diagnostic Trouble Code (DTC)Document5 pagesList of Diagnostic Trouble Code (DTC)Dev Vrat BohraNo ratings yet

- Dokumen - Tips Carte Ford C Max 2007Document278 pagesDokumen - Tips Carte Ford C Max 2007Rostás MiklósNo ratings yet

- Otago:Polytechnic: National Diploma in Drinking Water AssessmentDocument33 pagesOtago:Polytechnic: National Diploma in Drinking Water AssessmentThomas CollinsNo ratings yet

- Linthwaite: Conservatio N AreaDocument26 pagesLinthwaite: Conservatio N Areabill baileyNo ratings yet

- XXXXXXX XXXXXXX: Pour Exemple: Pour Exemple: ArteorDocument5 pagesXXXXXXX XXXXXXX: Pour Exemple: Pour Exemple: ArteorGilbert MartinezNo ratings yet

- Risc Cisc in Microcontroller and MicroprocessorDocument31 pagesRisc Cisc in Microcontroller and Microprocessormanvir kaurNo ratings yet

- Sennheiser MD 441Document2 pagesSennheiser MD 441ndujaNo ratings yet

- Proposed Rule: Domestic Mail Manual: Domestic Mailing Services New StandardsDocument45 pagesProposed Rule: Domestic Mail Manual: Domestic Mailing Services New StandardsJustia.comNo ratings yet

- Vista 128BPT Program ManualDocument72 pagesVista 128BPT Program ManualyalmanzaNo ratings yet

- BRAY SERIES 4X HIGH PERFORMANCE BRAY-McCANNLOCK VALVES - Technical ManualDocument28 pagesBRAY SERIES 4X HIGH PERFORMANCE BRAY-McCANNLOCK VALVES - Technical ManualLuis Daniel ContrerasNo ratings yet

- IIT-JEE-Physics-1997: Time: Three HourDocument9 pagesIIT-JEE-Physics-1997: Time: Three HourAdarsh UdayanNo ratings yet

- Electrostatic and Electromagnetic Forces: Electronic Address: Tim - Henley@mail - Utoronto.caDocument9 pagesElectrostatic and Electromagnetic Forces: Electronic Address: Tim - Henley@mail - Utoronto.caTimothy Murray HenleyNo ratings yet