Professional Documents

Culture Documents

Smart Lowside Power Switch Hitfet BSP 75N: Data Sheet Rev. 1.4

Uploaded by

Драгиша Небитни ТрифуновићOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Smart Lowside Power Switch Hitfet BSP 75N: Data Sheet Rev. 1.4

Uploaded by

Драгиша Небитни ТрифуновићCopyright:

Available Formats

Smart Lowside Power Switch HITFET BSP 75N

Data Sheet Rev. 1.4

Features

• Logic Level Input

• Input protection (ESD)

• Thermal shutdown with auto restart

• Overload protection

• Short circuit protection

• Overvoltage protection

• Current limitation

• Green Product (RoHS compliant)

• AEC Stress Test Qualification

Application

• All kinds of resistive, inductive and capacitive loads in switching applications

• µC compatible power switch for 12 V and 24 V DC applications and for 42 Volt

Powernet

• Replaces electromechanical relays and discrete circuits

General Description

N channel vertical power FET in Smart Power Technology. Fully protected by embedded

protection functions.

Type Ordering Code Package

HITFET BSP 75N on request PG-SOT223-4

Product Summary

Parameter Symbol Value Unit

Continuous drain source voltage VDS 60 V

On-state resistance RDS(ON) 550 mΩ

Current limitation ID(lim) 1 A

Nominal load current ID(Nom) 0.7 A

Clamping energy EAS 550 mJ

Data Sheet Rev. 1.4 1 2008-07-10

HITFET BSP 75N

Vbb

HITFET M

Logic OUTPUT

Stage

Over voltage

Protection

DRAIN

dV/dt

IN limitation

Short circuit

Over Protection

temperature

ESD Protection Current

Limitation

SOURCE

Figure 1 Block Diagram

1 IN

SOURCE

TAB

2 DRAIN

3 SOURCE

Figure 2 Pin Configuration

Pin Definitions and Functions

Pin No. Symbol Function

1 IN Input; activates output and supplies internal logic

2 DRAIN Output to the load

3 + TAB SOURCE Ground; pin3 and TAB are internally connected

Data Sheet Rev. 1.4 2 2008-07-10

HITFET BSP 75N

Circuit Description

The BSP 75N is a monolithic power switch in Smart Power Technology (SPT) with a

logic level input, an open drain DMOS output stage and integrated protection functions.

It is designed for all kind of resistive and inductive loads (relays, solenoid) in automotive

and industrial applications.

Protection Functions

• Over voltage protection: An internal clamp limits the output voltage at VDS(AZ) (min.

60V) when inductive loads are switched off.

• Current limitation: By means of an internal current measurement the drain current is

limited at ID(lim) (1.4 - 1.5 A typ.). If the current limitation is active the device operates

in the linear region, so power dissipation may exceed the capability of the heatsink.

This operation leads to an increasing junction temperature until the over temperature

threshold is reached.

• Over temperature and short circuit protection: This protection is based on sensing

the chip temperature. The location of the sensor ensures a fast and accurate junction

temperature detection. Over temperature shutdown occurs at minimum 150 °C. A

hysteresis of typ. 10 K enables an automatic restart by cooling.

The device is ESD protected according Human Body Model (4 kV) and load dump

protected (see Maximum Ratings).

Data Sheet Rev. 1.4 3 2008-07-10

HITFET BSP 75N

Absolute Maximum Ratings

Tj = 25 °C, unless otherwise specified

Parameter Symbol Values Unit Remarks

1)

Continuous drain source voltage VDS 60 V –

Drain source voltage for VDS 36 V –

short circuit protection

Continuous input voltage VIN -0.2 … +10 V –

Peak input voltage VIN -0.2 … +20 V –

Continuous Input Current IIN mA –

-0.2V ≤ VIN ≤ 10V no limit

VIN<-0.2V or VIN>10V | IIN |≤ 2mA

Operating temperature range Tj -40 … +150 °C –

Storage temperature range Tstg -55 … +150 °C

Power dissipation (DC) Ptot 1.8 W –

Unclamped single pulse inductive energy EAS 550 mJ ID(ISO) = 0.7 A;

Vbb =32V

Load dump protection 2) VLoadDump V VLoadDump =

IN = low or high (8 V); RL = 50 Ω 80 VP + VS;

IN = high (8 V); RL = 22 Ω 47 VP = 13.5 V

RI3) = 2 Ω;

td = 400 ms;

Electrostatic discharge voltage (Human VESD 4000 V –

Body Model)

according to MIL STD 883D, method

3015.7 and EOS/ESD assn. standard

S5.1 - 1993

Thermal Resistance

Junction soldering point RthJS ≤ 10 K/W –

Junction - ambient4) RthJA ≤ 70 K/W –

1)

See also Figure 7 and Figure 10.

