Professional Documents

Culture Documents

Closing Unit Report: Findings

Uploaded by

farman ali ahmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Closing Unit Report: Findings

Uploaded by

farman ali ahmedCopyright:

Available Formats

CLOSING UNIT REPORT

REPORT DATE: 5-5-2019

MANUFACTURER: WINDLASS(WEIR) UNIT SERIAL NUMBER: 01-2560 BUILD DATE: 6-2014

RESERVOIR CAPACITY: 240 USG VOLUME-180

INSPECTION CONDUCTED BY: MD.FARMAN ALI AHMED

INSPECTION DATE: 5 MAY 2019

Unit is located UCTC WAREHOUSE Saudi Arabia it is a 16 station unit with Electrical control system.

Findings:

Accumulator bottles:

All 24 accumulator bottles remove from unit. The four bottle manifold and bottle racks have the

capacity for twenty four (24). 11 Gallon, top loaders with 1-1/4” type port.

Air/hydraulic pumps:

All three pumps are 60:1 8-1/2” type and are in place.

Air Pressure switches: one is for controlling up to 3,000 psi .

Air Lubricator, air filters: (1ea.)

The air filter and lubricator is still in place.And high pressure filter still in place.

Y- strainers: (5 ea.)

All Y- strainers are in place.

Air gauges:

All air pressure gauges are in working order. Consist of one air system pressure and three regulator

gauges.(Need calibration),Due date-15 JUNE-2019

Hydraulic gauges/digital

Four manifold gauges (bottle) are in order,(need calibration).Due date-15/JUNE/2019.

CLOSING UNIT REPORT

Electric pump module:

One triplex pump, missing data plates on, have 1-1/4” plungers in unit.

Electric motors: Pump is belt driven from a 40 HP electric motor, power requirements 460V/3ph/60hz.

Motor starter: One motor starter panel in good condition and in place. Motor starter controls have

detent in hand operation mode. Chain guards are in place and in good condition.

Valves:

1. Annular selector valve: 1-1/2” Barksdale.

2. Upper pipe ram selector valve: 1” Barksdale.

3. Blind ram selector valve: 1” Barksdale.

4. Lower pipe ram selector valve: 1” Barksdale.

5. Upper choke selector valve: 1” Barksdale. Not in use.

6. Lower choke selector valve: 1” Barksdale. Not in use.

7. Upper kill selector valve: 1” Barksdale. Not in use.

8. Spare selector Valve: 1“Barksdale. Not in use.

9. Choke line: Selector valve 1” Barksdale.

10. Kill line: Selector valve: 1/2” Barksdale.

11. Emergency kill: Selector valve: 1/2” Barksdale..

12. Spare 1 Selector valve: 1/2” Barksdale.

13. Spare 2 Selector valve: 1/2” Barksdale.

14. Spare 3 Selector valve: 1/2” Barksdale.

15. Spare 4 Selector valve: ½” Barksdale.

16. Bypass Selector Valve: 1” Barksdale.

All above valves, air actuator cylinders and all connecting air tubing are in place and appear to be in

good general condition.(but have not been tested).

Annular Regulator TR5:

Air motor installed for remote control. Hand control valve on unit is in place an operational. Equipped

with 1-1/2” piping.

Manifold regulator: MTR5:

1” piping with selector valve.

CLOSING UNIT REPORT

Air receiver: (1 ea.)

Air tank is in place with data plate, pressure gauge and pressure relief valve.Due date 30-12-19

Alarm system:

Shear ram cover alarm switch is available.

Pipe SCH:

All 1” and 1-1/2” hydraulic pipe is SCH 160.

Observations:

The BOP accumulator control system appears to be in normal condition . Assessment without

pressurized the unit.

Pressure relief valves: (2 each)

System pressure relief valve on valve manifold is 3300psi and 4500PSI

CLOSING UNIT REPORT

Recommendations:

Conduct 5 year bottle inspection on the existing 24 ea. 11 gallon bottles.

Calibrate, inspect all gauges. Replace as necessary. (DUE DATE-15-JUNE-2019).

Remove isolation valve from triplex pump line.

Inspection air receiver tank 2.6year recertification.

Recommended hydraulic oil analysis (optional change new hydraulic oil AW68).

