Professional Documents

Culture Documents

Western India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANY

Uploaded by

Deipak HoleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Western India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANY

Uploaded by

Deipak HoleCopyright:

Available Formats

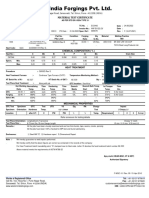

WESTERN INDIA FORGINGS PVT LTD TC No : 20189196

ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANY Date : 18/03/2019

Gat No 163, Hissa No 1, Sanaswadi, Nagar Road, Tal. Shirur, Dist. Pune - 412208 Page No. : 1

TEST CERTIFICATE

AS PER EN 10204 - 3.1 TYPE B

M/s : GECO SPECIAL MACHINERS

PO No : PO18-1906 Date: 08/02/2019 Challan No. DWIF/18-19/11483 Date : 18.03.2019

Die No. Description Condition Material Heat No. Size Qty (Nos)

RR 3-1755 FORGING FORGED ASTM A350 LF2 G0446 1

200011950-007-1125-RM HARDENED & ( As pe ASTM HT Lot No. 524 X 482 X 446

TEMPERED A350/ A350M-18) B1-1116

Chemical Composition (%)

Elements C Mn P S Si Cr Ni Mo Cu Nb V Cr+Mo Cu+Ni+Cr+V+Mo

ACTUAL 0.16 1.04 0.013 0.006 0.26 0.17 0.24 0.06 0.14 0.001 0.001 0.230 0.61

MINIMUM - 0.60 ---- ---- 0.15 - - - - - - - -

MAXIMUM 0.30 1.35 0.035 0.040 0.30 0.30 0.40 0.12 0.40 0.02 0.08 0.32 1.00

IMPACT TEST ( J ) TENSILE TEST UT Standard ASTM A 388-18

Heat Forgings Test Method ASTM A370-18 Test Method ASTM A370-18 THE ABOVE FORGINGS TESTED

Treatment Hardness Test Avg. Uts Y.S (0.2%) Elg.% R.A.% ULTRASONICALLY AND FOUND

I II III

BHN Method N/mm2 N/mm2 4D ACCEPTABLE.

156-Charpy 148 158 168 158.00 560.39 408.73 30.32 74.23

HARDENED & 163 V

TEMPERED TEMP. SPEC

197 BHN @ -46°C 27 J 485.00 250.00 22.00 30.00

MAX MIN 655.00 MIN MIN MIN

Remark : MATERIAL FOUND FREE FROM ANY SURFACE DEFECTS.

INCLUSION RATING : LESS THAN 2 ABCD

GRAIN SIZE : 6 ASTM

REDUCTION RATIO : 4.7:1

MICROSTRUCTURE : TEMPERED MARTENSITE

H. T. CYCLE :- HARDENING AT 950°C SOAKED FOR 4.0 HRS. K J Shetty

WATER QUENCH AND TEMPERING AT 590°C SOAKED FOR 7 HRS. AIR COOL MQC Incharge

We hereby certify that products supplied are in compliance with the above specification requirements. for WESTERN INDIA FORGINGS PVT. LTD.

F-MQC-09 / Rev. 00 / 01-Apr-2016

You might also like

- Rajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1Document1 pageRajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1qualityNo ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- Page 1 of 6: Test Certificate No. 0000052877Document6 pagesPage 1 of 6: Test Certificate No. 0000052877panduranganraghurama78% (9)

- Certified Material Test ReportDocument4 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- 1426 Ec2262Document3 pages1426 Ec2262Deepak HoleNo ratings yet

- MS SHEETS MTCDocument6 pagesMS SHEETS MTCAmit Kumar OjhaNo ratings yet

- 1426-EC1942Document3 pages1426-EC1942Deipak HoleNo ratings yet

- Certification As Per en 10204 3.1: Chemical Composition %Document2 pagesCertification As Per en 10204 3.1: Chemical Composition %BHUSHANNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- Test Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811Document1 pageTest Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811akash_smhs0% (1)

