Professional Documents

Culture Documents

Austenita Ferita PDF

Uploaded by

neyzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Austenita Ferita PDF

Uploaded by

neyzaCopyright:

Available Formats

Journal of Materials Physics and Chemistry, 2013, Vol. 1, No.

4, 65-68

Available online at http://pubs.sciepub.com/jmpc/1/4/2

© Science and Education Publishing

DOI:10.12691/jmpc-1-4-2

Microstructural Transformations of Dissimilar

Austenite-Ferrite Stainless Steels Welded Joints

Sara Aguilar*, Ramón Tabares, Claudia Serna

Materials Engineering Department, University of Antioquia, Pyrometallurgical and Materials Research Group GIPIMME, Medellín, Colombia

*Corresponding author: saritamaria272@gmail.com

Received October 25, 2013; Revised November 12, 2013; Accepted November 14, 2013

Abstract This research studies the metallurgical transformations happening during the SMAW welding of AISI

316L austenitic stainless steel with AISI 430 ferritic stainless steel. Two different electrodes, AWS E309L austenitic

and AWS E2209-16 duplex stainless steels 3.2 mm diameter, were used to perform the study. The joining was made

with a single pass welding and keeping a low heat input ranging from 700 - 1000 J/mm. The influence of the type of

electrode and the heat input on the microstructural evolution of the heat affected and the fusion zone was evaluated.

Differences between δ ferrite morphology were found for both weld metals. The heat affected zone of the ferritic

side showed grain coarsening and grain refinement with martensite at the grain boundaries. Tensile strength was

similar for both welding conditions. Microhardness and δ ferrite percent were measured as well.

Keywords: stainless steels welding, SMAW, welding metallurgy, austenitic stainless steel, ferritic stainless steel

Cite This Article: Sara Aguilar, Ramón Tabares, and Claudia Serna, “Microstructural Transformations of

Dissimilar Austenite-Ferrite Stainless Steels Welded Joints.” Journal of Materials Physics and Chemistry 1, no. 4

(2013): 65-68. doi: 10.12691/jmpc-1-4-2.

stainless steels weldings using two different electrodes:

austenitic AWS E309L and duplex AWS E2209-16 and

1. Introduction varying the heat input in a low range (0.7-1.0 J/mm).

Stainless steels are used in several applications such as

energy generation systems, heat exchangers and 2. Experimental Procedure

automotive, oil and chemistry industries [1,2]. Austenitic

stainless steels (ASS) have high toughness, low SMAW welding was performed on “V” notched AISI

machinability and the best resistance to scale formation 430 FSS and AISI 316L ASS parent metals with

among the stainless steel family. In addition, ASS have dimensions 200 mm x 100 mm and 4 mm thick. Welding

higher corrosion resistance than martensitic and ferritic was accomplished using two different electrodes (3.2 mm

stainless steels (FSS). In the other hand, FSS have higher diameter): austenitic AWS E309L and duplex AWS

resistance to chloride stress corrosion cracking and E2209-16. The joining was made with a single pass

represent an economic option than ASS [3]. In addition, welding and keeping a low heat input (HI), 0.8-1.0 kJ/mm

FSS have higher thermal conductivity and lower thermal for the austenitic electrode and 0.7-0.8 kJ/mm for the

expansion coefficient than ASS [4]. duplex electrode. The parameters used to control the heat

Some applications require joining ASS and FSS [5], input were current (I), voltage (V) and welding speed (ν)

which has been carefully studied because of the low (see Table 1). Chemistry of the parent metals was

weldability of FSS and the hot corrosion cracking of ASS determined by optical emission spectroscopy (OES).

