Professional Documents

Culture Documents

17017R2 - Tampines N8C32 Precast PBU

Uploaded by

RajuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

17017R2 - Tampines N8C32 Precast PBU

Uploaded by

RajuCopyright:

Available Formats

Co/GST Reg No.

201019721G

G & W Precast Pte Ltd

Attn: Mr Mark

Project: Tampines N8C32

Reference No: 17017R2 Date: 30th November 2018

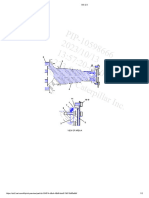

Design of Proprietary Lifting System

Based on the weights of the elements, central of gravity and dimensions given, we are pleased

to enclosed our design calculation for your necessary action. Please kindly check whether the

weight, sections, wall thickness & dimensions tally with those shown in our calculation before

installation of Lifting anchors supplied by CPI.

Furthermore, lifting frame with roller rigs must be used to ensure the load distribution

to all lifting anchors during lifting.

In no event shall our company be liable for any direct, indirect, punitive, incidental, special

consequential damages, to property or life, whatsoever arising out of or connected with the

misuse of our products.

Please do not hestitate to contact us if you have any further questions.

Mr Chris Ng

Director

10 Anson Road #10-08 Warehouse/ Delivery:

International Plaza 10 Admiralty Street #01-35

Singapore 079903 North Link Building

Tel: 6753 2885 Singapore 757695

Fax: 6752 9582

info@cpiholdings.sg

www.cpiholdings.sg

Co/GST Reg No. 201019721G

Design of Proprietary Lifting System

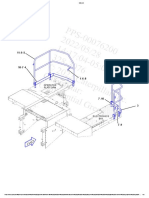

Subject: PBU

Project: Tampines N8C32

Client: G & W Precast Pte Ltd

Date: 30th November 2018

1. Design Parameters

Concrete Strength at the first lift fc = 15 N/mm^2 Adhesion Force ha = 1.2

Spread Angle Factor w = 1.16 Impact Factor y = 1.1

Factor of Concrete Strength Deduction a = (fc/fcu)(2/3) = 1.000 (fcu=15 N/mm²)

Minimum Safety Factor against Concrete failure = 3.00

2. Design of Anchors for Demoulding

The lifting frame with roller rigs are used during lifting to ensure load distribution to all lifting anchors.

Element Weight Design Load Over Load Max Load Req. No. Wall Thk. Capacity Part No. DRW

