Professional Documents

Culture Documents

Wifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-Signed

Uploaded by

Deipak HoleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-Signed

Uploaded by

Deipak HoleCopyright:

Available Formats

VENDOR'S NAME & ADDRESS QAP NO : WIFPL/QAP/2019-20/008

M/s. Western India Forgings Pvt. Ltd.

QUALITY ASSURANCE PLAN REVISION : 00

Gat No 163, Hissa No 1, Sanaswadi, Nagar CUSTOMER: HINDUSTAN EQUIPMENTS PVT. LTD. DATE : 23-APR-2019

Road, Tal. Shirur, Dist. Pune - 412208;

GENERIC QAP FOR 20MnCr5 RING FORGINGS MASTER COPY

RING SIZES : AS PER PO ITEM : RING ROLLING FORGINGS SPEC : EN 10084 : 2008 E

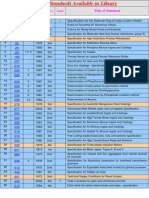

SR INSPECTION SAMPLING REFERENCE ACEEPTANCE FORMAT OF AGENCY

SCOPE OF INSPECTION D*

NO STAGE PLAN DOCUMENT NORMS RECORD P W V

Raw Material EN 10084 : 2008 E EN 10084 : 2008 E

1

Procurment

100% Verification of MTC

UNS :1.7147 UNS :1.7147

MTC P 2 - 1

C=0.17-0.22 Cr=1.00-1.30

EN 10084 : 2008 E Mn=1.00-1.40 Fe=Balance

Chemical 01 Sample per Chemical Compositon of REPORT

2

Composition Heat Raw Material

UNS :1.7147 P=0.025 Max

ON TC - 2 - 1

Grade : 20MnCr5 S=0.035 Max

Si= 0.40 Max

ASTM A255-18 / Hardenability of Steel shall be REPORT ON

3 Hardenability 01/ Heat Jominy Hardenability

ISO 642:1999 E as per 20MnCr5+H Grade TC

P 2 - 1

ASTM E112-13 / REPORT ON

4 Inclusion Rating 01/ Heat Inclusion Severity

ISO 4967

2 ABCD MAX ( Thin / Thick)

TC

P 2 - 1

Estimation of Austenitic ASTM E45-18 / REPORT ON

5 Grain Size 01/ Heat

Grain Size ISO 643:2012

05 or Finer

TC

P 2 - 1

Verification of Forging WIFPL Forging Method

6 Hot Working Ratio 100%

Method Sheet Sheet

FINAL RR= 3:1 MIN REPORT P 2 - 1

7 Heat Treatment 100% Normalizing EN 10084 : 2008 E Normalizing at 880°C-940°C HT Graph P 2 - 1

Microstructure 01 / Heat/ HT Microstructure Phase Uniform distribution of Ferrite REPORT ON

8

Analysis Batch Analysis

EN 10084 : 2008 E

and Pearlite TC

P 2 - 1

Dia 30 mm machined test piece

Test Piece Test Specimen Removal shall be removed for Blank

9

Preparation

01/ Heat

from Separately forged TP

EN 10084 : 2008 E

Hardening operation for

- P 2 - 1

Mecahnical Testing

WIFPL, Sanaswadi, Pune 1 OF 2 WIFPL/QAP/2019-20/008

VENDOR'S NAME & ADDRESS QAP NO : WIFPL/QAP/2019-20/008

M/s. Western India Forgings Pvt. Ltd.

