Professional Documents

Culture Documents

Aastho 2011 1b Spec 624

Uploaded by

Albertto GuardadoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aastho 2011 1b Spec 624

Uploaded by

Albertto GuardadoCopyright:

Available Formats

Note 2—The definiüons given in Scclions 3.10 and 3.

1 1 apply to Supcrpave mixes only and

dilTer from llie definitions publishcd in other AASHTO standards.

3.12. reclaimedasphalt pavement (RAP)—removed and/or processed pavement malcriáis conlainíng

asphalt binderand aggregate.

3.13. primary control sicvc (PCS)—Ihe sieve defíning the break point belween fine and coarse-graded

mixtures for each nominal máximum aggregate size.

4 ! S U M M A R Y O F T H E PRACTICE

4.1. Materials Seleclion—Binder, aggregale, and RAP stockpiles are selecled that meet llic

environmental and trafile requiremcnls applicable to the paving projcct. The bulk spccifíc gravity

of all aggregates proposed for blcnding and the specific gravity of the binder are determined.

Note 3—[f RAP is uscd, the bulk spccifíc gravity of the RAP aggregate may be estimated by

determining the theoretical máximum specific gravity (Gllim} of llie RAP mixture and using an

assumed asphalt absorption for the RAP aggregate to back-calculate the RAP aggrcgale bulk

specific gravity, if llie absorption can be estimaled wilh confidcncc. The RAP aggregate effective

specific gravity may be used in lieti of Ihe bulk specific gravity at the discretion of the agency. The

use oí"the effective specific gravity may introduce an error inío the combined aggregate bulk

spccifíc gravity and subsequent VMA calculations. The agency may choose to speciíy adjustments

to the VMA rcquircmcnts ío account for Ihis error based on experience with local aggregales.

4.2. Design Aggregate Sin/cutre—II is reeommended thal al least three trial aggregalc blend gradations

from selected aggregate stockpiles are blended. For each trial gradation, an initial trial binder

contení is determined, and at least two spccimens are compacted in accordancc with T 3 12. A

design aggregale structtire and an cstimated design binder contení are selected on the basis of

satisfactory conformance of a trial gradation meeting the requircments given in M 323 for Va,

VMA, VFA, dusl-lo-binder ratio al Micsign, and relative density at /"/¡muñí-

Note 4—Prevíous Supeipave mix design experience with specific aggregate blends may

elimínate the nced for three trial blends.

4.3. Dusign Binder ConteníSelection—Replícate spccimens are compacted in accordance with T 312

al the estimaled design binder contení and at the eslimaled design binder contení ±0.5 percent and

+ 1.0 percent. The design binder contení is selected on Ihe basis of satisfaclory conformance wiíh

the rcquiremenís of M 323 for Vtl, VMA, VFA, and dust-to-binder ratio at Ansien, and the relative

density at Nínítía] and /V max .

4.4. Evaluatíng Moislure Susceptibility—The moisture susceptibilily of the design aggregaíe structtire

is evaluated at the design binder contení: Ihe mixture is conditioned according to the mixture

eondítioning for Ihe volttmelric mixture design proeedure in R 30, compacted to 7.0 ± 0.5 percent

air voids in accordance with T 312, and evaluated aceording to T 2H3. The design shall meet the

tensile strenglh ratio rcquircmcnt of M 323.

sT~ SIGN1FICANCE AND USE

5.1. The proeedure dcscribcd in this standard practicc is used to produce HMA thal satis/les Superpave

HMA volumetric mix design requiremcnts.

TS-2d R 35-3 AASHTO

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Concrete Aggregates: Standard Specification ForDocument11 pagesConcrete Aggregates: Standard Specification ForHarold MantillaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Astm C 143 - 20Document4 pagesAstm C 143 - 20Albertto GuardadoNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Aashto T 217 - 14 (2018)Document5 pagesAashto T 217 - 14 (2018)Albertto GuardadoNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Tomografía Magnética para Evaluar Colocación de Dovelas PDFDocument4 pagesTomografía Magnética para Evaluar Colocación de Dovelas PDFAlbertto GuardadoNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Standard Specification For Aggregate For Masonry MortarDocument3 pagesStandard Specification For Aggregate For Masonry MortarAlbertto GuardadoNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Engineering Geology Maps Landslides and Geographical Information SystemsDocument71 pagesEngineering Geology Maps Landslides and Geographical Information SystemsAlbertto GuardadoNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Aastho 2011 1b Spec 622Document1 pageAastho 2011 1b Spec 622Albertto GuardadoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Engineering Geology SwedenDocument12 pagesEngineering Geology SwedenAlbertto GuardadoNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Electrical Resistivity in Support of Geological Mapping Along The Panama CanalDocument13 pagesElectrical Resistivity in Support of Geological Mapping Along The Panama CanalAlbertto GuardadoNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Disaster Risk Reduction and Resettlement Efforts at San Vicente (Chichontepec) Volcano, El Salvador Toward Understanding Social and Geophysical VulnerabilitytDocument18 pagesDisaster Risk Reduction and Resettlement Efforts at San Vicente (Chichontepec) Volcano, El Salvador Toward Understanding Social and Geophysical VulnerabilitytAlbertto GuardadoNo ratings yet