[3,4,6]. Controlling the solidification and reached Chemistry of the filler material was obtained from the

temperatures during welding becomes critical and provider data sheet (Table 2). The same welder made all

represents an engineering challenge, since many of the welds in flat position.

precipitates present in the austenitic parent metal can be

dissolved during the welding due to the high temperatures Table 1. Heat input welding parameters

reached during the process (near to the solidus ν I V HI HI

Electrode

(mm/s) (A) (V) (J/mm) average

temperature). This generates an oversaturation of the 1.9 50 49.0 1000

austenitic matrix upon cooling, which may lead to the AWS E309L 2.5 52 50.0 842 922 ± 79

formation of precipitates in the heat-affected zone (HAZ). 2.3 52 50.4 924

Such precipitates are mainly chromium carbides and AWS E2205-

2.7 50 48.8 731

chromium nitrides (M23C6 and Cr2N) that can decrease the 2.7 50 48.8 731 754 ± 40

16

2.4 50 48.8 800

corrosion resistance leading to intergranular corrosion [7].

This research studies the microestructural evolution of Microstructure analysis was performed in the welded

dissimilar austenitic (AISI 316L)-ferritic (AISI 430) metals and the heat affected zones (HAZ) of the samples

66 Journal of Materials Physics and Chemistry

in both sides (FSS and ASS). Samples were prepared The microstructure of the fusion zones (FZ) depended

using standard metallographic techniques with a 0.03µm on the composition of the filler metal. Austenitic stainless

alumina final polish. Etching was accomplished using steel weld metal provided a microstructure in the FZ

aqua regia. consisting on an austenitic matrix (white) with skeletal or

Tensile test was performed according to ASTM E8 [8]. vermicular ferrite -dark etching- (Figure 5a), this

Tensile specimens were 2 mm thick. Delta (δ) ferrite microstructure is obtained when weld cooling rates are

measurements were accomplished using a ferritoscope moderate and/or when Creq/Nieq is low but still within

(Fischer MP30E S). Vickers microhardness profiles were the ferrite-austenite (FA) range. The FA solidification

obtained using 500 g load for 15 s. All measurements mode starts with primary ferrite solidification followed by

were performed perpendicular to the welding direction. the formation of austenite along the ferrite cell and the

dendrite boundaries. As the weld metal cools the ferrite

Table 2. Chemistry of parent metals and electrodes becomes increasingly unstable and the austenite begins to

Stainless steel C (%w) Cr (%w) Ni (%w) Si (%w) Mn (%w) consume the ferrite by a diffusion-controlled reaction, [7].

AISI 430 0.030 16.660 0.147 0.491 0.345 The skeletal morphology is a consequence of the advance

AISI 316L 0.011 16.838 9.998 0.558 1.348 of the austenite consuming the ferrite. As the process

E309L 0.030 23.700 13.700 0.800 0.850 proceeds, the ferrite is enriched in ferrite promoting-

E2209-16 0.026 22.800 9.300 0.730 0.680 elements and depleted in austenite promoting elements,

Stainless steel Cu (%w) Ti (%w) Mo (%w) P (%w) N (%w) which makes it stable at lower temperatures where

AISI 430 0.103 0.013 - 0.025 - diffusion is limited.

AISI 316L 0.104 0.011 2.021 0.039 - Duplex stainless steel weld metal solidified as columnar

E309L 0.060 - 0.040 0.030 - ferrite grains perpendicular to the plate surface with fine

E2209-16 0.110 - 3.100 0.020 0.200 acicular austenite at the grain boundaries (Figure 5b).

High Creq/Nieq ratios lead to Type F solidification, i.e.,

ferrite is the only phase that forms directly from the liquid.

3. Results and Discussion Ferrite to austenite transformation subsequently occurs in

the solid state, at temperature between 1300°C and 800 °C.

