Professional Documents

Culture Documents

Nitoplate FRC: Constructive Solutions

Uploaded by

Doby YuniardiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nitoplate FRC: Constructive Solutions

Uploaded by

Doby YuniardiCopyright:

Available Formats

Nitoplate FRC constructive solutions

High strength carbon fibre composite plate system for structural

reinforcement

Uses Nitoplate FE-Z Epoxy Adhesive

Nitoplate FRC is a structural reinforcement system for use on Appearance

reinforced concrete, brickwork, steel & timber. Comp. A White Paste

It can be used to strengthen beams, slabs & walls in the following Comp. B Black Paste

structures: Mixed A+B Light grey, creamy

Bridges consistency

2

Commercial – high rise Compressive Strength >90 N/mm

Car parks ASTM D695

Industrial plants 2

Culverts Shear Strength >10 N/mm

Chimneys JIS K 6850

0 0

Power stations Application Temp. +10 C to +35 C

Historic structures Density 1.65 kg/litre (mixed)

0

Advantages Pot Life 120 minutes (+10 C)

0

Very high strength to weight ratio 40 minutes (+35 C)

Improves flexural strength capacity 0

High chemical resistance Open Time 30 minutes (+35 C)

Increases load carrying capacity of structure

Low build system – minimal effect on structural dimensions

Fast & easy installation – quick return to service Technical Support

No heavy equipment or temporary support during curing

required - as compared to steel plate bonding Fosroc offers a technical support package to specifiers, end

Simple detailing – cut to length on site, no splicing users and contractors, as well as unrivalled on site technical

Corrosion resistant – no maintenance costs assistance all over the world.

Description Instructions for Use

Surface Preparation

Nitoplate FRC is a high strength, high modulus, carbon fibre Concrete surfaces must be dry, flat, sound and free from debris

composite plate which, when used in conjunction with a specially and loose material. Surfaces must be fully Cured and free from

developed epoxy adhesive, improves structural performance by contamination. Blowholes or imperfections should be filled with

strengthening and improving flexural and deformation properties. Nitomortar FC.

Nitoplate FRC is very easy to handle and apply on-site with minimal Tolerance for flatness is 10mm maximum over a 2m length, with

equipment required, allowing quick & easy reinforcement of structural no steps or formwork marks more than 0.5mm.

members without major disruption.

Surface preparation is preferably by sand/grit blasting to remove

Specification the surface laitance and expose the fine aggregate.

Where indicated on the contract drawings, the carbon fibre reinforced Application

plate, consisting of pultruded carbon fibres embedded in epoxy resin, Ensure sufficient material, manpower & equipment to carry out

2

providing tensile strength >2,800 N/mm and modulus of elasticity the application within the pot-life of the resin.

2

>165,000 N/mm , shall be Nitoplate FRC supplied by Fosroc.

Mixing

Properties Add Comp. B to Comp. A of the Nitoplate FE-Z Adhesive and

Nitoplate FRC mix for 3 minutes using a spiral paddle fitted to a low speed

(<500 rpm) electric drill.

Fibre Volumetric Content >68%

Adhesive application

Dimensions To Substrate

Product Thickness Width X- Section Apply the mixed Nitoplate FE-Z Adhesive to the substrate with a

Nitoplate FRC Area spatula/scraper at a thickness of approx. 1mm.

2

(mm) (mm) (mm )

S-05 1.2 50 60 To Nitoplate FRC

S-08 80 96 Clean the side of the Nitoplate FRC to be applied to the

S-10 100 120 concrete with Fosroc Solvent 102, using clean white rags.

Modulus of Elasticity >165,000 N/mm

2 Apply 1-2mm thickness of Nitoplate FE-Z Adhesive to the plate

using a dome shaped spatula.

