Professional Documents

Culture Documents

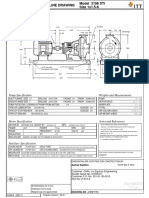

Sr. No. Particulars Value Unit of Measuremen T: MSGL-3KL-R002B/C

Uploaded by

Bhaumik BhuvaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sr. No. Particulars Value Unit of Measuremen T: MSGL-3KL-R002B/C

Uploaded by

Bhaumik BhuvaCopyright:

Available Formats

Unit Of

Sr. No. Particulars Measuremen value

t

MSGL-3KL-R002B/C

Working - 3 KL

1 Capacity KL Total Volume - 3.35 KL

Details of fluid being

2 handled

Toluene-99%

Traces of sulfuric acid

-Chemical compostion % Na2SO4-0.2%

water-0.8%

-Temperature °C

maximum 120

Operating 35

-Pressure Kg/Cm2 G

Maximum 1

Operating Atmospheric

-Viscosity Cp 8

-Vapor pressure of Kg/cm2G 0.07

liquid

-Specific gravity 1.1

-Percentage of solids % 0.2

3 Details of Jacket

agitated nozzle/Spiral

- Type of Jacket Jacket

4 Agitator RPM RPM Vendor to Specify

5 Agitator Type Vendor to Specify

Shaft Size MM Vendor to Specify

Thermowell

Thermowell Cum

6 With Tantalum Tip &

Baffle RTD(1Nos)

7 Sealing Arrangement Mech Seal

- Type of Mechanical Single Mech Seal

Seal

- Make of Seal Hi Fab

Carbon V/S SIC With

- Face combination Kalrez "O" Ring

8 Outlet nozzle size NB 100 NB

9 Motor Rating HP/KW Vendor to Specify

Power Consumption HP/KW Vendor to Specify

Flame proof Electric

motor- Crompton /BB

Type of Motor Make, IE2,50Hz,Issue 4,

VFD suitable(VFD in

customer scope)

Details of Drive Gear Box

- Type of Gear Box Inline Helical

Helical Inline

- Gearbox Make Bongfiglioli Make

Material of

10 Construction of all -

Parts Required

SA 516 Gr.55 or

Vessel Body

SAequivalent

516 Gr.55 or

Jacket

equivalent

Flanges for Jacket

SA 105

Nozzles

Jacket Nozzles SA 106 Gr.B or equivalent

PTFE enveloped with

Gaskets for Main Body

Compressed Asbestos

Openings

free Inserts

Manhole Cover, SA 516 Gr. 60/70 with

Protection Ring FEP lined protection ring

PTFE bushes for all

Nozzle Bushes nozzles including manhole

(Std. Length)

MS PTFE lined internally

11 Dip pipe and externally

80 NB-1 Nos

Jacket -6 kg/cm2(g)

12 Design Pressure KG/CM2 Vessel- F.V & 6 kg/cm2

(g)

Vessel & Jacket -28.8 to

13 Design Temperature °C 150°C

Corrosion Allowance Vessel 1.5 mm (External)

14 MM

(base metal) Jacket 1.5 mm (Internal)

Final Hydro test

15 Hydro Test KG/CM2 pressure: 6 kg/cm2 (g),

after glass lining.

Spark Test (20 kV during

process of glass lining,

16 Spark Test KV and 10 kV after hydro

test)

Glass Lining thickness

17 MM 0.8 to 2.0 mm.

range

18 Gore Gasket Optional quoted

Only GA drawing will be

19 Fabrication drawing

provided

Design & Manufacturing

standard-ASME VIII

DIV1 UNSTAMPED-

Latest Revision,

Pre-Treatment:Removal

of Rust by blasting.one

coat of zinc phospate

epoxy primer & two

20 Other details

coats of acrylick

polyurethene enamel

paint,

Dummy wooden flanges

for all Nozzle,

MSGL Manhole cover

with spring load & sight

glass assembly in MS

21 Nozzle Schedule

Description Size (NB in mm) Remarks

Manhole N1 450 with 100NB Sight Glass

Spare N2 100 80NB nozzle with blind

Spare N3 100

Thermowell

Temperature

200 With Tantalum Tip

transmitter N5

RTD(1Nos)

