Professional Documents

Culture Documents

Model 1LongWeldEndValve G02 PDF

Uploaded by

saraapci0 ratings0% found this document useful (0 votes)

47 views1 pageOriginal Title

Model-1LongWeldEndValve-G02.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

47 views1 pageModel 1LongWeldEndValve G02 PDF

Uploaded by

saraapciCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

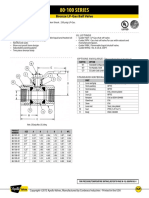

Model-1 Long Weld End Valve

Natural Gas Valve

Features Ordering Code Table for 740 PSI

Absolutely No

Maintenance Size Valve Approx.

Pressure

No Gland Tightening (in) No. Weight

No Lubrication 1* 1WS7 300 ANSI 740 MOP 9 lb

No Adjustment Of Any

1-1/4 1WS7 300 ANSI 740 MOP 9 lb

Kind

Standard Welding 2 1WS7 300 ANSI 740 MOP 24 lb

Practices Apply 3 1WS7 300 ANSI 740 MOP 36 lb

Full Opening – No

3 1WL7 300 ANSI 740 MOP 58 lb

Significant Pressure

Drop 4 1WL7 300 ANSI 740 MOP 74 lb

Lowest Operating 6 1WL7 300 ANSI 740 MOP 130 lb

Torque in The Industry 8 1WL7 300 ANSI 740 MOP 210 lb

Steel – Safety

Directional Solidification 10 1WL7 300 ANSI 740 MOP 390 lb

Weld Ends Meeting Rigid 12 1WL7 300 ANSI 740 MOP 535 lb

Code requirements 16 1WL7 300 ANSI 740 MOP 1505 lb

Seat Test @ 110% of

Rated Pressure, Shell * 1 inch in Socket Weld Ends

Test @ 150% of Rated NOTE: Valves built before July 10, 2006 have Class 300 API,

Pressure 720 MOP rating.

Patented Packing – No

Environmental Leaking

Back Seat – Full

Containment Of Pressure

Below Packing – No

Environmental Leakage

Patented Design

Specifications Dimensions:

2 Inch Operation Square

Malleable Iron End to

Size C/L to Top Number Temp

Buna “N” “O” Rings And End

(in) (in) of Turns (Fahr)

“V” Rings (in)

Brass Packing Actuator 1* 5 6 5-3/4

Steel Packing Gland Cover

1-1/4 5 6 5-3/4

Steel Bonnet ASTM A-216

Grade WCB 2 7 8-3/4 7-1/4

Stainless Steel Stem 3** 8 10-7/16 10-1/4

Alloy Steel Cap Screws –

3 11-1/8 10-7/16 10-1/4 - 30 degrees

ASTM A-574

Soft Iron Bonnet Gasket 4 12 12-11/16 13-1/4 to

(Refinery Gasket – Fire 6 15-7/8 16-7/16 19-3/4 200 degrees

Proof) 8 16-1/2 20-1/4 26-1/4

Steel Body – ASTM A-216

Grade WCB 10 18 27 21-3/4

12 19-3/4 30-3/4 25-3/4

16 33 41-3/8 69

* 1 inch in socket weld only

** Short Weld End

Distributed By: M&M Control Service, Inc. www.mmcontrol.com/Kerotest.php 800-876-0036 847-356-0566

You might also like

- Maya Keyboard ShortcutsDocument0 pagesMaya Keyboard ShortcutsDaryl Gomez TimatimNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- PC Assembly PlantDocument19 pagesPC Assembly Plantmuyenzo100% (1)

- Pigging Products: Safe and Effi Cient PiggingDocument16 pagesPigging Products: Safe and Effi Cient PiggingAnonymous qhVGVpNo ratings yet

- F Series - Floating Ball ValvesDocument8 pagesF Series - Floating Ball ValvesCarlos Alberto Aguilera MendezNo ratings yet

- Choke Valve DetailsDocument4 pagesChoke Valve DetailspagloosndgNo ratings yet

- OrificeMaster Single Chamber Orifice FittingDocument8 pagesOrificeMaster Single Chamber Orifice FittingPaul Wowor100% (1)

- Celiac DiseaseDocument14 pagesCeliac Diseaseapi-355698448100% (1)