2

Tensile Strength of Fibers >2,800 N/mm

(Mechanical values obtained from longitudinal direction of fibers)

Elongation at Break > 1.7%

Nitoplate FRC

Application of Nitoplate FRC to Substrate Storage

Within the open time of the adhesive, place the Nitoplate FRC onto Nitoplate FRC and Nitoplate FE-Z Adhesive should be stored in

the prepared substrate and press the plate firmly into the epoxy using covered warehouse conditions and out of direct sunlight.

a hard rubber roller. Ensure excess material is forced out of both

sides of the plate. Remove surplus epoxy. Shelf life

st

In case of plate intersections, allow the 1 application to harden Nitoplate FRC has a semi-permanent shelf life when properly

nd

before applying the 2 plate. Clean the overlapping plate surfaces stored.

with acetone before application of the adhesive.

Nitoplate FE-Z Adhesive has a shelf life of 12 months when

Limitations stored in normal warehouse conditions.

Nitoplate FRC should not be exposed to direct sunlight – Precautions

Fosroc has a range of UV resistant coatings suitable for

overcoating Nitoplate/Nitowrap products Nitoplate FRC is non-reactive. Protect against airborne carbon

dust generated by the cutting procedure.

Estimating

Nitoplate FE-Z Adhesive should not come in contact with skin or

eyes or be swallowed. Ensure adequate ventilation. Wear

Supply

suitable protective clothing, gloves and eye protection.

Nitoplate FRC 100 m rolls

Nitoplate FE-Z Adhesive 8 kg set (A+B)

In case of contact with skin, rinse with plenty of clean water,

then clean with soap and water. Do not use solvent. In case of

Coverage

contact with eyes, rinse immediately with clean water and seek

Nitoplate FE-Z Adhesive

medical advice. If swallowed, seek immediate medical attention

50 mm wide plate 0.35 kg/ lin m

– do not induce vomiting.

80 mm wide plate 0.55 kg/ lin m

100mm wide plate 0.80 kg/ lin m

For further information refer to the Material Safety Data Sheet.

The above figures are dependent on substrate roughness and plate

crossings and do not allow for wasteage

PT.Fosroc

Indonesia

Jl. Akasia II Blok A8 No.1

Delta Silicon Industrial Park

Lippo Cikarang - Bekasi 17550 telephone: fax: email:

Indonesia +6221 897 2103 +6221 897 2107 indonesia @fosroc.com

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard terms and conditions of sale, copies of which

may be obtained on request. Whilst Fosroc endeavors to ensure that the technical information on this data sheet is correct at the time of printing, it is the

customer’s responsibility to satisfy himself, by checking with the company that this information is still current at the time of use, that the product is suitable for the

intended application, and that the actual conditions of use are in accordance with those recommended. Because Fosroc has no control over the conditions of use

of its products, all recommendations or suggestions regarding the use of these products are made without guarantee.

www.fosroc.com PH/0001/04/GT R01

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Nitoflor TF5000: Constructive SolutionsDocument3 pagesNitoflor TF5000: Constructive SolutionstalatzahoorNo ratings yet

- Fosroc Nitoflor TF5000: Constructive SolutionsDocument4 pagesFosroc Nitoflor TF5000: Constructive SolutionsVincent JavateNo ratings yet

- TDS Nitoflor TF10000 Saudi ArabiaDocument3 pagesTDS Nitoflor TF10000 Saudi ArabiaCynthia Miller100% (1)

- Nitoflor TF10000Document3 pagesNitoflor TF10000mrameshceNo ratings yet

- Nitoplate CP StripsDocument4 pagesNitoplate CP StripstalatzahoorNo ratings yet

- Nitomortar FCFSDocument2 pagesNitomortar FCFSMansoor AliNo ratings yet

- Fosroc Nitomortar FC (FS) : Constructive SolutionsDocument2 pagesFosroc Nitomortar FC (FS) : Constructive SolutionsVincent JavateNo ratings yet

- Nitowrap FRC-Indonesia PDFDocument2 pagesNitowrap FRC-Indonesia PDFlilik riyantiNo ratings yet

- Nitowrap FRC IndonesiaDocument2 pagesNitowrap FRC Indonesialilik riyantiNo ratings yet

- Fosroc Nitoflor FC550: Constructive SolutionsDocument4 pagesFosroc Nitoflor FC550: Constructive SolutionsVincent JavateNo ratings yet