Light Glass N6 100

PG N7 200 80NB nozzle

LT N9 100

Vent N10 100

Jacket drain T11 25

Bottom outlet L 100

Jacket vent N13 25

Overflow shell side

100 80NB dip pipe

N18

Agitator M 150

Service N11 50

Service N15 50

Service N16 50

Service N17 50

Overflow shell side

100

N19

You might also like

- 3kl R 002ADocument3 pages3kl R 002ABhaumik BhuvaNo ratings yet

- 01.data SheetDocument1 page01.data SheetBhargav PatelNo ratings yet

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDocument5 pagesTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi VelNo ratings yet

- Valvula Seguridad Serie 2700 27da23 m21 FarrisDocument2 pagesValvula Seguridad Serie 2700 27da23 m21 Farrisesteban casanovaNo ratings yet

- ALPHA CVP-520 Solder Paste EN 25nov19 TBDocument6 pagesALPHA CVP-520 Solder Paste EN 25nov19 TBDeep SharmaNo ratings yet

- KSB MIL Steam Vent Valve Spec SheetDocument36 pagesKSB MIL Steam Vent Valve Spec SheetNutan PowerNo ratings yet

- Specification For Fire Pump - Part 10Document5 pagesSpecification For Fire Pump - Part 10Melisa MackNo ratings yet

- Gearboxes Series RD: Multipurpose HousingDocument21 pagesGearboxes Series RD: Multipurpose HousingAl BorkiNo ratings yet

- Final - Pump Datasheet - 5P0312ABCD - Code 1Document2 pagesFinal - Pump Datasheet - 5P0312ABCD - Code 1Rishabh VermaNo ratings yet

- Unicom ValveDocument27 pagesUnicom ValveSandi AslanNo ratings yet

- Norm Ex ValvesDocument6 pagesNorm Ex Valvesapi-3712612No ratings yet

- MST188X 699188 LowDocument1 pageMST188X 699188 LowGreg MeyerNo ratings yet

- Calorifier Data SheetDocument4 pagesCalorifier Data SheetgksakthiNo ratings yet

- RS-13 5-8-5m Annular BOP Operaion ManualDocument6 pagesRS-13 5-8-5m Annular BOP Operaion ManualAlexsandro Cordeiro100% (2)

- 10BFFRM2D0Document4 pages10BFFRM2D0Diego BarriosNo ratings yet

- Fv101x - Specsht2Document1 pageFv101x - Specsht2Claudio Rivadeneira CarrascoNo ratings yet

- V 020700905 B438 0003 GDocument11 pagesV 020700905 B438 0003 GHaroldCallanBacaNo ratings yet

- Catalogo Tecnico Valvula y Actuador GEMU 656Document6 pagesCatalogo Tecnico Valvula y Actuador GEMU 656Ronulfo GutierrezNo ratings yet

- TGSB(M) Turbine OilDocument3 pagesTGSB(M) Turbine OilQuy NguyenNo ratings yet

- STD Line ACD6: Product DescriptionDocument8 pagesSTD Line ACD6: Product DescriptionEugenio LombardiNo ratings yet

- Nle11cnl 105h6174 r290 220v 50hz 09-2019 DsDocument6 pagesNle11cnl 105h6174 r290 220v 50hz 09-2019 Dspadilla.marcos.420No ratings yet

- Newco Cast Steel Valves Tech DataDocument86 pagesNewco Cast Steel Valves Tech Dataeduardo goveaNo ratings yet

- ISO Standard End-Suction Centrifugal Pumps NJRP Series: GFRPP PP-HDocument7 pagesISO Standard End-Suction Centrifugal Pumps NJRP Series: GFRPP PP-HBrijesh GajjarNo ratings yet

- Technical Offer: Pump Description Pump ModelDocument4 pagesTechnical Offer: Pump Description Pump ModelPraveen PrajapatiNo ratings yet

- Heat Exchanger - Preliminary Data SheetDocument4 pagesHeat Exchanger - Preliminary Data SheetgksakthiNo ratings yet

- Activated Carbon Comparison SheetDocument4 pagesActivated Carbon Comparison SheetsoumitrabanNo ratings yet

- Technical Specification Sheet: Sr. No Project: Division: Doc. No: 3.1 IdentityDocument16 pagesTechnical Specification Sheet: Sr. No Project: Division: Doc. No: 3.1 IdentityRishabh VermaNo ratings yet

- Skfgrease lgmt3Document2 pagesSkfgrease lgmt3Suniil AjmeraNo ratings yet

- Enquiry Questionnaire-Spray Lubrication System: Customer: Project: EquipmentDocument1 pageEnquiry Questionnaire-Spray Lubrication System: Customer: Project: EquipmentRajmohan KushwahaNo ratings yet