3.1. Microstructural Characterization In the weld metal, ferritic solidification involves an

epitaxial growth from parent material at the fusion

Figure 1 and Figure 2 show the microstructure profiles

boundary. The epitaxial and competitive nature of ferrite

of the welded joints obtained with austenitic (AWS-

grain growth in duplex stainless steel welds promotes the

E309L) and duplex (AWS-E2209-16) filler metals,

formation of a coarse columnar ferrite grain structure. The

respectively. There was a difference in size of the HAZ on

austenite starts to precipitate at the ferrite grain boundaries

the ferritic side (HAZ-F), which was larger for the

and at the weld metal surface due to higher free energy of

austenitic electrode (~2 mm) than for the duplex electrode

these locations. The morphology of austenite, such as

(~1.5 mm), which may be attributed to the differences in

Widmanstätten side plates or intragranular plates, is

the heat input. In both cases, the HAZ on the austenitic

dependent on the ferrite grain size and cooling rate [7,9].

side (HAZ-A) showed the absence of grain growth, the

presence of equiaxial austenitic grains with twins and

precipitates at the grain boundaries (Figure 3), this

precipitation commonly occurs between 425°C y 800°C

[6,7]. In addition, the fusion boundary (FB) next to the

austenitic parent metal (ABM) has a partially melted zone

with equiaxial austenitic grains and δ ferrite dendrites in

the austenitic grain boundaries (Figure 4).

Figure 3. Heat affected zone on the austenitic side showing precipitates at

the grain boundaries

Figure 1. SMAW welding AISI 316L-AWS E309L-AISI 430

Figure 4. Fusion boundary microstructure a) AISI 316L-AWS E309L y b)

Figure 2. SMAW welding AISI 316L-AWS E2209-16-AISI 430 AISI 316L-AWS E2209-16

Journal of Materials Physics and Chemistry 67

austenitic filler metal because of the differences in thermal

properties.

Figure 5. Microstructure of FZ a) AWS 309L y b) AWS 2209-16

The following microstructural features were the same

for both filler metals: the fusion boundary next to the

ferritic parent metal (FB-F) showed a columnar

solidification growing from the ferrite parent grains

(Figure 6). A coarse grain zone follows by a refined grain

zone are observed in the HAZ-F and martensite was

formed at the ferrite grain boundaries in all HAZ-F (see

Figure 1, Figure 2, Figure 7). The coarse grain zone is

formed because grain growth is diffusion controlled,

driven by surface energy and requires no nucleation, the

energy is given by the welding process [10]. The refined Figure 8. HAZ-F showing grain boundaries free of precipitates

grains zone is due to a recrystallization process where new

grains are formed by the movement an annihilation of 3.2. Tensile Properties

dislocations in the grains previously deformed in the The tensile behavior of the welded joints was similar

parent metal [7,11]. Regarding martensite formation, any for both experimental conditions (Table 3). Failure occurs

austenite that forms at elevated temperature will transform at the ferritic parent metal and far away from the HAZ

to martensite upon cooling to room temperature leaving no with ductile fracture. These results indicated that grain

carbon available for carbide formation, this happens growth and martensite formation on HAZ-F were not

preferentially at the grain boundaries (see Figure 8) [7]. decisive factors in the failure of the tensile probe. Figure 9

shows stress in function of strain.

Table. 3 Tensile properties

Tensile strength Yield strength Elongation

Filler metal

(MPa) (MPa) (%)

AWS E309L 485 378 34

AWS E2209-16 505 361 36

Figure 6. Microstructure of FB a) AISI 430-AWS E309L y b) AISI 430-

AWS E2209-16

Figure 9. Stress vs strain curves of the welded joints

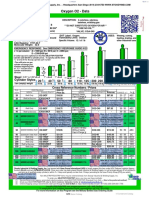

3.3. Microhardness and Amount of Delta

Ferrite

Figure 7. Microstructure of HAZ-F of AISI 430-AWS E309L

Microhardness profiles were taken along a line in

The austenitic filler metal generates a larger grain the middle of the thickness and included the parent

growth (264 μm mean grain size) than the duplex filler metals, HAZ and FZ (Figure 10). In Figure 8, ¨0¨

metal (156 μm mean grain size). This can be explained indicates the center of the fusion zone. The main

because of the heat input of the two experimental hardness differences are in the FZ and in the coarse

conditions, which was higher for the austenitic filler metal grain zone of the HAZ-F, which was expected because

(see Table 2). In addition, duplex filler metal may produce of the difference in the amount and morphology of

higher cooling rates and lower reached temperatures than delta ferrite for each filler metal [12] and the

68 Journal of Materials Physics and Chemistry

difference between the coarse ferritic grain sizes in the 4. Summary

HAZ-F zones. The average hardness of the austenitic

and duplex filler metals were 228 HV and 278 HV The microstructural evolution of a dissimilar austenite-

respectively. ferrite stainless steel welding was studied using two

different filler metals and small variations in the heat input.

