Professional Documents

Culture Documents

Vinegar Production Methods

Uploaded by

Qaiser AbbasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vinegar Production Methods

Uploaded by

Qaiser AbbasCopyright:

Available Formats

Assignment 2

Vinegar production

There are three well-known processes of producing vinegar

The Orleans Method

This is one of the older and slower methods of creating a high-quality vinegar. This method involves the

fermentation of vinegar inside a container. The container has holes drilled into it to allow oxygen inside. These

holes also contain screen filters which prevent insects and bugs from entering the cask which will disturb the

production. Oxygen is necessary to produce vinegar as the bacteria that turns the solution into vinegar requires

oxygen. To create the vinegar, the alcoholic liquid is poured into the cask and then about 20% of fresh vinegar

is poured into the cask to begin the fermentation process. Once the acetobacter bacteria oxidises the acetic

acid the vinegar is now finished. There is a plug on the container to collect the finished vinegar, and a tube to

add more substances without destroying the film of vinegar bacteria.

The Trickling, Quick Process

As the Orleans method is a very slow process, many people tried to increase the production by implementing

a new method. This method of producing vinegar involves spraying the alcoholic substrate in the top layer of

the fermentation chamber where it is filled with materials that carry a slime made of acetic bacteria so that the

bacteria could react with the substrate and create vinegar. Due to the heat that is made during the fermentation

of vinegar, air is forced through the chamber to keep it cool. The vinegar is recirculated two-three times until

the desired concentration of vinegar is achieved. Once the vinegar is achieved it is then collected from the

collection chamber.

The Submerged Fermentation Method

This method is the newer, faster, and more efficient methods of producing vinegar. It is mainly used in

industrial businesses where the needed equipment is present. In this method, a high-speed motor breaks down

air that is brought down from a stainless-steel tank into tiny bubbles and is forced into the solution of alcoholic

liquid and the bacteria for even faster oxidisation. The final steps are filtration and pasteurisation of the vinegar

to stop any more bacteria growth and enzyme actions. As this process usually takes one to two days to process

so this method is mainly used by big industries.

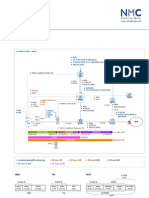

Flow chart of vinegar production

Quality Control

The growing of acetobacters, the bacteria that creates vinegar, requires vigilance. In the Orleans Method, holes

must be checked routinely to ensure that insects have not penetrated the netting. Workers routinely check the

thermostats on the container. Because a loss of electricity could kill the acetobacters within seconds, many

vinegar plants have backup systems to produce electrical power in the event of a blackout.

By products/Waste:

Vinegar production results in very little by-products or waste. In fact, the alcohol product is often the by-

product of other processes such as winemaking and baker’s yeast.

Some sediment will result from the submerged fermentation method. This sediment is biodegradable and can

be flushed down a drain for disposal.

References:

http://www.madehow.com/Volume-7/Vinegar.html

https://en.wikipedia.org/wiki/Vinegar

http://aceticacidvinegar.weebly.com/manufacturing-process.html

You might also like

- VinegarDocument17 pagesVinegarVirendra JoshiNo ratings yet

- Acetic Acid Production: UsesDocument4 pagesAcetic Acid Production: Usesmahmoud shehataNo ratings yet

- Production of VinegarDocument37 pagesProduction of VinegarAhmed AliNo ratings yet

- Vinegar Report 2021Document15 pagesVinegar Report 2021NkosinathiNo ratings yet

- Production of Acetic AcidDocument22 pagesProduction of Acetic AcidMd. Babul AktarNo ratings yet

- Acetic Acid: Biosynthesis and Fermentation Process - Industries - BiotechnologyDocument7 pagesAcetic Acid: Biosynthesis and Fermentation Process - Industries - Biotechnologyعبداللە عمر ابراهیمNo ratings yet

- Vinegar ProductionDocument9 pagesVinegar ProductionbanerjeerhiNo ratings yet

- Internship Report On Dashen BreweryDocument27 pagesInternship Report On Dashen Brewerydesalegn abera70% (10)

