Professional Documents

Culture Documents

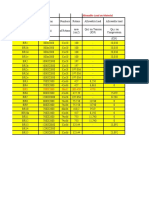

Table 4-1 Maximum Allowable Shell Stresses: (Not For Use For Reconstructed Tanks, See Note 6)

Uploaded by

muhd.qasimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Table 4-1 Maximum Allowable Shell Stresses: (Not For Use For Reconstructed Tanks, See Note 6)

Uploaded by

muhd.qasimCopyright:

Available Formats

4-4 API STANDARD 653

Table 4-1 Maximum Allowable Shell Stresses

(Not For Use For Reconstructed Tanks, see Note 6)

Allowable Product Allowable Hydrostatic

Stress, S (lbf/in.2) (7) Test Stress, Sf (lbf/in2) (7)

Minimum

Minimum

Specified

Material Specification Specified Lower Two Lower Two

Yield Stress, Tensile Upper Courses Upper Courses

and Orade Courses Courses

Strength, 0

Y (lbf/in. 2)

T (Ibf/in. 2)

ASTM Specifications

A 283-C 30,000 55,000 23,600 26,000 26,000 27,000

A285-C 30,000 55,000 23,600 26,000 26,000 27,000

A36 36,000 58,000 24,900 27,400 27,400 30,100

AI31-A, B, CS 34,000 58,000 24,900 27,400 27,400 30,100

AI31-EH 36 51,000 71,000 30,500 33,500 33,500 36,800

A573-58 32,000 58,000 24,900 27,400 27,400 28,800

A573-65 35,000 65,000 27,900 30,700 30,700 31,500

A573-70 42,000 70,000 30,000 33,000 33,000 36,300

A516-55 30,000 55,000 23,600 26,000 26,000 27,000

A516-60 32,000 60,000 25,600 28,200 28,200 28,800

A516-65 35,000 65,000 27,900 30,700 30,700 31,500

A516-70 38,000 70,000 30,000 33,000 33,000 34,200

A662-B 40,000 65,000 27,900 30,700 30,700 33,700

A662-C 43,000 70,000 30,000 33,000 33,000 36,300

A537- Class I 50,000 70,000 30,000 33,000 33,000 36,300

01 A537- Class 2 60,000 80,000 34,300 37,800 37,800 41,500

A633-C,D 50,000 70,000 30,000 33,000 33,000 36,300

A678-A 50,000 70,000 30,000 33,000 33,000 36,300

A678-B 60,000 80,000 34,300 37,800 37,800 41,500

A737-B 50,000 70,000 30,000 33,000 33,000 36,300

A841 50,000 70,000 30,000 33,000 33,000 36,300

AIO (1) 30,000 55,000 23,600 26,000 26,000 27,000

A7 (I) 33,000 60,000 25,700 28,300 28,300 29,700

A442-55 (1) 30,000 55,000 23,600 26,000 26,000 27,000

A442-60 (I) 32,000 60,000 25,600 28,200 28,200 28,800

CSA Specifications

040.21 M, 260W 37,700 59,500 25,500 28,100 28,100 30,900

040.21 M, 300W 43,500 65,300 28,000 30,800 30,800 33,900

040.21 M, 350W 50,800 65,300 28,000 30,800 30,800 33,900

040.21 M, 350WT 50,800 69,600 29,900 32,900 32,900 36,100

Unknown (2) 30,000 55,000 23,600 26,000 26,000 27,000

Riveted Tanks:

A7, A9 or AIO (1,3) NA NA 21,000 21,000 21,000 21,000

Known (4) Y T Note 4 Note 4 Note 4 Note 4

Unknown (5) NA NA 21,000 21,000 21,000 21,000

Notes: maximum allowable shell stress for both product and hydrostatic test

conditions are listed under column for Allowable Product Stress, S.

I. ASTM A7, A9, AIO and A442 are obsolete ASTM material speci-

fications previously listed in API Standards 12C and 650. 5. This provision is for riveted tanks, constructed of unknown grades

2. The yield stress and tensile strength values shown are per API 653 of material, evaluated per 4.3.4.2 of this standard. 01

01

for welded AST material of unknown origin. 6. The allowable stresses for reconstructed tanks are tabulated in API

3. This provision is for riveted tanks, constructed of any grade of Std 650, Table 3-2 or calculated per 8.4 of this standard.

material, evaluated per 4.3.4.1 of this standard.