The results indicated the size of the HAZ-F and the

average size of the ferrite in the coarse grain zone

depended on the heat input. In the other hand, the

morphology and amount of delta ferrite is a function of the

chemical composition of the filler metal.

Acknowledgement

The authors would like to acknowledge the financial

support from the University of Antioquia, CODI,

Figure 10. Microhardness profiles of the coupons

researching project MDC 01-7-10 and the financial

support from COLCIENCIAS through the Young

Researcher Scholarship Program. And acknowledge XIII

Congress of Science and Technology of Metallurgy and

Materials, Iguazú, Argentina, August 20-25, 2013.

References

[1] Khan, M.M.A., Romolia, L., Fiaschib, M., Dinia, G. and Sarri F.,

“Laser beam welding of dissimilar stainless steels in a fillet joint

configuration”, Journal of Materials Processing Technology, 28.

856-867. Nov. 2011.

[2] Celik, A. and Alsaran, A., “Mechanical and Structural Properties

of Similar and Dissimilar Steel Joints”, Materials Characterization,

43. 311-318. July 1999.

[3] Lakshminarayanan, A.K., “Effect of Welding Processes on Tensile

and Impact Properties, Hardness and Microstructure of AISI 409M

Ferritic Stainless Joints Fabricated by Duplex Stainless Steel Filler

Figure 11. Schaeffler diagram Metal”, Journal of Iron and Steel Research, International, 16. 66-

72. April 2009.

[4] Rajaković-Ognjanović, V., “Corrosion of an austenite and ferrite

stainless steel weld”, Journal of the Serbian Chemical Society, 76.

1027-1035. Dec. 2011.

[5] Reddy, G. M., Rao, K. S. and Sekhar, T., “Microstructure and

pitting corrosion of similar and dissimilar stainless steel welds”

Science and Technology of Welding and Joining, 13 (4). 363-377.

Jan. 2008.

[6] Folkhard, E. Welding Metallurgy of Stainless Steels; Springer-

Verlag Wien, New York, 1996.

[7] Lippold, J. and Kotecki, D., Welding metallurgy and weldability of

stainless steel, John Wiley and Sons, USA, 2005.

[8] ASTM E8 - 13a Standard Test Methods for Tension Testing of

Metallic Materials. ASTM International.

[9] Kaçar, R., “Effect of solidification mode and morphology of

microstructure on the hydrogen content of duplex stainless steel

weld metal”, Materials and Design, 25. 1–9. Aug. 2003.

[10] Easterling, K., Introduction to the physical metallurgy of welding,

Figure 12. Delta ferrite profiles of the coupons Butterworks Monographs in Materials, UK, 1983.

[11] Granjon, H., Fundamentals of welding metallurgy, Woodhead

Shaeffler’s diagram was used to predict the delta ferrite Publishing Ltd, UK, 1991, 123-130.

percent using 30% dilution. The results were 14% and [12] Duarte, P., “Mechanical and Microstrutural Characterization of

Weldments of Ferritic Stainless Steel AISI 444 Using Austenitic

43% of delta ferrite for the austenitic and the duplex filler Stainless Steels Filler Metals”. Journal of ASTM International, 9

metals, respectively (see Figure 11). Delta ferrite was also (2). 1-9. Jan. 2012.

measured using a ferritoscope, which indicated that delta [13] Kaςar, R., “An investigation of microstructure/property

ferrite were 9% for the austenitic electrode and 27% for relationships in dissimilar welds between martensitic and

austenitic stainless steels” Materials and design, 25. 317-329. Oct.

the duplex filler metal (see Figure 12). The differences

2003.

between the predicted and measured delta ferrite may be

explained by: (1) Shaeffler’s diagram does not take into

account nitrogen to calculate the equivalent nickel [6,7],

and (2) the real dilution may have been different than 30%

used for the prediction [13].

