Professional Documents

Culture Documents

Handbook - Welding Techniques

Uploaded by

Faizaan MirzaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Handbook - Welding Techniques

Uploaded by

Faizaan MirzaCopyright:

Available Formats

Variations-

Metal

Transfer

DEPOSITION RATE

Equipment

The deposition rate describes how much usable weld metal will be deposited in one hour of actual arc-on

time. Because the mig process is very efficient, only a very small amount of weld metal is lost as spatter.

Power The deposition rate for any wire is calculated by the equation:

Supply

(m/min)

deposition rate(lbs./hr.) = wire feed speed (in./min.) x 60 min./hr.

Shielding

Gases (kg/hr) inches of wire per lb.

(m/kg)

Wire

Electrodes

WIRE

DIAMETER .030 IN .035 IN .045 IN 3/64 IN 1/16IN 3/32 IN

Safety

MATERIAL (.76 mm) (.89mm) (1.14 mm) (1.18 mm) (1.58 mm) (2.38 mm)

Effects MILD STEEL 4956 IN 3648 IN 2196 IN -- 1152 IN 516 IN

Welding (276.9) (203.9) (122.7) (64.4) (28.8)

Techniques Weld Bead

Characteristics

STA I N LESS 4872 3588 2160 -- 1140 504

Torch Position

Welding STE EL (272.2) (200.5) (120.7) (63.7) (28.2)

Conditions (3XX SERIES)

ALUMINUM 14412 10596 -- 6408 3372 1500

Economics (805.3) (592.1 ) (358.1 ) (188.4) (83.8)

COPP ER 4356 3192 1932 -- 1020 432

Weld (243.4 ) (1 78.4) (108.0) -- (57.0) (24.1 )

Defects

SI L I CON 4596 3372 2040 -- 1068 480

BRONZE (256.8) (188.4) (114.0) -- (59.7) (26.8)

Mig Spot

Welding

10

Tables

You might also like

- Product Data Sheet: Afrox SpeedcraftDocument2 pagesProduct Data Sheet: Afrox SpeedcraftAdel AbduoNo ratings yet

- Hoffman Specialty: Series TD6420 Thermodisc Steam TrapsDocument2 pagesHoffman Specialty: Series TD6420 Thermodisc Steam TrapsnvmohankumarNo ratings yet

- A2 Multitrac welding tractor for SAW & GMAWDocument1 pageA2 Multitrac welding tractor for SAW & GMAWcarlosNo ratings yet

- Tonnage - Copy 2Document4 pagesTonnage - Copy 2ankit81164No ratings yet

- OKFlux 1062Document1 pageOKFlux 1062jpvtvNo ratings yet

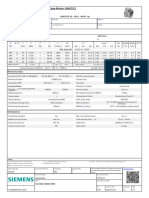

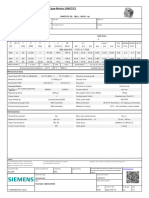

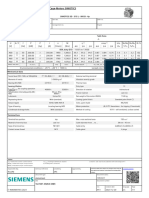

- 1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enDocument2 pages1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enranjithNo ratings yet

- Superarc L-59: Conformances Key FeaturesDocument2 pagesSuperarc L-59: Conformances Key FeaturesjustinNo ratings yet

- Atom Arc 8018Document2 pagesAtom Arc 8018Jagan TnNo ratings yet

- Innershield NS-3M: Welding Positions Key FeaturesDocument2 pagesInnershield NS-3M: Welding Positions Key FeaturesGiancarlo BlandinoNo ratings yet

- Codeline Ecoline Drawing 80-450 Rev Q Total PDFDocument2 pagesCodeline Ecoline Drawing 80-450 Rev Q Total PDFHardik VavdiyaNo ratings yet

- 1LE1601 2DC03 4AB4 Z L51 Datasheet enDocument2 pages1LE1601 2DC03 4AB4 Z L51 Datasheet enFaziNo ratings yet

- Esab, Ok 309L (29.12.16)Document1 pageEsab, Ok 309L (29.12.16)RodrigoNo ratings yet

