Professional Documents

Culture Documents

REY Hugo R2A 2016-2017

Uploaded by

Miguel EgidoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

REY Hugo R2A 2016-2017

Uploaded by

Miguel EgidoCopyright:

Available Formats

Adjustment of a Photovoltaic-Diesel hybrid system and

starting of it

Second year internship report

05/09/2016 – 20/01/2017

Rey Hugo

Sector: Mechanics and energetics

Problematic: How getting a hybrid photovoltaic system with standards?

Hugo REY – Internship Report

1

Acknowledgments

First and foremost, I would like to express my gratitude to my industrial supervisor

Dr. Miguel Angel Egido Aguilera for giving me the opportunity to get this internship, and for

giving me his help in the tasks which were detonated to me.

I then would like to thanks his colleagues, Dr Estefanía Caamaño Martín and Dr.

Álvaro Gutierrez for always proposing me their support and help in case of doubt and

difficulties met.

I would then express my gratitude to my academic supervisor M. Eric Delacourt,

for following my evolution and visiting me during my internship

After, I would thanks Mrs Jane Lauro for helping me in the internship research and

for giving me this chance

I also would like to thanks all the students and investigators in the IES for their

sympathy and their tips and help.

I would also like to express my gratitude to my family which always supported me in

my studies

Finally I would like to thanks Pierre Devos and Simon Lavaud, my two ENSIAME

colleagues, for the nice time we had in Madrid

Hugo REY – Internship Report

2

Summary

INTRODUCTION ................................................................................................................... 5

CHAPTER 1: PRESENTATION OF THE INTERNSHIP ENVIRONMENT ......................................... 6

1°) Internship in a foreign Country: Spain .......................................................................................... 6

a. Presentation of the country ........................................................................................................................6

b. History of the “Instituto de Energía Solar” ...............................................................................................7

2°) Investigation groups ........................................................................................................................ 8

a. Instruments and system integration (ISI) ..................................................................................................8

b. Photovoltaic system ..................................................................................................................................9

c. Renewable distributed generation and intelligent control (GEDIRCI) .....................................................9

d. Silicon and new solar cell concept (SNSCC) ..........................................................................................10

e. III-V conductors ......................................................................................................................................10

3°) Place of work.................................................................................................................................. 10

a. Desktop ...................................................................................................................................................10

b. Laboratory ...............................................................................................................................................11

c. The roof ...................................................................................................................................................11

CHAPTER 2: PRESENTATION OF THE PROJECT ................................................................... 11

1°) Context ........................................................................................................................................... 11

2°) Components of photovoltaic and hybrid systems working principle ............................................ 12

a. PV modules .............................................................................................................................................12

b. Battery and accumulation systems ..........................................................................................................17

c. Charge controller .....................................................................................................................................19

d. Inverter ....................................................................................................................................................21

e. Back-up generator ...................................................................................................................................22

Hugo REY – Internship Report

3

3°) Description of the system ............................................................................................................... 22

CHAPTER 3: FIRST OBJECTIVES ........................................................................................ 24

1°) Prior works ..................................................................................................................................... 25

a. Normalization of the connections ............................................................................................................25

b. Solve of the inverter breakdown .............................................................................................................26

2°) Photovoltaic generator layout ....................................................................................................... 27

a. Presentation of the place and previous installation .................................................................................27

b. Completed work ......................................................................................................................................28

CHAPTER 4: SECOND OBJECTIVES ..................................................................................... 34

1°) Virtual simulation of the system.................................................................................................... 34

a. Introduction an presentation of the software ...........................................................................................34

b. Building of the system on Homer............................................................................................................34

c. Presentation of the results .......................................................................................................................35

2°) Running and real tests on the system ............................................................................................ 36

a. Connection of the engine .........................................................................................................................36

b. Theoretical part of the experiment ..........................................................................................................38

c. Presentation of the first experiment and results.......................................................................................40

CONCLUSION AND PERSPECTIVE ........................................................................................ 42

REFERENCES .................................................................................................................... 43

APPENDIX ......................................................................................................................... 44

Hugo REY – Internship Report

4

INTRODUCTION

Since the last decades, the electricity consumption rose rapidly and this kind of energy became

probably the most important in the human life at all levels (particular, community, industry).

Its production is very variable, and today, the world has almost ten ways to produce electricity.

Nowadays, the most developed ones are the so called fossil energies and the nuclear energy.

For instance, France is one of the countries in Europe and in the World which opted to get

electricity from the nuclear power: Almost 90% of the electricity produced comes from Atomic

energy. In 2006, that was approximately the same situation with almost 80% of the electricity

production

Figure I.1 Picture from a wikipedia article: electricity

generation

Other sources as Hydroelectric or fuel and coal are also used, and have been used in the past as

principal sources of production. However, just like nuclear power represents a big danger for

the environment as many sad examples in the history show, the use of coal and fuel emits CO2,

a greenhouse gas. Moreover the two last sources of energy are fossil energies, used since

several decades, and are becoming more and rarer: some specialists preview still 50 years of

fuel if the consumption is not reduced.

Therefore, the stake for the future of our world is to get a way of electricity production which is

clean and reliable. In this context take place the renewable energies and so the solar energy.

Currently being a 4th year student for an Engineer Master Degree at the ENSIAME. It has been

proposed to me to realize an internship at the Solar Energy Institute (IES) from the Technical

university of Madrid (UPM). I was motivated in getting experience in a field which will take

an important role in the future and which remain very interesting.

The main line of my internship was the work on a hybrid system (photovoltaic-diesel)

Hugo REY – Internship Report

5

CHAPTER 1: PRESENTATION OF THE INTERNSHIP ENVIRONMENT

1°) Internship in a foreign Country: Spain

a. Presentation of the country

As seen above, I realize my internship in Spain and more precisely, in Madrid, the capital.

Spain officially the Kingdom of Spain, is a sovereign state largely located on the Iberian

Peninsula in southwestern Europe, with two large archipelagos, the Balearic Islands in

the Mediterranean Sea and the Canary Islands off the North African Atlantic coast. The country

also urban areas owns two cities Ceuta and Melilla in the North African cost and several small

islands in the Alboran Sea near the Moroccan coast. The country has a border with England in

Gibraltar; with France and Andorra in the north and northeast; with Portugal in the west; and

with Morocco in Ceuta and Melilla.

Figure II.1.a.2 European and Spanish Flag

Figure II.1.a.1 Map of Spain

With an area of 505,990 km2, Spain is the largest country in Southern Europe, the second

largest country in Western Europe and the European Union, and the fourth largest country in

the European continent. The country has a total population of 46,423,064 inhabitants and is

the sixth largest in Europe.

Spain's capital and largest city is Madrid. Other major cities include Barcelona, Sevilla,

Valencia.

Spain is a democracy organized in the form of a parliamentary government under a

constitutional monarchy. It is a middle power and a developed country with the

Hugo REY – Internship Report

6

world's fourteenth largest economy by nominal GDP and sixteenth largest by purchasing power

parity. The Country is part of the European Union since 1986.

The head of the state is the King of Spain Felipe VI and the head of the government is the

government president, also called Prime minister (currently Mariano Rajoy Brey).

