Professional Documents

Culture Documents

Works His Clients For Just 30 Minutes

Uploaded by

Lee ChorneyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Works His Clients For Just 30 Minutes

Uploaded by

Lee ChorneyCopyright:

Available Formats

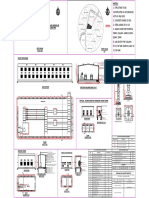

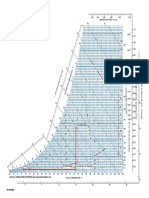

REVISIONS

# DATE DESCRIPTION

YS YA

01 DI PIC

What is a hotch? We provide an overfill alarm panel

that can be mounted in the fill box or mounted on the

AI

NorthPoint Parcel N

TANK FULL exterior wall. The overfill alarm includes all the items Residential Tower

(LT-04.01) shown in this cloud. It has an audible signal and a

OVER FLOW Cambridge, MA

light that will activate when the tank is 90% full. It

also has a test button that the delivery person can Pressure transmitter not

LA PT

press to verify proper operation prior to filling. The required - see lead/lag

alarm can be acknowledged by a push button or it FOS 01 sequence notes below.

DO

will automatically silence after 30 seconds. Note that

this panel requires 120 V power. Coordinate with

electrical.

FOR

BELL OR

OXERFILL

HOTCH

(LSH-04.03)

LA

AMBER

DO LC LSH

PILOT

LIGHT

G DI 01

LC LSH

A

GENERATOR DI 02

DAY TANK

(ON ROOF) (INTEGRAL TO

ACKNOWLEDGE LC LSL GENERATOR)

DI 01

HS YY

04.01 DI

LC LSL

DI 02

YS

04

FC ENABLE

FC

HOA

VENT DO DO RUPTURE VESSEL

OUTPUT

MOUNTED MIN. 12' TO MOTOR

ABOVE GROUND MOTOR STARTER

FC ISL

DI 01 YA

RELIEF DI

YS YA

03 DI

FILL

FOP

1,2

FOS

YS YA

R

05 DI

LA LSH

LT LI

DI 03 FC CONTAINMENT BASIN Everything in this cloud is part of the packaged fuel-oil pump set. The

01 AI control panel is not shown and is a key component for the fuel system. It

DO controls the pump set but also interfaces with the generator day/belly tank.

The day tank provides a start/stop signal (LSL-01/LSH-02) for the pump

set. The day tank alarms for low level (LSL-02), high level (LSH-01), and

STORAGE TANK FC ISL leak (YS-04) are all wired to the pump panel which has the associated

(ON 1ST FLOOR) DI 02 alarm contacts. Each alarm has a respective light and will sound the

OUTPUT audible alarm. These alarms can be relayed to the BMS via a dry contact

TO HOA

MOTOR

common alarm or via dry contact dedicated individual alarms. Similarly, the

LA I assume this is the tank monitoring pump panel also picks up containment pipe leak alarm(s) (YS-03) and the

LSL MOTOR

ENABLE panel. This panel interfaces with the tank day tank overflow alarm (YS-01) and relays them to the BMS in the same

03 STARTER

DI level probe, tank leak sensor and overfill fashion. Note that the pump set requires 460/480 V power. Coordinate

YA YS alarm near the fill point. Note this panel with electrical.

requires dedicated 120 V power,

DI 02 separate from the pump control panel to

LI U ELECTRONIC LEVER GAGE

avoid inteference. Also note this panel

FC AO 04.01 MOUNT ON WALL

requires a triple ground. Coordinate with

electrical.

CONTAINMENT BASIN DO

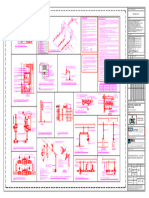

A. FUEL OIL SYSTEM CONTROL

1. GENERAL

a. THIS SEQUENCE APPLIES TO THE FUEL OIL SYSTEMS INSTALLED FOR THE 7. CONTAINNENT PIPING ALARMS

4. DAY TANK ALARMS AND SAFETIES

EMERGENCY GENERATORS.

a. LOW LEVEL SWITCH LSL-02 SHALL GENERATE A LOW DAY TANK LEVEL ALARM. a. LEAK DETECTION SHALL BE PLACED AT ALL LOW POINTS IN THE FOS AND OVERFLOW

b. ALL SYSTEMS SHALL BE OPERATIONAL AT ALL TIMES.

