Professional Documents

Culture Documents

2019.02.28 Ref 113 Khaleegh Company

Uploaded by

ThirukkumaranBalasubramanian0 ratings0% found this document useful (0 votes)

0 views8 pagesKhaleegh

Original Title

2019.02.28 Ref 113 Khaleegh Company(1)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentKhaleegh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

0 views8 pages2019.02.28 Ref 113 Khaleegh Company

Uploaded by

ThirukkumaranBalasubramanianKhaleegh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

Luileoataisa —[]

21440 8 giles 23 Qi (By Gaal aby

oe : ee 2OID/1/N/e sha sy

MO oy Sa) Saad godly [et

she a ob gt Baty ba ide Sys

tne ay: at

coc Ayal) aay

pABLaN Chelan yl 3 Byuayly

in git Ley gy yhal ekaud!

Biya ga Scie Sie agi ae FS 5 eajall Algal plocell Ayia!

sas Geb Ge Lasigll 5yla) Gl Ughe 45 5 SY As GL pple WS) LSC Ley deal pall

. By ay SI

GIS pig all) om 49 onal yodlaallg

olen oF polly aon

Bshatl dda yaad

Sj dig sel

~ 00218612229006: jya-uy - 263'>.09- 00218612220031 - 40 :ua yi

0218214919122: srerax - 693: v.ce- 00218214919114 - 18 tA Gi

0218627622422: snaruy - Ad :w.ve- 0021862762204 - 47 td > Gb

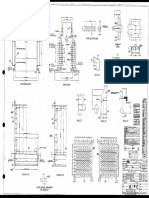

10.3.615-FIL-AGO-190225 LG

—2s

|Attachment 2

PEG Rohileitungssysteme GmbH 01.02.19

Ref. 70-9-0008 Enquiry for gate valves to API 600

2.1 Gate Valve Data Sheet

Item Qty TAG Valvesize Bore Cl: Ends Operator

ol Ol Tea 12 Inch Reg. ANSI 900 RTJ Gear + Handwheel

Design gate valve, bolted bonnet, OSE&Y, rising stem

Certified API 600

Firesafe APLOFA,

Design Temperature = 29° Cto+ 350°C

End Connections

RTJ to ANSI 16.5

Face to Face Dimensions. to ANSI B16.10

‘Components:

Part Material

Body ASTM A182 F6A WC9

Adapter

Bonnet ASTM A182 F6A WC9

Bolts! Studbolts ASTM A193 Gr B16

Nuts ASTM A194 Gr 2H

‘Trim Number to API No. 5

Gate wedge ASTM A182 F6A /13 Cr Steel plus Stellite 6

Stem. ASTM A182 F6A /13 Cr Steel plus Stelite 6

Seat Rings ASTM A182 F6A /13 Cr Steel plus Stelite 6

GENERAL NOTES

= Material certification

= Valve certification

~ Coating

Pressure containing parts to EN 10204 3.1.

Valve testing and final product to EN 10204 3.1

Shotblast SA 2%

I coat Inorganic Zine Silicate 75,

PEG Rohrleitungssysteme 01.02.19

Ref. 70-9-0008 Enquiry for gate valves to API 600

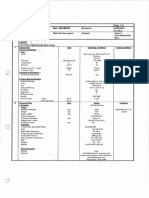

4.1 Testing, Inspection & Certification

Material Testing

Alll material for pressure containing parts shall be tested as follows:

AL. Determination of material chemical composition as per the applicable material standard

A2, Tensile testing will be performed as per the applicable material standard.

A3. Hardness testing will be performed as per the applicable material standard (if applicable).

‘A4. Charpy V-notch testing will be performed as per the applicable material standard if required by the

applicable material standard,

Finished Parts Testing

All valve pressure containing parts shal be tested as follo

BI, Visual examination (100 %)

B2, Inspection of critical dimensions (100%)

Pressure/Funetional Testing

Cl. Shell pressure testing to the certifying standard. Acceptance criteria for all pressure tests as per governing,

standards. All testing shall be done prior to any sealant injection if applicable).

Inspection

D1. Above testing may be witnessed by a customer's representative. Hold points to be identified.

Certification

El, Material certificates in accordance with EN 10204 3.1. for pressure containing parts.