- 62_prezentaciya_asmm_niiar-zaharychev_eng (2)Document13 pages62_prezentaciya_asmm_niiar-zaharychev_eng (2)sujayan2005No ratings yet

- DNC-100-125-PPV-A ISO cylinder data sheetDocument2 pagesDNC-100-125-PPV-A ISO cylinder data sheetRuBeN cruzNo ratings yet

- Standard Cylinder DNC-63 - PPV-A: Data SheetDocument1 pageStandard Cylinder DNC-63 - PPV-A: Data SheetAnonymous 1JHrgYNo ratings yet

- Features Material Specifications: ApplicationDocument1 pageFeatures Material Specifications: ApplicationMaulik ShahNo ratings yet

- Magnetic Level Gauges & Level Transmitters: FeaturesDocument3 pagesMagnetic Level Gauges & Level Transmitters: Featuressunshine dreamNo ratings yet

- Surface Condenser Specification Sheet: DesignDocument1 pageSurface Condenser Specification Sheet: DesignboeiniNo ratings yet

- Tsa 2Document6 pagesTsa 2Amit SurtiNo ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- Asco Series 210 Gas Shutoff No CatalogDocument2 pagesAsco Series 210 Gas Shutoff No CatalogManuel ParraNo ratings yet

- NiCu-7 solid wire for welding nickel-copper alloysDocument1 pageNiCu-7 solid wire for welding nickel-copper alloyssatnamNo ratings yet

- Socket Welded Ball Valve Data SheetDocument1 pageSocket Welded Ball Valve Data SheetSachin KumarNo ratings yet

- Trencor Electric (25k)Document72 pagesTrencor Electric (25k)Adades Safede EfdNo ratings yet

- Product data sheet valve designDocument1 pageProduct data sheet valve designIoana PopescuNo ratings yet

- Goulds 3196 Pump CurveDocument5 pagesGoulds 3196 Pump CurveCamilo Pinzon100% (1)

- Boiler MIURA - LX-300-16Document2 pagesBoiler MIURA - LX-300-16LuizPauloCostaNo ratings yet

- Pump Catalog 2017 enDocument124 pagesPump Catalog 2017 enBassam AmirNo ratings yet

- DS0124 Standard EU enDocument4 pagesDS0124 Standard EU enAli Abdul MannanNo ratings yet

- Aluminum 7075 SpecsDocument3 pagesAluminum 7075 SpecsZakaria MuhammadNo ratings yet

- Data Sheet - Rotary Gas Meter: RRPL-OGD-DOC-NO:-GGL-RPD-150-003 Sheet 1 of 1Document1 pageData Sheet - Rotary Gas Meter: RRPL-OGD-DOC-NO:-GGL-RPD-150-003 Sheet 1 of 1akshay bahalNo ratings yet

- Specification Sheet: MartensiticDocument7 pagesSpecification Sheet: MartensiticErick Renzo Hidalgo OrtegaNo ratings yet

- C2647546Document4 pagesC2647546Łukasz OlszewskiNo ratings yet

- Typical Uses: Product Description: Solids: Tubes: Rectangles: Standard Lengths: Shape/Form: ComplianceDocument2 pagesTypical Uses: Product Description: Solids: Tubes: Rectangles: Standard Lengths: Shape/Form: Compliance杜文欽No ratings yet

- Data Sheet 2 Less 800# PV - SW - LT-76Document1 pageData Sheet 2 Less 800# PV - SW - LT-76Sachin KumarNo ratings yet

- PRS XAS 48-7 G 6 kVA KD S5 EN Antwerp 2960 7180 00Document5 pagesPRS XAS 48-7 G 6 kVA KD S5 EN Antwerp 2960 7180 00duroux.thibaultNo ratings yet

- Quarter Turn Actuator DFPD-N-240-RP-90-RD-F0710-R3-EP: Data SheetDocument2 pagesQuarter Turn Actuator DFPD-N-240-RP-90-RD-F0710-R3-EP: Data SheetMiguel AngelNo ratings yet

- SizingDocument4 pagesSizingAlberto ReyesNo ratings yet

- Pentair Pilot Enclosures For Non-Hazardous LocationDocument6 pagesPentair Pilot Enclosures For Non-Hazardous LocationEdson MirandaNo ratings yet