2)

VLoadDump is setup without DUT connected to the generator per ISO 7637-1 and DIN 40 839. See also page 7.

3)

RI = internal resistance of the load dump test pulse generator LD200.

4)

Device on epoxy pcb 40 mm × 40 mm × 1.5 mm with 6 cm2 copper area for pin 4 connection.

Data Sheet Rev. 1.4 4 2008-07-10

HITFET BSP 75N

Electrical Characteristics

Tj = 25 °C, unless otherwise specified

Parameter Sym- Limit Values Unit Test Conditions

bol min. typ. max.

Static Characteristics

Drain source clamp voltage VDS(AZ) 60 – 75 V ID = 10 mA,

Tj = -40 … +150 °C

Off state drain current IDSS – – 5 µA VIN = 0 V,

VDS = 32 V,

Tj = -40 … +150 °C

Input threshold voltage VIN(th) 1 1.8 2.5 V ID = 10 mA

Input current: µA VIN = 5 V

normal operation, ID < ID(lim): IIN(1) – 100 200

current limitation mode, ID = ID(lim): IIN(2) – 250 400

After thermal shutdown, ID = 0 A: IIN(3) 1000 1500 2000

On-state resistance RDS(on) mΩ ID = 0.7 A,

Tj = 25 °C – 490 675 VIN = 5 V

Tj = 150 °C – 850 1350

On-state resistance RDS(on) mΩ ID = 0.7 A,

Tj = 25 °C – 430 550 VIN = 10 V

Tj = 150 °C – 750 1000

Nominal load current ID(Nom) 0.7 – – A VBB = 12 V,

VDS = 0.5 V,

TS = 85 °C,

Tj < 150 °C

Current limit ID(lim) 1 1.5 1.9 A VIN = 10 V,

VDS = 12 V

Dynamic Characteristics 1)

Turn-on time VIN to 90% ID: ton – 10 20 µs RL = 22 Ω,

VIN = 0 to 10 V,

VBB = 12 V

Turn-off time VIN to 10% ID: toff – 10 20 µs RL = 22 Ω,

VIN = 10 to 0 V,

VBB = 12 V

Data Sheet Rev. 1.4 5 2008-07-10

HITFET BSP 75N

Electrical Characteristics (cont’d)

Tj = 25 °C, unless otherwise specified

Parameter Sym- Limit Values Unit Test Conditions

bol min. typ. max.

Slew rate on 70 to 50% VBB: -dVDS/ – 5 10 V/ RL = 22 Ω,

dton µs VIN = 0 to 10 V,

VBB = 12 V

Slew rate off 50 to 70% VBB: dVDS/ – 10 15 V/ RL = 22 Ω,

dtoff µs VIN = 10 to 0 V,

VBB = 12 V

Protection Functions2)

Thermal overload trip Tjt 150 165 180 °C –

temperature

Thermal hysteresis ∆Tjt – 10 – Κ –

Unclamped single pulse inductive EAS mJ ID(ISO) = 0.7 A,

energy Tj = 25 °C 550 – – VBB = 32 V

Tj = 150 °C 200 – –

Inverse Diode

Continuous source drain voltage VSD – 1 – V VIN = 0 V,

-ID = 2 × 0.7 A

1)

See also Figure 9.

2)

Integrated protection functions are designed to prevent IC destruction under fault conditions described in the

datasheet. Fault conditions are considered as “outside” normal operating range. Protection functions are not

designed for continuous, repetitive operation.

Data Sheet Rev. 1.4 6 2008-07-10

HITFET BSP 75N

EMC-Characteristics

The following EMC-Characteristics outline the behavior of typical devices. They are not

part of any production test.