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Aws c2.25 2002 Thermal Spray Feedstock PDFDocument27 pagesAws c2.25 2002 Thermal Spray Feedstock PDFneyzaNo ratings yet

- Aws c2.25 2002 Thermal Spray Feedstock PDFDocument27 pagesAws c2.25 2002 Thermal Spray Feedstock PDFneyzaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Technical Seminar Agenda and Generator System OverviewDocument86 pagesTechnical Seminar Agenda and Generator System OverviewKenneth100% (1)

- Cp-117-Project EngineeringDocument67 pagesCp-117-Project Engineeringkattabomman100% (1)

- Vertebrates and InvertebratesDocument4 pagesVertebrates and InvertebratesJane Aubrey Saligan100% (2)

- AL Marone Layout PDFDocument3 pagesAL Marone Layout PDFneyzaNo ratings yet

- 1Document1 page1neyzaNo ratings yet

- Inconel 1 PDFDocument12 pagesInconel 1 PDFneyzaNo ratings yet

- PlasmaaDocument1 pagePlasmaaneyzaNo ratings yet

- Revista Temple Al 6061 PDFDocument13 pagesRevista Temple Al 6061 PDFneyzaNo ratings yet

- Faltan Ing. Papping - ScribdDocument1 pageFaltan Ing. Papping - ScribdneyzaNo ratings yet

- Inconel 1 PDFDocument12 pagesInconel 1 PDFneyzaNo ratings yet

- AWS 20free 20labs 20 20lab 203 20 20EC2 20 20student 20instructions PDFDocument7 pagesAWS 20free 20labs 20 20lab 203 20 20EC2 20 20student 20instructions PDFsrinubasaniNo ratings yet

- Cement Carb 5Document6 pagesCement Carb 5neyzaNo ratings yet

- 05 Catpg 021Document1 page05 Catpg 021neyzaNo ratings yet

- AWS 20free 20labs 20 20lab 203 20 20EC2 20 20student 20instructions PDFDocument7 pagesAWS 20free 20labs 20 20lab 203 20 20EC2 20 20student 20instructions PDFsrinubasaniNo ratings yet

- Irjet V4i2201 PDFDocument9 pagesIrjet V4i2201 PDFneyzaNo ratings yet

- 05 Catpg 029Document1 page05 Catpg 029neyzaNo ratings yet

- Nitrogen N2 Data Sheet Provides Gas Purity Levels, Cylinder DetailsDocument2 pagesNitrogen N2 Data Sheet Provides Gas Purity Levels, Cylinder DetailsneyzaNo ratings yet

- Lar 9Document1 pageLar 9neyzaNo ratings yet

- 05 Catpg 021Document1 page05 Catpg 021neyzaNo ratings yet

- Cement Carb 4Document7 pagesCement Carb 4neyzaNo ratings yet

- Lar 4Document1 pageLar 4neyzaNo ratings yet

- Lar 12Document1 pageLar 12neyzaNo ratings yet

- Lar 2Document1 pageLar 2neyzaNo ratings yet

- Lar 6Document1 pageLar 6neyzaNo ratings yet

- Lar 10Document1 pageLar 10neyzaNo ratings yet

- Lar 8Document1 pageLar 8neyzaNo ratings yet

- Lar 7Document1 pageLar 7neyzaNo ratings yet

- Lar 5Document1 pageLar 5neyzaNo ratings yet

- Lar 1Document1 pageLar 1neyzaNo ratings yet

- Lar 3Document1 pageLar 3neyzaNo ratings yet

- Sample Format PDFDocument5 pagesSample Format PDFRhod R. AvisoNo ratings yet

- Batangas State University - Testing and Admission OfficeDocument2 pagesBatangas State University - Testing and Admission OfficeDolly Manalo100% (1)