- Fosroc Nitoflor FC550: Constructive SolutionsDocument4 pagesFosroc Nitoflor FC550: Constructive SolutionsVincent JavateNo ratings yet

- TDS Nitoplate CP Strips Saudi ArabiaDocument4 pagesTDS Nitoplate CP Strips Saudi ArabiaKareem SaberNo ratings yet

- Nitobond PC PDFDocument2 pagesNitobond PC PDFAnonymous XVEucVMsENo ratings yet

- Nitoflor TS5000: Constructive SolutionsDocument4 pagesNitoflor TS5000: Constructive Solutionsnaveen_k2004No ratings yet

- Nitocote En901Document5 pagesNitocote En901ashishpearl100% (1)

- AERC8 Ramset-EpconC8 PDSDocument11 pagesAERC8 Ramset-EpconC8 PDSZilong ZhangNo ratings yet

- New 1550HTDocument2 pagesNew 1550HTSantiago MonteroNo ratings yet

- Nitoflor TF10000: Constructive SolutionsDocument3 pagesNitoflor TF10000: Constructive SolutionstalatzahoorNo ratings yet

- Tehnički List - KIMITECH CBDocument2 pagesTehnički List - KIMITECH CBMARKO MATUHANo ratings yet

- Nitoflor SL2050: Constructive SolutionsDocument4 pagesNitoflor SL2050: Constructive SolutionsNishant VasuNo ratings yet

- Fosroc Nitocote EN901 High Chemical Resistant Protective LiningDocument4 pagesFosroc Nitocote EN901 High Chemical Resistant Protective LiningVincent JavateNo ratings yet

- Nitoflor ET Slurry3Document4 pagesNitoflor ET Slurry3PUENTES2407No ratings yet

- Fosroc Nitoflor SL1000: Uses PropertiesDocument4 pagesFosroc Nitoflor SL1000: Uses PropertiesTheo TodingNo ratings yet

- Carbon Fibre Sheet SpecDocument4 pagesCarbon Fibre Sheet Specalexcus1539No ratings yet

- Nitoseal MS60Document62 pagesNitoseal MS60Gavriel NgNo ratings yet

- Ucrete Ud200 AseanDocument2 pagesUcrete Ud200 AseanDoby YuniardiNo ratings yet

- TDS Nitoplate CP SEADocument4 pagesTDS Nitoplate CP SEASefta MegaNo ratings yet

- HMG Epozinc1000Document2 pagesHMG Epozinc1000ben.ledwidgeNo ratings yet

- Isocrete K Screed Technical Data SheetDocument2 pagesIsocrete K Screed Technical Data SheetIoan PiuNo ratings yet

- TDS Nitowrap FRC Saudi ArabiaDocument3 pagesTDS Nitowrap FRC Saudi ArabiarayNo ratings yet

- Polyken Pipeline #1027,: Primers #1019Document3 pagesPolyken Pipeline #1027,: Primers #1019Azmi SyariefNo ratings yet

- Nitowrap FRC: Constructive SolutionsDocument2 pagesNitowrap FRC: Constructive SolutionsbinodNo ratings yet

- Nitocote EN901: High Chemical Resistant Protective LiningDocument4 pagesNitocote EN901: High Chemical Resistant Protective LiningIbrahim KhalilNo ratings yet

- PDS - Sika MonoTop-412 MYDocument4 pagesPDS - Sika MonoTop-412 MYNorlizawati YusofNo ratings yet

- 01 Vetotop CL530 - 141221 JODocument2 pages01 Vetotop CL530 - 141221 JOassala HaddadNo ratings yet

- Conbextra EP150 UAEDocument4 pagesConbextra EP150 UAEjasonNo ratings yet

- TDS - Nitobond PC - IndiaDocument2 pagesTDS - Nitobond PC - IndiaccNo ratings yet

- Flowcrete Asia Isocrete K Screed May2020 TdsDocument2 pagesFlowcrete Asia Isocrete K Screed May2020 TdsJiawen WeiNo ratings yet