Table 1 Test Conditions

Parameter Symbol Value Unit Remark

Temperature TA 23 ±5 °C –

Supply Voltage VS 13.5 V –

Load RL 27 Ω ohmic

Operation mode PWM – – fINx=100Hz, D=0.5

DC – – ON / OFF

DUT specific VIN(’HIGH’)=5V

Fast electrical transients

acc. to ISO 7637

Test Result

Max. Pulse Cycle Time

Test1) OUTx stressed

Test and Generator

Pulse

Level Impedance

ON OFF

1 -200V C C 500ms ; 10Ω

2 +200V C C 500ms ; 10Ω

3a -200V C C 100ms ; 50Ω

3b +200V C C 100ms ; 50Ω

4 -7V C C 0.01Ω

5 175V E(65V) E(75V) 400ms ; 2Ω

1)

The test pulses are applied at VS

Definition of functional status

Class Content

C All functions of the device are performed as designed after exposure to

disturbance.

E One or more function of a device does not perform as designed after

exposure and can not be returned to proper operation without repairing

or replacing the device. The value after the character shows the limit.

Data Sheet Rev. 1.4 7 2008-07-10

HITFET BSP 75N

Conducted Susceptibility

PULSE Acc. 47A/658/CD IEC 62132-4 (Direct

VBB Power Injection)

Direct Power Injection: Forward Power

RL CW

BSP75N

Failure Criteria: Amplitude or frequency

IN DRAIN variation max. 10% at OUT

SOURCE

Typ. Vbb Susceptibility at DC-ON/OFF

and at PWM

40

Figure 3 Test circuit for ISO pulse

35

30

Conducted Emissions

25

Acc. IEC 61967-4 (1Ω/150Ω method)

dBm

20

15

Typ. Vbb Emissions at PWM-mode with 10

Limit

150Ω-matching network 5 OUT, ON

OUT, OFF

100 OUT, PWM

Noise level 0

90 BSP75N 1 10 100 1000

150ohm Class6

80 150ohm Class1 f / MHz

70

60

50

150Ω / 8-H

dBµV

40

30 VBB

20

150Ω / 13-N BAN

10

-10

BSP75N RL

-20

0,1 1 10 100 1000

f / MHz IN DRAIN

SOURCE HF

VBB

Test circuit for conducted susceptibility

2)

BSP75N RL

IN DRAIN

1)

SOURCE 150Ω-Network For defined de coupling and high reproducibility a

defined choke (5µH at 1MHz) is inserted in the

Vbb-Line.

2)

Broadband Artificial Network (short: BAN) consists

of the same choke (5µH at 1MHz) and the same

Figure 4 Test circuit for conducted 150 Ohm-matching network as for emission

measurement for defined de coupling and high

emission 1) reproducibility.

Data Sheet Rev. 1.4 8 2008-07-10

HITFET BSP 75N

Block diagram

VBB

ID

uC Vcc BSP75N

IIN HITFET Px.1 IN D

IN DRAIN Vbb GND SOURCE

VIN SOURCE VDS

Figure 8 Application Circuit

Figure 5 Terms

IN

SOURCE

Figure 6 Input Circuit (ESD

protection)

ESD zener diodes are not designed for DC

current.

LOAD

Drain

VAZ

VDS

Power

DMOS Source

ID

Figure 7 Inductive and Over

voltage Output Clamp

Data Sheet Rev. 1.4 9 2008-07-10

HITFET BSP 75N

Timing diagrams

VIN

VIN

t

ID(lim)

t

ID

VDS

t

t

ϑj

thermal hysteresis

ID 0.9*ID

t

0.1*ID

t Figure 11 Short circuit

ton toff

Figure 9 Switching a Resistive

Load

VIN

VDS(AZ) t

VDS VBB

t

ID

Figure 10 Switching an Inducitve

Load

Data Sheet Rev. 1.4 10 2008-07-10

HITFET BSP 75N

1 Max. allowable power dissipation 2 On-state resistance RON = f(Tj);

Ptot = f(TAmb) ID = 0.7 A; VIN = 10 V

2 1000

P to t R ON

9m0Ω

0

1,6

W 800

m ax.

700

m a x.

1,2 600

500 typ .

0,8 400

300

0,4 200

100

0 0

0 25 50 75 1 00 °C

125 15 0 -5 0 -2 5 0 25 50 7 5 1 0 0 1°C

25 150

T Amb T j

3 On-state resistance RON = f(Tj); 4 Typ. input threshold voltage

ID = 0.7 A; VIN = 5 V VIN(th) = f(Tj); ID = 10 mA; VDS = 12 V

14 00 2 ,5

R ON V IN (th )

Ω

m 00

12

V2

typ .

10 00

m a x.

1 ,5

8 00

typ .