DELAY -- NONE. CONTAINMENT PIPING, THE MINIMUM QUANTITY IS SHOWN ON THIS SCHEMATIC.

c. ALL SYSTEMS SHALL BE CONNECTED TO EMERGENCY POWER.

b. HIGH LEVEL SWITCH LSH-01 SHALL CAUSE THE SHUT DOWN OF THE PUMP(S). b. IF A LEAK DETECTOR IN THE CONTAINMENT PIPING (YS-03) SENSES OIL, AN ALARM

d. ALL POWER AND CONTROL WIRING SHALL BE MINERAL INSULATED (MI) CABLE ADDITIONALLY A HIGH DAY TANK LEVEL ALARM SHALL BE GENERATED.

PER DIVISION 16000. SHALL BE GENERATED. DELAY -- NONE.

8. EMERGENCY FUEL OIL PUMP SHUTDOWN

The lead/lag pump sequence is handled within the pump set c. LEAK DETECTOR YS-04 SHALL CAUSE THE SHUTDOWN OF THE PUMP(S).

If an EPO switch is required, it would be furnished,

2. DAY TANK LEVEL CONTROL control panel. The pump set is equipped with a flow switch that THE OIL IN RUPTURE VESSEL ALARM SHALL BE installed and wired by others. Our pump control panel is

will bring on the lag pump if no flow is sensed. It is not activated GENERATED. DELAY -- NONE. a. PROVIDE ON THE ROOF LEVEL AT THE TOP OF STAIR NO.2, A FIRE DEPARTMENTS FUEL

set up for this switch to be wired to it for pump shutdown.

a. LOW LEVEL SWITCH LSL-01 SHALL CAUSE THE LEAD PUMP TO START. by pressure and no pressure transmitter is required. Similarly, OIL PUMP SHUTDOWN SWITCH UNDER BREAKEABLE GLASS.

IF, AFTER A 30 SECOND DELAY, A PRESSURE OF AT LEAST 15 there is no current sensor. The control panel is equipped with an d. UPON THE PRESENCE OF OIL IN THE OVERFLOW LINE, AS SENSED BY SWITCH YS-01,

PSIG IS NOT SENSED AT PT-01, THE LAG PUMP SHALL START. adjustable time delay that we typically set to 45 seconds to allow AN ALARM SHALL BE GENERATED. DELAY -- NONE.

time for flow to be established. When the there is a pump fail

b. HIGH LEVEL SWITCH LSH-02 SHALL CAUSE THE PUMP(S) TO SHUT DOWN. alarm, the control panel has an audible signal and light. e. MANUFACTURER TO FURNISH SWITCH TRANSMITTERS.

Furthermore, the panel can relay via dry contacts both a pump fail

alarm and a common alarm to the BMS.

5. MAIN TANK ALARMS

c. THE CONTROL SYSTEM SHALL ALTERNATE THE LEAD/LAG POSITION OF THE PUMPS AFTER

This is redundant. The level transmitter LT-01 (aka the level probe) has the capability of reading

EACH CYCLE. To be clear, the pumps set control panel is equipped with an alternator. The a. IF THE TANK LEVEL CAUSES HIGH LEVEL SWITCH LSH-03 TO ENGAGE, A MAIN TANK

and transmitting tank volume, critical high 95%, high level 90% (which activates the overfill alarm

alternation of the pumps is handled internally, not by an outside signal from ATC. OVERFILL ALARM SHALL BE GENERATED. THE ALARM SHALL CAUSE THE BELL AND A

in the fill box), and low level (adjustable but we recommend 50%). So LSH-03 and LSL-03