- Ingenieria Geologica - Gonzalez de VallejoDocument5 pagesIngenieria Geologica - Gonzalez de VallejoAlbertto GuardadoNo ratings yet

- Solved Probs in Hydro R by Eng'r. Ben David PDFDocument46 pagesSolved Probs in Hydro R by Eng'r. Ben David PDFMarkVincentTulinao100% (1)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- GPT Nadu NeduDocument222 pagesGPT Nadu NeduSwarna LathaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Pressure Drop in Horizontal WellDocument16 pagesPressure Drop in Horizontal WellDor SoNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

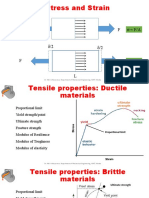

- Stress and Strain: σ = F/A F FDocument11 pagesStress and Strain: σ = F/A F FMd Arifuzzaman ArifNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Observational Methods and NATMDocument39 pagesObservational Methods and NATMKeshav KumarNo ratings yet

- Drilling Out Cement OperationDocument5 pagesDrilling Out Cement OperationmohanadNo ratings yet

- Sac SmaDocument21 pagesSac SmaIwan M SyariefuddinNo ratings yet

- Strap Beam FootingDocument4 pagesStrap Beam Footingrukesh104No ratings yet

- Reinforced Concrete Bridges: 9.2 Materials 9.3 Bridge Types 9.4 Design ConsiderationsDocument18 pagesReinforced Concrete Bridges: 9.2 Materials 9.3 Bridge Types 9.4 Design ConsiderationsalexNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Sedimentation Tank Design: Ce 316: Environmental Engineering Ii S ChakrabortyDocument10 pagesSedimentation Tank Design: Ce 316: Environmental Engineering Ii S ChakrabortyTushar GautamNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Rivets Multi Grip CountersunkDocument1 pageRivets Multi Grip CountersunkIsrael OluwagbemiNo ratings yet

- Composite Girder Design Based On AISC 360-10/16 & 2019 CBC / 2018 IBCDocument2 pagesComposite Girder Design Based On AISC 360-10/16 & 2019 CBC / 2018 IBCridho ziskaNo ratings yet

- Trenton: 20u 40u Stratagraph On Location at 5:00 PM Waiting On Rig To Trip Back To Bottom With Tri-ConeDocument24 pagesTrenton: 20u 40u Stratagraph On Location at 5:00 PM Waiting On Rig To Trip Back To Bottom With Tri-ConeFrancico Javier Ondo BitegueNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- W7-Bashir - Slop StabilityDocument55 pagesW7-Bashir - Slop Stability木辛耳总No ratings yet

- Design of Circular Base Plate Under Large Bending MomentDocument5 pagesDesign of Circular Base Plate Under Large Bending MomentAntonioMonteroNo ratings yet

- Sample Intellibuild EstimateDocument23 pagesSample Intellibuild EstimateRomani Noel S. Chavez Jr.No ratings yet

- 3 Structures Beam CalculationsDocument130 pages3 Structures Beam Calculationsdouglasjames196850% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Fatigue and CreepDocument19 pagesFatigue and CreepkhanNo ratings yet

- Certprepod SfpartnerDocument10 pagesCertprepod SfpartnerDpanraj DSNo ratings yet

- 06 31 Abuso de Anclajes Alberto CuevasDocument11 pages06 31 Abuso de Anclajes Alberto CuevasJOSE LUIS GONZALEZNo ratings yet

- Clotan Steel IBR Brochure DigitalDocument6 pagesClotan Steel IBR Brochure DigitalPieter SteenkampNo ratings yet

- New Infilled FramesDocument44 pagesNew Infilled FramesMohammad SaaduddinNo ratings yet

- BOQ For KIOSKS@Document3 pagesBOQ For KIOSKS@Ashiq NishmaNo ratings yet

- Astm D2899Document6 pagesAstm D2899btwilliNo ratings yet

- 612c (Uas 2019)Document37 pages612c (Uas 2019)jawarta simamoraNo ratings yet

- Construction of A 3 Bedroom BungalowDocument13 pagesConstruction of A 3 Bedroom BungalowElujekwute Benjamin100% (1)

- Composite Beam DesignDocument4 pagesComposite Beam DesignSunil PulikkalNo ratings yet

- Construction Management ReportDocument23 pagesConstruction Management ReportJanmar CordaNo ratings yet

- Neutral Axis Depth Profile of Reinforced Concrete BeamsDocument9 pagesNeutral Axis Depth Profile of Reinforced Concrete Beamsrahmat sahilNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- BD60 - 04 Design of Highway Bridges For Vehicles Collision LoadsDocument19 pagesBD60 - 04 Design of Highway Bridges For Vehicles Collision LoadsTaz Miña100% (1)