6 00

1

4 00

0 ,5

2 00

0 0

-50 -2 5 0 25 50 °C 15 0

75 1 00 125 -5 0 -2 5 0 25 50 75 1 0 0 1°C

25 150

T j T j

Data Sheet Rev. 1.4 11 2008-07-10

HITFET BSP 75N

5 Typ. on-state resistance RON = f(VIN); 6 Typ. current limitation ID(lim) = f(Tj);

ID = 0.7 A; Tj = 25 °C VDS = 12 V, VIN = 10 V

2000 2

R ON

I D (lim )

typ . typ .

5 0Ω0

1m 1A,5

1000 1

500 0 ,5

0 0

0 2 4 6 V

8 10 -5 0 -2 5 0 25 50 75 1 0 0 1°C

25 150

V IN T j

7 Typ. short circuit current 8 Max. transient thermal impedance

ID(SC) = f(VIN); VDS = 12 V, Tj = 25 °C ZthJA = f(tp) @ 6cm²; Parameter: D = tp/T

2 100

I D (S C )

Z th (J A )

typ .

1A,5

10

K /W

1

D=

0 .5

0 .2

1 0 .1

0 ,5 0 .0 5

0 .0 2

0 .0 1

0

0

0 2 4 6 V

8 10 0 ,1

0 ,0 0 0 0 1 0 ,0 0 1 0 ,1 10 1 0 0s0 100000

V IN tP

Data Sheet Rev. 1.4 12 2008-07-10

HITFET BSP 75N

Package Outlines HITFET‚ BSP 75N

1 Package Outlines HITFET BSP 75N

6.5 ±0.2 1.6±0.1

A

3 ±0.1 0.1 MAX.

4 B

15˚ MAX.

3.5 ±0.2

1 2 3 7 ±0.3

0.5 MIN.

0.7 ±0.1 2.3 0.28 ±0.04

4.6 0...10˚

0.25 M A

0.25 M B

GPS05560

Figure 12 PG-SOT223-4 (Plastic Green Small Outline Transistor Package)

Green Product (RoHS compliant)

To meet the world-wide customer requirements for environmentally friendly products

and to be compliant with government regulations the device is available as a green

product. Green products are RoHS-Compliant (i.e Pb-free finish on leads and suitable

for Pb-free soldering according to IPC/JEDEC J-STD-020).

Please specify the package needed (e.g. green package) when placing an order

You can find all of our packages, sorts of packing and others in our

Infineon Internet Page: http://www.infineon.com/packages. Dimensions in mm

Data Sheet 13 Rev. 1.4, 2008-07-10

HITFET BSP 75N

Revision History

2 Revision History

Version Date Changes

Rev. 1.4 2008-07-10 fixed a formatting error in Disclaimer page

Rev. 1.3 2008-04-14 package naming updated to PG-SOT223-4

Rev. 1.2 2007-04-12 released automotive green version

changed package naming from -11 to PG-SOT223-4-7

Rev. 1.1 2007-03-28 Package parameter (humidity and climatic) removed in

Maximum ratings

AEC icon added

RoHS icon added

Green product (RoHS-compliant) added to the feature list

Package information updated to green

Green explanation added

Rev. 1.0 2003-01-10 released production version

Data Sheet 14 Rev. 1.3, 2008-04-14

HITFET BSP 75N

Edition 2008-07-10

Published by Infineon Technologies AG,

81726 Munich, Germany

© Infineon Technologies AG 2008.

All Rights Reserved.

Legal Disclaimer

The information given in this document shall in no event be regarded as a guarantee of conditions or

characteristics (“Beschaffenheitsgarantie”). With respect to any examples or hints given herein, any typical values

stated herein and/or any information regarding the application of the device, Infineon Technologies hereby

disclaims any and all warranties and liabilities of any kind, including without limitation warranties of

non-infringement of intellectual property rights of any third party.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest

Infineon Technologies Office (www.infineon.com)

Warnings

Due to technical requirements components may contain dangerous substances. For information on the types in

question please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may only be used in life-support devices or systems with the express written

approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the failure

of that life-support device or system, or to affect the safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the human body, or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may

be endangered.

