Professional Documents

Culture Documents

2014 08 FLT OpenGear Brochure

Uploaded by

satfasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2014 08 FLT OpenGear Brochure

Uploaded by

satfasCopyright:

Available Formats

YOUR EFFICIENCY

IS OUR PASSION

Lubrication, Maintenance, Service

for Open Gears

www.fuchs-lubritech.com

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 1 07.08.14 11:21

» We are passionate about what we do. Together we

meet your challenges with our experience, dedication

and focused teamwork. «

About FUCHS LUBRITECH

Your Efficiency is our Passion

For over 60 years we at FUCHS LUBRITECH have dedicated ourselves to the performance and

efficiency of your machines and applications. We concentrate on the development, production

and distribution of trendsetting high-performance lubricants and release agents for the most

demanding applications in the most diverse branches of industry.

As part of the group of companies of FUCHS PETROLUB SE, Our product brands, like CEPLATTYN®, CASSIDA®, LUBRODAL®,

the world’s largest independent supplier of lubricants, we act gleitmo® or STABYL®, represent top quality and reliability in the

flexibly and independently – with our own self-contained prod- most diverse branches of industry, such as cement and mining,

uct range and strong, world-leading brands. forging, food and beverage, wind power, steel, construction,

railways, glass and surface technology.

Headquartered in Kaiserslautern, Germany and with locations

in the United Kingdom, France, Australia, the USA, Brazil, Japan, We consider service as a crucial and fundamental component of

China and India as well as distributors and partners in more than our products. Our local experts contribute through their broad

60 countries we guarantee the worldwide availability of our process-spanning expertise and on-site technical consultation to

products. You can always rely on a uniform quality standard all the performance, efficiency and process reliability of your entire

over the world. application.

Our range of products includes adhesive lubricants, lubricating

fluids and greases, pastes, solid film lubricants, concrete release We are specialists for high-performance lubricants for

agents, aerosols and metal-forming lubricants – overall more extreme tribological cases.

than 1,000 specialty products that are precisely tailored to

the respective application. Our high-performance lubricants

significantly contribute to the economical and eco-friendly

operation of your equipment.

Our employees on the front page (from left):

Sebastian Ansell, Technical Service and Business Development Manager for South East Asia

Davy Siger, Customer Service Export, FUCHS LUBRITECH GmbH

2 | FUCHS LUBRITECH

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 2 07.08.14 11:21

Specialty lubricants for Open Gears

High-performance lubricants for

the most demanding applications

With increasing size, the demands on the lubrication of Open Gears also increase. Wherever high

transmission of forces at low sliding speeds is required, we do everything we can to reduce the wear

on your technology to a minimum, thus maximising the reliability and safety of your equipment.

Together with gear and machinery manufacturers, we develop innovative adhesive lubricants for

Open Gears in kilns and mills. We always strive for the most application-specific solutions – and thus

achieve running times of 40 years and more.

Table of contents Page

Introduction.............................................................................. 4

Multi-Phase-Lubrication ............................................................ 6

Priming ..................................................................................... 8

Running-in .............................................................................. 10

Operational lubrication ........................................................... 12

Worldwide service .................................................................. 14

Repair service.......................................................................... 16

Re-conditioning service ........................................................... 18

Technical guidelines ................................................................ 19

FLT INSPECTOR – online documentation.................................. 20

Product selection .................................................................... 22

» We and our colleagues from the global team of

Application Engineers look back on many years of

considerable specialist expertise. Working together

with operators we ensure the proper selection and

YOUR EFFICIENCY

application of the lubricants through on-site tech - IS OUR PASSION

nical consultation and undertake an extensive range

of services.

We take care that our lubricants perform at the high-

est level and allow for your machine to run reliably

and efficiently. «

Peter Wagner, Sales Engineer, Europe, Africa & Asia (left)

Sidney Donizeti dos Santos, Sales Engineer, Brazil & South America (right)

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 3 07.08.14 11:21

FUCHS LUBRITECH in motion

Large Open Gear drives constitute a mechanical method of transmitting movement and force.

The level of success ultimately achieved does not only depend on the gear design and materials

used but also on the lubricant quality, volume of lubricant and the means of application. This

is particularly true for large, low-speed Open Gear drives where high torques are transmitted.

Demands grow with size Reliability of a system

The tolerances involved in the manufacture and assembly of Lubrication with the FUCHS LUBRITECH CEPLATTYN range of

girth gear drives increase in proportion to the size of the gear products fully meets the tough tribotechnical requirements. The

train. Distortions developing under the influence of load and CEPLATTYN range was developed in the early 60s as the first

temperature also increase with size. It is not uncommon to see sprayable non-asphaltic adhesive lubricants. The brand name is a

large gears with a diameter of 14 metres. Transmission ratios synonym for high-quality and reliable adhesive lubricants.

typically range between 1:8 and 1:12. Under these conditions

effective lubrication is often only possible with difficulty because The CEPLATTYN range includes more than 20 different products

of the slow sliding speed of the working tooth flanks. A special, and is approved by all major gear and machine manufacturers in

correctly applied adhesive lubricant will reliably prevent metal- the raw materials industry.

to-metal contact of the tooth flanks. Lubricants with a high pro-

portion of solids and with superior additives ensure safe running

properties in the area of boundary friction. As a result a service

life exceeding 20 years can be expected.

4 | FUCHS LUBRITECH

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 4 07.08.14 11:21

Where mighty forces rule

Open Gears transmit extreme forces. Their service life is subject to several factors, one of them being

the lubricants used. FUCHS LUBRITECH offers the ideal lubricant range for this heavy-duty

application. Our Multi-Phase-Lubrication is the key to the efficiency and long life of your Open Gear.

