Professional Documents

Culture Documents

MS 500 Excavation and Backfill - Earthworks Rev.1

Uploaded by

alfaza3Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS 500 Excavation and Backfill - Earthworks Rev.1

Uploaded by

alfaza3Copyright:

Available Formats

Al Geemi & Partners

Contracting Co. L.L.C.

INTERNAL ROADS AT VARIOUS LOCATIONS IN AL AIN

STAGE-17 CONTRACT-1

METHOD STATEMENT

EXCAVATION AND BACKFILLING - EARTHWORKS

Status

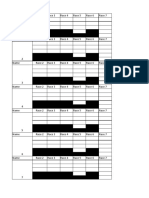

Rev. Prepared By: Checked By: Approved By: Submitted on: Returned on:

00 SE QA/QC-CM PM 20.03.2011

01 SE QA/QC-CM PM 26.03.2011 28.03.2011 Approved

as Noted

`

__________________________________________

Endorsed by Project Quality Assurance Team Leader

Doc No. AGP (MS) S17-C1/500Rev. 01 Page 1 of 7

CONTENTS

Part A – SiteWorks Particulars

A.1 Scope of Work.

A.2 Site Organization

A.3 Equipment

A.3.1 – Equipments

A.4 Work Procedure

A.5 Safety Requirements

Part B – List of References

Part C - Appendices:

C.1 Inspection and Test Plan

C.2 Risk Analysis Matrix

C.3 Contractors Risk Analysis Form

C.4 Drawings if needed.

Part A – Site Works Particulars

Doc No. AGP (MS) S17-C1/500 Rev. 01 Page 2 of 8

A.1 Scope of Work – this statement applies for excavation of road works, disposal of

unsuitable and surplus suitable material, stockpiling, embankments and backfilling.

A.2 Site Organization

Duties and Responsibilities

A.2.1 Project Manager – To provide overall functioning of the project organization,

planning, progress oversight and support the construction team to the smooth

and timely delivery and procurement of materials, provision of manpower,

machinery, generate documents required as per requirements of contract,

implement and monitor the proper execution of the project in compliance with

contract specification, drawings, related international and statutory regulatory

requirements all to the satisfactory completion of the project on time within

allocated budget.

A.2.2 Construction Manager – To provide technical oversight and guidance to lead the

project construction team, fast track the development of workshop drawings, the

timely approval of materials and other submittals including ordering and

immediate delivery to site, identify shortage of manpower, materials and

equipment to ensure the smooth execution of this activity.

A.2.3 Site Engineer - To execute construction work at site as per the approved shop

drawing, materials, specifications all in accordance with the project technical and

contractual requirements.

A.2.4 Project Safety Engineer. – Coordination and management of HSE monitoring

activities related to the work. Implement the HSE training and awareness

campaigns manage and supervise HSE team for onsite construction , manage

the HSE incident reporting and investigation system & to ensure that site staff is

familiar with the safety requirements for this activity to prevent accident.

A.2.5 QA/QC Engineer- To implement and monitor Quality assurance / Quality control

system and procedures in compliance with contract requirements and Project

Quality plan.

A.2.6 Surveyor - Coordination and management of survey , setting out line, level and

keep record of all actual datas for final measurement, as built drawings and

quantity of work activities at site.

A.2.7 Site Foreman – To ensure that the concerned work force under his team are

completely aware of the activities and hazards on their respective work. To

organize manpower, plant & materials at job site.

A.3 Equipment

Doc No. AGP (MS) S17-C1/500 Rev. 01 Page 3 of 8

A.3.1 – Equipment – shall undergo routine maintenance to ensure safety measures to

all its operators and drivers. All equipment shall have valid registration. List of

equipment are as follows.