Data Sheet 15 2008-07-10

You might also like

- Eightspeed Guide 2022 CompressedDocument14 pagesEightspeed Guide 2022 CompressedCarlos0% (1)

- Terex BHL Train ManualDocument116 pagesTerex BHL Train ManualViorel Gruia95% (22)

- Ford Everes PDFDocument584 pagesFord Everes PDFTiến Hồ100% (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Passive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2From EverandPassive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2No ratings yet

- High Voltage Linear LED Driver Description Features: Is A High Current PrecisionDocument6 pagesHigh Voltage Linear LED Driver Description Features: Is A High Current PrecisionEzequiel A O VillegasNo ratings yet

- Scasnia XCOM User GuideDocument33 pagesScasnia XCOM User GuideHarlinton descalzi83% (6)

- M.ATELIER D3 110-130-160-190 Groupe 30 EVCmc-C - (10-2007) - en Anglais - Pages.1 20Document20 pagesM.ATELIER D3 110-130-160-190 Groupe 30 EVCmc-C - (10-2007) - en Anglais - Pages.1 20oundilahmed0% (1)

- Fire Hydrant System Design Installation Commisioning and TestingDocument5 pagesFire Hydrant System Design Installation Commisioning and Testingjaianit89No ratings yet

- BSA D14 175 Bantam Supreme Sports Bushman Maintenance Instruction Manual PDFDocument37 pagesBSA D14 175 Bantam Supreme Sports Bushman Maintenance Instruction Manual PDFjvdkjdlkkNo ratings yet

- Lean Thinking Redefines O&M PracticesDocument10 pagesLean Thinking Redefines O&M PracticesAsel Juárez ViteNo ratings yet

- ECU 100, GCU 100, Engine Communication, 4189340804 UKDocument60 pagesECU 100, GCU 100, Engine Communication, 4189340804 UKJoaquin Andres Boilet Huerta100% (1)

- Gen00036-04 Wa600-6 Wheel LoaderDocument98 pagesGen00036-04 Wa600-6 Wheel LoaderJuan Araya BarrazaNo ratings yet

- Knowledge Based SystemsDocument57 pagesKnowledge Based SystemsRodel MoralesNo ratings yet

- PCM FlasherDocument5 pagesPCM FlasherДрагиша Небитни ТрифуновићNo ratings yet

- Tranzistor BSP75Document9 pagesTranzistor BSP75Admir OsmanovićNo ratings yet

- Data SheetDocument10 pagesData SheetRaphael Silveira de SouzaNo ratings yet

- Application: Smart Low Side Power Switch Power HITFET BTS 3118DDocument12 pagesApplication: Smart Low Side Power Switch Power HITFET BTS 3118DCarlos Luis ColmenaresNo ratings yet

- Infineon BSP76 PDFDocument11 pagesInfineon BSP76 PDFBio Eng Eslam TahaNo ratings yet

- Infineon ITS4140N DS v02 01 enDocument18 pagesInfineon ITS4140N DS v02 01 enRaul ContrerasNo ratings yet

- Smart High-Side Power Switch: Product SummaryDocument12 pagesSmart High-Side Power Switch: Product SummaryGerman Vera VeraNo ratings yet

- BTS 141Document11 pagesBTS 141RM MódulosNo ratings yet

- BSP75NDocument15 pagesBSP75NroozbehxoxNo ratings yet

- Infineon BTS410E2 DS v01 01 enDocument15 pagesInfineon BTS410E2 DS v01 01 enkarimNo ratings yet

- Smart Highside Power Switch One Channel: 20m: Product Summary PackageDocument12 pagesSmart Highside Power Switch One Channel: 20m: Product Summary PackageRumen IvanovNo ratings yet

- BSP 75NDocument14 pagesBSP 75NmikosoyNo ratings yet

- Smart Lowside Power Switch: Hitfet BTS 149Document11 pagesSmart Lowside Power Switch: Hitfet BTS 149Pablo AllosiaNo ratings yet

- Archive: DatasheetDocument10 pagesArchive: DatasheetDidier DoradoNo ratings yet

- Smart Power High-Side-Switch: Features Product SummaryDocument16 pagesSmart Power High-Side-Switch: Features Product SummaryMarquinho SilvaNo ratings yet

- Stp130N6F7: N-Channel 60 V, 4.2 Mω Typ., 80 A Stripfet™ F7 Power Mosfet In A To-220 PackageDocument12 pagesStp130N6F7: N-Channel 60 V, 4.2 Mω Typ., 80 A Stripfet™ F7 Power Mosfet In A To-220 PackageOsmir MonteiroNo ratings yet

- BTS 426 L1: Pin Symbol FunctionDocument1 pageBTS 426 L1: Pin Symbol FunctionKevin NightNo ratings yet