- Mask Fasteners Pvt. Ltd. CertificationDocument2 pagesMask Fasteners Pvt. Ltd. CertificationGaurav100% (1)

- Coupler Plate RM Pipe TCDocument1 pageCoupler Plate RM Pipe TCshindemitesh17No ratings yet

- D72307 TC2 PDFDocument2 pagesD72307 TC2 PDFshivdas bichukaleNo ratings yet

- Page 2 of 6: Test Certificate No. 0000052877Document1 pagePage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- CS PIPE MTC SampleDocument1 pageCS PIPE MTC SampleMark Joseph PagadorNo ratings yet

- 1466 - EC0044Document5 pages1466 - EC0044Deipak HoleNo ratings yet

- GR 70 32MMDocument1 pageGR 70 32MMquality nakodaNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romeroNo ratings yet

- C60 68719 - 25 QtyDocument1 pageC60 68719 - 25 QtyMohammad Shanawaz MNo ratings yet

- Tubacex 10Document2 pagesTubacex 10Akash SinhaNo ratings yet

- Bar No - 5763: Test CertificateDocument2 pagesBar No - 5763: Test CertificateDeepak HoleNo ratings yet

- Test Certificate DetailsDocument2 pagesTest Certificate Detailsshrikant bhirudNo ratings yet

- Rajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204-3.1Document1 pageRajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204-3.1qualityNo ratings yet

- Chandan Steel MTC for Stainless Steel Round Bars to ArgentinaDocument1 pageChandan Steel MTC for Stainless Steel Round Bars to ArgentinaAceros DessolNo ratings yet

- 1900 - EC2157-signedDocument4 pages1900 - EC2157-signedDeepak HoleNo ratings yet

- Certified Material Test ReportDocument4 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Coupler Plate RM Pipe TC 2Document1 pageCoupler Plate RM Pipe TC 2shindemitesh17No ratings yet

- Reporte Element T 47Document3 pagesReporte Element T 47Edson AragaNo ratings yet

- 2324MTC037 11363Document1 page2324MTC037 11363Shrikrushna DalviNo ratings yet

- Inspection Certificate: Customer: CommodityDocument1 pageInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

- HK 03 04 0041Document3 pagesHK 03 04 0041Šâįf ÄhmāđNo ratings yet

- Certif Tu InDocument18 pagesCertif Tu InSri GangaNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh MehtaNo ratings yet

- Material TCDocument1 pageMaterial TCgmbakshiNo ratings yet

- 1300 - Ec0313Document5 pages1300 - Ec0313Deepak HoleNo ratings yet

- Certificate: Parker Hannifin Instrumentation (Changzhou) Co., LTDDocument3 pagesCertificate: Parker Hannifin Instrumentation (Changzhou) Co., LTDgroupj.sr.servicesNo ratings yet

- Sample MTC For Anchor BoltDocument1 pageSample MTC For Anchor BoltSALMAN PARVEZ ROKADIANo ratings yet

- Page 1 of 9: Test Certificate No. 0000145263Document9 pagesPage 1 of 9: Test Certificate No. 0000145263Vishwanathan NagarajanNo ratings yet

- 1299 EC2153 SignedDocument5 pages1299 EC2153 SignedDeepak HoleNo ratings yet

- 1591 EC2213 SignedDocument5 pages1591 EC2213 SignedDeepak HoleNo ratings yet

- Heat No S13Document1 pageHeat No S13Siddharth ParmarNo ratings yet

- 1299 Ec1650Document4 pages1299 Ec1650Deepak HoleNo ratings yet

- Ribo TC 324 (00000003)Document1 pageRibo TC 324 (00000003)Vinay YadavNo ratings yet

- T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateDocument3 pagesT.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Material Test Certificate (En 10204 / 3.1) : A A 2-157 N U P, I - 201301Document1 pageMaterial Test Certificate (En 10204 / 3.1) : A A 2-157 N U P, I - 201301Devi SinghNo ratings yet

- UGINEDocument1 pageUGINEjesusNo ratings yet

- MTC Inv 053 PDFDocument1 pageMTC Inv 053 PDFBeshnu Garanaik100% (1)