QUALITY ASSURANCE PLAN REVISION : 00

Gat No 163, Hissa No 1, Sanaswadi, Nagar CUSTOMER: HINDUSTAN EQUIPMENTS PVT. LTD. DATE : 23-APR-2019

Road, Tal. Shirur, Dist. Pune - 412208;

GENERIC QAP FOR 20MnCr5 RING FORGINGS MASTER COPY

RING SIZES : AS PER PO ITEM : RING ROLLING FORGINGS SPEC : EN 10084 : 2008 E

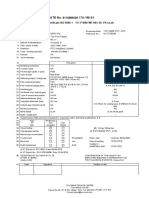

SR INSPECTION SAMPLING REFERENCE ACEEPTANCE FORMAT OF AGENCY

SCOPE OF INSPECTION D*

NO STAGE PLAN DOCUMENT NORMS RECORD P W V

Mechanical Ultimate Tensile Strength UTS=1000 N/mm² Min

Testing on dia 30

Proof Stress( 0.2%) ISO 6892-1 / YS= 700 N/mm² Min

mm Test bar in REPORT ON

10 Blank Hardened 01/ Heat % Elongation IS 1608 & %El= 9 % Min TC

P 2 - 1

Condition ISO 148-1/ IS 1757

% Reduction Area %RA= 35 % Min

(For Information

only) Charpy Impact Testing CVN= 30 J Min

11 Hardness 100% Hardness Testing ASTM E110 152-201 HBW REPORT ON TC P 2 - 1

Proof machining

12 100% Machining As per WIFPL Drawing As per WIFPL Drawing - - 2 - 1

(Light Cut)

Dimensional

13

Inspection

100% Verification of Dimensions As per WIFPL Drawing As per WIFPL Drawing REPORT P 2 - 1

14 Volumetric NDE 100% Ultrasonic Examination ASTM A388 3 mm EFBH By DGS Method REPORT ON TC P 2 - 1

Marking & Punching by low Stress Material, Heat No, Size/ Drg No

15 100% PO & Drawing - - 2 - 1

Treaceability Punch and Sr. No

Per Heat Per HT

16 Certification

Batch

Verfication of Documents EN 10204 3.1 Type EN 10204 3.1 Type REPORT P 2 - 1

LEGEND: P: PERFORM, W:WITNESS, V: VERIFICATION, INDICATE 1 FOR M/S.HINDUSTAN EQUIPMENTS PVT. LTD. QA ( OR M/s. HINDUSTAN EQUIPMENTS PVT. LTD. NOMINATED THIRD

PARTY) & 2 FOR WIFPL OR SUB VENDORS OF WIFPL/ NABL LAB * FOR ITEMS MARKED BY 'P' ( TICK) IN COLUMN 'D' ;TEST CERTIFICATES SHALL BE SUBMITTED TO M/S. HINDUSTAN

EQUIPMENTS PVT. LTD.

NOTE : 1) ULTRASONIC EXAMINATION SHALL BE CARRIED OUT BY TECHNICIAN HAVING QUALIFICAITON IN ACCORDANCE WITH ASNT-SNT-TC-1A LEVEL-II;

2) WIFPL SHALL PROVIDE DIA 75 X 300 MM MACHINED TEST PIECE FROM SEPARATELY FORGED TEST PIECE PER HEAT BASIS ONLY.

Preapared by Reviewed by Approved by Approved By

H. Dipak Shrikant Bhirud Vinod Sawale

MQC Engineer Asst Manager, MQC DGM, MQC & HT M/s. Hindustan Equipments Pvt. Ltd.

WIFPL, Sanaswadi, Pune 2 OF 2 WIFPL/QAP/2019-20/008

You might also like

- Epiterma Company Profile 2016 PDFDocument70 pagesEpiterma Company Profile 2016 PDFIna A. PutriNo ratings yet

- D & H Secheron Electrodes PVT - LTD.,: Type 5x450 5x350 4x450 4x350 3.15x450 3.15x350 2.5x350Document3 pagesD & H Secheron Electrodes PVT - LTD.,: Type 5x450 5x350 4x450 4x350 3.15x450 3.15x350 2.5x350Pradyumna Mohapatra100% (1)