A.3.1.1 – Dumper

A.3.1.2 – Loader

A.3.1.3 – Excavator

A.3.1.4 – 6 Wheel

A.3.1.5 – Roller compactor

A.3.1.6 – Plate compactor

A.3.1.7 – JCB

A.3.1.8 – Water tanker

A.3.1.9 – Mobile crane

A.4 Work Procedure

A.4.1 – Preparation activities

A.4.1.1– Method Statement submittal approval

A.4.1.2– Shop drawing approval

A.4.1.3– Material submittal approval

A.4.1.4 - Ascertain the actual locations of all existing services and obstructions before

commencing any part of the work.

A.4.1.5 – Survey and keep record of site setting out and levels in a manner agreed with

the Engineer.

A.4.1.6 – Provide and maintain temporary barriers, safety signs and security devices

prior to excavation.

A.4.1.7 – Obtain road cutting permit from consultant for excavation in roads, do not

close or obstruct roadways and sidewalks without permits.

A.4.1.8 – Submit request for inspection prior to proceed excavation for Consultant

approval.

A.4.2.1 Roadway Excavation – clause 3.1 – 3.7

A.4.2.1.1 – Verify shop drawings are the latest approved and ensure that excavation is

at the proper location as shown therein.

A.4.2.1.2 – After obtaining approvals from concerned authorities, carefully excavate all

necessary trial pits by hand to locate all services and obstructions. Trial pits

maximum interval of 25m.

Doc No. AGP (MS) S17-C1/500 Rev. 01 Page 4 of 8

A.4.2.1.3 – Excavate within the limits of the Right of Way for the preparation of the

road bed. Material declared unsuitable by the Engineer shall be considered to be

available for use at locations requiring fill.

A.4.2.1.4 – All materials removed from an excavation shall be used in the formation of

the embankment, shoulders and at such other places as directed, unless it is

declared unsuitable and ordered to be sent to tip by the engineer.

A.4.2.1.5 – Any extra depth of excavation below the top elevation of subgrade or the

required excavation level shall be made good with suitable material as

required under the specification.

A.4.2.1.6 – Materials encountered during excavation works which are determined by

the Engineer to be unsuitable for retention in the formation and subgrade or for

use elsewhere in the works shall be excavated and disposed of in tips.

A.4.2.1.7 – Make sure that the extent in open cut is the minimum necessary or

practicable for the construction of the works.

A.4.2.1.8 - The bottom of all excavations shall be carefully prepared to the levels and

profiles as shown on the drawings. Any pockets of soft soil or loose rock in the

bottom of excavation shall be removed.

A.4.2.1.9 – Suitable excavated material shall be stockpiled and subsequently used

elsewhere in the works.

A.4.2.1.10 – All open excavation shall be enclosed from all sides by temporary safety

cones, warning tapes and warning signs for deep excavation.

A.4.2.1.11 – Do not remove the temporary works supporting the excavation until the

permanent work is sufficiently allows such removal.

A.4.2.1.12 – Where dewatering is required, a qualified and experinced crew shall be

provided to perform the dewatering operation with complete fascilities to keep

the excavation in dry condition.

A.4.3 Disposal of Unsuitable and Surplus Suitable material

A.4.3.1 Remove from site all unsuitable material to be taken to tip. Spoil tips used shall

be levelled and maintained in a condition approved by the Engineer.

A.4.3.2 – Inform the Engineer in advanced to dispose off suitable material, which is

surplus to the requirements of the works and shall request the Engineer’s

instruction on disposal of the same.

A.4.4 – Stockpiling

A.4.4.1 – Suitable excavated material shall be stockpiled and subsequently used

elsewhere in the works as required.

Doc No. AGP (MS) S17-C1/500 Rev. 01 Page 5 of 8

A.4.4.2 – Make own arrangement for stockpiling if the material to be placed directly in

its final position and maintan uniform properties of materials through separating

stockpiles.

A.4.4.3 - Stockpile tips used shall be leveled and maintained in condition approved by

the Engineer.

A.4.4.4 - All stockpiled material shall be within fenced areas, and signs shall be erected

indicating what is within the fenced area.