- Test CertificateDocument2 pagesTest CertificatePRITESHNo ratings yet

- VTB-600-2 A105n W1834221,235,230.QR PDFDocument1 pageVTB-600-2 A105n W1834221,235,230.QR PDFJoe KylaNo ratings yet

- CHEMICAL TEST REPORT FOR STAINLESS STEEL SAMPLEDocument1 pageCHEMICAL TEST REPORT FOR STAINLESS STEEL SAMPLEESHWAR CHARYNo ratings yet

- Material Test Certificate: For: Priminox OverseasDocument2 pagesMaterial Test Certificate: For: Priminox OverseasDSAFNo ratings yet

- 10MM - 60.960 TonDocument4 pages10MM - 60.960 TonRAJKUMAR CHATTERJEE. (RAJA.)100% (1)

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1300 EC1986 SignedDocument4 pages1300 EC1986 SignedDeepak HoleNo ratings yet

- GLORIA MATERIAL TECHNOLOGY CORP. EVERCUT 316 STAINLESS STEEL SPECIFICATIONDocument1 pageGLORIA MATERIAL TECHNOLOGY CORP. EVERCUT 316 STAINLESS STEEL SPECIFICATIONViswanathan SrkNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOBilal Luhar100% (1)

- 1433 Ec0442Document6 pages1433 Ec0442Deepak HoleNo ratings yet

- Untitled Document2 PDFDocument1 pageUntitled Document2 PDFDeipak HoleNo ratings yet

- 1466 - EC0044Document5 pages1466 - EC0044Deipak HoleNo ratings yet

- 1335 - EC1904Document1 page1335 - EC1904Deipak HoleNo ratings yet

- Wifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDocument3 pagesWifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDeipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 456 PDFDocument4 pages456 PDFDeipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- Cameron CompDocument14 pagesCameron CompDeipak HoleNo ratings yet

- SC SIT Order 120911Document10 pagesSC SIT Order 120911Ranganaathan SoundararajanNo ratings yet

- Zora Test Astm A770Document1 pageZora Test Astm A770Deipak HoleNo ratings yet

- MPI Yoke QuotationDocument4 pagesMPI Yoke QuotationDeipak HoleNo ratings yet

- Punching Slip: Prepared by Date: MQC SignDocument1 pagePunching Slip: Prepared by Date: MQC SignDeipak HoleNo ratings yet

- StdReport10286 (7) 13.07.2019Document695 pagesStdReport10286 (7) 13.07.2019Deipak HoleNo ratings yet

- PD FileDocument3 pagesPD FileDeipak HoleNo ratings yet

- Zora Test Astm A770 PDFDocument126 pagesZora Test Astm A770 PDFDeipak HoleNo ratings yet

- Fishbone Diagram GeneratorDocument19 pagesFishbone Diagram GeneratormfernandNo ratings yet

- 4.01.1 Fish Bone Diagram InvoicesDocument22 pages4.01.1 Fish Bone Diagram InvoicesDeipak HoleNo ratings yet

- MQC RM Approval ModuleDocument5 pagesMQC RM Approval ModuleDeipak HoleNo ratings yet

- Punching Slip: Prepared by Date: MQC SignDocument1 pagePunching Slip: Prepared by Date: MQC SignDeipak HoleNo ratings yet

- Customer: Probe Oil Tools Ltd. Product Type: All Product: All Grade: All Sales Rep: All Location: WIFPLDocument1 pageCustomer: Probe Oil Tools Ltd. Product Type: All Product: All Grade: All Sales Rep: All Location: WIFPLDeipak HoleNo ratings yet

- मतदाता सूचना/Voter InformationDocument1 pageमतदाता सूचना/Voter InformationDeipak HoleNo ratings yet

- DEA R ScriptsDocument3 pagesDEA R ScriptsFrancisco SilvaNo ratings yet

- 050, 051Document28 pages050, 051kefaja67% (3)