7. The allowable stresses are calculated per 4.3.3.1 of this standard,

4. This provision is for riveted tanks, constructed of known grades of unless otherwise noted. The calculated allowable stresses are

material, evaluated per 4.3.4.2 of this standard. For all courses, the rounded to the nearest 100Ibf/in.2.

You might also like

- ASME 831.4-an2 allowable stress tableDocument1 pageASME 831.4-an2 allowable stress tablelechepinitoNo ratings yet

- KN/M KN/M KN/M: Answers 1 Week 1Document1 pageKN/M KN/M KN/M: Answers 1 Week 1Shavin Chand100% (1)

- M0Del Answers T0 Cpa 2 Examinati0N Set 0N 3 December 1996Document3 pagesM0Del Answers T0 Cpa 2 Examinati0N Set 0N 3 December 1996gakumoNo ratings yet

- Chemical and Mechanical Requirements for Steel PipesDocument1 pageChemical and Mechanical Requirements for Steel PipesFelipa ShanNo ratings yet

- ASCO 7000 Withstand and Close-On RatingsDocument2 pagesASCO 7000 Withstand and Close-On Ratingsadd8742No ratings yet

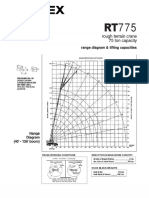

- Rated lifting capacities chart for construction crane boomDocument1 pageRated lifting capacities chart for construction crane boomasdasd dsadasdNo ratings yet

- Proppant TablesDocument20 pagesProppant TablesManuel ChNo ratings yet

- Grade F: Tabulation Allowable Within TheDocument1 pageGrade F: Tabulation Allowable Within ThelechepinitoNo ratings yet

- Impri MirDocument6 pagesImpri MirJhoe Frank MaximilianoNo ratings yet

- Grade Yield Strength Tensile Strength: Api 5LDocument1 pageGrade Yield Strength Tensile Strength: Api 5LArifinNo ratings yet

- ProfileDocument3 pagesProfilegh_damocNo ratings yet

- Wi Vs T(S)Document6 pagesWi Vs T(S)Joel Maximiliano GomezNo ratings yet

- 3 70a e Pa 140 Pa206 Pa436 Linear Pneumatic ActuatorsDocument6 pages3 70a e Pa 140 Pa206 Pa436 Linear Pneumatic Actuatorsryando fernandaNo ratings yet

- 02 Katalog CMSI 2017 OK Glassware Part 1Document26 pages02 Katalog CMSI 2017 OK Glassware Part 1IAK prodNo ratings yet

- Best Allocation of Cost 1 Engineering 2 Ba 3 Fine Arts 4 Aca 5 TykDocument15 pagesBest Allocation of Cost 1 Engineering 2 Ba 3 Fine Arts 4 Aca 5 TykAj PotXzs ÜNo ratings yet

- Motor TechNotes Direct Coupled-AlignmentDocument2 pagesMotor TechNotes Direct Coupled-AlignmentramoebpNo ratings yet

- Asme B31.4 - Allowable StressDocument2 pagesAsme B31.4 - Allowable Stressjoaquin torrano veraNo ratings yet

- Uygjks 2Document3 pagesUygjks 2Mattia MatrangaNo ratings yet

- 30 300 G7028SR3Document1 page30 300 G7028SR3ERASMO PEREZ IZQUIERDONo ratings yet

- Water Tank SizeDocument1 pageWater Tank SizeTerence LeongNo ratings yet

- Steady Flow MeterDocument5 pagesSteady Flow Meter송승준No ratings yet

- BoQ - Structure Steel Request CostingDocument12 pagesBoQ - Structure Steel Request CostingRanu JanuarNo ratings yet

- Total Quantity Raw MaterialDocument2 pagesTotal Quantity Raw MaterialHazim AziziNo ratings yet

- Analisa PedestalDocument21 pagesAnalisa PedestalRiski NugrohoNo ratings yet

- FUSE03Document1 pageFUSE03PukraDastNo ratings yet

- Bills of Material: Rev. Date Description by CHK'D Reviewed ClientDocument5 pagesBills of Material: Rev. Date Description by CHK'D Reviewed ClientBack to SumateraNo ratings yet

- Barrette Loads20170920Document24 pagesBarrette Loads20170920phuckha2012No ratings yet