- API602 Forged Steel Gate & Globe ValvesDocument4 pagesAPI602 Forged Steel Gate & Globe ValvesThomasFrenchNo ratings yet

- High Risk Medications in AyurvedaDocument3 pagesHigh Risk Medications in AyurvedaRaviraj Pishe100% (1)

- DPCVDocument4 pagesDPCVjamil voraNo ratings yet

- 601-A-006 - Avk021 - en 2232 - 471287Document2 pages601-A-006 - Avk021 - en 2232 - 471287bre brilianNo ratings yet

- AWWA C-504: Model 3900F & Model 3900MDocument2 pagesAWWA C-504: Model 3900F & Model 3900MPriyanka rajpurohitNo ratings yet

- Nutron TM Trunnion Mounted Ball Valve FlyerDocument2 pagesNutron TM Trunnion Mounted Ball Valve FlyerAlbert RubianoNo ratings yet

- Norm Ex ValvesDocument6 pagesNorm Ex Valvesapi-3712612No ratings yet

- Series Cast Iron Full Port Class 125 Flanged Ball Valve: DescriptionDocument2 pagesSeries Cast Iron Full Port Class 125 Flanged Ball Valve: DescriptionLuisPortorelliZambranoNo ratings yet

- Forged Gate, Globe & Check ValvesDocument4 pagesForged Gate, Globe & Check ValvesRavi KantNo ratings yet

- U B W, I .: Nited Rass Orks NCDocument1 pageU B W, I .: Nited Rass Orks NCMartin Villafuerte CruzNo ratings yet

- RV/RR - DETAIL DRAWING OF RESILIENT SEATED AND BUTTERFLY VALVESDocument64 pagesRV/RR - DETAIL DRAWING OF RESILIENT SEATED AND BUTTERFLY VALVESduc22198No ratings yet

- PASCAL Check Valves CatalogueDocument19 pagesPASCAL Check Valves Cataloguecrys100% (1)

- Gate Valve Specification Manuf'S Offer: Signature & Seal of ManufacturerDocument1 pageGate Valve Specification Manuf'S Offer: Signature & Seal of ManufacturerDIPANKAR LALANo ratings yet

- Tapping Saddle DimensionsDocument4 pagesTapping Saddle DimensionsAnonymous IgzACaiNo ratings yet

- Boiler Valve CatalogDocument74 pagesBoiler Valve CatalogEduardo DiegoNo ratings yet

- Data Sheets Series 155 FloatingDocument4 pagesData Sheets Series 155 Floatingbayarjargal SuwdusNo ratings yet

- Valvulas de Compuerta Hi-AlloyDocument2 pagesValvulas de Compuerta Hi-AlloyQuintin FedabNo ratings yet

- 6K High Temp 81Document4 pages6K High Temp 81InstNo ratings yet

- Specification For Fire Pump - Part 10Document5 pagesSpecification For Fire Pump - Part 10Melisa MackNo ratings yet

- Thermodynamic Steam Traps DT 32Document1 pageThermodynamic Steam Traps DT 32Son Trinh PhuongNo ratings yet

- T376APBI-Nibco Angular Bronze ValveDocument1 pageT376APBI-Nibco Angular Bronze Valvemax_powerNo ratings yet

- Fox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesDocument5 pagesFox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesNicolás Polito MuñozNo ratings yet

- Rubber Seated Butterfly Valves Spec SheetDocument2 pagesRubber Seated Butterfly Valves Spec SheetqcselvaNo ratings yet

- Control PH Valvulas-ItalcoDocument12 pagesControl PH Valvulas-Italcoluis m hueto castilloNo ratings yet

- V5-GRS-A125: Gate ValveDocument1 pageV5-GRS-A125: Gate ValveChristian oliverosNo ratings yet

- FT Valvula Compuerta Clase 800 SWDocument1 pageFT Valvula Compuerta Clase 800 SWFernando CarreñoNo ratings yet

- Flanged Ball ValveDocument20 pagesFlanged Ball ValveToty DzNo ratings yet

- Shinyi Catalogue 2017Document64 pagesShinyi Catalogue 2017Huy NguyễnNo ratings yet