- Fosroc Nitowrap Carbon Fibre SheetDocument4 pagesFosroc Nitowrap Carbon Fibre Sheetalexcus1539No ratings yet

- Fosroc Guncrete E: High Strength, Low Shrinkage, High Build Dry-Spray Applied Repair Mortar Uses Application InstructionsDocument3 pagesFosroc Guncrete E: High Strength, Low Shrinkage, High Build Dry-Spray Applied Repair Mortar Uses Application InstructionsJohnNo ratings yet

- Fosroc Nitoflor Conductive Epoxy FloorDocument2 pagesFosroc Nitoflor Conductive Epoxy FloorVincent JavateNo ratings yet

- Tehnički List - KIMITECH EP INDocument5 pagesTehnički List - KIMITECH EP INMARKO MATUHANo ratings yet

- Nitomortar TC2000 PDFDocument3 pagesNitomortar TC2000 PDFtalatzahoor100% (2)

- Conbextra HFDocument4 pagesConbextra HFm.elsanee.cubicNo ratings yet

- Fosroc Nitoflor Conductive Epoxy Floor CoatingDocument2 pagesFosroc Nitoflor Conductive Epoxy Floor CoatingSreenivasan Radha KrishnanNo ratings yet

- 589enint Greencoat Pural BTDocument4 pages589enint Greencoat Pural BTkokrasniqiNo ratings yet

- Nitofill EPLV (M)Document2 pagesNitofill EPLV (M)VaishamNo ratings yet

- Nitoflor FC150 PDFDocument4 pagesNitoflor FC150 PDFSameera HerathNo ratings yet

- Ucrete MF AsDocument2 pagesUcrete MF AsDoby YuniardiNo ratings yet

- Fosroc Nitoflor FC150: Constructive SolutionsDocument4 pagesFosroc Nitoflor FC150: Constructive SolutionsABHI MITRANo ratings yet

- Fosroc Conbextra EP150: Free Flow Epoxy Resin Grout Uses DescriptionDocument4 pagesFosroc Conbextra EP150: Free Flow Epoxy Resin Grout Uses DescriptionVincent JavateNo ratings yet

- 2020 05 10 Foreva Composite TFC350 ACI EN V1Document2 pages2020 05 10 Foreva Composite TFC350 ACI EN V1pabloNo ratings yet

- Fosroc Conbextra HF precision groutDocument4 pagesFosroc Conbextra HF precision groutThrtThrthNo ratings yet

- Lokfix: Polyester Resin Anchoring GroutDocument3 pagesLokfix: Polyester Resin Anchoring GroutMuneer ahmed100% (1)

- 10 - TDS - Emaco S22 NBDocument3 pages10 - TDS - Emaco S22 NBaahtagoNo ratings yet

- TDS-Conbextra-EP10M-IndiaDocument2 pagesTDS-Conbextra-EP10M-IndiaBabla SNo ratings yet

- TDS Conbextra EP10M IndiaDocument2 pagesTDS Conbextra EP10M Indiasyed AffanNo ratings yet

- 2-Nitoflor FC150Document4 pages2-Nitoflor FC150Ahmed I. GhallabNo ratings yet

- HIT Rebar Fatigue enDocument7 pagesHIT Rebar Fatigue enWalter CastilloNo ratings yet

- Renderoc HB25: Constructive SolutionsDocument4 pagesRenderoc HB25: Constructive SolutionsDoby YuniardiNo ratings yet

- Tabel Konversi SatuanDocument1 pageTabel Konversi SatuanSutopo AhmadNo ratings yet

- Intercure 99Document4 pagesIntercure 99Doby YuniardiNo ratings yet

- FOR DOCUMENTDocument2 pagesFOR DOCUMENTDoby YuniardiNo ratings yet

- Preco EAC-SDocument2 pagesPreco EAC-SDoby YuniardiNo ratings yet

- HIT Rebar Fatigue enDocument7 pagesHIT Rebar Fatigue enWalter CastilloNo ratings yet