W (t) W*w*y*ha (t) factor ŋ /Anchor (t) of Anchors (mm) /Anchor (t) No

PBU

32A-3G-PBU- T1G, T1GX 1.01 7.35 2 250 7.50 7FA300**

19.00 29.09 PB21

1.01 7.35 2 250 7.50 7FA300**

32B-3G-PBU- T1G, T1GX 1.01 7.35 2 250 7.50 7FA300**

19.00 29.09 PB21

1.01 7.35 2 250 7.50 7FA300**

32A-4R-PBU- TG, TGX, T, TX 1.01 7.13 2 250 7.50 7FA300**

18.40 28.17 PB21

1.01 7.13 2 250 7.50 7FA300**

32B-4R-PBU- TG, TGX, T, TX 1.01 7.13 2 250 7.50 7FA300**

18.40 28.17 PB21

1.01 7.13 2 250 7.50 7FA300**

32A-5R-PBU- TG, TGX, T, TX 1.01 7.25 2 250 7.50 7FA300**

18.70 28.63 PB21

1.01 7.25 2 250 7.50 7FA300**

32B-5R-PBU- T, TX 1.01 7.25 2 250 7.50 7FA300**

18.70 28.63 PB21

1.01 7.25 2 250 7.50 7FA300**

32A-3G-PBU- T2, T2X, T2G, 1.09 6.36 2 250 7.50 7FA300**

15.30 23.43 PB22

T2GX, T2AG, T2AGX, T2A, T2AX 1.14 6.67 2 250 7.50 7FA300**

32B-3G-PBU- T2, T2X, T2G, 1.09 6.36 2 250 7.50 7FA300**

15.30 23.43 PB22

T2GX 1.14 6.67 2 250 7.50 7FA300**

Note: * Side mould must be removed during demoulding

** Tensile Bar anchorage min 20 x 2160mm

3. Design of Rubber Recess Formers & Clutches

Description Load Group (t) Narrow Round

Rubber Recess Former 10 10RRFRO

Clutch 10.0 10LE

10 Anson Road #10-08 Warehouse/ Delivery:

International Plaza 10 Admiralty Street #01-35

Singapore 079903 North Link Building

Tel: 6753 2885 Singapore 757695

Fax: 6752 9582

info@cpiholdings.sg

www.cpiholdings.sg

Co/GST Reg No. 201019721G

Design of Proprietary Lifting System

Subject: Precast Component

Project: Tampines N8C32

Client: G & W Precast Pte Ltd

Date: 30th November 2018

1. Design Parameters

Concrete Strength at the first lift fc = 35 N/mm^2 Adhesion Force ha = 0.0

Spread Angle Factor w = 1.16 Impact Factor y = 1.3

Factor of Concrete Strength Deduction a = (fc/fcu)(2/3) = 1.000 (fcu=35 N/mm²)

Minimum Safety Factor against Concrete failure = 3.00

2. Design of Anchors for Installation

The lifting frame with roller rigs are used during lifting to ensure load distribution to all lifting anchors.

Element Weight Design Load Over Load Max Load Req. No. Wall Thk. Capacity Part No. DRW

W (t) W*w*y (t) Factor ŋ /Anchor (t) of Anchors (mm) /Anchor (t) No

PBU

32A-3G-PBU- T1G, T1GX 1.01 7.24 2 250 7.50 7FA300

19.00 28.65 PB21

1.01 7.24 2 250 7.50 7FA300

32B-3G-PBU- T1G, T1GX 1.01 7.24 2 250 7.50 7FA300

19.00 28.65 PB21

1.01 7.24 2 250 7.50 7FA300

32A-4R-PBU- TG, TGX, T, TX 1.01 7.02 2 250 7.50 7FA300

18.40 27.75 PB21

1.01 7.02 2 250 7.50 7FA300

32B-4R-PBU- TG, TGX, T, TX 1.01 7.02 2 250 7.50 7FA300

18.40 27.75 PB21

1.01 7.02 2 250 7.50 7FA300

32A-5R-PBU- TG, TGX, T, TX 1.01 7.14 2 250 7.50 7FA300

18.70 28.20 PB21

1.01 7.14 2 250 7.50 7FA300

32B-5R-PBU- T, TX 1.01 7.14 2 250 7.50 7FA300

18.70 28.20 PB21

1.01 7.14 2 250 7.50 7FA300

32A-3G-PBU- T2, T2X, T2G, 1.09 6.26 2 250 7.50 7FA300

15.30 23.07 PB22

T2GX, T2AG, T2AGX, T2A, T2AX 1.14 6.57 2 250 7.50 7FA300

32B-3G-PBU- T2, T2X, T2G, 1.09 6.26 2 250 7.50 7FA300

15.30 23.07 PB22

T2GX 1.14 6.57 2 250 7.50 7FA300

3. Design of Rubber Recess Formers & Clutches

Description Load Group (t) Narrow Round

Rubber Recess Former 10 10RRFRO

Clutch 10.0 10LE

10 Anson Road #10-08 Warehouse/ Delivery:

International Plaza 10 Admiralty Street #01-35

Singapore 079903 North Link Building

Tel: 6753 2885 Singapore 757695

Fax: 6752 9582

info@cpiholdings.sg

www.cpiholdings.sg

You might also like

- Equipment CapabilitesDocument19 pagesEquipment Capabilitesapi-1975359897% (194)

- Tg-500e-3-10505 5 Boom + Jib, 2M2D, KG56TXLDocument418 pagesTg-500e-3-10505 5 Boom + Jib, 2M2D, KG56TXLDemerson Tavares100% (1)