- Data Sheet UbsvDocument6 pagesData Sheet UbsvMeet JaniNo ratings yet

- Lead-Free 250 PSI WWP Iron Body Check Valves: Material ListDocument1 pageLead-Free 250 PSI WWP Iron Body Check Valves: Material ListArturo JimenezNo ratings yet

- Valvulas Apollo GLPDocument4 pagesValvulas Apollo GLPJuan Carlos Pardo RimachiNo ratings yet

- Ariel JGR and JGJ CompressorsDocument4 pagesAriel JGR and JGJ CompressorsVladimirNo ratings yet

- Rubber Seated Butterfly Valves For General Use - 700 Series PDFDocument48 pagesRubber Seated Butterfly Valves For General Use - 700 Series PDFs12originalNo ratings yet

- Asco Series 290 Angle Body CatalogDocument10 pagesAsco Series 290 Angle Body CatalogcillongNo ratings yet

- 3 Way Valve - BallDocument2 pages3 Way Valve - BallchintanNo ratings yet

- VMS - 3Document1 pageVMS - 3ritoh8657No ratings yet

- Comressor JGR JDocument4 pagesComressor JGR Jwahyu kurkur100% (1)

- Wheatley Series 822 Check Valves FlyerDocument2 pagesWheatley Series 822 Check Valves FlyerLorena DávilaNo ratings yet

- Quadrant Ball Valve BrochureDocument2 pagesQuadrant Ball Valve BrochureHecthor Gomez BelloNo ratings yet

- Dembla Gate ValvesDocument20 pagesDembla Gate ValvesMohit AroraNo ratings yet

- AbDex - Hammer UnionsDocument12 pagesAbDex - Hammer UnionsWilliam EvansNo ratings yet

- 5 Catalogue Winway DBB Valve-MinDocument19 pages5 Catalogue Winway DBB Valve-MinAsyadullah Al-FatihNo ratings yet

- Armstrong Isolation ValveDocument4 pagesArmstrong Isolation ValveAnggaNo ratings yet

- Lead Free: Cast Carbon & Alloy Steel Flanged & Butt Weld End Y StrainersDocument2 pagesLead Free: Cast Carbon & Alloy Steel Flanged & Butt Weld End Y StrainersRockny2011No ratings yet

- Forged High Pressure Ball Valves: SBVF360 SeriesDocument4 pagesForged High Pressure Ball Valves: SBVF360 SeriesToty DzNo ratings yet

- Valve Qap - IoclDocument96 pagesValve Qap - Ioclalokgoel_2006No ratings yet

- Kingston Emniyet Ventili ListeDocument2 pagesKingston Emniyet Ventili ListeBURAKNo ratings yet

- Victaulic H771Document8 pagesVictaulic H771Frank BlancoNo ratings yet

- Butterfly Valves GuideDocument28 pagesButterfly Valves GuideLAWRENCENo ratings yet

- Series Description: Universal Product Line: Steel Externals - Jacketed PumpsDocument9 pagesSeries Description: Universal Product Line: Steel Externals - Jacketed PumpsAnonymous uCYIu1No ratings yet

- 140 Sheree Blvd. PO Box 566, Exton, PA 19341-0566 US - Web SiteDocument3 pages140 Sheree Blvd. PO Box 566, Exton, PA 19341-0566 US - Web SitegeorgyNo ratings yet

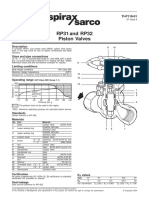

- Spirax Sarco Piston Valve RP31Document2 pagesSpirax Sarco Piston Valve RP31PaulNo ratings yet

- KW900WFPDocument1 pageKW900WFPAlfredo BravoNo ratings yet

- 489-100-A SERIES: Features Variations Available Ul ListingsDocument5 pages489-100-A SERIES: Features Variations Available Ul ListingsKhabbab Hussain K-hNo ratings yet

- Model 1LongWeldEndValve G02Document1 pageModel 1LongWeldEndValve G02saraapciNo ratings yet

- Model 1LongWeldEndValve G02Document1 pageModel 1LongWeldEndValve G02saraapciNo ratings yet

- Scope: Ir. Liew Shaw ShongDocument51 pagesScope: Ir. Liew Shaw ShongsaraapciNo ratings yet