3. MAIN TANK MONITORING FLASHING STROBE TO INITIATE. THIS ALARM MUST BE ACKNOWLEDGED VIA A KEYED

would be redundant unless you really want supplementary alarms. Note that that all the above

SWITCH (HS-01). listed alarms, as well as the interstitial tank leak alarm YS-02, are initiated at the tank monitoring

a. LEVEL TRANSMITTER LT-01 SHALL PROVIDE SIGNALLING TO THE BAS RELATING THE panel and can be relayed to the BMS, either as a dry contact common alarm or dry contact

TANK LEVEL. THE BAS SHALL PROVIDE INDICATION, IN GALLONS AND PERCENTAGE FULL b. LOW LEVEL SWITCH LSL-03 SHALL GENERATE AN ALARM IF THE TANK LEVEL DROPS individual dedicated alarms. The tank monitoring panel has an audible signal and a digital

OF THE TANK LEVEL STATUS. TO 20% CAPACITY. readout display for all alarms. The audible signal is silenced by pressing a button on the panel.

We provide this arrangement in lieu of a keyed switch and remote strobe. If the keyed switch

b. WHEN THE TANK LEVEL, AS SENSED BY LT-01, IS AT 30% OF FULL CAPACITY, THE c. LEAK DETECTOR YS-02 SHALL GENERATE AN ALARM IF OIL IS SENSED IN THE and remote strobe are required, it should be indicated that these items would be furnished,

BAS SHALL GENERATE A MESSAGE AT THE COMPUTER WORKSTATION INDICATING THE CONTAINMENT BASIN. installed and wired by the ATC contractor.

FOLLOWING:

6. PUMP ALARMS

"GENERATOR MAIN FUEL TANK REQUIRES FILLING"

a. PUMP FAILURE ALARM SHALL BE GENERATED IF AFTER A 15 SECOND DELAY AFTER

c. WHEN THE TANK IS BEING FILLED, AS DETERMINED BY A LEVEL INCREASE AS BEING COMMANDED TO RUN, A PUMP'S LOW CURRENT SWITCH (ISL) DOES NOT INDICATE

This should be "90%"

TRANSMITED TO THE BAS BY LT-01, AND THE TANK REACHES 98% CAPACITY, A CURRENT FLOW OR IF PRESSURE TRANSMITTER PT-01 DOES NOT INDICATE AT

BELL SHALL BE SOUNDED TO ALERT THE SERVICE PERSONNEL TO STOP FILLING THE LEAST 15 PSIG

TANK. THE BAS SHALL HAVE AN INTEGRAL TIMER TO AUTOMATICALLY STOP THE BELL

AFTER 30 SECONDS.

FUEL OIL SYSTEM CONTROL

NOT TO SCALE

MECHANICAL

3/25/2013 7:28:56 AM

CONTROLS 11

SCALE PROJECT # DATE ISSUED

N.T.S. 211108.00 03.27.13

M-511

You might also like

- Ec2-02a Second Floor Auxiliary LayoutDocument1 pageEc2-02a Second Floor Auxiliary LayoutSEDFREY DELA CRUZNo ratings yet

- Ea-000001.0002.0000 (Proposal-01)Document1 pageEa-000001.0002.0000 (Proposal-01)Noufal AsifNo ratings yet

- M-TRAMO I - Mod Editado perfil-DG-5Document1 pageM-TRAMO I - Mod Editado perfil-DG-5Xioxmi HilarioNo ratings yet

- 093 2018 0702 WBK JV TPPD F100Document1 page093 2018 0702 WBK JV TPPD F100陈耀No ratings yet

- 18 Ocs General Assemblies OverlapDocument36 pages18 Ocs General Assemblies OverlapMounikaNo ratings yet

- PVI 6000 TL OUTD W Quick Installation Guide en RevADocument2 pagesPVI 6000 TL OUTD W Quick Installation Guide en RevA王伯恩No ratings yet