- Government Engineering College Surveying Lab ManualDocument26 pagesGovernment Engineering College Surveying Lab ManualNittin BhagatNo ratings yet

- Pull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLineDocument7 pagesPull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLinecnuneza4No ratings yet

- CFS50 motor feedback installation instructionsDocument1 pageCFS50 motor feedback installation instructionsJavier AlzateNo ratings yet

- VDP08 Technical CatalogueDocument47 pagesVDP08 Technical CatalogueAdal VeraNo ratings yet

- EGIG - 10th - Report - Final - 09-03-2018 - v1Document50 pagesEGIG - 10th - Report - Final - 09-03-2018 - v1Paulo Marcos Cabral JuniorNo ratings yet

- Setting vpn1Document10 pagesSetting vpn1Unink AanNo ratings yet

- Technical Publications: Direction 2190775 100Document21 pagesTechnical Publications: Direction 2190775 100zakaria alhosinyNo ratings yet

- Schneider LV Switchboard Inspection GuideDocument59 pagesSchneider LV Switchboard Inspection GuideAlp Arslan Ok100% (1)

- Cs 180 Notes UCLADocument3 pagesCs 180 Notes UCLAnattaq12345No ratings yet

- Please Note That This Form Details Exploration and Production Api Titles Available For OrderDocument8 pagesPlease Note That This Form Details Exploration and Production Api Titles Available For Orderhaotran68No ratings yet

- Ford Essex V6 EngineDocument8 pagesFord Essex V6 EngineJoakamaster 16No ratings yet

- Acsomega 9b01541Document9 pagesAcsomega 9b01541Benedictus EduardoNo ratings yet

- ITILDocument16 pagesITILelenviegas82No ratings yet

- Timing Chain Tensioner ResetDocument4 pagesTiming Chain Tensioner ResetHybrid RacingNo ratings yet

- PHP AngularJS CRUD with Search and PaginationDocument18 pagesPHP AngularJS CRUD with Search and PaginationZaiful BahriNo ratings yet

- 3RInternational Tetzner Model Based Pipeline LDS 07-2003 PDFDocument6 pages3RInternational Tetzner Model Based Pipeline LDS 07-2003 PDFRene ParedesNo ratings yet

- Engine & Transmission ToolsDocument45 pagesEngine & Transmission Toolsabduallah muhammad100% (1)

- PVT Correlations McCain - ValkoDocument17 pagesPVT Correlations McCain - ValkoAlejandra Maleja RivasNo ratings yet

- LMDQDocument601 pagesLMDQMohd Azamuddin Mohd SaifullizanNo ratings yet

- Antena Eh para 10 MetrosDocument3 pagesAntena Eh para 10 Metros10sd156No ratings yet

- Asme B36.10M-2018Document36 pagesAsme B36.10M-2018امينNo ratings yet

- As 4123.4-2008 Mobile Waste Containers Containers With Four Wheels With A Capacity From 750 L To 1700 L WithDocument7 pagesAs 4123.4-2008 Mobile Waste Containers Containers With Four Wheels With A Capacity From 750 L To 1700 L WithSAI Global - APACNo ratings yet

- Versys Parts Catalogue (UK)Document111 pagesVersys Parts Catalogue (UK)BaronBaz001No ratings yet

- Department of Mechanical Engineering, Uet Lahore Refrigeration and Air Conditioning LaboratoryDocument7 pagesDepartment of Mechanical Engineering, Uet Lahore Refrigeration and Air Conditioning LaboratoryTauQeer ShahNo ratings yet

- Power and Simplicity: Pace ScientificDocument16 pagesPower and Simplicity: Pace ScientificAnonymous mNQq7ojNo ratings yet

- The Z-Transform: Introduction and DerivationDocument16 pagesThe Z-Transform: Introduction and DerivationAnanth SettyNo ratings yet

- Exploratory Boring Spacing & DepthDocument24 pagesExploratory Boring Spacing & Depth18106 Mahmudur RahmanNo ratings yet

- Memory Map and Address DecodingDocument9 pagesMemory Map and Address DecodingGhozi AlNo ratings yet