- VinegarDocument31 pagesVinegarRam VermaNo ratings yet

- Vinegar MakingDocument29 pagesVinegar MakingAmjad KhattakNo ratings yet

- Acetic Acid MFGDocument13 pagesAcetic Acid MFGveeryashraj.rtmNo ratings yet

- Process Selection:: 2.1 Types of ProcessesDocument16 pagesProcess Selection:: 2.1 Types of ProcessesNabeel BhuttaNo ratings yet

- Competitive Vinegar Technologies and Varieties in EuropeDocument6 pagesCompetitive Vinegar Technologies and Varieties in EuropeAnca Irimia0% (1)

- Fermentation Final.....Document18 pagesFermentation Final.....Ansh AroraNo ratings yet

- Vinegar and Rye Bread ProductionDocument26 pagesVinegar and Rye Bread ProductionmoniqueNo ratings yet

- Alcoholic Beverage Sugars Acids Enzymes Nutrients Yeast Consumes The Sugars Alcohol Carbon DioxideDocument38 pagesAlcoholic Beverage Sugars Acids Enzymes Nutrients Yeast Consumes The Sugars Alcohol Carbon DioxideMhelveneNo ratings yet

- 3.body of ReportDocument54 pages3.body of ReportaregawiNo ratings yet

- Wine Filtration ProcessDocument6 pagesWine Filtration ProcessChali HaineNo ratings yet

- SCOPE AND LIMITATION SCOPE ChemistryDocument2 pagesSCOPE AND LIMITATION SCOPE Chemistryprabhat solankiNo ratings yet

- Radico Khaitan Ltd: History and Process of Indian Beverage Company's Whiskey ProductionDocument26 pagesRadico Khaitan Ltd: History and Process of Indian Beverage Company's Whiskey ProductionVibhav GuptaNo ratings yet

- Modern method of extraction of crude drugsDocument13 pagesModern method of extraction of crude drugsamama khanNo ratings yet

- A Experimental Study of Vinegar Production From Different Fruit Products-IJAERDV04I0460188Document6 pagesA Experimental Study of Vinegar Production From Different Fruit Products-IJAERDV04I0460188Madel DalindingNo ratings yet

- Beer Clarification Methods and EquipmentDocument13 pagesBeer Clarification Methods and EquipmentІра ГончарNo ratings yet

- Final PDF AasthaDocument14 pagesFinal PDF Aasthaasmitmohanty2206No ratings yet

- 1.1.1. Description and Uses of The ProductDocument6 pages1.1.1. Description and Uses of The ProductAlbert Brun ArmonioNo ratings yet

- How Beer Is Made in Industrial Brewing ProcessDocument7 pagesHow Beer Is Made in Industrial Brewing ProcessRey Danielle Taray NaveaNo ratings yet

- Production of Cheese by Eric BioDocument15 pagesProduction of Cheese by Eric BioNkosinathiNo ratings yet

- Recovery of Tank Wash Water Paint FactoryDocument4 pagesRecovery of Tank Wash Water Paint Factorypattirajawane48No ratings yet

- Production of Citric AcidDocument5 pagesProduction of Citric AcidSonam SharmaNo ratings yet

- Organic Acid AssignmentDocument8 pagesOrganic Acid AssignmentHamza MalikNo ratings yet

- Overview of Dairy Processing MethodsDocument8 pagesOverview of Dairy Processing MethodsmuralirsNo ratings yet

- Chapter 15, Beverage Plant SanitationDocument17 pagesChapter 15, Beverage Plant SanitationAmogh Subhashbabu0% (1)

- Coca Cola Project Report FinalDocument20 pagesCoca Cola Project Report FinalAshwi MehrotraNo ratings yet

- Technology of WineDocument5 pagesTechnology of Winemawamaka90No ratings yet

- Enzyme Final ExamDocument16 pagesEnzyme Final ExamThuy AnhNo ratings yet

- 4.3 SingeingDocument18 pages4.3 SingeingManoja SamarasingheNo ratings yet

- Para DefenseDocument11 pagesPara DefensejenilenNo ratings yet

- 20 Facts You Should KnowDocument7 pages20 Facts You Should KnowDomagoj ĆosićNo ratings yet

- MCB 407 Lecture FiveDocument10 pagesMCB 407 Lecture FivePopoola OlakunleNo ratings yet