- Interlock Tile Phase 1 & 2Document1 pageInterlock Tile Phase 1 & 2amnaakmal070No ratings yet

- Refer To The Attached Comment's Sheet: Key PlanDocument1 pageRefer To The Attached Comment's Sheet: Key PlanSyed Munawar AliNo ratings yet

- Industrial Area: Administration BuildingDocument1 pageIndustrial Area: Administration BuildingAnas TawfiqNo ratings yet

- Incremental A1 - Erf 873-743 231 - 65-CombinedDocument50 pagesIncremental A1 - Erf 873-743 231 - 65-Combinedbuildingplans2008No ratings yet

- Plumbing SignedcombinedDocument10 pagesPlumbing SignedcombinedAsg DeraNo ratings yet

- Gedung 2 LT 1Document1 pageGedung 2 LT 1Rifani DewiNo ratings yet

- Sample 2Document1 pageSample 2Md SuruzzamanNo ratings yet

- 03 150000 4200000005 Ace Mec DRG 005204 - 02Document1 page03 150000 4200000005 Ace Mec DRG 005204 - 02Anas TawfiqNo ratings yet

- 01 01 2021 03-00-01 Pl01 Partition Layout - First Floor Rev ADocument1 page01 01 2021 03-00-01 Pl01 Partition Layout - First Floor Rev AcambacoismaelNo ratings yet

- EXCAVATION Shop DrawingsDocument5 pagesEXCAVATION Shop Drawingsko.sudan.esportsNo ratings yet

- 818 MAS DTD PLN THEATRE L2-indCDocument1 page818 MAS DTD PLN THEATRE L2-indCYaseer BhattiNo ratings yet

- SKEMA - TV - LG - 21FU3RL - Pdffilename - UTF-8SKEMA-20TV-20LG-2021FU3RLDocument1 pageSKEMA - TV - LG - 21FU3RL - Pdffilename - UTF-8SKEMA-20TV-20LG-2021FU3RLyusrianto Nusamaine windewani100% (2)

- g214599 Hmod 65 Paulander DR Kitchener DWGDocument2 pagesg214599 Hmod 65 Paulander DR Kitchener DWGJhonn StevNo ratings yet

- DrawingDocument9 pagesDrawingschaktenNo ratings yet

- Index Map: Lopez BayDocument1 pageIndex Map: Lopez BayPAUL PASTRANANo ratings yet

- PID 01 Rev 00 - PI-diag Tekerhat EME 190718Document1 pagePID 01 Rev 00 - PI-diag Tekerhat EME 190718Jay RabaneraNo ratings yet

- Ca-1231366 0007 0002Document1 pageCa-1231366 0007 0002Erfan KhanNo ratings yet

- Equipments Foundation Layout: Geographic North 22.377° Prevaling Summer Wind S/WDocument1 pageEquipments Foundation Layout: Geographic North 22.377° Prevaling Summer Wind S/Wtitir bagchiNo ratings yet

- Front Elevation: Department of Architecture, CHDDocument7 pagesFront Elevation: Department of Architecture, CHDSunil Tandan100% (1)

- Zahra Saadiya Putri Sda4t Hvac-Evakuasi-Sprikler-Fire-HydrantDocument45 pagesZahra Saadiya Putri Sda4t Hvac-Evakuasi-Sprikler-Fire-HydrantZahra S PNo ratings yet

- DRP001-OUF-GAL-940090-K-ERC-002-001-S1 - SignedDocument1 pageDRP001-OUF-GAL-940090-K-ERC-002-001-S1 - SignedpathanNo ratings yet

- P1 ReeDocument1 pageP1 ReeHUGO VARGAS LIJERONNo ratings yet

- Ec1-02a Second Floor Fdas LayoutDocument1 pageEc1-02a Second Floor Fdas LayoutSEDFREY DELA CRUZNo ratings yet

- Camana: Cuadro de MetradosDocument1 pageCamana: Cuadro de MetradosJohann Nick Flores AparicioNo ratings yet