- Smart High-Side Power Switch For Industrial Applications 1 Channel: 1 X 200mDocument19 pagesSmart High-Side Power Switch For Industrial Applications 1 Channel: 1 X 200mThomas ThomasNo ratings yet

- Smart Power High-Side-Switch: BSP 762 TDocument16 pagesSmart Power High-Side-Switch: BSP 762 TAlejandro ArangurenNo ratings yet

- 74HCT32 Quad 2-Input OR GateDocument7 pages74HCT32 Quad 2-Input OR Gateholej18237No ratings yet

- VB027 PDFDocument10 pagesVB027 PDFhskv20025525No ratings yet

- Bay Linear: Current Mode PWM ControllerDocument11 pagesBay Linear: Current Mode PWM ControllerShashikant PatilNo ratings yet

- NX4020HDocument4 pagesNX4020Holeg nakhimovichNo ratings yet

- TSM101/A: Voltage and Current ControllerDocument13 pagesTSM101/A: Voltage and Current ControllerRaka Satria PradanaNo ratings yet

- AC-DC LED Driver MT7930Document8 pagesAC-DC LED Driver MT7930Daniel GonzálezNo ratings yet

- Smart High-Side Power Switch 1 Channel: 1 X 200m: BTS 4141NDocument20 pagesSmart High-Side Power Switch 1 Channel: 1 X 200m: BTS 4141Njroyal692974No ratings yet

- BSP742R Cat 938H 1651286Document17 pagesBSP742R Cat 938H 1651286Leandro SilvaNo ratings yet

- 30V Dual Channel Pmoseft: Prospower Microelectronics Co., LTDDocument8 pages30V Dual Channel Pmoseft: Prospower Microelectronics Co., LTDLuis AlvarezNo ratings yet

- Dual Operational Amplifiers: Product Description FeaturesDocument9 pagesDual Operational Amplifiers: Product Description FeaturesMendez VeronicaNo ratings yet

- Smart Highside Power SwitchDocument14 pagesSmart Highside Power SwitchEdson CostaNo ratings yet

- Ka78Mxx: 3-Terminal 0.5A Positive Voltage RegulatorDocument14 pagesKa78Mxx: 3-Terminal 0.5A Positive Voltage RegulatorTinwin HtutNo ratings yet

- Infineon Bts409l1 E3062a Ds v01 00 enDocument13 pagesInfineon Bts409l1 E3062a Ds v01 00 enDendi ArisetiawanNo ratings yet

- (S) & (PBF) : Features Product SummaryDocument17 pages(S) & (PBF) : Features Product SummaryFebin PaulNo ratings yet

- BTS412BDocument14 pagesBTS412Bstodzathegreat100% (1)

- BTS 412 B2Document15 pagesBTS 412 B2KSNo ratings yet

- TC75S67TU: Single Operational Amplifier (Ultra Low Noise Operational Amplifier)Document11 pagesTC75S67TU: Single Operational Amplifier (Ultra Low Noise Operational Amplifier)amaza_prodeoNo ratings yet

- Smart Highside Power Switch: Features Product SummaryDocument14 pagesSmart Highside Power Switch: Features Product Summaryalfredo521No ratings yet

- Stk621 140b e SanyoDocument8 pagesStk621 140b e Sanyoliber hormigaNo ratings yet

- Bts442e2 InfinDocument14 pagesBts442e2 InfinVasyaNo ratings yet

- Bd9130efj e 208952Document18 pagesBd9130efj e 208952Raguraman Bems - R&DNo ratings yet

- pt1301 r3.2 PowtechDocument9 pagespt1301 r3.2 PowtechOscar Caetano FontNo ratings yet

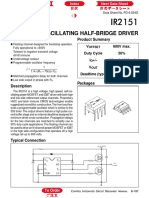

- Self-Oscillating Half-Bridge Driver: Features Product SummaryDocument6 pagesSelf-Oscillating Half-Bridge Driver: Features Product SummaryaheriadyNo ratings yet

- Preliminary: TE CHDocument8 pagesPreliminary: TE CHhsuhsu仔No ratings yet

- Maximum Ratings: Symbol Parameter Value UnitDocument1 pageMaximum Ratings: Symbol Parameter Value UnitGabriel EisenachNo ratings yet

- Datasheet 55Document6 pagesDatasheet 55Ahcene MenkouchaNo ratings yet

- Self-Oscillating Half-Bridge Driver: Features Product SummaryDocument6 pagesSelf-Oscillating Half-Bridge Driver: Features Product SummaryРуслан ЕгоровNo ratings yet