Open Gear drives do the heaviest work The best solution has a name: CEPLATTYN

in many branches of industry Wherever lubrication is required on highly stressed or pre-dam-

Open Gear drives are very common in the raw materials industry. aged gear drives, under arctic conditions or in high-

The girth gear drives that are used in tube mills, coolers, washing temperature environments, FUCHS LUBRITECH can offer the

drums, kilns, calciners and other machines have to transmit enor- right lubricant from the CEPLATTYN product range. CEPLATTYN

mous torques‚ i.e. often up to 50,000 Nm. It is only natural that adhesive lubricants are recommended by all leading manufactur-

this kind of force subjects the gear wheels to very high stresses. ers of gears and machines.

Such gears are usually designed as spur or helical gears with

modified involute profiles. The materials used for the gearing are

usually CrNiMo tempered steel (pinion) and alloyed CrMo steel

casting or cast iron (girth gear).

The lubricant plays an important role

The purpose of all design and tribotechnical efforts is to ensure,

in spite of the enormous stresses, long-term, trouble-free

operation. The primary cause of damaged gear wheels is not

exclusively the problem of faulty adjustment of the drives and

radial and axial run-out, but also the use of unsuitable lubricants,

shortage of lubricant and its incorrect application. Therefore an

optimum load-carrying capacity and smoothed gear teeth are

to be achieved. An extremely precise alignment of the gears

combined with the correct running-in procedures is essential. For

the lubrication of Open Gears adhesive sprayable lubricants are

most suitable.

FUCHS LUBRITECH | 5

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 5 07.08.14 11:21

MULTI-PHASE-LUBRICATION

LUBRITECH MULTI-PHASE-LUBRICATION (M-P-L) is a sophisticated system for optimum lubrication

and a long lifetime. Once the drive is precisely aligned, the selection of the correct lubricant is the

next step in achieving a long service life.

The most reliable method

LUBRITECH MULTI-PHASE-LUBRICATION (M-P-L) is the most Note

reliable method of averting serious mistakes. The use of M-P-L LUBRITECH M-P-L can only be applied to a limited extent to

is essential with new gears but it is also helpful after a repair drives that are not lubricated by an automatic spray system.

of damaged gear tooth flanks or at any time when the pinion FUCHS LUBRITECH Service Engineers will be pleased to ad-

or girth gear is changed. LUBRITECH M-P-L consists primarily of vise you on the running-in of gears, the operating lubrication

three components: priming, running-in and operating lubricants. of which is subsequently performed manually by dipping or

These special M-P-L lubricants are the result of many years of circulation lubrication.

research, and have proved themselves in practical applications

all over the world. The best solution has a name: CEPLATTYN

The best possible protection against wear

Optimum load transmission implies that the stress is evenly dis-

tributed across the full width and height of the teeth. However,

for Open Gear drives in particular, even state-of-the-art manu-

facturing techniques and the most precise alignment possible

hardly permit this optimum state to be achieved.

The consequences of inadequate load distribution are excessive

heating, scuffings, pitting and, in the worst case, even tooth

breakage. The operator can, however, have a significant

influence on such damage type, and thus on the lifetime of

the drive, by selecting the right lubricant.

6 | FUCHS LUBRITECH

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 6 07.08.14 11:21

Three lubrication steps to ensure a long service

life for the Open Gear

Priming

Priming lubricants prevent damage during initial operation and

are manually applied to the clean teeth of a new or repaired

gear. After the first rotations using an auxiliary drive the gear will

display the actual contact pattern. Any corrections needed will

be shown and can be implemented.

Running-in

Running-in is effected by our RN range of CEPLATTYN. Working

tooth flanks are smoothed in this process, which is considered

successful as soon as a load-carrying proportion of at least 80%

has been achieved.

Operational lubrication

Operational lubrication starts at the end of the running-in pro-

cess. It is not only subject to the condition and use of the drive

but also to environmental influences.

Reference table: the right lubricant for each lubrication step

M-P-L Lubricants

CEPLATTYN 300

n Initial lubrications

Priming lubricants CEPLATTYN GT P

n Manual applications

CEPLATTYN SF P

CEPLATTYN RN

n Surface smoothing

Running-in lubricants CEPLATTYN GT RN

n Automatic spray systems

CEPLATTYN SF RN

CEPLATTYN KG 10 HMF range

n Regular lubrication

Operational lubricants CEPLATTYN GT range

n Automatic spray systems

CEPLATTYN SF range

On page 23 of this brochure you will find the complete product selection guide, which shows the available lubricants for the different fields of applications.

FUCHS LUBRITECH | 7

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 7 07.08.14 11:21

Priming

Priming is the first process step of Multi-Phase-Lubrication. Priming the tooth flanks is necessary to

provide initial lubrication during the first revolution of the gears, in the course of assembly.

Priming lubricants prevent damage Priming and checking the contact pattern

Due to the surface finish of the gear teeth, priming is crucial to It is necessary to fully clean the tooth flanks before applying a

prevent damage during initial operation. In the context of FUCHS lubricant for the first time. The whole tooth flank area should be

LUBRITECH Multi-Phase-Lubrication (M-P-L) priming or initial thoroughly cleaned up to the bare metal. The tooth flanks are

lubrication is effected with CEPLATTYN 300 / CEPLATTYN GT P / then primed with CEPLATTYN 300 / CEPLATTYN GT P / CEPLAT-

CEPLATTYN SF P immediately after the assembly of the drive. TYN SF P using a stiff-bristled brush or a spatula. Its application

includes the working flanks, tooth roots and tips in order to

avoid corrosion and damage due to any movement during as-

sembly. After priming, turning the gears with the auxiliary drive

will result in the actual contact pattern being projected onto

the working tooth flanks. Any areas devoid of lubricant must

be primed again. The projection facilitates any correction of the

transmission gear that may be required.