- Sa128563 0002 0004Document1 pageSa128563 0002 0004Gavriel NgNo ratings yet

- Asbuilt Drawing Sample 2 - CompressedDocument13 pagesAsbuilt Drawing Sample 2 - CompressedRudi IrawanNo ratings yet

- Platform ADocument1 pagePlatform ACosmescu AnaNo ratings yet

- G216338-Hmod-Near 80 Black Walnut Dr-Kitchener-DwgDocument5 pagesG216338-Hmod-Near 80 Black Walnut Dr-Kitchener-DwgJhonn StevNo ratings yet

- A2-123 Level 62 and Level 63 Floor PlanDocument1 pageA2-123 Level 62 and Level 63 Floor PlanRyan BacalaNo ratings yet

- PB02-HRH-001 Hot Reheat Steam System: HoldsDocument1 pagePB02-HRH-001 Hot Reheat Steam System: HoldszhangNo ratings yet

- Ad-90.0-E-02108-Pdf Small Power Layout Ls&admin BLDNGDocument1 pageAd-90.0-E-02108-Pdf Small Power Layout Ls&admin BLDNGmcaslamNo ratings yet

- Maintenance Hangar: DepartureDocument2 pagesMaintenance Hangar: DepartureJoshua RegilmeNo ratings yet

- Tower 1B - Ground Floor PlanDocument1 pageTower 1B - Ground Floor PlanHimanshu KathuriaNo ratings yet

- Working Drawings: Key PlanDocument1 pageWorking Drawings: Key PlanSharanyaNo ratings yet

- 1.plan-Meghana Aac Blocks Industry-14082020Document1 page1.plan-Meghana Aac Blocks Industry-14082020technopreneurvizagNo ratings yet

- HV Compression Connectors: SYS SYT YcakaDocument1 pageHV Compression Connectors: SYS SYT YcakaGERARDONo ratings yet

- Produced by An Autodesk Student Version: Existing Repair & Maruti PointDocument1 pageProduced by An Autodesk Student Version: Existing Repair & Maruti PointAvinash SharmaNo ratings yet

- Nep SD BW 217 23 002Document1 pageNep SD BW 217 23 002مصطفى خضرNo ratings yet

- Ea-0685780.0000.0 1Document1 pageEa-0685780.0000.0 1vs6jghbngzNo ratings yet

- 818 MAS DTD PLN ARCHIVES L-1-indCDocument1 page818 MAS DTD PLN ARCHIVES L-1-indCYaseer BhattiNo ratings yet

- Roof Hvac Power and Cable Tray Layout (Part 1 of 4)Document1 pageRoof Hvac Power and Cable Tray Layout (Part 1 of 4)iunitedfactorysaNo ratings yet

- SCR 004934Document1 pageSCR 004934jeplgpbmcNo ratings yet

- Legend: Mark SpecificationDocument1 pageLegend: Mark SpecificationmccoytingosiaNo ratings yet

- Atcp Tvi 9F 03Document1 pageAtcp Tvi 9F 03Kenneth Dela CruzNo ratings yet

- FF-01 - Standard DetailsDocument1 pageFF-01 - Standard DetailsMubasshir AhmedNo ratings yet

- Bidp SDH 2022 Ar 119 DtcotDocument1 pageBidp SDH 2022 Ar 119 DtcotJeffNo ratings yet

- Typical Section: RevisionsDocument1 pageTypical Section: Revisionsno481630No ratings yet

- A10 A Pid Va 718577 203Document1 pageA10 A Pid Va 718577 203zhangNo ratings yet

- MANDE - SUBMISSION - OZAR - FINAL DRAWWING 29.06.2022-ModelDocument1 pageMANDE - SUBMISSION - OZAR - FINAL DRAWWING 29.06.2022-Modelsiddhivinayaksankul34No ratings yet

- Utility Mechanical Room Scada Room: - R KA 356289 01 - NA422Document1 pageUtility Mechanical Room Scada Room: - R KA 356289 01 - NA422John Philip BuntalesNo ratings yet