E2, Pressure tes/functionaltest/final product certificates in accordance with EN 10204 3.1.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- CEIL Engineering FinHR Advt 202324 02Document6 pagesCEIL Engineering FinHR Advt 202324 02ThirukkumaranBalasubramanianNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Report On Evaluation of Backfill Soil and Field Density TestDocument274 pagesReport On Evaluation of Backfill Soil and Field Density TestThirukkumaranBalasubramanianNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Job Description-Piping EngineerDocument1 pageJob Description-Piping EngineerThirukkumaranBalasubramanianNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Burner ManualDocument24 pagesBurner ManualThirukkumaranBalasubramanianNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Equipment ListDocument1 pageEquipment ListThirukkumaranBalasubramanianNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Refractory Application ProcedureDocument9 pagesRefractory Application ProcedureThirukkumaranBalasubramanianNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- DF - Bo P 03 SQ 0001 - Revc2Document27 pagesDF - Bo P 03 SQ 0001 - Revc2ThirukkumaranBalasubramanianNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- TDW Pipeline Pigs & AccessoriesDocument66 pagesTDW Pipeline Pigs & AccessoriesThirukkumaranBalasubramanianNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- TDW Guide To PiggingDocument44 pagesTDW Guide To PiggingThirukkumaranBalasubramanianNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Job Description-Process EngineerDocument1 pageJob Description-Process EngineerThirukkumaranBalasubramanianNo ratings yet

- Service Unit Key Plan XrefDocument1 pageService Unit Key Plan XrefThirukkumaranBalasubramanianNo ratings yet

- Job Description-Mechanical EngineerDocument1 pageJob Description-Mechanical EngineerThirukkumaranBalasubramanianNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 7-123-4 - PLC I-O ListDocument11 pages7-123-4 - PLC I-O ListThirukkumaranBalasubramanianNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Esd Logic Diagrams 7-124-3Document42 pagesEsd Logic Diagrams 7-124-3ThirukkumaranBalasubramanianNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- D2-001-AM Part 1Document118 pagesD2-001-AM Part 1ThirukkumaranBalasubramanianNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- DS 7502Document4 pagesDS 7502ThirukkumaranBalasubramanianNo ratings yet

- S 51 172a 411J - F1Document18 pagesS 51 172a 411J - F1ThirukkumaranBalasubramanianNo ratings yet

- 3 101 1FDocument1 page3 101 1FThirukkumaranBalasubramanianNo ratings yet

- Basic Lifting Plan Rev01optDocument4 pagesBasic Lifting Plan Rev01optThirukkumaranBalasubramanianNo ratings yet

- BS P 03 X N 0032.00 - C1Document2 pagesBS P 03 X N 0032.00 - C1ThirukkumaranBalasubramanianNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Final Report TOTAL EP MYANMARDocument24 pagesFinal Report TOTAL EP MYANMARThirukkumaranBalasubramanianNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Summarized Technical - Information Data'sDocument1 pageSummarized Technical - Information Data'sThirukkumaranBalasubramanianNo ratings yet

- Visual Inspection WeldDocument53 pagesVisual Inspection Weldshifa100% (1)

- Pipeline Materials SelectionDocument87 pagesPipeline Materials Selectionbieito1968No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- F2 Underground PipesDocument1 pageF2 Underground PipesThirukkumaranBalasubramanianNo ratings yet

- Mellitah Oil & Gas BV: Welding Procedure Specification For Stainless Steel PipingDocument9 pagesMellitah Oil & Gas BV: Welding Procedure Specification For Stainless Steel PipingThirukkumaranBalasubramanianNo ratings yet

- PALL FILTER - Process Data SheetDocument2 pagesPALL FILTER - Process Data SheetThirukkumaranBalasubramanianNo ratings yet

- CUI Risk Factors on Insulated PipingDocument21 pagesCUI Risk Factors on Insulated PipingRenan Soares KieferNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Guide to Failure Analysis in Oil and Gas IndustryDocument6 pagesGuide to Failure Analysis in Oil and Gas IndustryThirukkumaranBalasubramanian100% (1)

- G 65 D 0 2001 01 P2Document1 pageG 65 D 0 2001 01 P2ThirukkumaranBalasubramanianNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)