- Proppant Tables 2015Document16 pagesProppant Tables 2015nielgiantNo ratings yet

- Student Loan Relief Applications by Congressional DistrictDocument20 pagesStudent Loan Relief Applications by Congressional DistrictBoston 25 DeskNo ratings yet

- AesI: 500,000-word document on various topicsDocument9 pagesAesI: 500,000-word document on various topicsEmujin TNo ratings yet

- Price List: Harga Sewaktu-Waktu Dapat BerubahDocument10 pagesPrice List: Harga Sewaktu-Waktu Dapat Berubahboz fxNo ratings yet

- Fairchild T6000Document11 pagesFairchild T6000Black Cat ColorNo ratings yet

- Design of Bored Pile at Abut A & BDocument10 pagesDesign of Bored Pile at Abut A & BLenielle AmatosaNo ratings yet

- Triangulation ForecastsDocument4 pagesTriangulation Forecastsramblingman50% (2)

- PT DIETZEL INDONESIA PERKASA PROCESS EQUIPMENT BREAKDOWN PRICEDocument10 pagesPT DIETZEL INDONESIA PERKASA PROCESS EQUIPMENT BREAKDOWN PRICEcharles bronsonNo ratings yet

- Check Valves 50 Series (MS-01-98) R4Document2 pagesCheck Valves 50 Series (MS-01-98) R4herysyam1980No ratings yet

- ASTM A608 Supplementary ReqDocument6 pagesASTM A608 Supplementary ReqAnonymous 2zcLfLjWNo ratings yet

- Data AnnurDocument3 pagesData Annurraraara9000No ratings yet

- Price List-IDocument1 pagePrice List-Imohan_27109150No ratings yet

- Mobile Pumps SpecsDocument1 pageMobile Pumps SpecsIrpan Fauzy HarahapNo ratings yet

- Boiler I.B.R. CalculationDocument10 pagesBoiler I.B.R. CalculationGurinder Jit Singh100% (1)

- Geya MCCB Catalog-1Document32 pagesGeya MCCB Catalog-1satthubattuongNo ratings yet

- Necesar masti, halate, botosei, bonete si viziere pentru sectiile spitaluluiDocument31 pagesNecesar masti, halate, botosei, bonete si viziere pentru sectiile spitaluluiMorar Alexandru CristianNo ratings yet

- SPC V.M. %Document3 pagesSPC V.M. %Dhananjay PatilNo ratings yet

- Pipe Pressure RatingDocument2 pagesPipe Pressure RatingApoorv Singh100% (1)

- The Wear-Resistant SteelDocument16 pagesThe Wear-Resistant SteelredNo ratings yet

- Cash Flows 1Document2 pagesCash Flows 1ssembatya reaganNo ratings yet

- Highe Series: Siov Metal Oxide VaristorsDocument60 pagesHighe Series: Siov Metal Oxide VaristorsDanna PerezNo ratings yet

- 560-1 Load ChartDocument12 pages560-1 Load Chartjmsmech0% (1)

- Rafale Vs Typhoon PDFDocument12 pagesRafale Vs Typhoon PDFdundun92No ratings yet

- ProfilDocument2 pagesProfilBarbara KulisicNo ratings yet

- T9-Catalogo Tecnico Alberi Scanalati e BoccoleDocument4 pagesT9-Catalogo Tecnico Alberi Scanalati e BoccoleAlberto Paico LinarezNo ratings yet

- RT700 Capacity Chart PDFDocument6 pagesRT700 Capacity Chart PDFhenry ariasNo ratings yet

- On Site RTC 80130 Load ChartDocument8 pagesOn Site RTC 80130 Load Chartsrikanthc85No ratings yet

- SS - Beam Load Cell 50kgf 10tf: FeatureDocument1 pageSS - Beam Load Cell 50kgf 10tf: Featuresupriyo110No ratings yet

- Sa283c Stress-Strain CurveDocument7 pagesSa283c Stress-Strain CurveAnonymous AtAGVssJNo ratings yet

- Spine Beam - SCHEME 4Document28 pagesSpine Beam - SCHEME 4Edi ObrayanNo ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Westermann Tables: Steels For Hardening and TemperingDocument1 pageWestermann Tables: Steels For Hardening and Temperingmuhd.qasimNo ratings yet