You might also like

- Cad 10005479Document4 pagesCad 10005479farman ali ahmedNo ratings yet

- Accumulator and BOP Control Unit5 - Aly2Document65 pagesAccumulator and BOP Control Unit5 - Aly2Khaled YazidNo ratings yet

- Hydraulic Control System CompactDocument4 pagesHydraulic Control System CompactEmi MariniNo ratings yet

- Final Backup System Control Philosophy Rev4Document9 pagesFinal Backup System Control Philosophy Rev4AhmedNo ratings yet

- Enerflex: PHASE 4-RC-06 - x000D - Daily Activity ReportDocument21 pagesEnerflex: PHASE 4-RC-06 - x000D - Daily Activity ReportShahzad AhmadNo ratings yet

- SECTION7Document168 pagesSECTION7Palmério CarvalhoNo ratings yet

- 1 System Description LP3-RLU - 13.02.2006 New NHP5Document9 pages1 System Description LP3-RLU - 13.02.2006 New NHP5Andrei ZahaNo ratings yet

- Hydraulic Power UnitsDocument5 pagesHydraulic Power UnitsKhaled ZaherNo ratings yet

- Control Valve Characteristics PDFDocument20 pagesControl Valve Characteristics PDFPrem SagarNo ratings yet

- Standard Operating Procedure of Endurance Testing of 48GPM Hydraulic Gear PumpDocument6 pagesStandard Operating Procedure of Endurance Testing of 48GPM Hydraulic Gear PumpBrain TeaserNo ratings yet

- B.L.D.E.A'S Polytechnic, Bijapur Department of Mechatronics Engineering Electropneumatics Lab Viva Question - AnswersDocument6 pagesB.L.D.E.A'S Polytechnic, Bijapur Department of Mechatronics Engineering Electropneumatics Lab Viva Question - AnswersbharatNo ratings yet

- Accumulator (Koomey)Document26 pagesAccumulator (Koomey)Martin ToledoNo ratings yet

- Cold Startup 1Document51 pagesCold Startup 1Vel MuruganNo ratings yet

- Hydraulic Systems Design GuidelinesDocument29 pagesHydraulic Systems Design Guidelinesrajesh09100% (3)

- Subsea - Page 4Document79 pagesSubsea - Page 4lulalala8888100% (2)

- Operating Manual Manual de Instrucciones Manuel D'utilisationDocument16 pagesOperating Manual Manual de Instrucciones Manuel D'utilisationCarlos EscalonaNo ratings yet

- HP BypassDocument15 pagesHP Bypass150819850No ratings yet

- Module 4Document67 pagesModule 4Achsah K VijuNo ratings yet

- Accumulator - Yancheng RuihuaDocument26 pagesAccumulator - Yancheng RuihuaBoedi SyafiqNo ratings yet

- Williams V Series Pump IomDocument32 pagesWilliams V Series Pump IomHectorMaldonado100% (1)

- Hypress Compressor For VSP (Vertical Seismic Profile) JobDocument103 pagesHypress Compressor For VSP (Vertical Seismic Profile) JobIAN.SEMUTNo ratings yet

- Fire Pump PropertiesDocument62 pagesFire Pump Propertiesyamaha100% (2)

- Hydraulic Control System IntermediateDocument8 pagesHydraulic Control System IntermediateEmi MariniNo ratings yet

- Pneumatic Circuit TrainerDocument5 pagesPneumatic Circuit Trainerdipsankar chatterjeeNo ratings yet

- Summary TECNO WHOLE UNIT 2Document10 pagesSummary TECNO WHOLE UNIT 2EmiliamakedaNo ratings yet

- Hydraulic Valve Test Bench H300Document23 pagesHydraulic Valve Test Bench H300masakpNo ratings yet

- Hydraulic Valve Test Bench-H300Document23 pagesHydraulic Valve Test Bench-H300ValveTest100% (2)

- 4.oil Hydraulic Circuit Trainer KitDocument13 pages4.oil Hydraulic Circuit Trainer KitAlmas 1710No ratings yet

- BOP Control System Calculation Sheet PDFDocument8 pagesBOP Control System Calculation Sheet PDFAlecs Nedea100% (1)

- Super Choke BasicsDocument10 pagesSuper Choke BasicsTg TarroNo ratings yet

- Manual Comando Control Air Hd2Document12 pagesManual Comando Control Air Hd2Brian Schmidt100% (2)

- 980a2542 PDFDocument58 pages980a2542 PDFMichael DavenportNo ratings yet

- Hydraulic&Pneumatic (New)Document71 pagesHydraulic&Pneumatic (New)Saptarshi Basu100% (1)

- D2882Document6 pagesD2882rimi7alNo ratings yet

- 0 Hvac ChecklistDocument13 pages0 Hvac ChecklistAssem Elhajj100% (1)

- Major Works To Be DoneDocument6 pagesMajor Works To Be DoneAustin UdofiaNo ratings yet

- 938 Ds Hydraulic Power Unit Type Hv200Document4 pages938 Ds Hydraulic Power Unit Type Hv200shashikanth79No ratings yet

- Perguntas ANAC PROVA GMPDocument4 pagesPerguntas ANAC PROVA GMPLucas LaurentinoNo ratings yet

- PneumaticsDocument34 pagesPneumaticsLohath Unique67% (3)