Figure II.1.a.3 Puerta del sol, Madrid

b. History of the “Instituto de Energía Solar”

In the context of my second year engineering internship, I worked at the “Instituto de energía

solar” of Madrid. This center is specialized in solar energy investigation and technologies.

Figure II.1.b.1 IES building

The IES was founded in 1979 by Professor Antonio Luque also President of the Institute. The

institute began its works during the years 1970’s. It became a head center in the solar

photovoltaic investigation. Thanks to its several successes and its great creativity, the institute

built step by step an international renown. In fact, the institute achieved many important project

Hugo REY – Internship Report

7

in silicon solar cells technology, III-V material cells, including multi junction, and more

efficient new concepts for solar cells, including associated quantum calculations.

As an example of its great performance and competition position, we can point at the company

ISOFOTON created in 1981 at the institute and which took the leading position in Europe

during the first decade of the 21st century in the field of the solar cells manufacture; this

company was created in order to develop bi-facial cells. However, because of financial

difficulties, it closed in 2008.

The institute also owns records in some leading fields of solar energy investigation as the one

of 2008. The institute an efficiency of 32.4% record using GaInP/GaAs cells at a concentration

of 1000 suns. This record concerned two junctions’ cells.

Moreover the practical investigation makes also part of the work realized at the institute. In

fact, thanks to its renown, many industries or companies called their service to evaluate the

quality of photovoltaic plants.

2°) Investigation groups

The institute of solar energy is divided in five research teams:

a. Instruments and system integration (ISI)

This group aims to work on the development of concentration photovoltaic systems in

order to promote low-cost photovoltaic systems. Their current works consist in:

New concepts in CPV systems and fabrication methods for concentrator optics

Optical and electrical instrumentation

Characterization methods for CPV modules and receivers

Reliability of CPV systems and components

Hugo REY – Internship Report

8

b. Photovoltaic system

The origin of their work is the problems met in the industry with photovoltaic system.

The aim is to control and ensure the quality of the service for which the systems have

been built, and the reliability and durability of them. Thus, its works consist in:

The quality of large PV plants: from the energy yield simulation with low

uncertainty to the quality control procedures for bankability processes.

New market niches for PV systems: developing solutions with high potential

market as PV irrigation of PV cooling.

PV rural electrification: assuring the reliability of Solar Home Systems or PV

mini grids in rural areas of developing countries.

c. Renewable distributed generation and intelligent control (GEDIRCI)

This group is the one in which I worked. The aim of this group is to develop more and

more system able to supply sustainable electricity. Those solar systems which are

developed are of both types: grid connected or isolate. The context of their work takes

place with the big expansion of the photovoltaic technology since the years 1970’s.

Since then, photovoltaic electricity took a huge place on the market, for the energy

supplying and thus, it implies researchers to focus on the development of Photovoltaic

system, and the smart way of the use of the electricity produced.

Moreover, their work also concerns the supplying of energy for all humans, still a lot of

people have no access to electricity, and PV systems can be a solution.

Their research lines correspond to the following ones:

Distributed strategies of Maximum Power Point Tracking in PV modules

Active Demand Side Management with distributed PV and storage

PV generation and forecast in complex environments

Solar PV potential at urban scale: from buildings to cities

Building integrated photovoltaic PV heating and cooling

Quality assurance in decentralized PV applications

Basic and income-generation electrical services for developing countries

PV Hybrid off-grid systems

Hugo REY – Internship Report

9

d. Silicon and new solar cell concept (SNSCC)

This group concentrates its researches on the improving of the solar technology. It

consists in supporting the photovoltaic energy through reducing cost and increasing

efficiency by different ways. The different research lines of it are:

Intermediate band materials and solar cells

Quantum mechanical calculations Nanostructures

Molecular beam epitaxial

Advanced characterization tools and device processing

Light management

Modeling and other novel solar cell concepts

Three terminal hetero junction bipolar transistor solar cells

Energy Storage: Novel system based on molten silicon latent heat

Solar silicon refinement

Defect engineering in solar silicon

Crystalline silicon solar cell development

e. III-V conductors

This group started its investigation in III-V solar cells in 1985, it aims to improve and

the highest efficiency solar cells (III-V multi junction solar cells) in order to develop

reliable and low-cost photovoltaic system. Those improvements concern both terrestrial

and space technologies. Their investigations lines are presented below:

Concentrator solar cells

Space solar cells

Flat plate photovoltaics beyond silicon

3°) Place of work

a. Desktop

During my internship, a Desk has been me given. Concerning the means the institute gave me, I

had a computer was at my disposition. The softwares I could use were the Office pack and all

the simulation software essential for the simulation task I had to do.

Hugo REY – Internship Report

10

b. Laboratory

The laboratory was the place in which most of the part of the system I studied was located. The

means given were basically electronic tools as multimeters but also data scanners. A computer

was also at my disposition.

c. The roof

It is on the roof that I realized an important part of my internship. In fact, the photovoltaic

modules are located there. The means given were measure equipments and several tools for the

different part of the photovoltaic support installation.

Of course, all this means have been completed by the help all the IES workers offers to me,

particularly in the installation of the photovoltaic structure, but also in laboratory work.

CHAPTER 2: PRESENTATION OF THE PROJECT

1°) Context

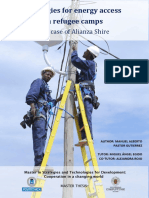

The concept of Hybrid systems takes place in the context of rural electrification. In some

countries, still today, many places have no access to electricity like for instance, in Africa or in

South America. In the case of the projects on which the IES is working on, those are

concerning countries of Latin America as Bolivia or Peru.

It is important to point out that the main difficulties of the areas where electrification does not

exist, is that those areas are remote areas where the main grid cannot feed the consumers.

Moreover, the possibility of building grid extensions and substations to distribute electricity is

not an option because of the high costs it implies.

A solution could be the Diesel generation, also called electric-diesel generation. However, the

cost of fuel is quite expensive and its transport can be difficult in remote areas (Amazonia for

example). Furthermore, the current environmental issues make one believe that the only diesel

generation is not a long term option. Thus, it appears that using renewable energies to produce

electricity is a good option in this context.

Hugo REY – Internship Report

11

Therefore, hybrid systems project, which council diesel generation with renewable energy

generation is now being developed. The entire stake is now to well design the different systems

in order to make them cost effective. Indeed, whatever the renewable source of energy one

uses, the cost is quite expensive.

This scheme is typically the kind of hybrid system we can meet. To improve the efficiency of the

system, several renewable sources can be combined. Thereafter, I will present the system on which

I worked, which is a photovoltaic-diesel system.

2°) Components of photovoltaic and hybrid systems working principle

Before Beginning on working on the project, I had to get the different useful knowledges. This

is the aim of this chapter in which I will present the several components of a hybrid system,

like the one I was working on, and their working principle.

a. PV modules

Solar Cell

The photovoltaic modules are composed of several solar cells connected each other. The

functioning of a solar cell is based on the physical properties of the silicon. The silicon belongs

to the semi-conductors materials:

Figure III.2.a.1

On the Left, the crystal lattice of

The Silicon. Silicon bonds with 4

other atoms thanks to its 4 valence

electrons.

That means that the energy required to break a bond is neither to high like for insulating

material nor equal to 0 like for metals. This energy is, in the case of semi-conductors, equal to

1.1eV. This is called the band gap.