A.4.5 – Embankment Materials - General

A.4.5.1 – Imported fill / sub-grade materials for road works shall be as per required

specification, free from organic / gypsum or other deleterious matter obtained

from the excavation or source approved by the Engineer.

A.4.5.2 – Do not allow dune sand to be mixed with borrow materials to achieve the

required criteria for suitable material.

A.4.5.3 – Dune sand may be accepted as suitable fill material for areas agreed and

approved by the Engineer and Client.

A.4.6 Backfilling and Compaction

A.4.6.1 – Selected material used for backfilling of roads / footpath etc. shall be

suitable material free from stones or other particles greater than 25mm in size.

A.4.6.2 – In case in roads and tiled/ paved areas, backfill with approved materials in

layers not exceeding 250mm to obtain 90% compaction of the relevant

maximum dry density of the material in accordance with BS 1377 part 9.

A.4.6.3 – Backfill roads and tiled/ paved areas including areas designated as future

roads in accordance with specification for backfilling of trenches and excavations

in asphalt roads, tiled/ paved parking areas and sidewalks..

A.4.6.4 – Material selected for use in the top 150mm or 300mm below the top elevation

of subgrade of cut or fill areas shall be suitable material to be compacted to 95%

of MDD.

A.4.6.5 – Material for the remainder of fill areas shall be suitable material to be

compacted to 90% MDD.

A.4.6.6 – Maintain optimum moisture content of fill materials to attain required

compaction density.

A.4.6.7 – Field density and moisture content – Not less than one test of the

suitable layer depth per 750 sq.m of fill. The relevant areas shall be

rejected if the test results do not satisfy the specified requirements.

Doc No. AGP (MS) S17-C1/500 Rev. 01 Page 6 of 8

A.4.6.8 – Road sub-base material shall be deliverd to the roadbed as uniform mixture

ans shall be spread in layers. Segregation shall be avoided and the sub-base

shall be free from pockets of coarse or fine materials.

A.4.6.9 – Each road sub-base layer shall be spread by grader or other approved

mechanical methods, watered, shaped to compacted thickness not exceeding

150mm and compacted to the required grade and cross section.

A.4.6.10 – The granular sub-base shall be compacted to not less than 98% of the

maximum density.

A.5 Safety Requirement

A.5.1 – Prior to commencing any activity, the labour force shall receive a toolbox talk

on the project site safety regulations by the foreman. Any process that is adopted that

may have a particular safety risk will be assessed and addressed as required. All the

hazards and the corresponding safety precautions in the respective risk assesment

shall be adhered to and communicated to the workers before starting work.

A.5.1.1 – Toolbox talks shall be conducted prior to commencing any activity.

A.5.1.2 – Equipments used to be inspected and approved by the Engineer.

A.5.1.3 – Required PPE (safety shoes, helments, hand gloves, dust mask, and safety

goggles) to be provided and used.

A.5.1.4 – Safety warning device of equipment to be in good condition.

A.5.1.5 – Banksman to be assigned to every heavy equipment.

Part B List of References

1. Contract 1 Vol. 3 General Specification – Earthworks

2. Shop Drawing No. AGP/232/T/SEC/01

Legend:

AGP- Al Geemi & Partners TBT - ToolBox Talk (Safety Briefing)

DCE – DIWI Consult Emirates HSE – Health, Safety and Environment

SE – Site Engineer QA/QC– Quality Assurance/Quality Control

MS - Method Statement PQP – Project Quality Plan

FM - Foreman ST – Survey Team

Doc No. AGP (MS) S17-C1/500 Rev. 01 Page 7 of 8

You might also like

- HM 17 18Document5 pagesHM 17 18alfaza3No ratings yet

- Justification ToolkitDocument4 pagesJustification Toolkitalfaza3No ratings yet

- Item Item Description Unit Quantity: MaterialDocument4 pagesItem Item Description Unit Quantity: Materialalfaza3No ratings yet