Note

CEPLATTYN 300 / CEPLATTYN GT P / CEPLATTYN SF P

cannot be applied with automatic spray systems.

A layer of lubricant must be applied evenly and without air bubbles.

Quantity of CEPLATTYN 300 / CEPLATTYN GT P / CEPLATTYN SF P

9,000

8,000

50

7,000

40

6,000

Quantity [kg]

m x n [mm]

5,000 n = total number of teeth

30

m = module

4,000

20 3,000

2,000

10

1,000

100 200 300 400 500 600 700 800 900

Tooth width [mm]

8 | FUCHS LUBRITECH

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 8 07.08.14 11:21

Various contact patterns and their causes

360° picture girth gear pinion

Contact pattern with opposing obliquity of the two halves

of the girth gear.

Check the impact point bolting.

Contact pattern for wobble impact of the girth gear.

Check alignment and fixing of the girth gear.

Contact pattern due to edge loading. Axles not sufficiently parallel.

Realign pinion.

Circulating pressure point, resulting from manufacturing

fault or isolated thermal deformation (protuberances).

Contact pattern from pinion expanded on both sides,

resulting from incorrectly assembled ring tensioning elements.

Contact pattern at the perimeter of the girth gear

when the pinion wobbles. Check seating of pinion.

Contact pattern when one half of the gear is oblique.

Check assembly.

Radial run-out of the gear wheel. The contact pattern appears

weaker or stronger over half the perimeter of the girth gear.

Readjust.

Contact pattern when the girth gear has protuberances on both

sides, resulting from excessive frictional heating of the jacket

seals (often found in oil-lubricated drives). Improve lubrication

of seals. Check assembly of seals.

FUCHS LUBRITECH | 9

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 9 07.08.14 11:21

Running-in

Running-in is the second process step of Multi-Phase-Lubrication or after Re-Conditioning.

The following case study offers a detailed overview of this process step.

Case study:

Better load-carrying pattern after Re-Conditioning The running-in procedure

Even after the drive has been correctly aligned, the initial The time required for running-in can only be assessed individu-

load-carrying proportion often remains below 50 to 60 per cent. ally and is subject to the hardness of materials, manufacturing

The reason for this is the surface roughness arising in the course tolerances and the way in which a gear has been assembled.

of manufacture on the one hand and deviations of the flanks On average, the time required to efficiently run in drives on ball

due to their shape and due to assembly on the other hand. This mills and kilns in single load steps is 350 hours, during which the

means that there is a very high risk that drives can be damaged lubricant should be continuously applied to the extent possible.

at this early stage of initial operation as a result of local overload.

Such damage can be slight local scuffing or cracks that propa- Values may vary in practical applications. The process must be

gate in the form of pitting caused by fatigue damage during adapted to the given operating conditions. The state of the tooth

subsequent operation. flanks should be checked throughout the running-in process.

This particularly applies to the change of grinding charge, which

Axial run-out deviations caused the contact pattern of a cement should only be undertaken when the load-carrying proportion

mill drive to be only 40% in some areas. Since it was not possible given in the table has been reached. If the contact pattern is

to achieve an improved contact pattern through alignment, the considerably worse, readjustment of the transmission gear will

drive had to be submitted to a forced running-in using RE-CON- be required. Running-in can be considered complete as soon as,

DITIONER. The load peaks that are obvious in the part marked at maximum charge or throughput, a load-carrying proportion

red of the working tooth flanks (left-hand picture) were elimina- of at least 80 per cent has been achieved, and the manufactur-

ted by Re-Conditioning (right-hand picture). The pitch line covers ing roughness of the loaded teeth surface has been smoothed.

the full width of the tooth (visible in the picture as a white line

on the working tooth flank). In cases where normal running-in does not result in a sufficient

contact pattern or the drive has to be run in at full load, a forced

CEPLATTYN RN / CEPLATTYN GT RN / CEPLATTYN SF RN running-in (the quick running-in method) represents the best

removes the manufacturing roughness and it smoothes the solution. This forced running-in procedure is also suitable for

working tooth flanks. achieving an optimum carrying capacity and surface finish if the

load-carrying surfaces show scuffings, or under unfavourable

The economical way to a higher gearing quality circumstances if old and new gears have been combined.

Controlled running-in with CEPLATTYN RN / CEPLATTYN GT RN /

CEPLATTYN SF RN running-in lubricants prevents damage in the

course of initial operation. CEPLATTYN RN / CEPLATTYN GT RN /

CEPLATTYN SF RN eliminates manufacturing roughness and

smoothes the load-carrying surfaces of tooth flanks, thus over-

coming slight deviations in shape and assembly and significantly

increasing the contact area. The result: significantly enhanced

gearing quality that provides the basis for a long service life.

Before running-in Even load contact

Due to assembly and misalignments load peaks often occur After a selective running-in using CEPLATTYN RN /

when starting a new drive. CEPLATTYN GT RN / CEPLATTYN SF RN these load

peaks are eliminated and a good contact pattern

across the flank width is achieved.

10 | FUCHS LUBRITECH

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 10 07.08.14 11:21

Surface roughness profiles of tooth flanks

Load-carrying pattern before running-in approx. 50% Load-carrying pattern after running-in approx. 85%

0.8 mm

0.8 mm

Before running-in with After running-in with

CEPLATTYN RN CEPLATTYN RN

CEPLATTYN GT RN CEPLATTYN GT RN

CEPLATTYN SF RN CEPLATTYN SF RN

Quantity of CEPLATTYN RN / CEPLATTYN GT RN / CEPLATTYN SF RN

Mill double-pinion drive: 1.2 g/h • mm Mill single-pinion drive: 0.8 g/h • mm

Kiln double-pinion drive: 0.9 g/h • mm Kiln single-pinion drive: 0.6 g/h • mm

400

Quantity [kg/350 h]

300

200

100

100 200 300 400 500 600 700 800 900

Tooth width [mm]

FUCHS LUBRITECH | 11

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 11 07.08.14 11:21

Operational lubrication

Operational lubrication is the third process step of Mulit-Phase-Lubrication. The selection of the right

lubricant in the process step plays an important role in the overall lifetime of the gear set.

