Professional Documents

Culture Documents

Lesson Learned

Uploaded by

R KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lesson Learned

Uploaded by

R KumarCopyright:

Available Formats

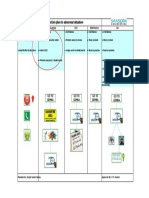

Lesson Learned from Existing supplies

Part Name :Tie Rod Model : B515 & 562 Supplier : Punch Ratna Fasteners Pvt. Ltd.

Controls in

Sl.No Description Details Requirments (if any) Remarks

Punch Ratna

100% Bend check assuracne Mark

1 Bend (up to 1.5 mm) 100% Checked. Ok

(Error Proof)

Back stopper in Sphere Side

2 Thread Length Under size (3mm) Error Proof

provided.

100% Setting Control. Oversize Not

Possible After Setting Approval. Exist

3 Thread Length Oversize (1mm) Error Proof Ok

Stopper From Thread roll side not

allow oversize.

It is possible to detect in

Back stopper in thread

4 Pointing operation Miss Error Proof rolling Process because of

Length oversize.(When

Pointing Opn. Miss)

Go & No go Snap gauge

5 Shank Dia Under size Process Control / Error Proof provide to operator to check

Periodically

6 Thread operation Miss 100% visual at final stage Error Proof Ok

In pointing process holding location is

7 Hex Miss Process Control / Error Proof Ok

HEX.

150 Nos dispatched 3.5.19,

100% Cleaned and apply Exist RP MPI tested Dust / Packing Dust

8 Thread area Dust accumulation with Dust, Thread Roll Oil

Quality Problem Oil. - Cleaning method

cleaned surface and applied

Faced RP oil.

100% Cleaned and apply Exist RP Feedback Awaited from

9 Thread area Oil accumulation No Oil in Thread area

Oil.

Yagachi.

Thread Laps

10 (Go not enter / Line mark / Thread 100% visual at final stage Error Proof Ok

miss match)

Rust Oil to be studied for duration and Part dispatched with RP oil,

11 Rust ( Shank and Thread) 100% apply RP Oil approved. Application method to be Feedback Awaited from

submitted Yagachi.

12 Surface Finish (Coarse) Need to prove the process Not applicable

Drop Part Management

13 Heat Treatment Miss 100% Eddy current Process Control / Error Proof

Prepared.

Raw material Mark on OD

14 100% visual at final stage Process Control Ok

(Deep Scratch Mark)

Bend Removal Mark on OD

15 100% visual at final stage Process Control Ok

(Step on OD)

16 Eddy Current to check 100% 100% Eddy current Process Control Ok

Master samples will be

Nick Damage Handling Control method

16 made during mass

(Body / Thread area) AQL Letter

production.

You might also like

- Rohingya Poems in RohingyalishDocument32 pagesRohingya Poems in RohingyalishMohammed Siddique Basu100% (7)

- CARA NC Management Tool Instructions For Client: IATF OversightDocument8 pagesCARA NC Management Tool Instructions For Client: IATF OversightOBSC PerfectionNo ratings yet

- Expository Essay Rough DraftDocument4 pagesExpository Essay Rough Draftapi-292792461No ratings yet

- Audit Evidence Evaluation Comments: Internal Audit Check List Mr/Cip/Training/Customer ComplaintsDocument3 pagesAudit Evidence Evaluation Comments: Internal Audit Check List Mr/Cip/Training/Customer ComplaintsganrashNo ratings yet

- 12 MGD MRM Report Jan-2020Document156 pages12 MGD MRM Report Jan-2020Manish KaushikNo ratings yet

- Control PlanDocument6 pagesControl PlanFahmy Khoerul HudaNo ratings yet

- Flooring Spec No RDSO-2017-CG-05 For Rubberized FlooringDocument15 pagesFlooring Spec No RDSO-2017-CG-05 For Rubberized FlooringIshanNo ratings yet

- Supplier Manual-7th Revision - April 23 FinalDocument35 pagesSupplier Manual-7th Revision - April 23 FinalvishnuNo ratings yet

- BGL-FM-HR-38 Training Cum Effectiveness Record 01Document2 pagesBGL-FM-HR-38 Training Cum Effectiveness Record 01Mohit SinghNo ratings yet

- FIR-garments PDFDocument4 pagesFIR-garments PDFTarun PariharNo ratings yet

- 3 3bb0aDocument7 pages3 3bb0aEleandro JoaquimNo ratings yet

- COPQ Training - EPC (Repaired)Document15 pagesCOPQ Training - EPC (Repaired)syedfahadraza627No ratings yet

- Part Name: Sample Size: Part No.: Date: Customer:: Verificatio NDocument25 pagesPart Name: Sample Size: Part No.: Date: Customer:: Verificatio Nsatrughana patraNo ratings yet

- Anicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateDocument9 pagesAnicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateAnicon Flowcontols llpNo ratings yet

- Test Paper: Name: DateDocument2 pagesTest Paper: Name: DateDhinakaranNo ratings yet

- Updates Dec09 AIAG FMEA-Ranking-TablesDocument3 pagesUpdates Dec09 AIAG FMEA-Ranking-TablesSuresh Velu100% (1)

- TKW Fasteners ProfileDocument37 pagesTKW Fasteners ProfileRishi GautamNo ratings yet

- Past Defect History 2021Document10 pagesPast Defect History 2021RahulNo ratings yet

- TEAM fEASIBILITYDocument2 pagesTEAM fEASIBILITYPk NimiwalNo ratings yet

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument36 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- Skill Matrix: 1 - Basic Trg. AcquiredDocument4 pagesSkill Matrix: 1 - Basic Trg. AcquiredDinesh KumarNo ratings yet

- MRM PlanDocument2 pagesMRM Plang.kannan100% (1)

- Process Audit Check SheetDocument5 pagesProcess Audit Check SheetaliNo ratings yet

- Target For ProductivityDocument1 pageTarget For ProductivityPk NimiwalNo ratings yet

- Fmea (Failure Modes and Effects Analysis)Document11 pagesFmea (Failure Modes and Effects Analysis)Oswaldo VallesNo ratings yet

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- Grafica XRDocument1 pageGrafica XRAlfonso CruzNo ratings yet

- Supply Packaging Approve FormDocument1 pageSupply Packaging Approve Formcong daNo ratings yet

- Blank Turtle DiagramDocument1 pageBlank Turtle DiagramnormalNo ratings yet

- Potential Failure Modes and Effects AnalysisDocument15 pagesPotential Failure Modes and Effects AnalysisPrakash RanjanNo ratings yet

- Nikhil Quality 6YOEDocument3 pagesNikhil Quality 6YOENikhil DhimanNo ratings yet

- 5.6 MRM Minutes 2020Document7 pages5.6 MRM Minutes 2020Musyoka Urbanus100% (1)

- Master TimingDocument4 pagesMaster TimingPk NimiwalNo ratings yet

- Thyssenkrupp - Supplier Rating PDFDocument18 pagesThyssenkrupp - Supplier Rating PDFmihaichfNo ratings yet

- 8.fixture Inspection ReportDocument1 page8.fixture Inspection ReportBASAVA ENGINEERINGNo ratings yet

- Gauge Repeatability & Reproduceability Report (MSA Study)Document2 pagesGauge Repeatability & Reproduceability Report (MSA Study)Karan MalhiNo ratings yet

- Supplier-QUAL TM 0027-01 PPAP PackageDocument67 pagesSupplier-QUAL TM 0027-01 PPAP PackageMahe RonaldoNo ratings yet

- Part Submission ChecklistDocument8 pagesPart Submission ChecklistGeovanny HernándezNo ratings yet

- MF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionDocument1 pageMF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionRohit VishwakarmaNo ratings yet

- Toaz - Info Red Bin Analysis Procedure PRDocument4 pagesToaz - Info Red Bin Analysis Procedure PRRohit QualityNo ratings yet

- APQPDocument3 pagesAPQPsam1hi5No ratings yet

- IPQC General FormatDocument17 pagesIPQC General FormatMohd Isa HarunNo ratings yet

- MSA FormatDocument4 pagesMSA FormatSaurabh PhandNo ratings yet

- PFEMA Attachment B Rev 16fe15Document1 pagePFEMA Attachment B Rev 16fe15Saulo TrejoNo ratings yet

- Standard Reaction Plan To Abnormal Situation: Restart ProcessDocument1 pageStandard Reaction Plan To Abnormal Situation: Restart ProcessDeepak kumarNo ratings yet

- Test Paper: Fifo & TraceabiltyDocument2 pagesTest Paper: Fifo & TraceabiltyAtul SharmaNo ratings yet

- Product Part Approval Process: Automotive Quality Management SystemDocument3 pagesProduct Part Approval Process: Automotive Quality Management SystemrajaNo ratings yet

- SPTR Rev Check ListDocument5 pagesSPTR Rev Check ListSAKTHIVEL ANo ratings yet

- Personal Annual Plan For The Year: 2019: BAM International BV Projects Ade Tedi Subcon ManagerDocument3 pagesPersonal Annual Plan For The Year: 2019: BAM International BV Projects Ade Tedi Subcon ManagerMark RamirezNo ratings yet

- PFD and Pqcs of Can Rear BreakDocument16 pagesPFD and Pqcs of Can Rear BreakVikas KashyapNo ratings yet

- F16 (SOP - hrd.01) Kaizen Implementation SheetDocument1 pageF16 (SOP - hrd.01) Kaizen Implementation SheetRAHUL YADAVNo ratings yet