- Water Works RTADocument15 pagesWater Works RTAalfaza3No ratings yet

- Hand Roller Plate Compactor 3: EquipmentDocument1 pageHand Roller Plate Compactor 3: Equipmentalfaza3No ratings yet

- 2.02 Quality of RoadsDocument1 page2.02 Quality of RoadsМихаил АхремцевNo ratings yet

- Al Mnafis Gen - Trans.est.Document3 pagesAl Mnafis Gen - Trans.est.alfaza3No ratings yet

- HM-17-18 20-2-2020-M PDFDocument1 pageHM-17-18 20-2-2020-M PDFalfaza3No ratings yet

- Description Unit Qty Remarks Electrical UPVC End Caps " 200mm Dia " Pcs 184 MCC UPVC End Caps " 75mm Dia " Pcs 160Document1 pageDescription Unit Qty Remarks Electrical UPVC End Caps " 200mm Dia " Pcs 184 MCC UPVC End Caps " 75mm Dia " Pcs 160alfaza3No ratings yet

- Trial Trenches Check ListDocument3 pagesTrial Trenches Check Listalfaza3No ratings yet

- Transco System Safety Rules Summary For Contractors v4.1-301212 PDFDocument12 pagesTransco System Safety Rules Summary For Contractors v4.1-301212 PDFEngr.bilalNo ratings yet

- Construction Tools Supplier ListDocument2 pagesConstruction Tools Supplier Listalfaza3No ratings yet

- Trial Trenches Check List1Document1 pageTrial Trenches Check List1alfaza3No ratings yet

- Genesis G80sport Catalogue en PDFDocument9 pagesGenesis G80sport Catalogue en PDFalfaza3No ratings yet

- Meydan Racecourse Form Guide March 2018Document26 pagesMeydan Racecourse Form Guide March 2018alfaza3No ratings yet

- Form Guide Al Ain Racecourse Saturday 10 December 2016Document26 pagesForm Guide Al Ain Racecourse Saturday 10 December 2016alfaza3No ratings yet

- DU FormDocument2 pagesDU Formalfaza3No ratings yet

- Jabil AliDocument2 pagesJabil Alialfaza3No ratings yet

- HHHHHHVJHVDocument2 pagesHHHHHHVJHValfaza3No ratings yet

- Excavation PermitDocument1 pageExcavation Permitalfaza3No ratings yet

- Answers SheetsDocument14 pagesAnswers Sheetsalfaza3No ratings yet

- Location:: Activities Starting Date Finishing Date Duration Resources Manpower EquipmentDocument1 pageLocation:: Activities Starting Date Finishing Date Duration Resources Manpower Equipmentalfaza3No ratings yet

- Work Order Snag Lists Rectify IssuesDocument2 pagesWork Order Snag Lists Rectify Issuesalfaza3No ratings yet

- Proposal Layout NEW ROAD (Rev.01) - Layout1Document1 pageProposal Layout NEW ROAD (Rev.01) - Layout1alfaza3No ratings yet

- Structural Design Manual for Improved Inlets & CulvertsDocument314 pagesStructural Design Manual for Improved Inlets & CulvertsTakis ApostolidesNo ratings yet

- اسئلة واجوابة فى الجسور 2Document16 pagesاسئلة واجوابة فى الجسور 2alfaza3No ratings yet

- Bridge Hydraulic Design (2000)Document60 pagesBridge Hydraulic Design (2000)ArmandoNo ratings yet

- JapanDocument8 pagesJapanalfaza3No ratings yet

- Crosswalk HumpDocument3 pagesCrosswalk Humpalfaza3No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Bio SaftyDocument7 pagesBio Saftyapi-283956320No ratings yet

- Principles of Health AdminDocument42 pagesPrinciples of Health AdminAnne BattulayanNo ratings yet