- Valve Rocker ArmDocument3 pagesValve Rocker Armsulistyo enginedieselNo ratings yet

- Base Ring AnalysisDocument9 pagesBase Ring Analysisasirul_meNo ratings yet

- RDX 5 Parts ManualDocument40 pagesRDX 5 Parts ManualDELTA ROCKNo ratings yet

- Mechanical Testing of MaterialsDocument38 pagesMechanical Testing of MaterialsAanand Rishabh DagaNo ratings yet

- Corrosion in Oil and Gas Industry A Perspective On Corrosion InhibitorsDocument1 pageCorrosion in Oil and Gas Industry A Perspective On Corrosion InhibitorsAsma Sed100% (1)

- Ball MillsDocument8 pagesBall MillsBoy Alfredo PangaribuanNo ratings yet

- 1170 Imagerunner Advance DX 4700 Series PC r0 200228Document180 pages1170 Imagerunner Advance DX 4700 Series PC r0 200228Marco Antonio Valverde MarinNo ratings yet

- SYNOPSIS For Job PortalDocument6 pagesSYNOPSIS For Job PortalAkanksha Verma90% (10)

- Software Test ReportDocument4 pagesSoftware Test ReportSabahat HussainNo ratings yet

- Type: T1637K11 5272003349 FG/FGS: SERIAL NO.: 5272003349 BOM NO.: T1637K11Document194 pagesType: T1637K11 5272003349 FG/FGS: SERIAL NO.: 5272003349 BOM NO.: T1637K11Víctor MatíasNo ratings yet

- Yanmar 4tnv98t Gge Engine Parts CatalogDocument3 pagesYanmar 4tnv98t Gge Engine Parts Cataloglawrence100% (42)

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- PB 92202 006Document4 pagesPB 92202 006Rafael Dutil LucianaNo ratings yet

- Safety ValvesDocument11 pagesSafety Valvesravindra_jivaniNo ratings yet

- Lockup Clutch CX31 TransmisionDocument5 pagesLockup Clutch CX31 Transmisiontonny.sitompulNo ratings yet

- Profile of the International Pump Industry: Market Prospects to 2010From EverandProfile of the International Pump Industry: Market Prospects to 2010Rating: 1 out of 5 stars1/5 (1)

- 3TNV76Document31 pages3TNV76Mohsen Moghadam100% (2)

- 2.813 SX Selective Test Tool Design SpecificationDocument3 pages2.813 SX Selective Test Tool Design Specificationsong Li100% (3)

- Eng CD 55PC0211 HDocument1 pageEng CD 55PC0211 HEhsan pour sarabiNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument8 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Specs Toyo Tires At2Document4 pagesSpecs Toyo Tires At2sirpitorcasNo ratings yet

- Ltp-Structur 2 - Bom - 11-11-2020Document16 pagesLtp-Structur 2 - Bom - 11-11-2020vidyaNo ratings yet

- FI GalpertyDocument80 pagesFI GalpertyWahyu PamungkasNo ratings yet

- Air-Compressor User ManualDocument67 pagesAir-Compressor User ManualSAMIR BEL HADJ HMIDANo ratings yet

- Review Water Tank Tower Perumahan Bumi Palir Sejahtera-Kota SemarangDocument13 pagesReview Water Tank Tower Perumahan Bumi Palir Sejahtera-Kota SemarangOktaSaputraNo ratings yet

- D6T Eje PivoteDocument2 pagesD6T Eje PivotericsnikNo ratings yet

- Vtech Material QuantityDocument1 pageVtech Material QuantitySalvatore ShwNo ratings yet

- Vtech Material QuantityDocument1 pageVtech Material QuantitySalvatore ShwNo ratings yet

- E240668 DTRDocument2 pagesE240668 DTRAmogh AbhyankarNo ratings yet

- Quotation BEEP Tejado 1 20230223Document4 pagesQuotation BEEP Tejado 1 20230223Juan PalomoNo ratings yet