- Management Review Agenda and Minutes: M: Name Title Here Name Title HereDocument5 pagesManagement Review Agenda and Minutes: M: Name Title Here Name Title HereTrivesh SharmaNo ratings yet

- Statistical Process Control For Attribute Data (SPC)Document45 pagesStatistical Process Control For Attribute Data (SPC)RajanishshettyNo ratings yet

- IN-PROCESS INSPECTION SHEET (Version 1)Document1 pageIN-PROCESS INSPECTION SHEET (Version 1)rishi gautamNo ratings yet

- ZED PresentationDocument13 pagesZED PresentationSatbir SinghNo ratings yet

- PFMEA - 4th Edition PFMEA RankingDocument2 pagesPFMEA - 4th Edition PFMEA RankingDjurdjina PetkovicNo ratings yet

- EEN Audit Format Sample GuideDocument2 pagesEEN Audit Format Sample GuideDuane SchumacherNo ratings yet

- Manufacturing Process LabDocument9 pagesManufacturing Process LabJing HengNo ratings yet

- Psy 1 Chap 3 Human DevelopmentDocument24 pagesPsy 1 Chap 3 Human Developmentjeanette8riosNo ratings yet

- HOTS How To Answer QuestionsDocument3 pagesHOTS How To Answer QuestionsEldad KarniNo ratings yet

- Masterfile - Archer & Bull - UG 2022 - IITMDocument9 pagesMasterfile - Archer & Bull - UG 2022 - IITMSam TyagiNo ratings yet

- Samakande A UnprotectedDocument190 pagesSamakande A Unprotectedathilla27No ratings yet

- Gui 0001 EngDocument102 pagesGui 0001 EngBalaji MysoreNo ratings yet

- Schopenhauer S LebenDocument345 pagesSchopenhauer S LebenVeRa100% (1)

- Health Indicators DemographyDocument35 pagesHealth Indicators DemographyZoe RodriguezNo ratings yet

- The Other Side of The Last Boss 01Document210 pagesThe Other Side of The Last Boss 01KristianNo ratings yet

- A Project Report ON: Admerit IIT & ME, Patna LC Code:-01780Document74 pagesA Project Report ON: Admerit IIT & ME, Patna LC Code:-01780Santosh FranNo ratings yet

- Samsung CL21K3W PDFDocument4 pagesSamsung CL21K3W PDFNelson Muñoz BautistaNo ratings yet

- Flat Glass-Pilkington-2009finalDocument74 pagesFlat Glass-Pilkington-2009finalKancharla AnandNo ratings yet

- Cics Abend CodesDocument9 pagesCics Abend CodesGupta KanduriNo ratings yet

- SSRN Id3126098Document3 pagesSSRN Id3126098Aditya kompalliNo ratings yet

- MGT602 Quiz 2 290411Document8 pagesMGT602 Quiz 2 290411sonutilkNo ratings yet

- C2 - Linear ProgramingDocument76 pagesC2 - Linear ProgramingLy LêNo ratings yet

- Olivine and SpinelDocument2 pagesOlivine and SpinelPablo MurilloNo ratings yet

- Habitat Lesson PlanDocument2 pagesHabitat Lesson Planapi-177886209No ratings yet

- Mabini Colleges, Inc: College of Education Daet, Camarines NorteDocument8 pagesMabini Colleges, Inc: College of Education Daet, Camarines NorteFrancia BalaneNo ratings yet

- Simulation of IEEE 802.15Document8 pagesSimulation of IEEE 802.15heriedsNo ratings yet

- Kindergarten Weekly Lesson Plan TemplateDocument2 pagesKindergarten Weekly Lesson Plan TemplateRobin Escoses MallariNo ratings yet

- Work Immersion Schedule Matrix: TLV - He - Hairdressing 12Document4 pagesWork Immersion Schedule Matrix: TLV - He - Hairdressing 12Fobe Lpt NudaloNo ratings yet

- Recurrent Neural Processes: Preprint. Under ReviewDocument12 pagesRecurrent Neural Processes: Preprint. Under Reviewgheorghe garduNo ratings yet

- ENFSIDocument8 pagesENFSIkmrdNo ratings yet

- Application of Sensors in An Experimental Investigation of Mode DDocument284 pagesApplication of Sensors in An Experimental Investigation of Mode DHamed MasterNo ratings yet

- Ben-Arieh, A. How Do We Measure and Monitor The"state of Our ChildrenDocument7 pagesBen-Arieh, A. How Do We Measure and Monitor The"state of Our ChildrenBENITO LUIS SOVERO SOTONo ratings yet

- ONLINE20042111 MoDocument16 pagesONLINE20042111 MoPhương HoàngNo ratings yet

- Extra Counting ProblemsDocument25 pagesExtra Counting ProblemsWilson ZhangNo ratings yet