- Masterflex 828: Hot Pour Joint Sealant, ASTM D1190Document2 pagesMasterflex 828: Hot Pour Joint Sealant, ASTM D1190Doby YuniardiNo ratings yet

- HIT Rebar Fatigue enDocument7 pagesHIT Rebar Fatigue enWalter CastilloNo ratings yet

- MBrace Putty ASEANDocument2 pagesMBrace Putty ASEANDoby YuniardiNo ratings yet

- Mastertop Primer 9Document3 pagesMastertop Primer 9Doby YuniardiNo ratings yet

- Mastertop 102: Natural Aggregate Concrete Surface HardenerDocument2 pagesMastertop 102: Natural Aggregate Concrete Surface HardenerDoby YuniardiNo ratings yet

- ProdukDocument3 pagesProdukDoby YuniardiNo ratings yet

- Intercryl 520Document4 pagesIntercryl 520Doby YuniardiNo ratings yet

- Intergard 774Document4 pagesIntergard 774Doby YuniardiNo ratings yet

- Interlac 826Document4 pagesInterlac 826Doby YuniardiNo ratings yet

- Masterflex 3000: Masterflex Sealing System For Irregular and Unconventional JointsDocument3 pagesMasterflex 3000: Masterflex Sealing System For Irregular and Unconventional JointsDoby YuniardiNo ratings yet

- Mastertop 566: Self Smoothing Cementitious Based Floor LevellerDocument2 pagesMastertop 566: Self Smoothing Cementitious Based Floor LevellerDoby YuniardiNo ratings yet

- Masterflex 3000Document2 pagesMasterflex 3000Doby YuniardiNo ratings yet

- Backer RodDocument2 pagesBacker RodDoby YuniardiNo ratings yet

- Preco EAC-SDocument2 pagesPreco EAC-SDoby YuniardiNo ratings yet

- Conbextra EUW: Water Insensitive Epoxy MaterialDocument2 pagesConbextra EUW: Water Insensitive Epoxy MaterialDoby YuniardiNo ratings yet

- Masterflex 3000: Masterflex Sealing System For Irregular and Unconventional JointsDocument3 pagesMasterflex 3000: Masterflex Sealing System For Irregular and Unconventional JointsDoby YuniardiNo ratings yet

- Mastertop 1240 AseanDocument2 pagesMastertop 1240 AseanDoby YuniardiNo ratings yet

- Ucrete Ud200 AseanDocument2 pagesUcrete Ud200 AseanDoby YuniardiNo ratings yet

- Mastertop 1220 AseanDocument3 pagesMastertop 1220 AseanDoby YuniardiNo ratings yet

- Mastertop 1240 AseanDocument2 pagesMastertop 1240 AseanDoby YuniardiNo ratings yet

- Intergard 774Document4 pagesIntergard 774Doby YuniardiNo ratings yet

- Intergard 774Document4 pagesIntergard 774Doby YuniardiNo ratings yet

- Aircraft MaterialsDocument44 pagesAircraft MaterialsIan100% (2)

- Hydraulics and Fluid Mechanics (Indiabix)Document24 pagesHydraulics and Fluid Mechanics (Indiabix)Jawahir GomezNo ratings yet

- Unit 5 Vibration and Strain MeasurementDocument12 pagesUnit 5 Vibration and Strain Measurement08 Dadarkar Mujtaba MEANo ratings yet

- Info Iec60740-1 (Ed1.0) enDocument8 pagesInfo Iec60740-1 (Ed1.0) enadimas.yudistira124No ratings yet

- P N Junction Theory and Diodes Part II - GATE Problems 001Document32 pagesP N Junction Theory and Diodes Part II - GATE Problems 001ayush guptaNo ratings yet

- Lecture 1 - Stress-Strain RelationshipDocument26 pagesLecture 1 - Stress-Strain RelationshipSri JaiandranNo ratings yet

- Ba2487 PDFDocument19 pagesBa2487 PDFHazel Liow HYNo ratings yet

- Flow Handbook PDFDocument69 pagesFlow Handbook PDFRebwar ChalabianiNo ratings yet