- 07-Rajasthani Ghat KDocument1 page07-Rajasthani Ghat KVinod Kumar GaurNo ratings yet

- ST02 - FOUNDATION-Layout1Document1 pageST02 - FOUNDATION-Layout1Fazil RizhafNo ratings yet

- Revisions: Research in MotionDocument2 pagesRevisions: Research in MotionAshardgsm kroyaNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- Ex-Texas Cop Charged For Shooting Teen Eating HamburgerDocument11 pagesEx-Texas Cop Charged For Shooting Teen Eating HamburgerLee ChorneyNo ratings yet

- Cuomo Impeachment Investigation Head Wa... Percussions - After Senior Aide - S TweetDocument6 pagesCuomo Impeachment Investigation Head Wa... Percussions - After Senior Aide - S TweetLee ChorneyNo ratings yet

- Dramatic Elevator Footage Shows Model Assaulting Boyfriend Moments Before His Murder (Update)Document10 pagesDramatic Elevator Footage Shows Model Assaulting Boyfriend Moments Before His Murder (Update)Lee ChorneyNo ratings yet

- Britney Spears Poses Topless in Daisy Dukes For New Instagram PicDocument6 pagesBritney Spears Poses Topless in Daisy Dukes For New Instagram PicLee ChorneyNo ratings yet

- Hawkeye' Spoilers Say Fan-Favorite Marvel Villain Is Coming To The MCUDocument5 pagesHawkeye' Spoilers Say Fan-Favorite Marvel Villain Is Coming To The MCULee ChorneyNo ratings yet

- 8 CENM-HV-F1: Certified Performance DataDocument10 pages8 CENM-HV-F1: Certified Performance DataLee ChorneyNo ratings yet

- Flexmaster U.S.A.® 4NI: Submittal DataDocument1 pageFlexmaster U.S.A.® 4NI: Submittal DataLee ChorneyNo ratings yet

- Riello RTC Data Sheet Rev4Document8 pagesRiello RTC Data Sheet Rev4Lee ChorneyNo ratings yet

- 101 83 - DE - 4300 - 4380 - withIVSDrive - Quick - Installation - GuideDocument4 pages101 83 - DE - 4300 - 4380 - withIVSDrive - Quick - Installation - GuideLee ChorneyNo ratings yet

- State Point & Process Report: Psychrometric Chart Psychrometric ChartDocument1 pageState Point & Process Report: Psychrometric Chart Psychrometric ChartLee ChorneyNo ratings yet

- FL TZDocument1 pageFL TZLee ChorneyNo ratings yet

- 235-Custom Air Handling Unit Submittal (For Record) - Record Purpose Shop Drawings - 2017-02-03-115802 PDFDocument173 pages235-Custom Air Handling Unit Submittal (For Record) - Record Purpose Shop Drawings - 2017-02-03-115802 PDFLee ChorneyNo ratings yet

- 4/6/19, 7@15 PM Page 1 of 4Document4 pages4/6/19, 7@15 PM Page 1 of 4Lee ChorneyNo ratings yet

- Why This Trainer Works His Clients For Just 30 MinutesDocument10 pagesWhy This Trainer Works His Clients For Just 30 MinutesLee ChorneyNo ratings yet

- Salma Hayek, 53, Posts Revealing Photo To Celebrate Reaching 12 Million Instagram FollowersDocument8 pagesSalma Hayek, 53, Posts Revealing Photo To Celebrate Reaching 12 Million Instagram FollowersLee ChorneyNo ratings yet

- Premier-24 - Installation ManualDocument92 pagesPremier-24 - Installation ManualathmaneNo ratings yet

- List of IEC StandardsDocument9 pagesList of IEC StandardsWira Adi Putra INo ratings yet

- Add. No 1 For Subsection 11 4 1 - Downlight Type Led LuminairesDocument7 pagesAdd. No 1 For Subsection 11 4 1 - Downlight Type Led LuminairesEvon ChayNo ratings yet