Central lubricant supply with CEPLATTYN CEPLATTYN lubricants are adhesive lubricants which are suitable

Once priming and running-in have been successfully comple- for extremely high pressures. They are resistant to water and

ted, the next point to be considered is operational lubrication. approved by all leading gear and machine manufacturers.

Making the right selection here is very important in terms of

low wear, operation without damage, and lifetime of the Open Changeover to operational lubrication

Gear drive. The selection of the lubricant depends on a large In practice the changeover is achieved through a gradual quan-

number of factors including stress on the working tooth flanks, tity reduction to a targeted minimum (see graph on the right).

rotary speed of the transmission gear, actual flank temperatures It is necessary to measure the quantity every time this value is

and condition of the drive. Environmental influences such as reduced by the spray system. Small volumes frequently applied

dust contamination, humidity and very low or very high ambient avoid phases in which the drive is excessively saturated with

temperatures must also be considered. lubricant, thus preventing fling-off. The short breaks between

cycles prevent a lack of lubrication. Quantity guidelines for vari-

On the safe side with CEPLATTYN ous drives are included in the diagram on the right.

The changeover to operating lubrication starts at the end of

running-in. When changing to the operating lubricant a cleaning

procedure is not required. It is just the drum container attached

to the lubrication system that has to be replaced.

12 | FUCHS LUBRITECH

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 12 07.08.14 11:21

Quantity reduction

e.g. for a single-pinion drive

Note

Specific consumption [g/h × mm]

The attainable minimum quantity is directly subject to the

0.8

operating conditions. Lubrication rates below the minimum

may create an increased risk of wear and damage on the

tooth flanks. 0.6

0.4

0.2

24 48 72 96

Time [h]

Quantity of CEPLATTYN for certain cases of operational lubrication

Mill drives: 0.2–0.4 g/h • mm Kiln drives: 0.1–0.2 g/h • mm

Note

0.4

For double-pinion drives, please cal-

culate at a factor of 1.5.

Quantity [kg/h]

0.3

0.2

0.1

100 200 300 400 500 600 700 800 900

Tooth width [mm]

FUCHS LUBRITECH | 13

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 13 07.08.14 11:21

» We regard service as a crucial and fundamental component

of our business. Your Efficiency is our Passion.«

Global service and application engineers of FUCHS LUBRITECH

Worldwide service

Tailor-made service and maintenance

Our local experts contribute through their broad process-spanning expertise and on-site technical

consultation to the performance, efficiency and process reliability of your entire application. Whether

you want specialist advice with a view to reducing your number of lubricants, longer lubrication

intervals or the perfect Open Gear services, we provide you with precisely the support you need to

further optimise your use of lubricants.

FUCHS LUBRITECH Open Gear inspection procedure Running-in of new plants

n Visual check of Open Gear and surrounding conditions Specially trained service engineers assist with the commissioning

n Pinion and girth gear check and running-in of new plants. They ensure that the drive is run-in

n Vibrations on the pinion bearings optimally according to the principle of the LUBRITECH MULTI-PHASE

n Temperature conditions on the pinion bearings LUBRICATION (M-P L) with accurately defined application quan-

n Temperature conditions on the mill/kiln shell tities of the appropriate CEPLATTYN adhesive lubricant.

n Check of the spray system

n Inspection of spray and pump equipment

n Temperature conditions across the surfaces

of the pinion and girth gears

n Quantity determination of the lubricant

n Documentation of the result in the

FLT INSPECTOR online system

14 | FUCHS LUBRITECH

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 14 07.08.14 11:21

Regular inspection of Open Gears

For drive units that are lubricated with CEPLATTYN, our service engineers carry out regular in-

spections over the entire service life. They make written notes of the general operational status,

ascertain the amount of wear on the load-carrying tooth flanks, check the spray lubrication and,

if necessary, reset it. In addition, the service engineer takes extensive measurements (oscillation

speed, flank temperature, etc.), which are recorded in the FLT INSPECTOR, a modern documenta-

tion system, and are always available to our customers.

Measuring vibrations of the pinion bearing Measuring the tooth flank temperature

Dynamic check of the contact pattern with a stroboscope Dynamic check by infrared video thermography

FUCHS LUBRITECH | 15

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 15 07.08.14 11:21

Repair service

The repair of damaged tooth flanks on Open Gear drives is part of the extended service offered by

FUCHS LUBRITECH. Such repair work is primarily a matter of the mechanical treatment of the work-

ing tooth flanks by grinding pittings or larger breakages, smoothing scuffings, forced running-in

and assistance with alignment of the transmission gears. On heavily worn-out or damaged tooth

flanks FUCHS LUBRITECH can provide complete reprofiling of the entire gear set.

Tooth flanks before grinding Grinding process

Older pitting and reworked pitting Tooth flanks after grinding

16 | FUCHS LUBRITECH

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 16 07.08.14 11:21

Tooth flank damage and its causes in Open Gears

Gears in a wide variety of designs provide movement throughout the industry. If a gear wheel sud-

denly stops, the causes can differ considerably. Statistically speaking, damaged tooth flanks account

for about 60 per cent of gear drive defects.