- MQP - 1 PDFDocument15 pagesMQP - 1 PDFDoita Dutta ChoudhuryNo ratings yet

- Total Project Cost For 2nos. 25KL Tanks and One 40 KL TankDocument2 pagesTotal Project Cost For 2nos. 25KL Tanks and One 40 KL Tankarajamani78No ratings yet

- S-8018 B2Document5 pagesS-8018 B2Abhishek AnandNo ratings yet

- Abj Corporate Brochure - SmallsizeDocument36 pagesAbj Corporate Brochure - Smallsizeumer shafiqueNo ratings yet

- ISO 9001 Quality System for Production PlanningDocument7 pagesISO 9001 Quality System for Production PlanningS M Arif HussainNo ratings yet

- High Strength Alloy Data Sheet for EN AW-6082Document1 pageHigh Strength Alloy Data Sheet for EN AW-6082Vanessa Gomes100% (1)

- Back Weld Repair Procedure QualificationDocument15 pagesBack Weld Repair Procedure QualificationFelipe Vásquez ArribasplataNo ratings yet

- Scanned Indian Standards ListDocument30 pagesScanned Indian Standards ListJignesh TrivediNo ratings yet

- NO. PNB/DC-QAD-04/ ISSUE:2.0 / Revision: 00/ DATE:-01.04.16 Page 1 of 2Document2 pagesNO. PNB/DC-QAD-04/ ISSUE:2.0 / Revision: 00/ DATE:-01.04.16 Page 1 of 2sonnu151No ratings yet

- Painting Procedure 4288 Danem 28-04-13Document24 pagesPainting Procedure 4288 Danem 28-04-13Rejoy baby100% (1)

- SL Item Specification Dimenssion Quantity Area: PlateDocument6 pagesSL Item Specification Dimenssion Quantity Area: Plateruhul43No ratings yet

- Astm 1.05Document3 pagesAstm 1.05asprclms durgapurNo ratings yet

- Subodh Lab Pricelist Rev1Document7 pagesSubodh Lab Pricelist Rev1anubhavlNo ratings yet

- Cutting Plan FormatDocument1 pageCutting Plan FormatPrinceRaghavNo ratings yet

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- Data Table For Grades Tool Die Steels SKD-11Document3 pagesData Table For Grades Tool Die Steels SKD-11Adhi candra irawanNo ratings yet

- M2010051in-Mcb - Rolling Suggestions PDFDocument42 pagesM2010051in-Mcb - Rolling Suggestions PDFthaivinhtuyNo ratings yet

- Is 5624Document9 pagesIs 5624jselwyn1980No ratings yet

- Supplier Comparison 0.22: Grade C % Max MN% Max S % M P % MaxDocument13 pagesSupplier Comparison 0.22: Grade C % Max MN% Max S % M P % MaxShihab Aziz0% (1)

- Is 1570 7Document18 pagesIs 1570 7Raj K Sharma100% (1)

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 pagesTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNo ratings yet

- Improving Quality of Welding with ISO 3834Document53 pagesImproving Quality of Welding with ISO 3834AlienshowNo ratings yet

- ASTM A519 GR 4130 Seamless Pipe QDocument1 pageASTM A519 GR 4130 Seamless Pipe QsirjamlesNo ratings yet

- ThyssenDocument0 pagesThyssenAbbas RizviNo ratings yet

- Cold Forging Process For The Manufacturing of Nuts&boltDocument35 pagesCold Forging Process For The Manufacturing of Nuts&boltaseemk1No ratings yet

- D72307 TC2 PDFDocument2 pagesD72307 TC2 PDFshivdas bichukaleNo ratings yet

- CV Mechanical Engineer Project Manager 11 Years ExperienceDocument2 pagesCV Mechanical Engineer Project Manager 11 Years ExperienceDARA SINGHNo ratings yet

- Mahesh Pandit Updated CV 09.01.2021Document12 pagesMahesh Pandit Updated CV 09.01.2021Mahesh PanditNo ratings yet