- Lincoln, TECHALLOY® 606 (c14107)Document2 pagesLincoln, TECHALLOY® 606 (c14107)RodrigoNo ratings yet

- Datasheet-Sandvik-23-12-2-Lr-En-V2018-06-13 16 - 33 Version 1Document3 pagesDatasheet-Sandvik-23-12-2-Lr-En-V2018-06-13 16 - 33 Version 1Filipe CordeiroNo ratings yet

- SANDVIK 23.12.2.LR Covered Electrodes: DatasheetDocument3 pagesSANDVIK 23.12.2.LR Covered Electrodes: DatasheetFilipe CordeiroNo ratings yet

- TPT 20221220a Rev.1Document5 pagesTPT 20221220a Rev.1Kaajma EngineeringNo ratings yet

- 278 en US FactSheet Main 01Document1 page278 en US FactSheet Main 01Jorge Manuel GuillermoNo ratings yet

- Diamondspark Pipeline Cored Wires: FCAW and MCAW Seamless Welding Wires For Pipeline ApplicationsDocument2 pagesDiamondspark Pipeline Cored Wires: FCAW and MCAW Seamless Welding Wires For Pipeline ApplicationsRMNo ratings yet

- Esab E7018-1-H4r Ebds1-Ok 55Document2 pagesEsab E7018-1-H4r Ebds1-Ok 55PubcrawlNo ratings yet

- Equipment PriceDocument2 pagesEquipment Pricemajid aziziNo ratings yet

- Pamphlet TG-X SeriesDocument2 pagesPamphlet TG-X SeriesrajeshNo ratings yet

- 1le5584 3aa03 4ab4Document2 pages1le5584 3aa03 4ab4Dharmesh ChanawalaNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-14 Beam Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-14 Beam Section DesignkennysawegNo ratings yet

- sdd2000 Service Manual PDFDocument27 pagessdd2000 Service Manual PDFSaverioCorNo ratings yet

- Extra High Strength Structural Plate Data SheetDocument2 pagesExtra High Strength Structural Plate Data SheetStefano BarbieriNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE5633-3AB73-4FB0-Z Safe AreaDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE5633-3AB73-4FB0-Z Safe AreaSamir SabicNo ratings yet

- ETABS 2016 Shear Wall Design: ETABS 2016 16.2.1 License # 1AUN6BX3X4K2DLDDocument1 pageETABS 2016 Shear Wall Design: ETABS 2016 16.2.1 License # 1AUN6BX3X4K2DLDFabi DearmasNo ratings yet

- 1le1502 2BB03 4aa4Document3 pages1le1502 2BB03 4aa4Atlanta Bolivia100% (1)

- 1LE1523-1EB43-4AA4 Datasheet enDocument1 page1LE1523-1EB43-4AA4 Datasheet enmuhammad nazmiNo ratings yet

- Mechanical Properties ZA-8 ZA-27: Respectively. ZAPDocument1 pageMechanical Properties ZA-8 ZA-27: Respectively. ZAPs_padu3003@yahoo.comNo ratings yet

- EV Woofer Data SummaryDocument1 pageEV Woofer Data SummaryRafRouf SehiliNo ratings yet

- 1LE1503-1EA23-4AB4 Datasheet enDocument1 page1LE1503-1EA23-4AB4 Datasheet enpatilshailesh123No ratings yet

- 1LE1501 2DA03 4AA4 Datasheet enDocument1 page1LE1501 2DA03 4AA4 Datasheet enGismart 11No ratings yet

- 1LE1503-1DB43-4FK4_datasheet_enDocument1 page1LE1503-1DB43-4FK4_datasheet_enNicolas RossettoNo ratings yet

- XHD Durt Tracker - BastidorDocument4 pagesXHD Durt Tracker - BastidorCarlos BolvaranNo ratings yet

- Bar Bending Machine gw42d 4Document4 pagesBar Bending Machine gw42d 4Christopher SleimanNo ratings yet