The photovoltaic effect, discovered by Edmond Becquerel, is the mechanism of conversion of

solar energy (described by a photon) in electrical energy. When solar radiation impacts on the

semi-conductor material, the material is no more, no less receiving energy through photons,

which in turn can interact with the several bonds of the silicon. When it occurs, the photon

Hugo REY – Internship Report

12

gives all its energy to the bon. In theory, if the energy is less than the band gap like for the

insulating material, the bond is not broken, and all the energy is converted in heat (as well as

there is an energy surplus), but, when the energy is equal or exceed the band gap, the electron

of the bon is freed and can move into the crystal as a charge carrier:

ℎ𝑐

𝐸𝑝ℎ𝑜𝑡𝑜𝑛 = ≥ 𝐸𝑔

𝜆

𝜆 = 𝑤𝑎𝑣𝑒 𝑙𝑒𝑛𝑔𝑡ℎ ℎ = 𝑃𝑙𝑎𝑛𝑘 𝐶𝑜𝑛𝑠𝑡𝑎𝑛𝑡 𝒂𝒏𝒅 𝑐 = 𝑐𝑒𝑙𝑒𝑟𝑖𝑡𝑦 𝑜𝑓 𝑙𝑖𝑔ℎ𝑡

This process of increasing the energy of an electron to make it a charge carrier is called

generation. But the reverse also exists, when an electron meet a hole, and become again part of

a bond. That is what is called recombination.

However, this only effect on pure silicon cannot serve to produce any electricity, because the

free electrons are moving randomly and so, the rate of recombination is very high.

Therefore, Impurities are injected in the material in very small quantity in order to keep the

crystal lattice. This process is called doping and is divided in two forms. First N-doping which

consist in injecting impurities with one valence electron more than Silicon (usually phosphor),

then the P-doping which consist in injecting impurities with one valence electron less than

Silicon (usually Bore).

When an N-doping region is in contact with a P-doping region during the process of

homogenization, the surplus of electrons is locally attired by the uncompleted bond of the P-

doping region. It as if the negative charges (electrons) go to the P-doping region and fictive

positive charges (called “holes”) go to the N-doping region. Thus, the P region is getting a

global negative charge and the N region a global positive charge. In consequence, a field is

created from N to P: this is what is called the PN junction.

This field gives the moving direction to the free electrons when solar radiation impacts on the

solar cell:

That is what compose the solar cell, here, on the left, is the

scheme of a solar cell, on the top face and on the bottom,

there are charge collectors for electrons and holes. The one

on the top is a grid to be able to let the light go through the

material

Figure III.2.a.PN junction

Hugo REY – Internship Report

13

Concerning the physical functioning of a solar cell, the current generated by the solar radiation

can be measured by an Ammeter connected in parallel of the cell. This current, also called

Isc(short circuit) is almost proportional to the solar irradiance.

On the other hand, when the cell is not connected to another component, if the cell receives

solar radiation, the charges are being accumulated on each side of the cell, depending on their

sign. This creates a potential and a tension called Voc(open circuit). Of course, if no radiation

impacts the cell, the Voc value is almost 0, but when the cell is exposed to a lot of photons, this

value grows until a limit constant value which means that there is almost no more dependence

with the radiation.

Furthermore, a solar cell could be represented with an electrical scheme:

Figure III.2.a.3 Solar cell electric schemes

Scheme (a) represents the perfect model of a solar cell. IL represents the photocurrent, and ID,

the Diode current, represents the current passing through the PN junction.

In consequence, the current which would go through an external resistance would be equal to:

𝐼 = IL - ID(V)

In this equation, we can see that the value of ID depends on the value of the cell Voltage and

its expression can be written thanks to the Shockley equation:

Scheme (b) shows the real model, including the serie resistance and the parallel resistance. The

serie resistance represents the resistive characteristics of the material, it depend in general a lot

on the separation between each finger of the collector. It’s presence in the electrical

representation is very important, because its electrical influence is big. Nevertheless, this is not

Hugo REY – Internship Report

14

the case of the parallel resistance, which represents the leakage current. Finally the expression

becomes:

This equation is hard to manipulate and thus it is more practical to consider the following

hypotheses to study the electrical characteristic of a solar cell:

𝑞𝑉

An infinite parallel resistance, the term exp(𝑚𝑘𝑇) ≫ 1 in the field of application, and finding

Voc thanks to the first equation considering I equal to 0.

Finally the equation becomes:

Even if this new writing is more easy to use because all the parameters can be known or can be

easy measured, it is more usual to use a representation of I/V curve to represent a solar cell.

Figure III.2.a.4 I/V curve profile

On this graph we can see the I/V curve but also the Power curve. The I/V curve is obtained

considering specific condition of irradiance, temperature, and air mass, called Standard Test

Condition (STC). On the graph we can also note that there is a value of tension and current for

which power reach its maximum value. This point is called MPP (Maximum Power Point) and

in general, all the photovoltaic systems aim to work in this point.

The fact that this curve corresponds to the STC means that all this characteristics depends of

irradiance and temperature.

Hugo REY – Internship Report

15

Concerning the irradiance dependence, as seen before, only the Isc can be considered as

variable. Thus, the following equation permits to find its value with considering a certain

irradiance of G (W/m²):

∗

𝐼𝑠𝑐

𝐼𝑠𝑐 = ∗ 𝐺

𝐺

The terms with * representing the values in STC.

However, the temperature has no effect on the Isc, but yes it has on the Voc. Indeed, when the

temperature increases, it leads to a diminution of the energy gap between free electrons and

bond electrons. The following equation describes the evolution Voc in function of temperature

of the cell:

Photovoltaic modules

A photovoltaic module is the component composed by solar cell. The connection between each

cell is realized depending on the power the global system need. Connecting several cells in

series allows the module to multiply the value of Voc by the number of cells in series, while

connecting in parallel permits it to increase its Isc value.

Because of the fragility of solar cells, the manufacturing of a module should assure its

resistance to the different kind of mechanic test. Moreover, the module has to protect the cells

from the water; therefore, the cells are encapsulated between treated glass on the top (to let a

maximum of photon pass through it) and a cap of tedlar (in general) which is a black material at

the bottom.

In most of the cases, the modules are composed of several crystalline cells in series, to increase

the value of the open circuit voltage, encapsulated between glass and tedlar.

The electrical characterization is realized through an I/V curve, but also with the measured of

the Temperature in Nominal Operation Condition (TNOC) which corresponds to the

temperature of the encapsulated cells when they work with specific condition of irradiance,

temperature air mass and wind.

Hugo REY – Internship Report

16

The valor of this temperature is given by the equation:

Thanks to this equation, and to the value of G, completed by the relationship between Tc and

Voc. The I/V curve can be drawn in each conditions of work.

In reality, not all the cells of a module are working with the same characteristics, and that

affects the global functioning of one module to another. For this reason, it is usual to put

together in the same array of one photovoltaic generator, modules with similar characteristic.