- Rekap Invoice PT Tim Perbulan 2020Document160 pagesRekap Invoice PT Tim Perbulan 2020herdiNo ratings yet

- Steel Connections: ResultsDocument23 pagesSteel Connections: ResultsRidha AuliaNo ratings yet

- Keystone - 1C - PVCDocument2 pagesKeystone - 1C - PVCYongJun LiuNo ratings yet

- Lennox EvenHeat ECB29EH 11 2007Document15 pagesLennox EvenHeat ECB29EH 11 2007ghaitmaNo ratings yet

- Hydraulic Circuitry (Boom Chain Kit) - T40.180SLPDocument2 pagesHydraulic Circuitry (Boom Chain Kit) - T40.180SLPvincent orengoNo ratings yet

- Transistores TO3 PDFDocument2 pagesTransistores TO3 PDFjoao victorNo ratings yet

- GB Instruction Manual for POWERTEX Chain Block PCB-S2 0.25-10 TonDocument14 pagesGB Instruction Manual for POWERTEX Chain Block PCB-S2 0.25-10 TonSanthoshNo ratings yet

- 244-2702 LINES GP-AIR CONDITIONER S/N D9W146-UP PARTDocument2 pages244-2702 LINES GP-AIR CONDITIONER S/N D9W146-UP PARTMiguel FloresNo ratings yet

- MR Developers Plumbing - ITIDocument31 pagesMR Developers Plumbing - ITIUmamaheshwarrao Varma100% (1)

- Awning DesignDocument17 pagesAwning DesignDiyana Mohd SamsiNo ratings yet

- QA - Paint PH 1.1 PDFDocument20 pagesQA - Paint PH 1.1 PDFPeter ThomsonNo ratings yet

- Plant and Machinery - Audit FileDocument31 pagesPlant and Machinery - Audit FileirfanNo ratings yet

- Fha 2Document2 pagesFha 2usfa fatihNo ratings yet

- RC 09-02 - 2024Document1 pageRC 09-02 - 2024fantoni swiNo ratings yet

- Mol DurasDocument24 pagesMol DurasxxNSAxxNo ratings yet

- CHIKO 1MW Quotation List-221206Document1 pageCHIKO 1MW Quotation List-221206Carlos ArayaNo ratings yet

- VCB & CT BBSDocument6 pagesVCB & CT BBSMohd imranNo ratings yet

- HV19153C22PVCDocument1 pageHV19153C22PVCHiVoltageONo ratings yet

- Steel Connections: ResultsDocument23 pagesSteel Connections: ResultsRidha AuliaNo ratings yet

- SG Series Pto: Parts List and Service ManualDocument4 pagesSG Series Pto: Parts List and Service Manualmantenimiento automotrizNo ratings yet

- Sa Modules Datasheet KentDocument1 pageSa Modules Datasheet KentCarlos Gallardo LagosNo ratings yet

- PUMP - 5.5 GPM at 3500 PSIDocument1 pagePUMP - 5.5 GPM at 3500 PSIManutenção PerpecNo ratings yet

- Romex Brand Simpull: Indoor Wire Copper NM-B CableDocument3 pagesRomex Brand Simpull: Indoor Wire Copper NM-B CableARN18No ratings yet

- Cost Price 2023Document15 pagesCost Price 2023bryaninmyanmarNo ratings yet

- P1000TDocument1 pageP1000TsanracNo ratings yet

- Welding consumable calculation for Petrofac Berantai projectDocument10 pagesWelding consumable calculation for Petrofac Berantai projectkeymal9195No ratings yet

- Data Sheet GripsDocument23 pagesData Sheet GripsSoup PongsakornNo ratings yet

- Bulletin # New 111684-305008-323080 # PS Ocean Jean1Document3 pagesBulletin # New 111684-305008-323080 # PS Ocean Jean1Md Amin Uddin SajibNo ratings yet

- Boss dd3 TDocument10 pagesBoss dd3 TVictor AriizNo ratings yet

- 05-Sitema de Combustivel PDFDocument61 pages05-Sitema de Combustivel PDFFabioMacielNo ratings yet