- Flux Cored - Welding Wire - E71T-1Document1 pageFlux Cored - Welding Wire - E71T-1Hafiz HidayaturrakhmanNo ratings yet

- Etals Nternational Imited: Table 8.2Document2 pagesEtals Nternational Imited: Table 8.2SSMNo ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- EGW Welding Wire Guide for 490MPa SteelDocument2 pagesEGW Welding Wire Guide for 490MPa SteelpratishgnairNo ratings yet

- Fisa Tehnica Pentur Cablu Anti Incendiu JHSTH-2x2x0.8x500MDocument2 pagesFisa Tehnica Pentur Cablu Anti Incendiu JHSTH-2x2x0.8x500MSava SergiuNo ratings yet

- Rs 400 M Brosura SRBDocument1 pageRs 400 M Brosura SRBRatkoNo ratings yet

- W Section 1 Mma Welding Saf Fro General Catalogue68475045296859596Document8 pagesW Section 1 Mma Welding Saf Fro General Catalogue68475045296859596sarahrouNo ratings yet

- Comparision of Three & Four Tandem Wire SystemDocument15 pagesComparision of Three & Four Tandem Wire SystemKumawat PrakashNo ratings yet

- 1LE1503-2BB03-4AA4 Datasheet enDocument1 page1LE1503-2BB03-4AA4 Datasheet enAnil Kumar KnNo ratings yet

- 1le5533 3ab63 4ab3Document2 pages1le5533 3ab63 4ab3Whipman ArduinoNo ratings yet

- Tapcon Technical DataDocument5 pagesTapcon Technical DataAndreaParraNo ratings yet

- 1LE1503-1EB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1EB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- 1le1523 1eb43 4ab4Document2 pages1le1523 1eb43 4ab4pmf engineering limitedNo ratings yet

- h2066-HASTELLOY C-22 Welding DataDocument4 pagesh2066-HASTELLOY C-22 Welding DataGovindarajalu PadmanabhanNo ratings yet

- Dyadic Mechatronics Cylinder CatalogDocument16 pagesDyadic Mechatronics Cylinder CatalogJuan Francisco Sanchez MassadiNo ratings yet

- 1le1523 1eb43 4FB4Document2 pages1le1523 1eb43 4FB4pmf engineering limitedNo ratings yet

- Hoja Tecnica - G5+Document3 pagesHoja Tecnica - G5+fabians77No ratings yet

- Wearshield 60: Typical Applications Key FeaturesDocument2 pagesWearshield 60: Typical Applications Key FeaturesDieng MessatsuNo ratings yet

- Placas de Anclaje: IPE 160 (En Blanco)Document12 pagesPlacas de Anclaje: IPE 160 (En Blanco)Josu RamonNo ratings yet

- 1LE1501-3AB53-4AB4 Datasheet enDocument1 page1LE1501-3AB53-4AB4 Datasheet enfarid.chira2No ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PSedlynNo ratings yet

- 800 MHZ Antennas (806-869 MHZ) : Fiberglass OmniDocument1 page800 MHZ Antennas (806-869 MHZ) : Fiberglass OmniJuan TiradoNo ratings yet

- REXWAY Rigid Metal Conduit Catalogue (RMC)Document10 pagesREXWAY Rigid Metal Conduit Catalogue (RMC)hashimelecNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Universal Testing Machine Median - Up To 600 KNDocument32 pagesUniversal Testing Machine Median - Up To 600 KNSupriya ManojNo ratings yet

- 10 Book Review Muhammad Haron MuhammadDocument1 page10 Book Review Muhammad Haron MuhammadAbzay FarahNo ratings yet

- File HandlerDocument1 pageFile HandlerFaizaan MirzaNo ratings yet

- MBD Book PDF VersionDocument1 pageMBD Book PDF VersionFaizaan MirzaNo ratings yet