One of the objectives given to me concerns this point and is a good example that we will see in

the following. In parallel to this problem, modules also are susceptible to be affected by hot

spot or shadow on one or several of its cells. In consequence the photocurrent of the shadowed

cells limits the global photocurrent of all the series cells to its value. Sometimes, these cells can

act as resistances and dissipate all the current produced by the other in heat. This phenomenon

is called hot spot (see annex). It is characterized by a cell getting a brown color. To limit it, two

kind of diodes are used: the ones called “by-pass diodes” and the ones called “blocking diodes”

By-pass diodes are connected in parallel

of each module, when one of the cells

of one module is shadowed, the diode

becomes forward and the current will

no pass through the cell, and also the

energy will not be dissipated

Figure III.2.a.5 disposition of bypass diodes

Extended to the array scales, blocking diodes have the same role than by-pass, but for one

array.

b. Battery and accumulation systems

First of all, it is important to know that not only batteries can accumulate the electrical energy

produced by a generator. Other means of accumulation, like flywheel unit or pumping stations,

are also used. Nevertheless, concerning the project on which I worked, batteries were used to

stock the energy. Therefore I will present the characteristic of this component.

Hugo REY – Internship Report

17

Most of the batteries used are lead-acid batteries, because of their interesting price and their

high presence on the market. But concerning isolated installation, we can also meet gel

batteries. The main difference between them is the electrolyte form. Concerning the lead-acid

batteries, the electrolyte is liquid while for gel batteries, it is gelled. Even if the functioning

principle is the same, gel batteries are more adapted for a repetitive use (several cycles per day)

thanks to its higher tolerance to deep discharge. Another kind of battery used in the

photovoltaic field is the solar batteries, built with thicker plates in order to prolong its cycle

resilience. The acid concentration is also reduced to prolong its life.

The functioning principle is based on a red-ox reaction between the electrodes and the

electrolyte:

Discharge

Charge

During the charge and discharge, the electrons go from the anode, where an oxidation of the

first electrode takes place, to the cathode, where a reduction of the second electrode takes place

and during the charge, the reverse is being produced. That what is described by the chemical

equations.

Figure III.2.b.1 Battery decomposition

Hugo REY – Internship Report

18

Each cell like this one, are composed by many couple of Negative and positive plates separated

by the separator. The positive plates are connected to the cathode and the negatives one to the

anode (in the case of discharge). All of these couples are sunk in the electrolyte which permits

the movement of ions.

Finally, it is important to be vigilant on the state of charge (SOC) of the battery. In fact,

overcharge like over discharge are harmful for the battery time of life. This is the role of the

charge controller. In fact, overcharging can lead to an oxidation of the positive plate and

moreover, after reaching a certain value, the water contained in the electrolyte is separated in

hydrogen and oxygen (highly explosive mixture). This is called gasification. Gasification is

sometimes wanted to homogenize the liquid electrolyte. Then, the opposite extreme: over

discharging, also have negative consequences on the battery life time. When its voltage reach

the so called “deep-discharge” voltage, the acid concentration is highly reduced which leads to

sulphation. Contrary to the overcharge, over discharge is always avoided because it cannot

have no benefits for the battery

c. Charge controller

The charge controller is the component which aims to protect the battery from overcharging

and over discharging by controlling its SOC and regulating the electrical flow coming from the

photovoltaic generator. To control the state of charge of the battery, the charge controller

measured its tension. The limit values of tension are chosen by the user.

For this component, two connections with the modules are possible. In series or in parallel:

Figure III.2.c.1 Charge controller in series and in parallel

Because of its better efficiency, the parallel version is recommended, but only for installations

where loads are consuming all the year. Indeed, in the case of an installation where

consumption is null during 2 month (for example a school during the summer holydays), until

Hugo REY – Internship Report

19

the battery will be charged, the controller will cut the current going to the battery by short-

circuiting the photovoltaic generator (this is the principle of this configuration). During a long

period, it could be dangerous for the modules, creating the problem of “hot spot”. Another

limitation of this configuration is that it can only protect the battery from overcharge. In

standalone systems where consumption is generally considered as constant, the charge

controller in parallel is chosen, because of its better efficiency. This is not the case of the series

configuration which can also protect the battery from over discharge. The effect on the battery

concerns its state of charge, or also its tension, which is a good sign to evaluate the SOC when

the battery cannot be open to measured the concentration of acid in the electrolyte (in gel

battery for example). Bellow we can see a curve of a battery voltage controlled by a charge

controller.

Figure III.2.c.2 influence of a charge controller on batteries tension

Another function of the charge controller can be, in the case of it owns the option, the

Maximum Power Point Tracking (MPPT). This option allows the solar modules to work on its

optimum power point. Indeed, when the Solar generator is connected directly (with or without a

basic charge controller) to the batteries, its work voltage will be imposed by the batteries

voltage and this voltage generally does not correspond to the MPP voltage. The MPPT is a

DC/DC converter which regularly search and find the value of the MPP voltage. It let it work

with it MPP values of tension and current, and then adapt this tension to the battery charging

voltage conserving the energy produced. Thus, the efficiency of the charge is better, because

the charging energy corresponds to the maximum of energy the modules can produce on this

moment.

Hugo REY – Internship Report

20

d. Inverter

The inverter is a very important component in a photovoltaic generating installation, because, it

permits to consume the produced energy with AC loads, which represents almost all the loads

we use. Indeed batteries supply DC current. Therefore its role is to convert the DC current

given by the batteries to AC current for the loads. Its working principle is based on transform,

thanks to interrupters, the DC current into a square signal. And then, by filtering it, the investor

obtains a sine wave signal.

SINTETIZATOR FILTER

Figure III.2.d.1 functioning of an inverter

This component owns very good electrical properties. Its efficiency is quite high: its

consumption is very low in vacuum operation and moreover, the power is demanded in a large

power range. Inverters are very reliable: they are very safe component, protecting short circuits,

and resist to intensity peak when starting the system.

This is an example of an efficiency curve for an

invertors SMA (a brand). The choice of inverter

in one system is made considering the input and

output power imposed by the system

Figure III.2.d.2 Inverter efficiency curve

Hugo REY – Internship Report

21

e. Back-up generator

In photovoltaic standalone system, the production of electricity is very dependent on the hour

of the day and on the meteorological conditions. For instance, during the night, when solar

irradiance is null, and the batteries are being discharged, they risk to overpass the deep-

discharge voltage. This is the utility of a back-up generator, it supply the batteries in energy

when they reach the limit discharge voltage and when the modules cannot work.

Generally, back-up generators are electric-diesel generator, because of their low cost and their

efficiency.

3°) Description of the system

This project was developed by the IES in order to respond to the needs of non electrified areas.

The aim of the project was to study a hybrid photovoltaic diesel system in which are connected

inverter and diesel engine, and to evaluate the system’s fuel consumption. This project has two

main objectives. The first one is that it makes part of a big project with Latin America

(Colombia, Ecuador and Peru) as part of ecotourism. The areas part of this program are areas

still not connected to the main grid and with a big touristic attraction power, thanks to their

natural landscape. The stake is thus a double stake; those areas have to be supplied in energy

while the environment has to be preserved. This kind of installation is designed to be connected

to what is called mini-grid installation in order to feed in electricity a little community. These

kinds of hybrid systems are thought to be connected to the so called “mini-grids” allowing

getting larger and more efficient system for rural electrification. Thanks to its solar generator, it

permits to reduce the CO2 emissions and also the cost of resupply in fuel.