- GRINNEL Fig 577Document4 pagesGRINNEL Fig 577rutyNo ratings yet

- Ecoline Est 150-600Document21 pagesEcoline Est 150-600Yosses Sang NahkodaNo ratings yet

- DATA SHEET FIRE PEERLESS ELECTRICO 75HP-220V-MOD-4AEF10C (500 GPM at 150P...Document20 pagesDATA SHEET FIRE PEERLESS ELECTRICO 75HP-220V-MOD-4AEF10C (500 GPM at 150P...LUIS SOTELO50% (2)

- New - 6Document1 pageNew - 6Bhaumik BhuvaNo ratings yet

- Support ShortcutsDocument14 pagesSupport ShortcutsBhaumik BhuvaNo ratings yet

- Analytical Modelling and Experimental Validation of 2017 International JourDocument9 pagesAnalytical Modelling and Experimental Validation of 2017 International JourBhaumik BhuvaNo ratings yet

- N.V. Dale, C. Y. Biaku, M. D. Mann, H. Salehfar, A. J. PetersDocument8 pagesN.V. Dale, C. Y. Biaku, M. D. Mann, H. Salehfar, A. J. PetersBhaumik BhuvaNo ratings yet

- Tank Design Criteria For Loads Exceeding Allowable LoadsDocument1 pageTank Design Criteria For Loads Exceeding Allowable LoadsBhaumik BhuvaNo ratings yet

- Piping material specification for RO feed and reject linesDocument3 pagesPiping material specification for RO feed and reject linesBhaumik BhuvaNo ratings yet

- New 4Document58 pagesNew 4Bhaumik BhuvaNo ratings yet

- New 5Document58 pagesNew 5Bhaumik BhuvaNo ratings yet

- PDF To ExcelDocument59 pagesPDF To ExcelBhaumik BhuvaNo ratings yet

- PDF To ExcelDocument59 pagesPDF To ExcelBhaumik BhuvaNo ratings yet

- Item Tag Qty. Designation Component Properties Material Cl. WeightDocument1 pageItem Tag Qty. Designation Component Properties Material Cl. WeightBhaumik BhuvaNo ratings yet

- GTU CIVIL ENGINEERING COURSE ON PLATES AND SHELLSDocument2 pagesGTU CIVIL ENGINEERING COURSE ON PLATES AND SHELLSBhaumik BhuvaNo ratings yet

- New 3Document1 pageNew 3Bhaumik BhuvaNo ratings yet

- Item Tag Qty. Designation Component Properties Material Cl. WeightDocument1 pageItem Tag Qty. Designation Component Properties Material Cl. WeightBhaumik BhuvaNo ratings yet

- Tank Design FormDocument26 pagesTank Design FormBhaumik BhuvaNo ratings yet

- Tank Design FormDocument26 pagesTank Design FormBhaumik BhuvaNo ratings yet

- Tank Design FormDocument26 pagesTank Design FormBhaumik BhuvaNo ratings yet

- Cryogenic Pipe SupportDocument24 pagesCryogenic Pipe SupportVikas Kumar PathakNo ratings yet

- 019-02 - 50 KL Mee Feed Storage Tank 21ST-017 & 21ST-018Document26 pages019-02 - 50 KL Mee Feed Storage Tank 21ST-017 & 21ST-018Bhaumik BhuvaNo ratings yet

- Tank Design FormDocument26 pagesTank Design FormBhaumik BhuvaNo ratings yet

- Lecture1Document17 pagesLecture1Cernat MihaiNo ratings yet

- Analysis and Design of Flat Slab and Grid Slab and Their CostDocument12 pagesAnalysis and Design of Flat Slab and Grid Slab and Their CostNayan K. Giri100% (1)

- PDF To ExcelDocument59 pagesPDF To ExcelBhaumik BhuvaNo ratings yet

- 1970 MECh 19 03 - R0 (E504)Document1 page1970 MECh 19 03 - R0 (E504)Bhaumik BhuvaNo ratings yet

- TSS Static Mixer - 16SM001Document1 pageTSS Static Mixer - 16SM001Bhaumik BhuvaNo ratings yet

- CF BLOWER 530 CFM SS316Document1 pageCF BLOWER 530 CFM SS316Bhaumik BhuvaNo ratings yet

- Valve ListDocument2,711 pagesValve ListBhaumik BhuvaNo ratings yet

- STRAINER - MEE - Cooling Water PumpDocument2 pagesSTRAINER - MEE - Cooling Water PumpBhaumik BhuvaNo ratings yet