- Schneider Electric - Easy-Harmony-XA2 - XA2ED41Document6 pagesSchneider Electric - Easy-Harmony-XA2 - XA2ED41Trung Trinh BaoNo ratings yet

- Hot Lithography Sla 3d Printing of Epoxy ResinDocument6 pagesHot Lithography Sla 3d Printing of Epoxy ResinMircavid HeydəroğluNo ratings yet

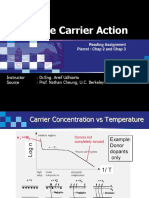

- Mobile Carrier Action: Instructor: DR - Eng. Arief Udhiarto Source: Prof. Nathan Cheung, U.C. BerkeleyDocument23 pagesMobile Carrier Action: Instructor: DR - Eng. Arief Udhiarto Source: Prof. Nathan Cheung, U.C. BerkeleyMess YeahNo ratings yet

- Yasuda 1974Document15 pagesYasuda 1974Rodrigo Rodrigues de BarrosNo ratings yet

- Unlock-Durcomet 100 (CD-4MCu)Document8 pagesUnlock-Durcomet 100 (CD-4MCu)Dimas Pratama PutraNo ratings yet

- Astm - F 477 (2002)Document4 pagesAstm - F 477 (2002)Calidad.comecaranNo ratings yet

- Wiley - Progress in Thermal Barrier CoatingsDocument5 pagesWiley - Progress in Thermal Barrier CoatingsHozefa TinwalaNo ratings yet

- Ihsan Ullah Khan ThesisDocument66 pagesIhsan Ullah Khan ThesisBehramand KhanNo ratings yet

- Lamco - New Instruction Manual (LA)Document18 pagesLamco - New Instruction Manual (LA)sarat sahooNo ratings yet

- Standardi U Oblasti Ispitivanja Metodama Bez RazaranjaDocument6 pagesStandardi U Oblasti Ispitivanja Metodama Bez Razaranjastefanvaljevo100% (1)

- "Tunnel Field Effect Transistors (TFET) ": Prepared By:-Group 10Document24 pages"Tunnel Field Effect Transistors (TFET) ": Prepared By:-Group 10Rajesh Sharma50% (2)

- Advances in Bioengineering - Pier Andrea Serra PDFDocument384 pagesAdvances in Bioengineering - Pier Andrea Serra PDFAgustiany MonicaNo ratings yet

- HYSYS Stream ReportDocument16 pagesHYSYS Stream Reportkh!mNo ratings yet

- Lesson Plan 38Document6 pagesLesson Plan 38suhailielias0% (2)

- (반도체공학) Fundamentals of Semiconductor Devices SolutionsDocument195 pages(반도체공학) Fundamentals of Semiconductor Devices Solutionsjuyun010514No ratings yet

- Preparatory Notes For ASNT NDT Level III Examination - Ultrasonic Testing, UTDocument19 pagesPreparatory Notes For ASNT NDT Level III Examination - Ultrasonic Testing, UTsafeer ahmadNo ratings yet

- Design of Shear ReinforcementDocument29 pagesDesign of Shear ReinforcementLuan Truong VanNo ratings yet

- Minimum Thickness Requirements for Two-Way SlabsDocument33 pagesMinimum Thickness Requirements for Two-Way SlabsJamal RkhNo ratings yet

- X-Ray Diffraction (XRD)Document39 pagesX-Ray Diffraction (XRD)Shaba ShaikhNo ratings yet

- Wachemo University Department of Mechanical Engineering Wachemo UniversityDocument14 pagesWachemo University Department of Mechanical Engineering Wachemo UniversityZó LáNo ratings yet

- Asset Integrity ManagementDocument31 pagesAsset Integrity ManagementParesh HaribhaktiNo ratings yet

- 8.3 The Carnot Cycle As A Two-Phase Power Cycle: (Cycle in - Coordinates) (Cycle inDocument26 pages8.3 The Carnot Cycle As A Two-Phase Power Cycle: (Cycle in - Coordinates) (Cycle inAkatew Haile MebrahtuNo ratings yet