- 3 Digits LCD Display, 3260-Count A/D For DMM: DescriptionDocument17 pages3 Digits LCD Display, 3260-Count A/D For DMM: DescriptionDyogo MondegoNo ratings yet

- MME70R380P: 700V 0.38 N-Channel MOSFETDocument10 pagesMME70R380P: 700V 0.38 N-Channel MOSFETLeandro RoldanNo ratings yet

- Lonten N-Channel 650V, 47A, 0.07Ω Lonfet Power Mosfet: Lsb65R070GfDocument7 pagesLonten N-Channel 650V, 47A, 0.07Ω Lonfet Power Mosfet: Lsb65R070GfgusiusNo ratings yet

- Dtd113ek 1017968Document7 pagesDtd113ek 1017968Dry SpaceNo ratings yet

- Self-Oscillating Half-Bridge Driver: Features Product SummaryDocument6 pagesSelf-Oscillating Half-Bridge Driver: Features Product SummaryJean AlvesNo ratings yet

- Smart Power High-Side-Switch: Product Summary FeaturesDocument18 pagesSmart Power High-Side-Switch: Product Summary FeaturesbelchiorNo ratings yet

- IRAMS10UP60B: Series 10A, 600VDocument5 pagesIRAMS10UP60B: Series 10A, 600Vprairote pengCNo ratings yet

- MMRF1016HDocument19 pagesMMRF1016HandreasmonNo ratings yet

- MIP2K20MS Panasonic PDFDocument6 pagesMIP2K20MS Panasonic PDFnita_alecsandruNo ratings yet

- S29GL128N OverviewDocument2 pagesS29GL128N OverviewДрагиша Небитни ТрифуновићNo ratings yet

- tl866 - Device - Support IcDocument12 pagestl866 - Device - Support IcheokbwNo ratings yet

- BTS412BDocument14 pagesBTS412Bstodzathegreat100% (1)

- Irf9540n PDFDocument9 pagesIrf9540n PDFKrista TranNo ratings yet

- MPC823 Mobile Computing Microprocessor: Technical SummaryDocument12 pagesMPC823 Mobile Computing Microprocessor: Technical SummaryДрагиша Небитни ТрифуновићNo ratings yet

- Smart Lowside Power Switch Hitfet BSP 75N: Data Sheet Rev. 1.4Document15 pagesSmart Lowside Power Switch Hitfet BSP 75N: Data Sheet Rev. 1.4Драгиша Небитни ТрифуновићNo ratings yet

- Dspic30F: Dspic High Performance 16-Bit Digital Signal Controller Family OverviewDocument46 pagesDspic30F: Dspic High Performance 16-Bit Digital Signal Controller Family OverviewДрагиша Небитни ТрифуновићNo ratings yet

- MPC823 Mobile Computing Microprocessor: Technical SummaryDocument12 pagesMPC823 Mobile Computing Microprocessor: Technical SummaryДрагиша Небитни ТрифуновићNo ratings yet

- Dac8412 8413Document20 pagesDac8412 8413Драгиша Небитни ТрифуновићNo ratings yet

- Tja1041 PDFDocument26 pagesTja1041 PDFKeno0No ratings yet

- M58BW016Document71 pagesM58BW016Драгиша Небитни ТрифуновићNo ratings yet

- Ir2117 Igbt Driver PDFDocument18 pagesIr2117 Igbt Driver PDFismifaizulNo ratings yet

- UDE CAN SupportDocument10 pagesUDE CAN SupportДрагиша Небитни ТрифуновићNo ratings yet

- sk13 DiodeDocument3 pagessk13 DiodeДрагиша Небитни ТрифуновићNo ratings yet

- Texas Instruments 74595 Scls041i PDFDocument40 pagesTexas Instruments 74595 Scls041i PDFduriiNo ratings yet

- st10f269 DsDocument160 pagesst10f269 DsДрагиша Небитни ТрифуновићNo ratings yet

- Catalogue DCM PDFDocument108 pagesCatalogue DCM PDFДрагиша Небитни ТрифуновићNo ratings yet

- UDE CAN SupportDocument10 pagesUDE CAN SupportДрагиша Небитни ТрифуновићNo ratings yet

- LM342 Series 3-Terminal Positive Regulators: General DescriptionDocument6 pagesLM342 Series 3-Terminal Positive Regulators: General DescriptionДрагиша Небитни ТрифуновићNo ratings yet