- Manual Lift Release System: Parts List and DiagramsDocument4 pagesManual Lift Release System: Parts List and DiagramsPartagon PowNo ratings yet

- MTH101 Practice Qs Solutions Lectures 1 To 22 PDFDocument50 pagesMTH101 Practice Qs Solutions Lectures 1 To 22 PDFRubab Babar75% (4)

- MR - Abhishek JiDocument4 pagesMR - Abhishek Jimalikgaurav01No ratings yet

- Pamantasan NG Lungsod NG Maynila - Freshmen AdmissionDocument6 pagesPamantasan NG Lungsod NG Maynila - Freshmen AdmissionPoppy HowellNo ratings yet

- AMX-3 Prom AdaptorDocument18 pagesAMX-3 Prom AdaptorEmmanuel RamirezNo ratings yet

- Idioma IV Cycle Q1 Exam (2021-1) - STUDENTS ANSWERDocument9 pagesIdioma IV Cycle Q1 Exam (2021-1) - STUDENTS ANSWEREdward SlaterNo ratings yet

- Communication Thesis PDFDocument2 pagesCommunication Thesis PDFBarbara0% (2)

- Dada and Buddhist Thought - Sung-Won Ko PDFDocument24 pagesDada and Buddhist Thought - Sung-Won Ko PDFJuan Manuel Gomez GarcíaNo ratings yet

- Chapter #11: Volume #1Document35 pagesChapter #11: Volume #1Mohamed MohamedNo ratings yet

- Pagewriter TC Cardiograph Service Manual Addendum Battery MaintenanceDocument9 pagesPagewriter TC Cardiograph Service Manual Addendum Battery MaintenanceCarlos ArturoNo ratings yet

- Tauros TBM Guidance SystemDocument3 pagesTauros TBM Guidance SystemMiloš StanimirovićNo ratings yet

- Chartered Accountants and Accountans in AmbalaDocument3 pagesChartered Accountants and Accountans in AmbalaGurmeet kaurNo ratings yet

- Handouts For Semantics GradDocument8 pagesHandouts For Semantics GradPhuong Thao DangNo ratings yet

- Introduction to Philippine LiteratureDocument61 pagesIntroduction to Philippine LiteraturealvindadacayNo ratings yet

- Handout Week10.1Document7 pagesHandout Week10.1Antoniette Niña YusonNo ratings yet

- Anselm's Ontological Argument ExplainedDocument8 pagesAnselm's Ontological Argument ExplainedCharles NunezNo ratings yet

- IT Department - JdsDocument2 pagesIT Department - JdsShahid NadeemNo ratings yet

- Vision CSP22 Abhyaas Test 3SDocument44 pagesVision CSP22 Abhyaas Test 3SManasa DevarakondaNo ratings yet

- Shakuntala and Other Works, by KåalidåasaDocument255 pagesShakuntala and Other Works, by KåalidåasaMohamed Sayed AbdelrehimNo ratings yet

- Blasting 001 Abb WarehouseDocument2 pagesBlasting 001 Abb WarehouseferielvpkNo ratings yet

- The Biologic Width: - A Concept in Periodontics and Restorative DentistryDocument8 pagesThe Biologic Width: - A Concept in Periodontics and Restorative DentistryDrKrishna DasNo ratings yet

- Introduction To Computing Week 2Document23 pagesIntroduction To Computing Week 2Jerick FernandezNo ratings yet

- Laplace Transform solved problems explainedDocument41 pagesLaplace Transform solved problems explainedduchesschloeNo ratings yet

- 2.3 Temperature Conversions: Chapter 2 Energy and MatterDocument18 pages2.3 Temperature Conversions: Chapter 2 Energy and MatterBeverly PamanNo ratings yet

- AA Practice Problems on Amino Acids and Peptides (less than 40 charsDocument20 pagesAA Practice Problems on Amino Acids and Peptides (less than 40 charsNurlaeli NaelulmunaMajdiyahNo ratings yet