Figure III.3.1

A similar project of hybrid system

for mini grid in Colombia, lead by

the IES-UPM

Hugo REY – Internship Report

22

The second objective is an academic objective. The IES of Madrid giving the possibility to do

solar energy master, it permits to make them have an approach of this kind of installation.

Design and description

The system on which I worked is a photovoltaic-diesel generator installed in the IES building.

The system is composed of twelve photovoltaic modules, six solar batteries, two charge

controllers, one inverter and one diesel generator. The different characteristic of each

component will be presented in this part.

The sizing of this installation was made considering the available space for the photovoltaic

generator, and then, considering the power of it, the inverter was chosen.

The technical characteristics of each component can be found in Annex 1A to 1E.

First of all, the photovoltaic generator is composed by twelve modules of 150Wp: GAT150P

from Grealtec displayed as follows: four arrays of three modules each one. In each array, the

modules are connected in series. The first and the second arrays are connected in parallel just

like the third and the fourth arrays. The technical characteristics can be found in Annex 1A.

Figure III.3.2

This figure represents the connection between two of

the 4 arrays.

The two parallel connections were then connected to two different charge controllers. The first

one is the MPPT OUTBACK MX-60 admitting a maximum voltage of 150V. The second one

is the MPPT CIRCUTOR UD80. As we can see, both of them own the MPPT.

This disposition is available with the electrical tolerance of both controllers; still the maximum

voltage given by one parallel connection is 76V and its maximum current would be 22.4A

which corresponds to 900W for a maximum power. Knowing that for the OUTBACK controller

the maximum tension is 150V and power 900W, and that for the CIRCUTOR, the maximum

current admitted is 80A and voltage 120V.

Hugo REY – Internship Report

23

The inverter of the system is the VICTRON MULTIPLUS 2000. Its input voltage range goes

from 9.7V to17V and its output power is equal to 1600W. The Maximum power in is 2200W

with a nominal power in of 2000W.

Concerning the batteries used, they come from the brand SONNENSCHEIN. Each cell has a

voltage of 2V. Six batteries are used, which make a global battery of 12V

Finally the diesel engine bought is the KIPOR KDE 2500E, which has a nominal power of

2000W. This last one must normally be connected to the inverter. The inverter’s role is to send

a signal of start or stop to the engine, depending on the SOC of the batteries.

Figure III.3.3

Inside system and Photovoltaic generator(charge controller, inverter and batteries)

CHAPTER 3: FIRST OBJECTIVES

In this chapter, I will present the several objectives that have been given to me. And also the

work I did after the first time of my internship, in which I had to learn the necessary knowledge

to well understand the functioning of this kind of system.

To introduce all the objectives I had, it is important to note that I worked on a project almost

finished. My job was first to improve some points of the system, in order to get a norm

respectful arrangement.

Hugo REY – Internship Report

24

1°) Prior works

a. Normalization of the connections

The first task I had to do was to change the wires connecting the several component of the

system each other. Indeed, when the project was built, the connection, from the charge

controllers to the batteries was realized with earth cable. The problem was not concerning the

current passage, because earth cables are physically the same cable as the others. The aim of

this work was to make the connections in accordance with the standards connections which are

specified below:

Positive : black

Negative : blue

Figure IV.1.a.1 Previous connection

This two pictures show the panel where are installed the two charge controllers, the batteries

and the inverter. As it is notable, all the connections to change were those in yellow/green. The

first step of my approach was to check the diameter of the cables, to know which section was

convenient in reference to the current it has to transport.

For that I used the software called Prysmitool. This software takes into account the kind of

installation you have: in this case it is low tension and wires on the air. Then it asks the user on

the electrical characteristics. First, the wires’ metal. Then the current, the voltage and the

voltage drop are considered. Finally it gives you the results.

Its calculation can be realized by hand, following the Joule law: 𝑃 = 𝑅𝐼 2

Hugo REY – Internship Report

25

𝜌𝐿

Knowing that 𝑃 = 𝑈𝐼 and 𝑅 = with ρ= metal resistivity S= the section and L=the length and

𝑆

𝐼∗𝜌∗𝐿

replacing P and R one obtains 𝑆 = 2 ∗ with ε the factor of voltage drop (here 0.5%)

𝑈∗𝜀

because it concerns the connection between batteries and charge controller. The factor two is

here to consider the length back and forth of the cable. A numerical application of the

calculation of the section for the wires between charge controller and photovoltaic generator is

given in Annex 2.

As a result I used cables of 16mm² to realize the connection for each charge controller. Both of

them then are connected to the batteries, which receive the double of the current given by each

parallel array. A cable of 32mm² could be used, however, with the disposition of the

connection; it was easier to make a connection with both wires of 16mm² at the batteries

electrodes. Finally, the connections looked like below:

Figure IV.1.a.2 New connection

b. Solve of the inverter breakdown

The second task I had to do before beginning the improvement of the system was to solve the

problem of the inverter. In fact, when I arrived at the IES, the inverter was not functioning

properly. In other word, it could not start. I also began a research work on the data sheet and on

the operating manual of the inverter in order to find out help concerning classical break down.

The Victron Energy Multiplus Compact has good indicators to communicate its problems to the

user, through led codes. In this case, the led were all off. In the manual, a table is given with the

most usual failure led codes.

Hugo REY – Internship Report

26

It gives some help for the most often problems which occur. However, none of those problems

corresponded to the current one. Therefore, I try to know, thanks to the Internet, if some other users

had met the same problem, but it was not the case. Finally, I downloaded the application for

Smartphone that Victron Energy had developed in order to have more information on the several

problems the inverter could have. The result is presented in annex 3.

Thanks to it I found what avoided the Multiplus to work. The fact was during the last utilization, the

user let wire RJ-45 connected to the inverter, and even if the PC was not connected too, the inverter

interpreted that the user was still configuring it. As for safety reason, it doesn’t let the inverter to

work when the cable is connected and when there is no synchronization with the computer

2°) Photovoltaic generator layout

One of the most important tasks to ensure the well working and the efficiency of a photovoltaic

generator is the layout of the modules. That concerns the supports and the connection.

a. Presentation of the place and previous installation

The photovoltaic generator is located on the roof of the IES building on the little tower also

called “torreon”. The place has the advantage that none building shadow it.

Concerning the geographical position, the face of the building is almost oriented to the south,

which makes of it, the most convenient place.

Concerning the technical characteristics of the area, it was built as a rectangle; its surface is

equal to 35.72m². The place was before used also for PV modules; therefore some rests old

parts of structures are still present: two beams were built on the site and it has to be considered

as part of the area. These two characteristics are important because they have an influence on

the layout of the generator and on the power it produces.

Presentation of the first layout

This project actually have been already built when I came to the Institute, some measurements

had already been done. However, the layout of the modules was made using parts of several

rests of supports. This implies that the separations between each array were not always the

same and moreover, the inclination of each one was also different. That had bad consequences

on the functioning of the generator. Indeed, depending on the season, the angle has to be more

Hugo REY – Internship Report

27

or less big, but the worse still remain the separation because it generates shadow on the cells

which reduce a lot the productivity of the panel. Below a picture of the old layout and an

example of an I/V curve with a shadowed cell are given.