- WPS PQR 12 PDFDocument9 pagesWPS PQR 12 PDFVinay YadavNo ratings yet

- Sintered Metal Bush ProductionDocument5 pagesSintered Metal Bush Production124swadeshiNo ratings yet

- I S 3658 - 1999Document12 pagesI S 3658 - 1999Subhendu KhantuaNo ratings yet

- Mat 3800 For Suppliers PDFDocument3 pagesMat 3800 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- TDC-10B Heat Treatment For C12A Steel CastingsDocument2 pagesTDC-10B Heat Treatment For C12A Steel CastingsGohilakrishnan ThiagarajanNo ratings yet

- WPQR SBM 029Document3 pagesWPQR SBM 029HoJienHauNo ratings yet

- Preheating Procedure For Equipment Nozzle Modification (Cs and LTCS)Document6 pagesPreheating Procedure For Equipment Nozzle Modification (Cs and LTCS)Rakesh RanjanNo ratings yet

- Hot Rolled Carbon Steel Sheet, Plate and Strip According To IS 1079:2017Document8 pagesHot Rolled Carbon Steel Sheet, Plate and Strip According To IS 1079:2017raghavendragouda patilNo ratings yet

- S No. Description Quantity: Comparision of RatesDocument4 pagesS No. Description Quantity: Comparision of Ratesk.sankaranandNo ratings yet

- SS 304 8MMDocument1 pageSS 304 8MMRavi MehtaNo ratings yet

- Mig WireDocument10 pagesMig WireSathishkumar SrinivasanNo ratings yet

- IS 2062 E 250 GR A BS EN 10025-2 S 235 JR Chamical Thikness 16 16 40 40 C% SI% MN% P% S% Cu% N%Document10 pagesIS 2062 E 250 GR A BS EN 10025-2 S 235 JR Chamical Thikness 16 16 40 40 C% SI% MN% P% S% Cu% N%kartikNo ratings yet

- Vendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefDocument3 pagesVendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefAmit KumarNo ratings yet

- Is 4948 2002 PDFDocument11 pagesIs 4948 2002 PDFTousif ShaikhNo ratings yet

- ISO 9001 Certified Stainless Steel Fastener Manufacturer Test CertificateDocument16 pagesISO 9001 Certified Stainless Steel Fastener Manufacturer Test CertificateSales ITANo ratings yet

- Technical Supply Conditions For Threaded Steel FastenersDocument18 pagesTechnical Supply Conditions For Threaded Steel Fastenersrohita kumar dahNo ratings yet

- Billet Cutting Process Quality Control SheetDocument1 pageBillet Cutting Process Quality Control SheetBalram JiNo ratings yet

- Macroetching Test ProcedureDocument3 pagesMacroetching Test ProcedurerohitNo ratings yet

- Camy Plants: Material History ChartDocument10 pagesCamy Plants: Material History Chartshailesh deshmukh100% (1)

- Cross Cut Kit ManualDocument5 pagesCross Cut Kit ManualYuvaraj Sathish100% (1)

- Repair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6Document6 pagesRepair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6mohd as shahiddin jafriNo ratings yet

- Selection For Welding Consumables: A 479 Gr.316LDocument2 pagesSelection For Welding Consumables: A 479 Gr.316LanandmlNo ratings yet

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Document5 pagesA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableNo ratings yet

- TES 101-158 - 7 - Hi PDFDocument8 pagesTES 101-158 - 7 - Hi PDFRossoNo ratings yet

- Chemical and Mechanical PropertiesDocument5 pagesChemical and Mechanical PropertiesAristotle MedinaNo ratings yet

- Welder Certificate ISO 9606-1 QualificationDocument1 pageWelder Certificate ISO 9606-1 QualificationDeepak Das100% (1)

- REPORTSDocument18 pagesREPORTSShailesh DeshmukhNo ratings yet

- Material Product Data SheetDocument4 pagesMaterial Product Data SheethungNo ratings yet