The correct lubricant eliminates many damage causes. It does A poor-quality lubricant also has a direct adverse effect on the

not matter whether a light oil or an adhesive lubricant is under occurrence of fretting corrosion, scoring and scuffings. The

consideration. Nor does it matter whether it is a high-speed consequences of a lack of lubricant usually include increased

vehicle gearing or a low-speed Open Gear drive: whenever teeth wear or deformations such as the development of rippling and

mesh the appropriate lubricant is one of the most important hot or cold flow. The chart below gives a basic overview of the

factors for smooth operation. Scuffings and abrasive wear, for problems that can be experienced.

example, can be influenced to a large extent by the lubricant.

Cracks Pittings/seizure Deformations Tooth breakages

The causes of tooth flank damage in Open Gears

Tooth Other types

Cracks Pittings Deformations breakage Wear Corrosion of damage

Chemical corrosion

Overload breakage

Fretting corrosion

Interference wear

Initial/destructive/

Fatigue breakage

Hardness cracks

Grinding cracks

Material cracks

Fatigue cracks

Abrasive wear

fatigue pitting

Normal wear

Indentations

Overheating

Cavitation

Cold flow

Scratches

Scuffings

Hot flow

Rippling

Spalling

Scoring

Erosion

Flaking

Alignment errors n n n n n n

Fixing of pinion n n n n

Frequent load changes n n

Overload n n n n n n n n n

Operational conditions/assembly faults

Impact/vibration stress n n n n n n n n

Incorrect running-in n n

Speeds too low/high n n n n

Dust ingress n n n n n n n

Dynamic changes n n n n n n

Shortage of lubricant n n n n n n

Wrong consistency n n n n n

Lubrication faults

Inadequate quality n n n n n

Soiling with solids/liquids n n n n n n n

Incorrect application n n n

FUCHS LUBRITECH | 17

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 17 07.08.14 11:21

Re-conditioning service

Forced running-in with RE-CONDITIONER

In cases where normal running-in does not result in a sufficient Forced running-in involves a service lubricant known as

contact pattern or the drive has to be run in at full load, a forced RE-CONDITIONER being manually applied to the working sur-

running-in (the quick running-in method) represents the best faces in addition to the regular CEPLATTYN RN lubricant during

solution. This forced running-in procedure is also suitable for production. This RE-CONDITIONER effects a smoothing of the

achieving an optimum load-carrying capacity and surface finish if working surfaces within in a shorter time, thus tremendously

the load-carrying surfaces show scuffings. In case a new pinion reducing the running-in time.

is installed in combination with an old girth gear Re-Condition-

ing is used to reprofile the old girth gear with the new profile of

the pinion.

The use of RE-CONDITIONER

Before After

red = no contact complete tooth contact

Case study: smoother running after Re-Conditioning

When restarting a helical, double-pinion cement mill small devi- The manufacturer of the machinery therefore initiated a forced

ations in axial and radial run-out of the girth gear had the effect running-in. The application of RE-CONDITIONER for nine hours

of high vibration differences between the pinion bearings. At the resulted in a carefully controlled redistribution of the load:

run-out pinion the vibration levels were well below 2 mm/s, but the vibrations of both bearings were eventually below 2 mm/s.

they were above 8 mm/s at the run-in pinion. The operator could Result: a smooth operation.

not accept this large difference. Even after several corrections of

the transmission gear no improvement was achieved.

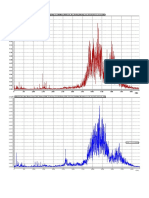

Vibration monitoring

Z711.00SW2,MV Z711.00SW1,MV

2-day measurement

20.0

Note

The aggressive material removal generated through using

15.0

the RE-CONDITIONER requires specialised technical know-

ledge. Forced running-in is only carried out by FUCHS

10.0 LUBRITECH Service Engineers. For gears under warranty the

machine or gear manufacturer must agree to this procedure

being conducted prior to the start of the procedure.

5.0

0.0

13:00 01:00 13:00 01:00

2009 - 09 - 21 2009 - 09 - 22 2009 - 09 - 22 2009 - 09 - 23

Extract from permanent vibration monitoring at the plant.

Reduction of vibrations during forced running-in.

18 | FUCHS LUBRITECH

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 18 07.08.14 11:21

Technical guidelines

Guide values for adjustment and assembly

The commissioning engineer of Open Gear drives is faced with critical importance for the service life of the drive. This is why it

extremely tough requirements when aligning or correcting the is usual for assembly companies to prepare records of measure-

drive. Careful alignment of girth and transmission gears is of ments of radial and axial run-outs, backlash and root clearance.

Maximum concentric and axial run-out deviation of Adjustment of the tooth flank clearance for mills and

Open Gears as a function of girth gear diameter rotary kilns

Axial run-out Radial run-out Mills Kilns

9,000 4,500

8,000 4,000

Axial distance [mm]

Girth gear Ø [mm]

7,000 3,500

6,000 3,000

5,000 2,500

4,000 2,000

3,000 1,500

2,000 1,000

1,000 500

0.25 0.50 0.75 1.00 1.25 1.80 2.00 2.20 2.40 2.60 2.80 3.00

Tolerance value [mm] Backlash [mm]

Inspecting the spray system

The following points should be observed before

commending operation of the machinery:

n Functional test

n Spray pattern and overlap

n Spray angle

n Nozzle distance

n Lubricant quantity

The increased throughput of a running-in lubricant is

necessary in order to flush out any metallic particles due

to the removal of the rough surface peaks. The lubricant

must then flow freely and drain away to prevent blockages 30° mm

- 200

and build-up of any waste. 150 30°

00 mm

Note

150 - 2

If a gear set must be reversed because of wear, it will no

longer be possible to align the gears by means of the back-

lash. The drive must be set up using the tip clearance. A suit-

able guide value for the tooth tip clearance is 0.25 to 0.3 times Inward running pinion Outward running pinion

the module.