- Westermann Table 8Document1 pageWestermann Table 8muhd.qasimNo ratings yet

- Westermann Table 7Document1 pageWestermann Table 7muhd.qasimNo ratings yet

- Tray of ColumnDocument1 pageTray of Columnmuhd.qasimNo ratings yet

- Flow Power of ExchangerDocument1 pageFlow Power of Exchangermuhd.qasimNo ratings yet

- Westermann Table 7Document1 pageWestermann Table 7muhd.qasimNo ratings yet

- Westermann Tables: IS:1762-1961 IS:4843-1968Document1 pageWestermann Tables: IS:1762-1961 IS:4843-1968muhd.qasimNo ratings yet

- Existing Bottom Plate Existing Bottom Plate: NotesDocument1 pageExisting Bottom Plate Existing Bottom Plate: Notesmuhd.qasimNo ratings yet

- Westermann Tables: Specific Weights, Melting Points, Coefficients of Thermal Expansion and ShrinkageDocument1 pageWestermann Tables: Specific Weights, Melting Points, Coefficients of Thermal Expansion and Shrinkagemuhd.qasimNo ratings yet

- Materials classification and properties tableDocument1 pageMaterials classification and properties tablemuhd.qasimNo ratings yet

- Air Compressor PowerDocument1 pageAir Compressor Powermuhd.qasimNo ratings yet

- Rate of Heat Lost From TurbineDocument1 pageRate of Heat Lost From Turbinemuhd.qasimNo ratings yet

- 160 Principles of HVAC, 8th Edition: Table 5-11 Relative Thermal Resistances of Building MaterialDocument1 page160 Principles of HVAC, 8th Edition: Table 5-11 Relative Thermal Resistances of Building Materialmuhd.qasimNo ratings yet

- Seismic Zones of PakistanDocument1 pageSeismic Zones of Pakistanmuhd.qasimNo ratings yet

- Tehsil Seismic Zone Tehsil Seismic Zone Tehsil Seismic Zone: BCP SP-2007 CH-02Document1 pageTehsil Seismic Zone Tehsil Seismic Zone Tehsil Seismic Zone: BCP SP-2007 CH-02muhd.qasimNo ratings yet

- PEB Structure SampleDocument1 pagePEB Structure Samplemuhd.qasimNo ratings yet

- Seismic Zones of Pakistan Part 2Document1 pageSeismic Zones of Pakistan Part 2muhd.qasimNo ratings yet

- 1.0 Scope of This ManualDocument1 page1.0 Scope of This Manualmuhd.qasimNo ratings yet

- Common Load Types and Categories Common Load Types and Categories Primary Loads Primary LoadsDocument1 pageCommon Load Types and Categories Common Load Types and Categories Primary Loads Primary Loadsmuhd.qasimNo ratings yet

- PF For Heat ExchangerDocument1 pagePF For Heat Exchangermuhd.qasimNo ratings yet

- Nozzle/Pro Load Cases and Combinations: NozzleproDocument1 pageNozzle/Pro Load Cases and Combinations: Nozzlepromuhd.qasimNo ratings yet

- CalibrationDocument1 pageCalibrationmuhd.qasimNo ratings yet

- Bending Stresses.: ... Two Kinds of Bending StressDocument1 pageBending Stresses.: ... Two Kinds of Bending Stressmuhd.qasimNo ratings yet

- SQ Honeycomb SketchDocument1 pageSQ Honeycomb Sketchmuhd.qasimNo ratings yet

- Bending Stresses.: ... Two Kinds of Bending StressDocument1 pageBending Stresses.: ... Two Kinds of Bending Stressmuhd.qasimNo ratings yet

- Index 7thedDocument4 pagesIndex 7thedmuhd.qasimNo ratings yet

- Occasional LoadDocument1 pageOccasional Loadmuhd.qasimNo ratings yet

- Heating Load Calculation ExampleDocument1 pageHeating Load Calculation Examplemuhd.qasimNo ratings yet

- Fabric Pad Sliding BearingsDocument1 pageFabric Pad Sliding Bearingsmuhd.qasimNo ratings yet

- Analyse de La Déformation Et Évaluation de La Sécurité Des Tunnels de Métro ExistantsDocument11 pagesAnalyse de La Déformation Et Évaluation de La Sécurité Des Tunnels de Métro ExistantsMed El Hadi AbidiNo ratings yet

- Metodo ASTM D402Document5 pagesMetodo ASTM D402Roberto ChamorroNo ratings yet

- Hardness Testing Comparison Table enDocument1 pageHardness Testing Comparison Table ennedim cılız100% (1)