Figure IV.2.a.1 Previous layout

Figure IV.2.a.2 Shading Influence on power

b. Completed work

To get an installation which responds to the norms, all of these points had to be fixed. This part of

this chapter will present the procedure followed in order to get a good modules display.

First step: Research of adequate supports

This first step was not so easy that it appears. Indeed, as stated before, the place is quite peculiar,

because the supports have to be adaptable to the floor, in case, the two bears. In a first instance, I

did global research on the internet to see what kind of supports we could find on the market. The

problem was that all of them were conceived to lie on the floor and not on two fulcrums. Then I

Hugo REY – Internship Report

28

searched on known website tipped by my supervisor like ATERSA or TECHNOSUN, both of them

presented similar products as the other websites I visited, however, TECHNOSUN proposed

example of supports in kit that could correspond to the place, or at least, of which we could be

inspired to create the support on measured to the place.

Figure IV.2.b.1 First structures

At that stage, the objective is to get an estimation of the price it could cost. I realized this task and

the results are given in the table below. Actually we didn’t opt for this solution, because,

performing the command, I noticed that many of the components were not in stock and would not

be. After speaking with the brand, which purposed another solution much more expensive, the

Institute opted for another kind of support which technical characteristics are given in annex 4 A-B.

Producto Quantidad precio en €

Pata trasera estructura inclinación ajustable 30/60º - TECHNO SUN 8 119.36

Pata frontal estructura inclinación ajustable - TECHNO SUN 8 34.08

Carril de aluminio para FV 2.56m - TECHNO SUN 16 253.92

Sujeción en Z final de panel 40mm - TECHNO SUN 16 15.52

Sujeción en T entre dos paneles 40mm - TECHNO SUN 16 17.12

Union entre carriles - TECHNO SUN 8 17.04

TOTAL 457.04

Figure IV.2.b.2 First structure-price estimation

Second step: installation of the structures

This step is crucial in all photovoltaic system design, because it permits to have an installation

which allowed to each array to receive the wanted irradiance along the year. In this step, I

calculated the separation between each row.

Hugo REY – Internship Report

29

Procedure of calculation:

The distance of separation is calculated in function of, how many hours for example, the modules

have to receive irradiance. This parameter is chose by the user. In the case of this project, the aim is

to produce the maximum of energy. The decision has to be taken in consideration of the space

available where the modules have to be installed. The optimal disposition is the one which

guaranties at least 4 hours of irradiance received per day. The following will show how was made

this calculation. The scheme below represents quite rapidly the installation:

Sunray at the limit of the obstacle

L

z1

γs β

Figure IV.2.b.3 Scheme of the photovoltaic generator S2 S1

In this kind on installation, the separation between each arrays are calculated considering the worse

day in the year in terms of sun. The installation is located in Madrid, so in the Northern hemisphere.

The worse day in the year corresponds to the winter solstice, which corresponds to December the

21st or 22nd each year. The calculation has also to take into consideration the worse point on the

modules, which will be the most shadowed. This point corresponds to the middle point on the

bottom of the module. Concerning the space available, the two beams on which the supports are laid

are 7.60 meters long, and the width of the tower measures 4.70 meters.

The separation between each array corresponds to the sum S1+S2. As said before, the worse day in

the year in term of irradiance corresponds to December 21st or 22nd. The sun position in the sky is

given by the declination angle below:

360

𝛿(°) = 23.45° ∗ sin(365 (𝑑𝑛 + 284)) With dn= [1; …; 365]

Replacing dn by 356 or 355 the factor sin is almost equal to -1 (-0.99) which give a declination of -

23.45°. Then, the installation is oriented face to the true south, which implies that the Azimuth

angle (angle between the south direction and the orientation of the module) is null. Finally the two

𝑍1

distances S1 and S2 can be found thanks to trigonometry: S1= L.cos (β) and S2=

tan(𝛾𝑠 )

With γs given by 𝜸𝒔 = 𝐚𝐫𝐜𝐬𝐢𝐧(𝐬𝐢𝐧(𝜹) 𝐬𝐢𝐧(𝝋) + 𝐜𝐨𝐬(𝜹) 𝐜𝐨𝐬(𝝋)) φ represents the latitude and

Z1=L.sin (β).

Hugo REY – Internship Report

30

For these calculation, I used a excel document, created by our teacher at the IES, in which the user

put in the parameters of irradiance average per month, the latitude of the location, the azimuth angle

and the β angle, and finally the module row measurements (see annex 5). After that, the software

draws on a graph the elevation angle γs in function of the azimuth angle for each solstice and each

equinox. On the same graph, the obstacle profile is also draw (in this case it is the row’s profile). It

traduces the shadow that the row of modules produces in function of the sun position. Finally the

user can change the value of the separation between each row, and observe the change on the

obstacle profile:

90 Elevación (º) 90

80 80

70 70

60 60

50 50

40 40

30 30

20 20

10 10

0 0

-180-150-120-90 -60 -30Acimut

0 30 (º)

60 90 120150180

Figure IV.2.b.4 obstacle profile

In my case, in this kind of installation, the criterion often chosen is at least four hours of sun. On

this graph we can note that black curves are also drawn: one interval between two of them

represents one hour. The procedure I followed is to change step by step the separation distance in

order to let four intervals free of obstacle (four hours) for the sun trajectory corresponding to the

winter solstice (represented in blue). We can observe that actually, the obstacle profile (in purple)

let pass the entire light during four hours on the December solstice.

The corresponding separation distance is equal to 1.6 meters. We could also choose more than 1.6

meters and get maybe almost 6 hours of sun. However, the goal was also to let free of modules

behind the last row in order to be able to let space in case of need for another installation. It also

makes easier the work on the modules. In the same idea, the structures were laid 1 meter shifted on

the left, so that it enables the user traveling in each row.

Hugo REY – Internship Report

31

As a result of the installation, an estimate of the solar loss has been possible (annex5). I obtain an

approximate loss of 3,4% of the global irradiation, so 66kWh/m².

Concerning the practical work, I also participate to the installation of the structure, I work with the

technician in order to help him and to give him the indications he needed.

Figure IV.2.b.5 evolution of the installation

Installation of the Modules

After having installed the structure, we install also the modules, in a first time randomly. In this way,

each of them had the same inclination and exposition conditions. After that, as we saw in the second

chapter, in a photovoltaic generator, the modules in the same array are those with the most similar

characteristics. For this reason, I did measurements on each module to get their I/V curve. For that I

use the electronic equipment TRIKA/TRISEN which will be described below:

TRIKA/TRISEN equipment:

This equipment is a very useful one concerning the installation of PV modules and also the

maintenance of them. It is composed by two equipments: TRIKA and TRISEN. Both of them

measured different physical quantities, and the combination of them allowed the user to get the

module characteristics.

Hugo REY – Internship Report

32

The TRIKA can measure the values of Voc, Isc, Vmpp and Impp for the

measurement conditions. It can also measure the value for the STC.

It draws then the I/V curve for measurement conditions and STC

but also the one which corresponds to the Ideal case.