FUCHS LUBRITECH | 19

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 19 07.08.14 11:21

Service

FLT INSPECTOR – online documentation

With the FLT INSPECTOR, FUCHS LUBRITECH is making a unique online documentation database

with an integrated, graphical trend analysis available that enables the customer to retrieve all rele-

vant information on their system and the lubricants used at any time.

The open gear service, combined with the online provision of in- Your benefits with the FLT INSPECTOR

spection reports, is a further step towards being able to operate n Availability of all reports at a glance

open running drives reliably. n Online access at any time

n Instant check via a traffic light system

Page one of the two-page inspection report contains customer n Graphical trend analysis for temperatures and vibrations

and system data, as well as images and comments (Fig. 1). n Rapid transmission of data and reports

n Individual access hierarchy

Measurements of values for temperatures and vibrations, inclu- n Optional extra information (attachments) for each

ding reference values relating to the previous inspection, can inspection report

be found in the second part (Fig. 2).

Focus on: Instant check via a traffic light system

Fig. 1 Fig. 2

20 | FUCHS LUBRITECH

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 20 07.08.14 11:21

Tooth flank temperature run-in pinion

18 Feb. 2005 11 May 2005 23 Mar. 2006 26 Jul. 2006

64

62

60

Temperature [°C]

58

56

54

52

50

48

46

1 2 3 4 5

Checkpoints accross the tooth width [mm]

Graphic trend analysis enables informative display of temperatures and vibrations over time

Vibration run-out of pinion/fixed end

Horizontal Vertical Axial

10

9

8

Vibration [mm/s] [m/s]*

7

6

5

4

3

2

1

0

18 Feb. 2005 11 May 2005 23 Mar. 2006 26 Jul. 2006

FUCHS LUBRITECH | 21

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 21 07.08.14 11:21

Product selection

Complete solutions: the CEPLATTYN ranges

FUCHS LUBRITECH offers three different CEPLATTYN ranges, thus always providing our customers

with the ideal lubricant for mill or kiln gears.

CEPLATTYN KG 10 HMF range

The lubricants of the CEPLATTYN KG 10 HMF range include

black, graphite-containing greases suitable for any kind of Open

Gear. The CEPLATTYN KG 10 HMF range provides excellent wear

and damage protection for mill and kiln gears. Suitable grades

for spray, bath and circulation application are available.

CEPLATTYN GT range

The CEPLATTYN GT range includes milk-coloured, white solid

lubricant-containing, high viscosity-fluids suitable for all kinds

of Open Gears. Like the graphite-containing greases they pro-

vide optimum wear and damage protection for mill gears and

low-speed kiln gears. They contain flame-retardant additives to

prevent fire on kilns, build up a suitable sealing layer to avoid

the occurence of oil leakages and are well pumpable. The

CEPLATTYN GT range comprises suitable viscosities for spray,

bath and circulation applications and can be used on AGMA

and DIN/ISO-designed gears.

CEPLATTYN SF range

The CEPLATTYN SF range includes light-coloured, high-viscos-

ity fluids without solid lubricants. They are designed for use

in any kind of mill gear and are especially suitable for use on

AGMA-designed gears for high-powered mills in the mining

industry. The lubricants of the CEPLATTYN SF range are mainly

intended for spray application.

22 | FUCHS LUBRITECH

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 22 07.08.14 11:21

Open Gear CEPLATTYN® products and application

Product Description Field of application Method of application

Paste with a high graphite As primer for large Open Gears, Manually to clean surfaces; do not use

CEPLATTYN® 300

content, high-pressure additives gear racks and sliding surfaces in centralised lubrication systems!

Can be applied to single- and Via automatic spraying systems.

Sprayable running-in lubricants

CEPLATTYN® RN double-pinion drives of any kind Spraying should be effected permanently

for Open Gears

of tube mills and kilns and highest possible quality

Is used on Open Gear drives of

CEPLATTYN® KG 10 Sprayable running-in lubricants Applied via standard spray lubrication

tube mills and kilns, dryers and

HMF for large Open Gears systems

crushers

Is used for heavy-load applica-

CEPLATTYN® KG 10 Sprayable, graphite-containing

tions because of its high base oil Applied via standard spraying system

HMF-1000 adhesive lubricant for Open Gears

viscosity

Suited for shock loads in heavy-

CEPLATTYN® KG 10 Highly viscous, sprayable adhesive duty applications because of its Sparingly applied by commercially

HMF-2500 lubricant for Open Gear drives high base oil viscosity and the available spraying systems

resulting good cushioning effect

High base oil viscosity and thus

Applied economically via conventional

Sprayable, extremely high- good damping characteristics

CEPLATTYN KG 10®

spray lubrication systems. At temperatures

viscosity adhesive lubricant make it especially suitable for

HMF LC below +5°C / +40°F additional heating

for Open Gears shock-loaded gear in heavy-duty

systems may have to be used for spraying

applications

By spatula, brush or non-fibre cloth onto

Priming lubricant with white Is used as priming lubricant for

CEPLATTYN® GT P previously cleaned surfaces. Not suitable

solid lubricants Open Gears

for spray lubrication systems

Is used to smoothen the

Via automatic spraying systems. The

tooth surface of newly

Sprayable running-in lubricant lubricant quantity should be 2–3 times

CEPLATTYN GT RN®

installed gear rims or pinions

for Open Gears higher compared to operational lubricant

and for optimisation of the

quantities

load-carrying pattern

Especially for Open Gears under

critical operating conditions,

such as slow-speed kiln drives

Light-coloured, high-viscosity Suitable for application in immersion

with increased tooth flank

CEPLATTYN® GT 10 adhesive lubricant with white baths, circulation lubrication and spraying

temperatures, mill drives with

solid lubricants for Open Gears systems

extreme drive power, and drives

which are frequently operated

under start-stop conditions

Light-coloured, high-viscosity Especially for application on

Suitable for the application in immersion

CEPLATTYN® GT 3 adhesive lubricant with white solid Open Gears under critical

bath and circulation lubrication systems

lubricants for Open Gears operating conditions

By spatula, brush or non-fibre cloth onto

Priming lubricant for Open Gears Used as priming lubricant for

CEPLATTYN® SF P previously cleaned surfaces; caution: not

with white solid lubricants Open Gears

suitable for spray lubrication systems!