- Super Choke BasicsDocument10 pagesSuper Choke Basicsel_guariquenoNo ratings yet

- Mec2407: Electromechanics Fluid Power System - Pneumatic SystemDocument12 pagesMec2407: Electromechanics Fluid Power System - Pneumatic SystemEdwin Jesu DassNo ratings yet

- Technical Report 1Document19 pagesTechnical Report 1jaigemuk0% (1)

- Exercise 6 AnswersDocument39 pagesExercise 6 AnswersadeelsnNo ratings yet

- Chapter 1 Pneumatic SystemDocument95 pagesChapter 1 Pneumatic SystemNazer Mangirapin BarisNo ratings yet

- SECTION 07 Hydraulics2 9020-9030Document16 pagesSECTION 07 Hydraulics2 9020-9030Vjz10997100% (2)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Accumulator or Koomey UnitDocument3 pagesAccumulator or Koomey Unitmmohsinaliawan100% (3)

- Gas Turbine StartupDocument9 pagesGas Turbine Startuppawangwl100% (2)

- ATA 29 SummaryDocument12 pagesATA 29 Summarypknight2010No ratings yet

- MZQ-B300-38-C Computer Control Push Down Valve Test Bench R.2Document11 pagesMZQ-B300-38-C Computer Control Push Down Valve Test Bench R.2ahsun habibNo ratings yet

- 05-MAR Ammonia PurgerDocument2 pages05-MAR Ammonia PurgerlhotapNo ratings yet

- API 6A Hydraulic Actuator Operation InstructionDocument7 pagesAPI 6A Hydraulic Actuator Operation InstructionSrikanth Bammhide100% (1)

- Report: Pneumatic UTMDocument14 pagesReport: Pneumatic UTMadibah ismail50% (2)

- CH - 36Document5 pagesCH - 36mpusNo ratings yet

- Primary Foam Tender (PFT)Document7 pagesPrimary Foam Tender (PFT)rmaffireschoolNo ratings yet

- TC02 DigitalDocument17 pagesTC02 DigitalNebojsa CekicNo ratings yet

- 8 Most Common Problems in Hydraulic Operated Remote Valve System On ShipsDocument23 pages8 Most Common Problems in Hydraulic Operated Remote Valve System On ShipsVasileios PantouvakisNo ratings yet

- Descritivo de Manutenção - Guindaste Appleton Marine - SWL 30 TonsDocument9 pagesDescritivo de Manutenção - Guindaste Appleton Marine - SWL 30 TonsSérgio Meneses VieiraNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- 4.1. Working HoursDocument1 page4.1. Working Hoursfarman ali ahmedNo ratings yet

- Quotation Caravan BladderDocument1 pageQuotation Caravan Bladderfarman ali ahmedNo ratings yet

- Requirement For Bop Control Unit Lying at Uctc Yard: 6nos 22NOS 16NOSDocument1 pageRequirement For Bop Control Unit Lying at Uctc Yard: 6nos 22NOS 16NOSfarman ali ahmedNo ratings yet

- Daily PlaniningDocument1 pageDaily Planiningfarman ali ahmedNo ratings yet

- Resume For Control & Instrumentation Engineer: 2. Continue)Document6 pagesResume For Control & Instrumentation Engineer: 2. Continue)farman ali ahmedNo ratings yet

- Weir SPMDocument1 pageWeir SPMfarman ali ahmedNo ratings yet

- Dues/Survey Date Sheet of Flow Lines 2016-2017Document2 pagesDues/Survey Date Sheet of Flow Lines 2016-2017farman ali ahmedNo ratings yet

- Cameron Spare KitDocument1 pageCameron Spare Kitfarman ali ahmedNo ratings yet

- FILE-21 FILE-22: United Caravan United Caravan Oil & Gas Oil & Gas Servicing ServicingDocument2 pagesFILE-21 FILE-22: United Caravan United Caravan Oil & Gas Oil & Gas Servicing Servicingfarman ali ahmedNo ratings yet

- Material Request: United Caravan Trading & Contracting (Oil & Gas Division)Document1 pageMaterial Request: United Caravan Trading & Contracting (Oil & Gas Division)farman ali ahmedNo ratings yet

- Survey Report: Bop Control System With For Land Rig Bop Stack ON WeatherfordDocument5 pagesSurvey Report: Bop Control System With For Land Rig Bop Stack ON Weatherfordfarman ali ahmedNo ratings yet

- Closing Unit Report: FindingsDocument2 pagesClosing Unit Report: Findingsfarman ali ahmedNo ratings yet

- List of Engineer/Tech/Helper of Well Control Service: Name Qualification Knowledge SkillDocument7 pagesList of Engineer/Tech/Helper of Well Control Service: Name Qualification Knowledge Skillfarman ali ahmedNo ratings yet