Figure IV.2.b.6 TRIKA

The TRISEN measures the global irradiance thanks to the cell it has

on its face: the equipment is positioned parallel to the module as the

picture below shows and so the TRISEN can get the same irradiance

that the panel; so that, it also calculates the inclination. A

temperature captor located on the top of it allows the users to

Figure IV.2.b.7 TRISEN measure the cell temperature.

As seen in the theory chapter, the combination of these values permits the TRIKA to draw the

characteristic curve completely. The values collected by the TRISEN are communicated to the

TRIKA through Radio signal. All the data are saved then in the SD card of the TRIKA so that the

results can be transferred then to the PC. I then did the measurements for each modules and I got for

all of them their characteristics that I presented in annex 6A-6D.

It is usual to class each module by the more similar ones in terms of Impp. Considering that this

classification still true for other weather conditions, I draw four groups which will compose the four

arrays. Unfortunately, the weather in Madrid during the period we made the measurements was

really bad, so it took a long time to get all the characteristics. And because we had to make

simulation and experiments, the correct installation has not been made.

Hugo REY – Internship Report

33

CHAPTER 4: SECOND OBJECTIVES

1°) Virtual simulation of the system

a. Introduction an presentation of the software

Because this project aims to produce electricity in reducing the CO2 and other gasses emission, it is

important, to have an idea of the fuel consumption of the diesel engine during the year. For this

work, I used the software HOMER, which is first of all a software optimization in order to design

the system you need. It takes into account many parameters like fuel cost, inflation rate or discount

rate, which will help it to find the better solution. The user is also able to ask HOMER to simulate

the system with many values of one or several parameters: for example, see the evolution if the fuel

price increases or decreases.

In our case, the system was already designed. My work has been to build the exact system in Homer

and to launch the simulation to evaluate the fuel consumption. So that optimization was not

necessary.

b. Building of the system on Homer

The first step was to build the system with the real characteristics of each component. Indeed,

HOMER has a library in which the most current component are available, and can be used to create

the system, however, in our case, the different components used were not defined in the library, so I

created them helping me of the datasheet of each one.

After having created the components, came the step of the building of the system. First of all, I had to

create the load profile of the installation. In order to be realistic with the photovoltaic production, we

considered a consumption of 4 kWh per days considering 4 hours of irradiance per days and 1kW of

photovoltaic production per hours. This correspond to a production average, in winter the production

can be lower as well as in summer, it can be higher. We considered a constant load for the all year. The

profile is described below:

Hugo REY – Internship Report

34

Figure V.1.b Daily load profile

To design this curve, I try to imitate a consumption model curve and to be the closer as possible to the

consumption we wanted: 4kWh/day

HOMER takes also in consideration the location of your installation, indeed, it is important when you

realized this kind of simulation to know the true place in order to have the good solar and temperature

data. Therefore, it is possible to enter the geographical coordinates of the place or search directly on

the map and point it.

After this step, the software needed the resources information data. This concerned here the

solar data and the temperature data. The Solar data are divided in two categories: The global

horizontal irradiance and the direct normal irradiance. The last one corresponds to the power

received per unit of area by a surface which is perpendicular to the sunrays which fall on it. The

first one corresponds to the sum of the direct normal irradiance plus the diffuse one. For this, I

used data collected by meteorological station and I import it to HOMER:

The other resources HOMER needed were temperatures and fuel data. Fuel was already present

in the library with its characteristics, only I had to give the liter price. Concerning temperature

HOMER gave me the possibility to download the data directly from an internet from its

database.

c. Presentation of the results

As stated before, the aim of the simulation is to evaluate the participation of the diesel

generator and by the way, the fuel consumption of the system. HOMER gives after its

calculation a detailed report in which the different curves of power for each component, but

also the curves of comparison between each of them, and economics curves. The interesting

Hugo REY – Internship Report

35

parts of report concerning the comparison between the modules and the engine production are

given in annex 7: a little bug appears concerning the price of replacement for the PV generator:

the report took 0 euro even if I put in the price of investment.

First of all, we can see that the participation of the Photovoltaic generator is superior to the (see

report in annex)

We can also notice that during the winter, the diesel generator produce more than during the

summer, which seems logical because of a lower irradiance during this season. So the diesel

consumption is increased in winter. The consumption average is 1.76 L/day so 0.0732 L/hour.

According to the simulation data, the consumption reached its maximum in January (see graph

up) with a value of almost 0.2 liters.

However, we are still observing that the consumption average is lower during the summer than

during the winter.

Finally we can see that in general, if the system had been conceived without photovoltaic

generator, the diesel consumption would be almost three times more than in the case of this

hybrid system: this confirm the efficiency of creating a hybrid system in term of environment.

In fact, the production of electricity has more renewable energy origins.

Thanks to this simulation, we can know estimate for a constant load, the consumption of fuel of

the system.

2°) Running and real tests on the system

After having simulated the system, the next step was to launch the real tests on the system. This

aimed to get an example of functioning of it for a predetermined load and consumption.

a. Connection of the engine

The first stage was to find a solution in order to connect properly the diesel engine to the

inverter. The connection must let the inverter command the start and stop of the engine, when

batteries state of charge are critic and when solar energy is not available.

Searching on the inverter datasheet, it appears that the inverter is able to be set (thanks to its

software VE CONFIG) to start the engine. This option is called transfer switch

Hugo REY – Internship Report

36

As it can be observed, the setting is done depending on the battery state of charge but can also

take into consideration the load. For example, when consumption becomes too much high and

the batteries can’t give the sufficient energy, as well as the solar generator, the diesel engine

can help the system to get the wanted production.

Concerning the connection, the inverter owns the ATS connection (automatic transfer switch)

which is intended to be connected to the ATS generator connection. The problem we met is that

the generator we had didn’t have the automatic start possibility. As seen before, just the

mechanic and electric start. We finally opted for giving back the diesel engine to the

manufacturer in order to install on it the ATS wires.

The connection has been done after the experiment presented in the next paragraph because of

the delay we had to wait.

Figure V.2.a Modification of the engine

The procedure has been first to calculate the AC cables section (see annex 8 A). After that, the

two AC cables and the two signal cables for the ATS have been connected between each

component (see pictures in annex 8 B)

The multifunction relay is an electro mechanics relay with the broaching NO COM NC (normal

open, common, normal close). When the relay is closed, the start signal is transmitted and the

engine start, when the relay is open, the circuit is open, and the engine stops. Here the engine

has to start when the voltage battery lower limit is reached. So the relay has to be normally

open.

After, the procedure has been to set this relay. Thanks to the guide of VE CONFIG given by

Victron Energy, and thanks to the example of setting for the automatic start of an engine, the

settings have been made.

Hugo REY – Internship Report

37

The interface for the programming of the transfer switch with VE CONFIG is given in annex

8C. For programming the start and stop of the engine, the relay as to be set as a multifunction

relay (first window for settings) the little checkbox on the right top corner allows the inversion

of the virtual switch (on=open off=close or on=close off=open); the useful setting is here

on=close and off =open.

In this case, we wanted to start the engine when battery voltage goes under a certain limit. This

limit had been set as 60% of depth of discharge: 11.75V. This is programmable in the SET VS

ON tab. In the VS OPTION tab, it is possible to set a minimum of switch on duration (here 15

min)

Finally, in the SET VS OFF, the value of the Battery voltage has been set as 14.2 which

correspond to the absorption voltage. Other condition of switch off as “no AC input” or “no VS

ON condition for” can be set in this tab.