- Model 1LongWeldEndValve G02Document1 pageModel 1LongWeldEndValve G02saraapciNo ratings yet

- Bajaj Auto Company NewDocument94 pagesBajaj Auto Company Newbhas_786No ratings yet

- Masturbation It Might Feel Good But ItsDocument7 pagesMasturbation It Might Feel Good But ItsKshivam KhandelwalNo ratings yet

- DGPS Sensor JLR-4331W Instruction ManualDocument42 pagesDGPS Sensor JLR-4331W Instruction ManualantonioNo ratings yet

- QUESTION A2 and A3 Examples PDFDocument24 pagesQUESTION A2 and A3 Examples PDFDemian VeNo ratings yet

- Presentation 123Document13 pagesPresentation 123Harishitha ManivannanNo ratings yet

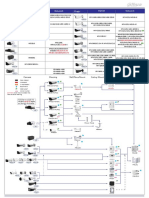

- Belden CatalogDocument24 pagesBelden CatalogMani MaranNo ratings yet

- Module 37 Nur 145Document38 pagesModule 37 Nur 145Marga WreatheNo ratings yet

- 2nd Quarter Summative Test in MusicDocument2 pages2nd Quarter Summative Test in MusicIverAlambraNo ratings yet

- Wirkungen FlechtenstoffeDocument21 pagesWirkungen FlechtenstoffeLogge UliNo ratings yet

- Absence Makes The Heart Grow FonderDocument27 pagesAbsence Makes The Heart Grow FondereljhunNo ratings yet

- Techniques for Studying FossilsDocument11 pagesTechniques for Studying FossilsP. C. PandeyNo ratings yet

- Tec Relay 52GDocument3 pagesTec Relay 52Gimmer nainggolanNo ratings yet

- PDLAMMPS - made easy: An introductionDocument8 pagesPDLAMMPS - made easy: An introductionSaeed AbdNo ratings yet

- LOGARITHMS, Exponentials & Logarithms From A-Level Maths TutorDocument1 pageLOGARITHMS, Exponentials & Logarithms From A-Level Maths TutorHorizon 99No ratings yet

- D6528-07 ASTM Standard Consolidated Undrained Direct Simple Shear Testing of Cohesive SoilsDocument9 pagesD6528-07 ASTM Standard Consolidated Undrained Direct Simple Shear Testing of Cohesive SoilsDayana HernandezNo ratings yet

- 37th APSDC Scientific PresentationsDocument7 pages37th APSDC Scientific PresentationsSatyendra KumarNo ratings yet

- IIT2019 RIT-1-CPM Chemistry TestDocument15 pagesIIT2019 RIT-1-CPM Chemistry TestPRAKHAR GUPTANo ratings yet

- Sony HCD-GTX999 PDFDocument86 pagesSony HCD-GTX999 PDFMarcosAlves100% (1)

- Elemental Composition of Dalang': A Food Condiment From Evaporated Extract of Borassus Aethiopum Fruit AshDocument3 pagesElemental Composition of Dalang': A Food Condiment From Evaporated Extract of Borassus Aethiopum Fruit AshsardinetaNo ratings yet

- Dahua Pfa130 e Korisnicko Uputstvo EngleskiDocument5 pagesDahua Pfa130 e Korisnicko Uputstvo EngleskiSaša CucakNo ratings yet

- Crimson Holdings Fact Sheet As of April 14Document3 pagesCrimson Holdings Fact Sheet As of April 14WDIV/ClickOnDetroitNo ratings yet

- ARES SC4 Service Manual (HP-300UA)Document20 pagesARES SC4 Service Manual (HP-300UA)mike_net8903No ratings yet

- Analysis of Financial Statements Project: GUL AHMAD Textile MillsDocument32 pagesAnalysis of Financial Statements Project: GUL AHMAD Textile MillsHanzala AsifNo ratings yet

- Medium Strength High Conductivity MaterialsDocument37 pagesMedium Strength High Conductivity MaterialsNut AssanaiNo ratings yet

- Retired Car Jacker Screen PlayDocument4 pagesRetired Car Jacker Screen Playapi-633948182No ratings yet

- SC Earthquake GuideDocument8 pagesSC Earthquake GuideNevin SmithNo ratings yet