- Wifpl Qap 2019-20-058 Rev 00 Konecranes 18crnimo7 6 SignedDocument2 pagesWifpl Qap 2019-20-058 Rev 00 Konecranes 18crnimo7 6 SignedDeepak HoleNo ratings yet

- 1466 - EC0044Document5 pages1466 - EC0044Deipak HoleNo ratings yet

- 1335 - EC1904Document1 page1335 - EC1904Deipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1433 Ec0442Document6 pages1433 Ec0442Deepak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- SC SIT Order 120911Document10 pagesSC SIT Order 120911Ranganaathan SoundararajanNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- 456 PDFDocument4 pages456 PDFDeipak HoleNo ratings yet

- Wifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDocument3 pagesWifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDeipak HoleNo ratings yet

- StdReport10286 (7) 13.07.2019Document695 pagesStdReport10286 (7) 13.07.2019Deipak HoleNo ratings yet

- Untitled Document2 PDFDocument1 pageUntitled Document2 PDFDeipak HoleNo ratings yet

- Punching Slip: Prepared by Date: MQC SignDocument1 pagePunching Slip: Prepared by Date: MQC SignDeipak HoleNo ratings yet

- PD FileDocument3 pagesPD FileDeipak HoleNo ratings yet

- Zora Test Astm A770 PDFDocument126 pagesZora Test Astm A770 PDFDeipak HoleNo ratings yet

- Cameron CompDocument14 pagesCameron CompDeipak HoleNo ratings yet

- MQC RM Approval ModuleDocument5 pagesMQC RM Approval ModuleDeipak HoleNo ratings yet

- MPI Yoke QuotationDocument4 pagesMPI Yoke QuotationDeipak HoleNo ratings yet

- 4.01.1 Fish Bone Diagram InvoicesDocument22 pages4.01.1 Fish Bone Diagram InvoicesDeipak HoleNo ratings yet

- मतदाता सूचना/Voter InformationDocument1 pageमतदाता सूचना/Voter InformationDeipak HoleNo ratings yet

- Zora Test Astm A770Document1 pageZora Test Astm A770Deipak HoleNo ratings yet

- Fishbone Diagram GeneratorDocument19 pagesFishbone Diagram GeneratormfernandNo ratings yet

- Customer: Probe Oil Tools Ltd. Product Type: All Product: All Grade: All Sales Rep: All Location: WIFPLDocument1 pageCustomer: Probe Oil Tools Ltd. Product Type: All Product: All Grade: All Sales Rep: All Location: WIFPLDeipak HoleNo ratings yet

- Punching Slip: Prepared by Date: MQC SignDocument1 pagePunching Slip: Prepared by Date: MQC SignDeipak HoleNo ratings yet

- How To Build A Backyard PergolaDocument15 pagesHow To Build A Backyard PergolaMichael Wilkins100% (1)

- PCR200Document4 pagesPCR200Rudy SalimNo ratings yet

- Making Your Chain Run For Longer: Effective Chain Maintenance Advice From Renold JeffreyDocument2 pagesMaking Your Chain Run For Longer: Effective Chain Maintenance Advice From Renold JeffreyCương Phạm NgọcNo ratings yet

- Coiled Tubing For Downhole ProcessDocument10 pagesCoiled Tubing For Downhole ProcessCristian BarbuceanuNo ratings yet

- Mousavi, Aliha, Imani - 2020 - On The Use of Edge Cracked Short Bend Beam Specimen For PMMA Fracture Toughness Testing Under Mixed-ModeDocument1 pageMousavi, Aliha, Imani - 2020 - On The Use of Edge Cracked Short Bend Beam Specimen For PMMA Fracture Toughness Testing Under Mixed-ModeMorteza AtaeiNo ratings yet