- Developing Cost Effective Automation For Cotton Seed DelintingDocument8 pagesDeveloping Cost Effective Automation For Cotton Seed DelintingIJMERNo ratings yet

- DAIRY INDUSTRY, Sugar Industry, Paper and Pulp, Textile Mill WasteDocument79 pagesDAIRY INDUSTRY, Sugar Industry, Paper and Pulp, Textile Mill WasteHemantha RajuNo ratings yet

- Assignment-Vinegar Production RA1812036010016Document4 pagesAssignment-Vinegar Production RA1812036010016Rajan sigdelNo ratings yet

- Sensors 22 06247 v2Document11 pagesSensors 22 06247 v2nimmi kumariNo ratings yet

- Water Test ReportDocument8 pagesWater Test Reportruhul01No ratings yet

- Organic Acids by MicroorganismsDocument38 pagesOrganic Acids by MicroorganismsMuhammad Adeel JavedNo ratings yet

- Industrial Fermenters: Growing Cells On A Large ScaleDocument10 pagesIndustrial Fermenters: Growing Cells On A Large ScaleNatty ArendtNo ratings yet

- Organic AcidDocument38 pagesOrganic AcidMuhammad Adeel JavedNo ratings yet

- Fit-Out: Plant Design & FitoutDocument1 pageFit-Out: Plant Design & FitoutElaine YoungNo ratings yet

- New Microsoft Word DocumentDocument28 pagesNew Microsoft Word DocumentmulerNo ratings yet

- De SizingDocument11 pagesDe SizingarafathosainNo ratings yet

- KV No 2 Bangalore student water purification projectDocument26 pagesKV No 2 Bangalore student water purification projectAnurag Kashyap0% (1)

- Vinegar Production - Role of MicroorganismsDocument20 pagesVinegar Production - Role of MicroorganismsVirendraNo ratings yet

- Homeowner's guide to wastewater treatment systemDocument14 pagesHomeowner's guide to wastewater treatment systemjim STAMNo ratings yet

- Solation of Citric Acid From MicroorganismsDocument4 pagesSolation of Citric Acid From MicroorganismsResearch ParkNo ratings yet

- UntitledDocument12 pagesUntitledLisbonNo ratings yet

- Production of Detergent From Castor OilDocument8 pagesProduction of Detergent From Castor OilLenh DavidleNo ratings yet

- Production of industrial vinegarDocument6 pagesProduction of industrial vinegarMicro ShamimNo ratings yet

- BreweryDocument11 pagesBreweryAndrea GibsonNo ratings yet

- Study Concerning The Quality of Apple Vinegar Obtained Through Classical MethodDocument7 pagesStudy Concerning The Quality of Apple Vinegar Obtained Through Classical MethodfaradayzzzNo ratings yet

- CPRP SkilledDocument10 pagesCPRP SkilledHammad RazaNo ratings yet

- Verities of Mushrooms: Assignment 1Document2 pagesVerities of Mushrooms: Assignment 1Qaiser AbbasNo ratings yet

- LTE RhodesDocument55 pagesLTE Rhodesg_kukadeNo ratings yet

- Huawei KPI ManagementDocument65 pagesHuawei KPI ManagementSabea100% (1)

- NMC - Lte Identifiers.v1.0Document3 pagesNMC - Lte Identifiers.v1.0Hemant Singh RawatNo ratings yet

- SEEPZ Special Economic ZoneDocument2 pagesSEEPZ Special Economic ZonetarachandmaraNo ratings yet

- FEM IntroductionDocument47 pagesFEM IntroductionShanmuga RamananNo ratings yet

- DS 20230629 SG3300UD-MV SG4400UD-MV Datasheet V16 ENDocument2 pagesDS 20230629 SG3300UD-MV SG4400UD-MV Datasheet V16 ENDragana SkipinaNo ratings yet

- Wordbank Restaurants 15Document2 pagesWordbank Restaurants 15Obed AvelarNo ratings yet

- VSP-12Way - Is Rev.03Document55 pagesVSP-12Way - Is Rev.03Marcelo AlmeidaNo ratings yet