- Nursing Abbreviations, Acronyms and Symbols QuizDocument3 pagesNursing Abbreviations, Acronyms and Symbols QuizAjeng Citra S SeptiyantriNo ratings yet

- Mds Periodontics Thesis TopicsDocument7 pagesMds Periodontics Thesis Topicsamyholmesmanchester100% (2)

- Fibre Cement Slates Fixing GuideDocument26 pagesFibre Cement Slates Fixing GuideMuhammad HafizuddinNo ratings yet

- PamphletDocument1 pagePamphletAldenn MinotaurNo ratings yet

- Commissioning Federal Facilities Chiller (PQ)Document19 pagesCommissioning Federal Facilities Chiller (PQ)Yu-Chih PuNo ratings yet

- Ethical Decision Making in ResearchDocument2 pagesEthical Decision Making in ResearchChandraKurniawanNo ratings yet

- USMLE High YieldDocument8 pagesUSMLE High YieldNajia ChoudhuryNo ratings yet

- The Star News November 20, 2014Document37 pagesThe Star News November 20, 2014The Star NewsNo ratings yet

- Interim Public Health Operational Guidelines For Amoebiasis: (Entamoeba Histolytica)Document34 pagesInterim Public Health Operational Guidelines For Amoebiasis: (Entamoeba Histolytica)QworldNo ratings yet

- Macronutrients ProteinsDocument2 pagesMacronutrients ProteinsEllice O. MonizNo ratings yet

- Mapeh 10 2nd PrelimsDocument4 pagesMapeh 10 2nd PrelimsBlaize PascualNo ratings yet

- Uttarakhand Dealers Data, JanviDocument8 pagesUttarakhand Dealers Data, JanviVAISHNAVI TAYALNo ratings yet

- 296402-Official ESTA Application Website U.S. Customs and Border Protection PDFDocument5 pages296402-Official ESTA Application Website U.S. Customs and Border Protection PDFLouise Ann TunstallNo ratings yet

- Assisted SuicideDocument30 pagesAssisted SuicideAlex Mini AndraNo ratings yet

- KCC Mall 69kV Substation DesignDocument18 pagesKCC Mall 69kV Substation DesignRomie ArazaNo ratings yet

- D A Up To 2 YearDocument7 pagesD A Up To 2 YearNischitha G CNo ratings yet

- Wound HealingDocument44 pagesWound HealingSorin Niky MocanuNo ratings yet

- TB Teaching PlanDocument5 pagesTB Teaching PlanTrisha Fae Loyola Balagot100% (1)

- Cardiac MarkersDocument23 pagesCardiac MarkersAsmaaYLNo ratings yet

- Water, Sanitation and Hygiene in SchoolsDocument6 pagesWater, Sanitation and Hygiene in SchoolsDux Mercado100% (1)

- Bailey SafeMedPharmacyTechnicianDocument10 pagesBailey SafeMedPharmacyTechnicianRazak AbdullahNo ratings yet

- AMEE 2023 Final Programme OverviewDocument2 pagesAMEE 2023 Final Programme OverviewMohamed IshagNo ratings yet

- Clinical Profile of Hoarseness of Voice: A Hospital-Based Cross-Sectional StudyDocument5 pagesClinical Profile of Hoarseness of Voice: A Hospital-Based Cross-Sectional Studynurul atika havizNo ratings yet

- Respiratory MechanicsDocument27 pagesRespiratory MechanicsKarla Hernandez100% (1)

- HO#1.1 Caring For The BodyDocument7 pagesHO#1.1 Caring For The BodyGemma CanlapanNo ratings yet

- CyberneticsDocument3 pagesCyberneticsTanya ChawdaNo ratings yet

- Mdbsis09 CA A III 2017Document4 pagesMdbsis09 CA A III 2017Guneyden GuneydenNo ratings yet

- Memory Manipulation PDFDocument381 pagesMemory Manipulation PDFAlapan Bandyopadhyay100% (2)