- MBD Book PDF VersionDocument94 pagesMBD Book PDF VersionnknfiveNo ratings yet

- BlueDocument18 pagesBluekarishma nairNo ratings yet

- Single Wall Fuel Tank: FP 2.7 A-C Fire Pump SystemsDocument1 pageSingle Wall Fuel Tank: FP 2.7 A-C Fire Pump Systemsricardo cardosoNo ratings yet

- StandardsDocument3 pagesStandardshappystamps100% (1)

- Chill - Lease NotesDocument19 pagesChill - Lease Notesbellinabarrow100% (4)

- 1LE1503-2AA43-4AA4 Datasheet enDocument1 page1LE1503-2AA43-4AA4 Datasheet enAndrei LupuNo ratings yet

- Quezon City Department of The Building OfficialDocument2 pagesQuezon City Department of The Building OfficialBrightNotes86% (7)

- KDL 23S2000Document82 pagesKDL 23S2000Carlos SeguraNo ratings yet

- Milton Hershey's Sweet StoryDocument10 pagesMilton Hershey's Sweet Storysharlene sandovalNo ratings yet

- AHP for Car SelectionDocument41 pagesAHP for Car SelectionNguyên BùiNo ratings yet

- Logistic Regression to Predict Airline Customer Satisfaction (LRCSDocument20 pagesLogistic Regression to Predict Airline Customer Satisfaction (LRCSJenishNo ratings yet

- 2020-05-14 County Times NewspaperDocument32 pages2020-05-14 County Times NewspaperSouthern Maryland OnlineNo ratings yet

- Mayor Byron Brown's 2019 State of The City SpeechDocument19 pagesMayor Byron Brown's 2019 State of The City SpeechMichael McAndrewNo ratings yet

- Instrumentos de Medición y Herramientas de Precisión Starrett DIAl TEST INDICATOR 196 A1ZDocument24 pagesInstrumentos de Medición y Herramientas de Precisión Starrett DIAl TEST INDICATOR 196 A1Zmicmarley2012No ratings yet

- Nature of ConversionDocument18 pagesNature of ConversionKiranNo ratings yet

- Model:: Powered by CUMMINSDocument4 pagesModel:: Powered by CUMMINSСергейNo ratings yet

- Tyron Butson (Order #37627400)Document74 pagesTyron Butson (Order #37627400)tyron100% (2)

- Analytical DataDocument176 pagesAnalytical DataAsep KusnaliNo ratings yet

- Department of Ece Vjec 1Document29 pagesDepartment of Ece Vjec 1Surangma ParasharNo ratings yet

- 9 QP - SSC - MOCK EXAMDocument5 pages9 QP - SSC - MOCK EXAMramNo ratings yet

- Fabric Bursting StrengthDocument14 pagesFabric Bursting StrengthQaiseriqball100% (5)

- Discretionary Lending Power Updated Sep 2012Document28 pagesDiscretionary Lending Power Updated Sep 2012akranjan888No ratings yet

- Lister LRM & SRM 1-2-3 Manual and Parts List - Lister - Canal WorldDocument4 pagesLister LRM & SRM 1-2-3 Manual and Parts List - Lister - Canal Worldcountry boyNo ratings yet

- Corruption in PakistanDocument15 pagesCorruption in PakistanklutzymeNo ratings yet

- Chapter 1 Qus OnlyDocument28 pagesChapter 1 Qus OnlySaksharNo ratings yet

- Introduction To Elective DesignDocument30 pagesIntroduction To Elective Designabdullah 3mar abou reashaNo ratings yet

- ABBBADocument151 pagesABBBAJeremy MaraveNo ratings yet

- Bob Wright's Declaration of BeingDocument1 pageBob Wright's Declaration of BeingBZ Riger100% (2)

- 2.8 V6 5V (Aha & Atq)Document200 pages2.8 V6 5V (Aha & Atq)Vladimir Socin ShakhbazyanNo ratings yet

- Railway RRB Group D Book PDFDocument368 pagesRailway RRB Group D Book PDFAshish mishraNo ratings yet

- Geneva IntrotoBankDebt172Document66 pagesGeneva IntrotoBankDebt172satishlad1288No ratings yet