- FZ16 9B 1KD2 (Patada) PDFDocument62 pagesFZ16 9B 1KD2 (Patada) PDFPanthukalathil Ram100% (1)

- Blum2020 Book RationalCybersecurityForBusineDocument349 pagesBlum2020 Book RationalCybersecurityForBusineJulio Garcia GarciaNo ratings yet

- Manual de Instalare Centrala de Incendiu Adresabila 1-4 Bucle Teletek IRIS PRO 250bucla 96 Zone 10000 EvenimenteDocument94 pagesManual de Instalare Centrala de Incendiu Adresabila 1-4 Bucle Teletek IRIS PRO 250bucla 96 Zone 10000 EvenimenteAlexandra DumitruNo ratings yet

- VB 2Document11 pagesVB 2Sudhir IkkeNo ratings yet

- Draft of The English Literature ProjectDocument9 pagesDraft of The English Literature ProjectHarshika Verma100% (1)

- UNIT: 01 Housekeeping SupervisionDocument91 pagesUNIT: 01 Housekeeping SupervisionRamkumar RamkumarNo ratings yet

- Vallance - Sistema Do VolvoDocument15 pagesVallance - Sistema Do VolvoNuno PachecoNo ratings yet

- Courier - Capstone WebApp - Round 3 ReportDocument23 pagesCourier - Capstone WebApp - Round 3 Reportmarmounette26No ratings yet

- PDF Problemas Ishikawa - Free Download PDF - Reporte PDFDocument2 pagesPDF Problemas Ishikawa - Free Download PDF - Reporte PDFNewtoniXNo ratings yet

- Green Solvents For Chemistry - William M NelsonDocument401 pagesGreen Solvents For Chemistry - William M NelsonPhuong Tran100% (4)

- MSDS Metafuron 20 WPDocument10 pagesMSDS Metafuron 20 WPAndi DarmawanNo ratings yet

- JWCh06 PDFDocument23 pagesJWCh06 PDF007featherNo ratings yet

- Career Guidance Activity Sheet For Grade IiDocument5 pagesCareer Guidance Activity Sheet For Grade IiJayson Escoto100% (1)

- 702190-Free PowerPoint Template AmazonDocument1 page702190-Free PowerPoint Template AmazonnazNo ratings yet

- Chi Square LessonDocument11 pagesChi Square LessonKaia HamadaNo ratings yet

- Best Homeopathic Doctor in SydneyDocument8 pagesBest Homeopathic Doctor in SydneyRC homeopathyNo ratings yet

- Corena s2 p150 - Msds - 01185865Document17 pagesCorena s2 p150 - Msds - 01185865Javier LerinNo ratings yet

- Technical Skills:: Surabhi SrivastavaDocument3 pagesTechnical Skills:: Surabhi SrivastavaPrasad JoshiNo ratings yet

- Pyramix V9.1 User Manual PDFDocument770 pagesPyramix V9.1 User Manual PDFhhyjNo ratings yet

- JIS K 6250: Rubber - General Procedures For Preparing and Conditioning Test Pieces For Physical Test MethodsDocument43 pagesJIS K 6250: Rubber - General Procedures For Preparing and Conditioning Test Pieces For Physical Test Methodsbignose93gmail.com0% (1)

- Formal 17 12 04 PDFDocument184 pagesFormal 17 12 04 PDFJose LaraNo ratings yet

- RS-RA-N01-AL User Manual of Photoelectric Total Solar Radiation TransmitterDocument11 pagesRS-RA-N01-AL User Manual of Photoelectric Total Solar Radiation TransmittermohamadNo ratings yet

- Exercise No. 7: AIM: To Prepare STATE CHART DIAGRAM For Weather Forecasting System. Requirements: Hardware InterfacesDocument4 pagesExercise No. 7: AIM: To Prepare STATE CHART DIAGRAM For Weather Forecasting System. Requirements: Hardware InterfacesPriyanshu SinghalNo ratings yet

- Farmers InterviewDocument5 pagesFarmers Interviewjay jariwalaNo ratings yet

- Oscar Ortega Lopez - 1.2.3.a BinaryNumbersConversionDocument6 pagesOscar Ortega Lopez - 1.2.3.a BinaryNumbersConversionOscar Ortega LopezNo ratings yet