Is used to smoothen the tooth Via automatic spraying systems. The

Sprayable running-in lubricant surface on newly installed gear lubricant quantity should be 2–3 times

CEPLATTYN® SF RN

for Open Gears rims or pinions and for optimisa- higher compared to operational lubricant

tion of the load-carrying pattern quantities

Light-coloured, highly viscous Especially for heavy-duty, high-

Via commercially available spraying

CEPLATTYN® SF 10 adhesive lubricant for Open Gears speed open mill drives subject to

systems

on mills high vibrations

Especially for extremely

Sprayable, extremely high-viscos-

CEPLATTYN® SF 30 heavy-duty Open Gear drives Via spray systems

ity lubricant for Open Gears

exposed to high shock loads

Disclaimer: The above-mentioned products are our general suggestions. The lubricants recommended by individual machine and component manufacturers may include different products.

Our advice is to adhere to the manufacturer’s recommendations. For detailed information please refer to our product information sheets or contact us at www.fuchs-lubritech.com.

FUCHS LUBRITECH | 23

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 23 07.08.14 11:21

The information contained in this product information is based on the ex- criteria of the products before the product is used. It is the responsibility of

© FUCHS LUBRITECH GmbH. All rights reserved. Edition 07/2014, 601209

perience and know-how of FUCHS LUBRITECH GmbH in the development the user to test the functional suitability of the product and to use it with

and manufacturing of lubricants and represents the current state of the art. the corresponding care.

The performance of our products can be influenced by a series of factors, espe-

cially the specific use, the method of application, the operational environ- Our products undergo continuous improvement. We therefore retain the

ment, component pretreatment, possible external contamination, etc. right to change our product range, the products, and their manufacturing

For this reason, universally valid statements about the function of our processes as well as all details of our product information sheets at any time

products are not possible. The information given in this product information and without warning. With the publication of this product information, all

represents general, non-binding guidelines. No warranty expressed or previous editions cease to be valid.

implied is given concerning the properties of the product or its suitability for

any given application. Any form of reproduction requires express prior written permission from

FUCHS LUBRITECH GmbH.

We therefore recommend that you consult a FUCHS LUBRITECH GmbH

application engineer to discuss application conditions and the performance

Global Headquarters

FUCHS LUBRITECH GmbH

Werner-Heisenberg-Strasse 1

67661 Kaiserslautern, Germany

Tel.: +49 (0)6301 32060

Fax: +49 (0)6301 3206 940

Email: info@fuchs-lubritech.de

www.fuchs-lubritech.com

A Member of the

FUCHS PETROLUB Group

702342_FLT_Broschuere_Offene_Getriebe_RZ_BM.indd 24 07.08.14 11:21

You might also like

- Single Plane BalancingDocument6 pagesSingle Plane BalancingFelipe SanhuezaNo ratings yet

- I.D FAN Vibration SpectrumDocument3 pagesI.D FAN Vibration SpectrumsatfasNo ratings yet

- Vibration Analysis and Diagnostic GuideDocument66 pagesVibration Analysis and Diagnostic Guidejunhyol100% (2)

- Maintenance IndicatorsDocument12 pagesMaintenance IndicatorssatfasNo ratings yet

- Laser Jet AlignmentDocument190 pagesLaser Jet AlignmentsatfasNo ratings yet

- IB84E-FN01 Bag House Fan CM-E/ Motor (GRR 72%) Step 21/ 1H-Motor NDE/ 224 VSC Rolling Be Aring Ac C 10/ 18/ 2022 9:14:13 AMDocument2 pagesIB84E-FN01 Bag House Fan CM-E/ Motor (GRR 72%) Step 21/ 1H-Motor NDE/ 224 VSC Rolling Be Aring Ac C 10/ 18/ 2022 9:14:13 AMsatfasNo ratings yet

- 22DST 01Document1 page22DST 01satfasNo ratings yet

- Reliability Expert RoleDocument9 pagesReliability Expert RolesatfasNo ratings yet

- GM80L 1050453Document3 pagesGM80L 1050453satfasNo ratings yet

- Hu Humegard Maintenance GuideDocument11 pagesHu Humegard Maintenance GuidesatfasNo ratings yet

- 30 Years' of Focused Leadership in Portable: Ultrasonic Testing EquipmentDocument55 pages30 Years' of Focused Leadership in Portable: Ultrasonic Testing EquipmentNithiya VasuthevanNo ratings yet

- Hu Humeceptor Maintenance Guide 2017Document12 pagesHu Humeceptor Maintenance Guide 2017satfasNo ratings yet

- Neet Hi PosterDocument1 pageNeet Hi PostersatfasNo ratings yet

- Reliability Engineer - Jobs in Kuwait by UnitedDocument2 pagesReliability Engineer - Jobs in Kuwait by UnitedsatfasNo ratings yet

- GM35S 1054971Document2 pagesGM35S 1054971satfasNo ratings yet

- HealthDocument11 pagesHealthsatfasNo ratings yet

- FAN ReadingsDocument3 pagesFAN ReadingssatfasNo ratings yet

- CompressorDocument456 pagesCompressorsatfasNo ratings yet

- Annual Report 2014Document161 pagesAnnual Report 2014satfasNo ratings yet

- Vibxpert Catalog EN 04122014 PDFDocument78 pagesVibxpert Catalog EN 04122014 PDFRizal RivaldiNo ratings yet