- 3.2 Design & Procure Ment DataDocument8 pages3.2 Design & Procure Ment DataBhaumik BhuvaNo ratings yet

- E 50 Parts ManualDocument13 pagesE 50 Parts Manualsteve@air-innovations.co.zaNo ratings yet

- Electromagnetic Braking SystemDocument14 pagesElectromagnetic Braking SystemTanvi50% (2)

- Love Your Design Getting Started GuideDocument14 pagesLove Your Design Getting Started GuideOnalevel100% (9)

- U1L2 - Definitions of 21st Century LiteraciesDocument19 pagesU1L2 - Definitions of 21st Century LiteraciesJerry Glenn Latorre CastilloNo ratings yet

- 5 Tests of Significance SeemaDocument8 pages5 Tests of Significance SeemaFinance dmsrdeNo ratings yet

- An Introduction To Community DevelopmentDocument21 pagesAn Introduction To Community DevelopmentThuyAnh NgnNo ratings yet

- Best Mesl StudoDocument15 pagesBest Mesl StudoJoenielNo ratings yet

- Mil B 49430BDocument36 pagesMil B 49430Bparam.vennelaNo ratings yet

- 2VAA001695 en S Control NTCS04 Controller Station Termination UnitDocument43 pages2VAA001695 en S Control NTCS04 Controller Station Termination UnitanbarasanNo ratings yet

- J05720020120134026Functions and GraphsDocument14 pagesJ05720020120134026Functions and GraphsmuglersaurusNo ratings yet

- Brake System PDFDocument9 pagesBrake System PDFdiego diaz100% (1)

- University Reserch Worksheet PDFDocument7 pagesUniversity Reserch Worksheet PDFapi-410567922No ratings yet

- Timeline of Internet in The PhilippinesDocument29 pagesTimeline of Internet in The PhilippinesJhayson Joeshua Rubio100% (1)

- Writing A Spooky Setting DescriptionDocument4 pagesWriting A Spooky Setting DescriptionAayan AnjumNo ratings yet

- CEILING BOARDING GUIDEDocument5 pagesCEILING BOARDING GUIDEahahNo ratings yet

- Sea Cities British English Teacher Ver2Document6 pagesSea Cities British English Teacher Ver2Kati T.No ratings yet

- BA 302 Lesson 3Document26 pagesBA 302 Lesson 3ピザンメルビンNo ratings yet

- 3.1-Pile Design Calculation For Boundary (p1 To p50)Document24 pages3.1-Pile Design Calculation For Boundary (p1 To p50)layaljamal2No ratings yet

- ST326 - Irdap2021Document5 pagesST326 - Irdap2021NgaNovaNo ratings yet

- Guimaras State CollegeDocument5 pagesGuimaras State CollegeBabarianCocBermejoNo ratings yet

- Schwarzschild Metric and Black Hole HorizonsDocument39 pagesSchwarzschild Metric and Black Hole Horizonsসায়ন চক্রবর্তীNo ratings yet

- Pop-Up SystemDocument4 pagesPop-Up Systemkothat82No ratings yet

- READING 4.1 - Language and The Perception of Space, Motion, and TimeDocument10 pagesREADING 4.1 - Language and The Perception of Space, Motion, and TimeBan MaiNo ratings yet

- Lolita An Intelligent and Charming Holstein Cow Consumes Only TwoDocument1 pageLolita An Intelligent and Charming Holstein Cow Consumes Only Twotrilocksp SinghNo ratings yet

- Y06209 November 2015Document28 pagesY06209 November 2015Fredy CoyagoNo ratings yet

- Penomoran Bantex - K64&COMPDocument8 pagesPenomoran Bantex - K64&COMPVigour Rizko MurdyneNo ratings yet

- Lab 01 - HCV and LCV by Gas CalorimeterDocument6 pagesLab 01 - HCV and LCV by Gas CalorimeterTakreem SindhuNo ratings yet

- UN Habitat UPCL Myanmar TranslationDocument254 pagesUN Habitat UPCL Myanmar TranslationzayyarNo ratings yet

- Hyd Schematic 2658487205 - 005Document3 pagesHyd Schematic 2658487205 - 005Angelo Solorzano100% (2)

- Holacracy FinalDocument24 pagesHolacracy FinalShakil Reddy BhimavarapuNo ratings yet