- Handrail 834HDocument2 pagesHandrail 834HAlexander LauraNo ratings yet

- #16 Batch - Delivery Note - 17.02.2020Document1 page#16 Batch - Delivery Note - 17.02.2020Shiva RajNo ratings yet

- Cateye Enduro 2 (Bike Computer)Document4 pagesCateye Enduro 2 (Bike Computer)Eddy WadeNo ratings yet

- Coal Gallery Conveyor Isometric DrawingDocument16 pagesCoal Gallery Conveyor Isometric DrawingBudhi KurniantoNo ratings yet

- Drg. No. Fd05-002 Date:-30/08/2019 Bill of Material For Ote Duct Side Shuttering Panel (P1)Document6 pagesDrg. No. Fd05-002 Date:-30/08/2019 Bill of Material For Ote Duct Side Shuttering Panel (P1)AshishNo ratings yet

- Profile of the Worldwide Semiconductor Industry - Market Prospects to 1997: Market Prospects to 1997From EverandProfile of the Worldwide Semiconductor Industry - Market Prospects to 1997: Market Prospects to 1997No ratings yet

- Elink For Windows: List of Pages in This Trip KitDocument130 pagesElink For Windows: List of Pages in This Trip KitAhmed GvNo ratings yet

- Multi-disciplinary profile of IS/IT outsourcing researchDocument47 pagesMulti-disciplinary profile of IS/IT outsourcing researchIsabel MirandaNo ratings yet

- Sennheiser MD 441Document2 pagesSennheiser MD 441ndujaNo ratings yet

- Catalogo - CATUDocument132 pagesCatalogo - CATUxis-zeroNo ratings yet

- User's Guide: BondekDocument8 pagesUser's Guide: BondekMing ChongNo ratings yet

- Goodyear Brochure Bandas-48Document1 pageGoodyear Brochure Bandas-48DavidNo ratings yet

- Pairwise testing: A powerful technique for reducing test casesDocument26 pagesPairwise testing: A powerful technique for reducing test casesvineeta1234No ratings yet

- SQL Server 2008 R2 Express Installation GuideDocument53 pagesSQL Server 2008 R2 Express Installation GuideGersonGamas100% (2)

- BTSDocument75 pagesBTSgyanesh198450% (2)

- PARTSDocument10 pagesPARTSTestrooteNo ratings yet

- Twice As Sharp Operators ManualDocument34 pagesTwice As Sharp Operators ManualLeonardo CHTZNo ratings yet

- MMMDocument1 pageMMMkhan22imranNo ratings yet

- Software TestingDocument3 pagesSoftware TestingDr. P. N. Renjith Associate Professor - CSENo ratings yet

- JETL industrial wastewater treatment reportDocument6 pagesJETL industrial wastewater treatment reportPremKumarNo ratings yet

- Partitioned Data Set Extended Usage Guide Guide: Front CoverDocument364 pagesPartitioned Data Set Extended Usage Guide Guide: Front CoverCsutka PocsNo ratings yet

- KALEKİMDocument18 pagesKALEKİMqaisalkurdyNo ratings yet

- Theory of Metal Cutting-Module 1Document116 pagesTheory of Metal Cutting-Module 1rejeesh_rajendranNo ratings yet

- Pump HydraulicsDocument5 pagesPump HydraulicsSiddharth Kharat100% (1)

- Catalogo DeltaDocument2 pagesCatalogo DeltaHelena ChagasNo ratings yet

- Ma-Mscmt-10 J16Document5 pagesMa-Mscmt-10 J16Dilip BhatiNo ratings yet

- Measurement & Calculation of Vehicle Center of Gravity Using Portable Wheel ScalesDocument11 pagesMeasurement & Calculation of Vehicle Center of Gravity Using Portable Wheel ScalesVedant KodagiNo ratings yet

- Instructions For Installation, Operating and Maintenance InstructionDocument30 pagesInstructions For Installation, Operating and Maintenance InstructionmilacronNo ratings yet