- Silo Fluidizer: Keep Dry Bulk Materials MovingDocument2 pagesSilo Fluidizer: Keep Dry Bulk Materials MovingHùng Thanh NguyễnNo ratings yet

- Lightning Protection SystemDocument5 pagesLightning Protection SystemRifki FathurrahmanNo ratings yet

- Ibm Lenovo Whistler Rev s1.3 SCHDocument52 pagesIbm Lenovo Whistler Rev s1.3 SCH1cvbnmNo ratings yet

- MWD Log Quality & StandardsDocument168 pagesMWD Log Quality & StandardsHamed Sadeghi100% (1)

- Regional Contest Package in EIM NC IIDocument3 pagesRegional Contest Package in EIM NC IIAlNo ratings yet

- M103C 10/11 Meter Maximum Beam AntennaDocument9 pagesM103C 10/11 Meter Maximum Beam AntennaRádio Técnica AuroraNo ratings yet

- EN 12663-1 - 2010 - IndiceDocument6 pagesEN 12663-1 - 2010 - IndiceOhriol Pons Ribas67% (3)

- SAFETY DATA SHEET TITLEDocument8 pagesSAFETY DATA SHEET TITLESukanta ChowdhuryNo ratings yet

- 18,21. Naidian CatalogueDocument31 pages18,21. Naidian CatalogueTaQuangDucNo ratings yet

- Project-BOQ - (Excluding VUP, LVUP)Document127 pagesProject-BOQ - (Excluding VUP, LVUP)Shivendra KumarNo ratings yet

- Autodesk 2010 Product Key PDFDocument6 pagesAutodesk 2010 Product Key PDFDragon NestNo ratings yet

- Technical VolumeDocument162 pagesTechnical Volumeiamskg63891583No ratings yet

- ZMD402AT-CT Technical DataDocument7 pagesZMD402AT-CT Technical DataCarlos SandersNo ratings yet

- BSBPMG410+Apply+project+time+management+techniques V170225Document35 pagesBSBPMG410+Apply+project+time+management+techniques V170225Sabrina Gao100% (1)

- Lime Metering Tomal GB PDFDocument6 pagesLime Metering Tomal GB PDFJose Antonio Caballero BeldaNo ratings yet

- LAP Register To WLCDocument12 pagesLAP Register To WLCAditya NugrahaNo ratings yet

- J320 Maintenance Spare Parts ListDocument1 pageJ320 Maintenance Spare Parts ListKeith ChengNo ratings yet

- Maintenance Manual: Models 7200/7300/7310 Reach-Fork TrucksDocument441 pagesMaintenance Manual: Models 7200/7300/7310 Reach-Fork TrucksMigue Angel Rodríguez Castro100% (2)

- John Deere X145 Lawn Tractor Service Repair Technical Manual (TM113319)Document16 pagesJohn Deere X145 Lawn Tractor Service Repair Technical Manual (TM113319)zhuangfuqian31No ratings yet

- 10 Inch Pipe Calculations For HydrostatDocument13 pages10 Inch Pipe Calculations For Hydrostatגרבר פליקסNo ratings yet

- Rocket Icluster V8.1Document16 pagesRocket Icluster V8.1Felipe Cervantes EspinosaNo ratings yet

- VP Director Finance Controller in Washington DC Resume Brenda LittleDocument2 pagesVP Director Finance Controller in Washington DC Resume Brenda LittleBrendaLittleNo ratings yet

- TNK500P Taneko Industrial Generator (TNK JKT)Document2 pagesTNK500P Taneko Industrial Generator (TNK JKT)Rizki Heru HermawanNo ratings yet

- Optimal Transformer Tap Changing SettingDocument7 pagesOptimal Transformer Tap Changing Settingtrust4joshNo ratings yet

- Calcium Sulfate Crystallization in Phosphoric Acid PDFDocument133 pagesCalcium Sulfate Crystallization in Phosphoric Acid PDFabderrahimnNo ratings yet