- Cameron Spare KitDocument1 pageCameron Spare Kitfarman ali ahmedNo ratings yet

- RIG Description PSI Type Make Status Union QNT Status Received Date Repair Kit P/NoDocument2 pagesRIG Description PSI Type Make Status Union QNT Status Received Date Repair Kit P/Nofarman ali ahmedNo ratings yet

- Pipe JobDocument7 pagesPipe Jobfarman ali ahmedNo ratings yet

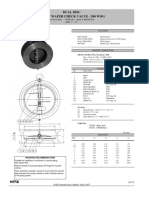

- Dual Disc Silent Wafer Check Valve - 200 Wog: Code No. 7032Document1 pageDual Disc Silent Wafer Check Valve - 200 Wog: Code No. 7032thilina lakhithaNo ratings yet

- Installation, Operation, Repair and Parts Manual: Series 9300 Hydraulically-Driven Centrifugal PumpsDocument28 pagesInstallation, Operation, Repair and Parts Manual: Series 9300 Hydraulically-Driven Centrifugal PumpsvandoNo ratings yet

- General Overview of Types of Pumps On ShipDocument3 pagesGeneral Overview of Types of Pumps On ShipGiorgi KandelakiNo ratings yet

- RoDocument60 pagesRosiva ramanNo ratings yet

- Plano Hidraulico 336DL PDFDocument13 pagesPlano Hidraulico 336DL PDFLEONo ratings yet

- Pulsafeeder PumpsDocument12 pagesPulsafeeder Pumpsanirudh278No ratings yet

- BBU For Yard PipingDocument6 pagesBBU For Yard Pipingkalyanm203515No ratings yet

- Hydraulic Main Valves (A40397.0100) - 20211004 - 033121Document5 pagesHydraulic Main Valves (A40397.0100) - 20211004 - 033121MIKELAM09No ratings yet

- A Presentation On PumpsDocument34 pagesA Presentation On PumpsSajjad Rasool ChaudhryNo ratings yet

- Hydraulics and CPCDocument202 pagesHydraulics and CPCKaan SarıoğluNo ratings yet

- Best PPT On VALVESDocument155 pagesBest PPT On VALVESPanda BoyNo ratings yet

- 2014 - 0011b Pipe Sizing For Water Supply and DistributionDocument34 pages2014 - 0011b Pipe Sizing For Water Supply and Distributiondino100% (1)

- EXCEL For Pump DesignDocument2 pagesEXCEL For Pump Designkad-7No ratings yet

- Valves: "Hose Bibb"Document3 pagesValves: "Hose Bibb"queeneequeeneeNo ratings yet

- Barrage 1 PDFDocument1 pageBarrage 1 PDFMuhammad ArhamNo ratings yet

- Rose NewDocument24 pagesRose NewRescos KasarachiNo ratings yet

- Engineering All in OneDocument245 pagesEngineering All in OneozchrisNo ratings yet

- 336e m08 Mainhydcntrval en StuDocument9 pages336e m08 Mainhydcntrval en StuKJDNKJZEFNo ratings yet

- Classification of Rotary PumpsDocument3 pagesClassification of Rotary Pumpsapi-26349602100% (2)

- US-8214-15.v8.25 (1) Hai An 500hp PDFDocument1 pageUS-8214-15.v8.25 (1) Hai An 500hp PDFViệt Đặng XuânNo ratings yet

- D7100 en PDFDocument19 pagesD7100 en PDFSasko DimitrovNo ratings yet

- 2 - Manut. Hydraulic M2Document64 pages2 - Manut. Hydraulic M2Ney HoraNo ratings yet

- 12s1ry 12s1gy 12s1gy 12R 12s1gy 12RDocument11 pages12s1ry 12s1gy 12s1gy 12R 12s1gy 12RJohn Fredy Simancas FierroNo ratings yet

- 326F Excavator Hydraulic System: Fluid Power SymbolsDocument2 pages326F Excavator Hydraulic System: Fluid Power SymbolsDozer KamilNo ratings yet

- CB-B2,5 PompaDocument2 pagesCB-B2,5 PompaÖzgür BiliciNo ratings yet

- Modul Amali Elektro-Pneumatik - 5nov08Document22 pagesModul Amali Elektro-Pneumatik - 5nov08saliana binti sanusiNo ratings yet

- Plumbing Engineering LecturesDocument60 pagesPlumbing Engineering LecturesEngr. IanNo ratings yet

- Centrifugal Pump - Theory and ProceduresDocument4 pagesCentrifugal Pump - Theory and ProceduresJelyn BenjaminNo ratings yet

- 10 AirbrakeDocument40 pages10 AirbrakebannetNo ratings yet

- BoQ MEP Club House KosongDocument53 pagesBoQ MEP Club House KosongkelikNo ratings yet