- Catalogue DCM PDFDocument108 pagesCatalogue DCM PDFДрагиша Небитни ТрифуновићNo ratings yet

- Infineon Irs2183 DataSheet v01 00 enDocument24 pagesInfineon Irs2183 DataSheet v01 00 endiego rotpeNo ratings yet

- Vivid S60: GE HealthcareDocument4 pagesVivid S60: GE HealthcareДрагиша Небитни ТрифуновићNo ratings yet

- ISL6612A, ISL6613A: Advanced Synchronous Rectified Buck MOSFET Drivers With Pre-POR OVPDocument14 pagesISL6612A, ISL6613A: Advanced Synchronous Rectified Buck MOSFET Drivers With Pre-POR OVPДрагиша Небитни ТрифуновићNo ratings yet

- Deutz BFM 1013: For Generator Sets 81 - 225 KW - 109 - 302 HP at 1500/1800 Min - RPM EU Stage II / US EPA Tier 2Document2 pagesDeutz BFM 1013: For Generator Sets 81 - 225 KW - 109 - 302 HP at 1500/1800 Min - RPM EU Stage II / US EPA Tier 2Rafael VenturaNo ratings yet

- Wabco Trailerguard™: Telematics System For TrailersDocument2 pagesWabco Trailerguard™: Telematics System For TrailersДрагиша Небитни ТрифуновићNo ratings yet

- Creeping Flow Near A Rotating Sphere PDFDocument10 pagesCreeping Flow Near A Rotating Sphere PDFne gerek var anonimNo ratings yet

- Exercise 4.7: CH 4 SupplementalDocument12 pagesExercise 4.7: CH 4 SupplementalAngelica Diolata100% (1)

- Av36d303 SchematicDocument30 pagesAv36d303 SchematicLuis MorenoNo ratings yet

- Teodoriu 2010Document13 pagesTeodoriu 2010JhormanNo ratings yet

- Service Manual: Model Code - Kib19Bp3-CmgDocument11 pagesService Manual: Model Code - Kib19Bp3-Cmgpravin jadavNo ratings yet

- Codex 2017 enDocument713 pagesCodex 2017 enJIgnacio123No ratings yet

- Valtra Tractor All Model Diagnostics and Programming ManualDocument22 pagesValtra Tractor All Model Diagnostics and Programming Manualpicax1879100% (17)

- West Beverly Homes-BoqDocument6 pagesWest Beverly Homes-BoqERICNo ratings yet

- Seb 1242-Soil Mechanics II SuppDocument2 pagesSeb 1242-Soil Mechanics II Suppcharler kinyuajNo ratings yet

- Fastening SystemsDocument74 pagesFastening SystemsskyvaneNo ratings yet

- DMPCDocument49 pagesDMPCiprassandyNo ratings yet

- 906 Release InfoDocument3 pages906 Release Infommontasir7417No ratings yet

- Dating Torrential ProcessesDocument29 pagesDating Torrential ProcessesJulio Montenegro GambiniNo ratings yet

- LRVP PowerDocument28 pagesLRVP Powermnbvcx213323No ratings yet

- Fly Ash 1Document9 pagesFly Ash 1Az AbqariNo ratings yet

- Westfalia Cycle CarrierDocument20 pagesWestfalia Cycle CarrierBarry John FitzGeradNo ratings yet

- ProxTransSysOpDocument41 pagesProxTransSysOpNorman MoralesNo ratings yet

- DsPIC33F - 01 - IntroductionDocument8 pagesDsPIC33F - 01 - IntroductionLau SandovalNo ratings yet

- HN1000 HN2000Document44 pagesHN1000 HN2000Mose SodeNo ratings yet

- Uahel NoticeDocument2 pagesUahel NoticeChiranjivi ChudharyNo ratings yet

- Design of Earth-Quake Resistant Multi Storied RCC Building On A Sloping GroundDocument24 pagesDesign of Earth-Quake Resistant Multi Storied RCC Building On A Sloping GroundKakula SasidharNo ratings yet

- Single Head Nest Detail: Turbonest F644-12Mm-S355-04Document5 pagesSingle Head Nest Detail: Turbonest F644-12Mm-S355-04Vv ZzNo ratings yet

- Flexibility and Safety: BERNSTEIN Safety Hinge SwitchesDocument12 pagesFlexibility and Safety: BERNSTEIN Safety Hinge SwitchespiterNo ratings yet