Concerning the simulation, I did not have time for a real functioning of the system and a real

test. Just note that the relay has been well set, it goes off when the battery voltage reaches the

low limit and it opens again when the battery voltage is again acceptable. However, concerning

the engine, this one does not start properly. I realized a scheme of the circuit (annex 8D) to try

to find out the reason of the mal functioning. After a test of run, it appears that one can hear the

12V relay click several times instead of one, during the period that the inverter send the signal.

It is most likely that the problem comes from and bad contact in the relay (maybe because of

the solenoid) which does not transmit the signal to the starter relay. I had no time to make other

test, however, a simple change of this component could solve the problem. It can also be tried,

in a first time, to connect through a little electric bridge the contact between the cable from the

inverter and the one which transmit the signal after the activation of the 12V relay. In other

words, the 12V relay could be replaced by a direct connection: So that the engine will start

when the inverter relay will be activated, and it will stop when the relay will open again.

b. Theoretical part of the experiment

The second step was to launch the system in real conditions to get an example of functioning of

it: a consumption curve, a flow curve from the battery.

For that, a data scanner as been used and also shunts:

Hugo REY – Internship Report

38

The first step has been to create a model of consumption in a theoretical way: for that, I first

made some measurements of the consumption of each load we had in the laboratory:

6 AC lights (100 W) Corresponding to the maximum power

One heater/ventilator (2500 W) consumed

First of all, the system was run in order to get this consumption values (by the way, as the

engine was still not prepared, the first measurements were done without back up engine, still

the inverter owns a over discharge protection, it had no risks for the batteries)

For each loads, the following consumptions have been found:

1 light: 0.083 kW

Ventilator: 0.552 kW

Heater: 1.283 kW

The simulation has been done trying to test the system for a private individual consumption. It

is characterized by a little peak around 12 and a bigger around 21. An example is given in

annex 9. Considering the different loads we had and considering the maximum power that the

inverter could deliver, I tried to draw a similar profile composed by one consumption value for

each hour, and simulating the two peaks.

I finally create the profile, with a minimum constant value of 0.083 kW, corresponding to one

light on (annex 10). As the inverter can work with an output power of 1600 kW for an input

power of 2000, the objective was to reach at least 1500 W. The following simulation previews

1459 W, which is quite close to this value. As it had been considered in the virtual simulation,

the mean of the daily consumption is around 4kWh (4.5kWh).

Hugo REY – Internship Report

39

c. Presentation of the first experiment and results

Figure V.2.c Experiment progress

In order to create a similar consumption than the one created before, each hour; a different

combination of loads has been turned on. For instance, the first 10 hours of the day,

corresponds to one light on. A description of these combinations is given in annex 10.

Considering the progress of the first experiment, no major problems have been detected. Only

the battery voltage was not good:

Each cell of batteries has a voltage of 2 V. The bank being composed by six batteries, it results

that the voltage is of 12 V. However, when they are connected to the solar generator, it is

acceptable to get a voltage between 13 V and 14 V. The results are presented in annex 11.

As it can be observed, the battery voltage reaches a maximum of 17 V. considering the

experimental conditions, this corresponds to the moment when the loads were not at the

maximum but when the solar production was high (during the day):

In fact, the experiment was launched during the morning, at 10:00 AM. That is to say that the

voltage peak corresponds to the time 3:00 PM. A time when consumption is at minimum and

solar production is almost equal to its maximum.

Interpretation: either one of the two charge controller is not working well or the batteries are

damaged.

A test was made during the day, without consumption to get a voltage curve of the battery. As

it can be observed on the curve in annex 12, the voltage reaches around 13 V on its maximum.

Hugo REY – Internship Report

40

The maximum corresponds to the moment when solar irradiance is at its highest point. Even if

the test gave us positive results, the same problem occurred in the days after. A possible reason

is that the day of the experiment, the weather was good but however a bit cloudy. That is to say

that the solar production did not reach its maximum and thus, the electrical flow to the battery

was not enough to over pass the maximum state of charge authorized.

In those conditions, the only possibility was that one of the charge controllers did not run well.

As each of them had their own circuit, I measured the battery voltage with just one of them

connected. It has been observed that when the OUTBACK was connected, the battery voltage

didn’t reach dangerous values, but when the CIRCUTOR was connected, the voltage reached

17 V. In other words, the CIRCUTOR did not well run.

After having search more information about it, we figure that the programming of the charge

controller is possible once a password given in the manual is entered:

In fact, whatever the reason, maybe a lot of time without running, the charge controller had a

voltage limit for the battery equal to 59V. So the controller was running good, the

programming just did not correspond to the battery voltage.

Hugo REY – Internship Report

41

CONCLUSION AND PERSPECTIVE

To conclude this report of my Internship, I would first say that it teaches me a lot on the solar

energy and particularly on the photovoltaic energy. Indeed, the first part of my internship was

dedicated to learn the essential knowledge of the photovoltaic science and industry application.

Then, the different objectives I had, which concerned the hybrid system, gave me an example

of what can be the work of a solar energy engineer, and gave me new abilities and experience

in this field, concerning the method of work.

The project on which I worked was already designed. Therefore, my work can be divided in

two parts: a first part which has consisted in “normalizing” the system, in other words, it has

consisted in getting a system which responds to the norms (cables) and which has a more

rigorous displaying (photovoltaic layout) allowing a better control of the functioning and an

higher efficiency. The second part of my work which concerned simulation and running, has

permitted to get an example of real use of the system and to point out the several problems the

system could met when running. It permits to fix some parameters of the system as for the

charge controller. The connection to the generation has been done. Now, the last thing to do is

to test the system in real condition having the back-up engine.

Even if this I did not have time to run the finished system, all the part of connection of the

Diesel engine to the system has been done. The following test on the system will show if all the

settings have been well done.

As a following perspective of my work, it could be a useful thing to create a kind of manual of

the system.

Hugo REY – Internship Report

42

REFERENCES

Books and documents:

Planning &installing Photovoltaic System

Sistemas Híbridos- Soluções Energéticas para a Amazônia 2008

Manual-A-Guide-to-VEConfigure-EN

Manual-MultiPlus-Compact-2000-230V-EN

Courses received in the field of Photovoltaic solar energy

Websites:

http://www.ies.upm.es/

https://www.victronenergy.com/

Hugo REY – Internship Report

43

APPENDIX

Appendix 1A

Hugo REY – Internship Report

44

Appendix 1A(second part)

Hugo REY – Internship Report

45

Appendix 1B

Hugo REY – Internship Report

46

Appendix 1B(second part)

Hugo REY – Internship Report

47

Appendix 1C

Hugo REY – Internship Report

48

Appendix 1C(second part)

Hugo REY – Internship Report

49

Appendix 1D

Hugo REY – Internship Report

50

Appendix 1D(second part)

Hugo REY – Internship Report

51

Appendix 1E

Hugo REY – Internship Report

52

Appendix 2

Example of section calculation

Connection of the PV generator to the charge controller:

𝐼∗𝜌∗𝐿

𝑆 =2∗

𝑈∗𝜀