- Vincent PDFDocument4 pagesVincent PDFSarinKorthawornwongNo ratings yet

- Verification of steam ejector refrigeration model performanceDocument8 pagesVerification of steam ejector refrigeration model performance고현No ratings yet

- Using Phase Change Material in Heat Sinks To Cool Electronics Devices With Intermittent UsageDocument19 pagesUsing Phase Change Material in Heat Sinks To Cool Electronics Devices With Intermittent UsagekaushikNo ratings yet

- Choi 2012Document5 pagesChoi 2012tuanhoa123No ratings yet

- Lab Report 1 (EXP1-Draft)Document17 pagesLab Report 1 (EXP1-Draft)Jamiel CatapangNo ratings yet

- ChemDocument29 pagesChemPearl LingbawanNo ratings yet

- Duct Design For "Super" SupermarketDocument47 pagesDuct Design For "Super" Supermarketkevin_thian_1100% (4)

- Propagation of Surface Waves in Thermoelastic Materials with VoidsDocument10 pagesPropagation of Surface Waves in Thermoelastic Materials with VoidsSOUMIK DASNo ratings yet

- Thermotron CE Catalogue 2022 VOL10 - MidresDocument54 pagesThermotron CE Catalogue 2022 VOL10 - MidresChristy LaheteNo ratings yet

- SEMIKRON Technical Explanation SEMITOP® Classic EN 2021-07-30 Rev-06Document20 pagesSEMIKRON Technical Explanation SEMITOP® Classic EN 2021-07-30 Rev-06carlosmitecNo ratings yet

- Ecosystem Lesson PlanDocument3 pagesEcosystem Lesson PlanClarence RiveraNo ratings yet

- Astm D-6432Document18 pagesAstm D-6432Lorenzo CampaniniNo ratings yet

- Auditorium case study reveals sound absorption strategiesDocument16 pagesAuditorium case study reveals sound absorption strategiesAshi Chandak0% (1)

- B62 0030 (Rev. B 2003.05) EN - THERMOPLASTIC, THERMOSETTING MATERIALS AND THERMOPLASTIC ELASTOMERS SPECIFICATIONS - SYMBOLSDocument10 pagesB62 0030 (Rev. B 2003.05) EN - THERMOPLASTIC, THERMOSETTING MATERIALS AND THERMOPLASTIC ELASTOMERS SPECIFICATIONS - SYMBOLSDiego CamargoNo ratings yet

- Tutorial 2Document2 pagesTutorial 2sakinah azizanNo ratings yet

- Knuckle Joint ProjectDocument9 pagesKnuckle Joint ProjectDANGER M.K.SNo ratings yet

- RCC DesignDocument71 pagesRCC Designsirfmein100% (1)

- Spisok e Books 04 09 2014-2Document162 pagesSpisok e Books 04 09 2014-2TimNo ratings yet

- Displacement and Posotion SensorsDocument3 pagesDisplacement and Posotion SensorsAnimesh ChhotrayNo ratings yet

- IAPWS Technical Guidance for Flexible Power PlantsDocument40 pagesIAPWS Technical Guidance for Flexible Power PlantsOsu AmpawanonNo ratings yet

- M11 Bor Pile Load Lateral 15257 0Document28 pagesM11 Bor Pile Load Lateral 15257 0Yusril RamadhanNo ratings yet

- Week - 09 - Pressure and Velocity MeasurementsDocument21 pagesWeek - 09 - Pressure and Velocity MeasurementsMohammad MohiuddinNo ratings yet

- 5054 w16 QP 11 PDFDocument20 pages5054 w16 QP 11 PDFMuhammad SaifNo ratings yet

- Heat & Mass Transfer Tutorial ProblemsDocument2 pagesHeat & Mass Transfer Tutorial ProblemsSaifullah AhmadNo ratings yet

- Damped Free VibrationDocument9 pagesDamped Free VibrationAdeoti OladapoNo ratings yet

- Murray Centennial P.S. - Revised Carrier Shop Drawings (KP)Document68 pagesMurray Centennial P.S. - Revised Carrier Shop Drawings (KP)Gonzalo OviedoNo ratings yet

- Checklist Pekerjaan Spun PileDocument1 pageChecklist Pekerjaan Spun PileBudhi Kurniawan100% (1)