- Lakki College Pkg-3 (Adm & Support Staff)Document16 pagesLakki College Pkg-3 (Adm & Support Staff)Farhan AshrafNo ratings yet

- Aw HT 0031-0071Document54 pagesAw HT 0031-0071Chris CowapNo ratings yet

- Section-9-Control - Relay Panels - LTAC PanelDocument80 pagesSection-9-Control - Relay Panels - LTAC Panelthumula.rameshNo ratings yet

- Sabah ScheduleDocument12 pagesSabah ScheduleLee RoNo ratings yet

- ATEX Du 496-185888Document14 pagesATEX Du 496-185888Bright OkunkpolorNo ratings yet

- Uputstvo Invertor ZVF9VDocument87 pagesUputstvo Invertor ZVF9VAliRouyouNo ratings yet

- Netsure 731 A41 插框电源系统 Netsure 731 A41 Subrack Power System User ManualDocument44 pagesNetsure 731 A41 插框电源系统 Netsure 731 A41 Subrack Power System User ManualsunnguyenNo ratings yet

- Skoda Octavia Mk1 - 07 - Vehicle ElectricsDocument35 pagesSkoda Octavia Mk1 - 07 - Vehicle ElectricsTamás Alföldi67% (3)

- Serie E Ford Wiring DiagramsDocument28 pagesSerie E Ford Wiring DiagramsSantiago Urgiles75% (4)

- LightSYS Manual Instalador - ENDocument232 pagesLightSYS Manual Instalador - ENarturolectura76No ratings yet

- DEF STAN 61-12 Part 4Document32 pagesDEF STAN 61-12 Part 4YASHASHWYNo ratings yet

- Re95203 2007-11 PDFDocument20 pagesRe95203 2007-11 PDFrenatNo ratings yet

- UntitledDocument202 pagesUntitledOngwae Mathew TeyaNo ratings yet

- Safety Precaution: General InformationDocument27 pagesSafety Precaution: General InformationPaulo Gomes de SouzaNo ratings yet

- 05 Article 810 Download PDFDocument21 pages05 Article 810 Download PDFdarwin gualotoNo ratings yet

- Getjobid 2239460Document51 pagesGetjobid 2239460Muhammad NabeelNo ratings yet

- JKR Malaysia - Street Lighting RequirmentDocument54 pagesJKR Malaysia - Street Lighting RequirmentMuhd Najeli76% (29)

- TK 7102H (Sup)Document25 pagesTK 7102H (Sup)Julio Cesar QuintelaNo ratings yet

- CIAT Coadis - Line - 900 KASETADocument17 pagesCIAT Coadis - Line - 900 KASETAIgor SpasovicNo ratings yet

- Cf-m34 Service ManualDocument266 pagesCf-m34 Service ManualMichael HaisleyNo ratings yet

- Manual CP500Document107 pagesManual CP500javier_cimNo ratings yet

- ECL-ACC980 ManualDocument4 pagesECL-ACC980 ManualAneal LiverpoolNo ratings yet

- Electricity Suppliers: These Exemptions Do Not Apply To The Installation of non-MEC Metering EquipmentDocument5 pagesElectricity Suppliers: These Exemptions Do Not Apply To The Installation of non-MEC Metering EquipmentwarrenronaldNo ratings yet

- VIP5: Lubrication System Controller: Quickstart Guide User Operating and Maintenance Manual Warranty InformationDocument29 pagesVIP5: Lubrication System Controller: Quickstart Guide User Operating and Maintenance Manual Warranty Informationjorge eduardoNo ratings yet

- Fbs-Plc User'S Manual【Hardware】Document67 pagesFbs-Plc User'S Manual【Hardware】Igal GalilNo ratings yet

- bs1363 PDFDocument3 pagesbs1363 PDFMuhammed Talha QureshiNo ratings yet

- Updates On RTCA DO-160 Lightning TestDocument21 pagesUpdates On RTCA DO-160 Lightning TestosmyavNo ratings yet