- Install, Operate and Maintain Dewatering Pump ManualDocument18 pagesInstall, Operate and Maintain Dewatering Pump ManualsatfasNo ratings yet

- Belt Feeder FLSDocument436 pagesBelt Feeder FLSsatfasNo ratings yet

- Vibration Analysis Survey Report For 421 FN 2 (Bag House Fan)Document6 pagesVibration Analysis Survey Report For 421 FN 2 (Bag House Fan)satfasNo ratings yet

- Belly Fat in MenDocument4 pagesBelly Fat in MensatfasNo ratings yet

- Belt Weigh FeederDocument808 pagesBelt Weigh FeedersatfasNo ratings yet

- Assured Reliability TechnologiesDocument242 pagesAssured Reliability TechnologiessatfasNo ratings yet

- Installation, Operation and Maintenance Manual for Solid Flow MeterDocument125 pagesInstallation, Operation and Maintenance Manual for Solid Flow Metersatfas100% (3)

- Sampler - Manual & MotorizedDocument16 pagesSampler - Manual & MotorizedsatfasNo ratings yet

- Rasheed Tosho Dare: Curriculum VitaeDocument3 pagesRasheed Tosho Dare: Curriculum VitaesatfasNo ratings yet

- KPI Dashboard for Cement Plant PerformanceDocument90 pagesKPI Dashboard for Cement Plant PerformancesatfasNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SPIE/COS Photonics Asia Abstract Submission Guidelines: Important DatesDocument1 pageSPIE/COS Photonics Asia Abstract Submission Guidelines: Important Dates李健民No ratings yet

- Bus 102 QuestionsDocument4 pagesBus 102 Questionsali2aliyuNo ratings yet

- CH 5 Audit-Planning MCQDocument3 pagesCH 5 Audit-Planning MCQEhab hoba0% (1)

- Cryogenics 50 (2010) Editorial on 2009 Space Cryogenics WorkshopDocument1 pageCryogenics 50 (2010) Editorial on 2009 Space Cryogenics WorkshopsureshjeevaNo ratings yet

- Data Sheet ECU-TESTDocument2 pagesData Sheet ECU-TESTmeetbalakumarNo ratings yet

- Vda. de Consuegra v. Government Service Insurance System (1971)Document1 pageVda. de Consuegra v. Government Service Insurance System (1971)Andre Philippe RamosNo ratings yet

- Royal Harare Golf Club: An Oasis of Excellence in The Midst of Political and Economic DevastationDocument24 pagesRoyal Harare Golf Club: An Oasis of Excellence in The Midst of Political and Economic DevastationCompleatGolferNo ratings yet

- Bamboo in AsiaDocument72 pagesBamboo in Asiafitria lavitaNo ratings yet

- Business Analysis-Xiaomi 30.8.15Document8 pagesBusiness Analysis-Xiaomi 30.8.15ocgNo ratings yet

- Brushed Axial Fans: VA85-A101-96A Performance DiagramDocument3 pagesBrushed Axial Fans: VA85-A101-96A Performance DiagramJaskaran SinghNo ratings yet

- Official Sponsorship LetterDocument3 pagesOfficial Sponsorship LetterWinona Marie Borla100% (1)

- Advance NewsletterDocument14 pagesAdvance Newsletterapi-206881299No ratings yet

- Politics FinalDocument29 pagesPolitics Finalmaychelle mae camanzoNo ratings yet

- 803 Web Application Class XI 1Document254 pages803 Web Application Class XI 1Naina KanojiaNo ratings yet

- Pakistan Relations With EnglandDocument4 pagesPakistan Relations With Englandpoma7218No ratings yet

- ElasticityDocument27 pagesElasticityJames Baryl GarceloNo ratings yet

- Introduction To Global Business 2nd Edition Gaspar Test BankDocument26 pagesIntroduction To Global Business 2nd Edition Gaspar Test BankJerryGarrettmwsi100% (56)

- TOT Calendar Oct Dec. 2018 1Document7 pagesTOT Calendar Oct Dec. 2018 1Annamneedi PrasadNo ratings yet

- Office of The Integrity Commissioner - Investigation Report Regarding The Conduct of Councillor Mark Grimes (July 05, 2016)Document44 pagesOffice of The Integrity Commissioner - Investigation Report Regarding The Conduct of Councillor Mark Grimes (July 05, 2016)T.O. Nature & DevelopmentNo ratings yet

- PHB 55n03lta Logic Level FetDocument15 pagesPHB 55n03lta Logic Level FetyusufwpNo ratings yet

- M100 PD ENDocument2 pagesM100 PD EN윤병택No ratings yet

- Banking DictionaryDocument499 pagesBanking DictionaryVanessa Jenkins100% (4)

- NCP Ineffective Breathing PatternDocument1 pageNCP Ineffective Breathing PatternMarc Johnuel HumangitNo ratings yet

- Urban Altoids EDC Kit v2.2.1Document2 pagesUrban Altoids EDC Kit v2.2.1richard philpNo ratings yet

- Development Approach PlanDocument15 pagesDevelopment Approach PlanGaurav UpretiNo ratings yet

- Winter 2011Document128 pagesWinter 2011baoHVLABNo ratings yet

- Module 2 - Introduction To A Web-AppDocument17 pagesModule 2 - Introduction To A Web-AppJASPER WESSLYNo ratings yet

- Simple Mortgage DeedDocument6 pagesSimple Mortgage DeedKiran VenugopalNo ratings yet

- Improving Network Quality Through RTPO 2.0 InitiativesDocument21 pagesImproving Network Quality Through RTPO 2.0 InitiativesArgya HarishNo ratings yet

- Expressing Interest in NIBAV LiftsDocument9 pagesExpressing Interest in NIBAV LiftsSetiawan RustandiNo ratings yet