Professional Documents

Culture Documents

Preface Chapter 1. Cutting Forces in Milling Processes: B B Q C Q, B

Uploaded by

Hariharan0 ratings0% found this document useful (0 votes)

21 views3 pagesHhh

Original Title

Doc Vycngaad

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHhh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views3 pagesPreface Chapter 1. Cutting Forces in Milling Processes: B B Q C Q, B

Uploaded by

HariharanHhh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Chapter 1. Cutting Forces in Milling Processes . . . . . . . . . 1

1.1. Formulations of cutting forces . . . . . . . . . . . . . . . . . . . 1

1.1.1. Mechanics of orthogonal cutting . . . . . . . . . . . . . . . . 1

1.1.2. Cutting force model for a general milling cutter . . . . . . . 4

1.2. Milling process geometry . . . . . . . . . . . . . . . . . . . . . . 8

1.2.1. Calculations of uncut chip thickness . . . . . . . . . . . . . . 8

1.2.2. Determination of entry and exit angles . . . . . . . . . . . . 12

1.3. Identification of the cutting force coefficients . . . . . . . . . . . 24

1.3.1. Calibration method for general end mills . . . . . . . . . . . 24

1.3.2. Calibration method in the frequency domain . . . . . . . . . 33

1.3.3. Calibration method involving four cutter

runout parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

1.3.4. Identification of shear stress, shear angle and

friction angle using milling tests . . . . . . . . . . . . . . . . . . . 48

1.4. Ternary cutting force model including bottom

edge cutting effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

1.4.1. Calculations of FB (ϕ) . . . . . . . . . . . . . . . . . . . . . 57

1.4.2. Calculations of FB (ϕ) . . . . . . . . . . . . . . . . . . . . . 57

1.4.3. Calibration of Kqc (q = T, R) . . . . . . . . . . . . . . . . . 58

1.4.4. Calibrations of Kq,B (q = T, R) . . . . . . . . . . . . . . . . 59

1.4.5. Experimental work . . . . . . . . . . . . . . . . . . . . . . . 61

vi Milling Simulation

1.5. Cutting force prediction in peripheral milling

of a curved surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

1.5.1. Calculations of instantaneous uncut chip thickness . . . . . 65

1.5.2. Calculations of entry and exit angles . . . . . . . . . . . . . 67

Chapter 2. Surface Accuracy in Milling Processes . . . . . . . 71

2.1. Predictions of surface form errors . . . . . . . . . . . . . . . . . 71

2.1.1. Calculation of cutting forces and process geometries . . . . 73

2.1.2. Iterative algorithms of surface form errors . . . . . . . . . . 81

2.2. Control strategy of surface form error . . . . . . . . . . . . . . . 89

2.2.1. Development of control strategy . . . . . . . . . . . . . . . . 89

2.2.2. Verification of control strategy . . . . . . . . . . . . . . . . . 93

2.3. Surface topography in milling processes . . . . . . . . . . . . . 95

2.3.1. Prediction method for flat-end milling . . . . . . . . . . . . . 97

2.3.2. Prediction method for multi-axis ball end milling . . . . . . 101

Chapter 3. Dynamics of Milling Processes . . . . . . . . . . . . . 115

3.1. Governing equation of the milling process . . . . . . . . . . . . 115

3.2. Method for obtaining the frequency response function . . . . . 120

3.2.1. Derivation of calculation formulations . . . . . . . . . . . . 121

3.2.2. Identification of model parameters . . . . . . . . . . . . . . . 134

3.3. Prediction of stability lobe . . . . . . . . . . . . . . . . . . . . . 139

3.3.1. Improved semi-discretization method . . . . . . . . . . . . . 139

3.3.2. Lowest envelope method . . . . . . . . . . . . . . . . . . . . 144

3.3.3. Time-domain simulation method . . . . . . . . . . . . . . . . 155

Chapter 4. Mathematical Modeling of the

Workpiece-Fixture System . . . . . . . . . . . . . . . . . . . . . . . 165

4.1. Criteria of locating scheme correctness . . . . . . . . . . . . . . 165

4.1.1. The DOFs constraining principle . . . . . . . . . . . . . . . 165

4.1.2. The locating scheme . . . . . . . . . . . . . . . . . . . . . . . 168

4.1.3. Judgment criteria of locating scheme correctness . . . . . . 172

4.1.4. Analysis of locating scheme incorrectness . . . . . . . . . . 173

4.2. Analysis of locating scheme correctness . . . . . . . . . . . . . 175

4.2.1. Localization source errors . . . . . . . . . . . . . . . . . . . 175

4.2.2. Fixture modeling . . . . . . . . . . . . . . . . . . . . . . . . . 176

4.2.3. Locating scheme correctness . . . . . . . . . . . . . . . . . . 182

4.3. Analysis of workpiece stability . . . . . . . . . . . . . . . . . . . 186

Contents vii

4.3.1. Modeling of workpiece stability . . . . . . . . . . . . . . . . 186

4.3.2. Solution techniques to the model of

workpiece stability . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

4.4. Modeling of the workpiece-fixture geometric

default and compliance . . . . . . . . . . . . . . . . . . . . . . . . . . 201

4.4.1. Source error analysis . . . . . . . . . . . . . . . . . . . . . . 201

4.4.2. Workpiece position error . . . . . . . . . . . . . . . . . . . . 207

4.4.3. Machining error analysis . . . . . . . . . . . . . . . . . . . . 212

4.5. Optimal design of the fixture clamping sequence . . . . . . . . . 218

4.5.1. Effect of clamping sequence on

high-stiffness workpiece . . . . . . . . . . . . . . . . . . . . . . . . 218

4.5.2. Effect of clamping sequence on

low-stiffness workpiece . . . . . . . . . . . . . . . . . . . . . . . . 224

4.5.3. Optimization of clamping sequence . . . . . . . . . . . . . . 225

Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

You might also like

- Crane Inspection ChecklistDocument1 pageCrane Inspection ChecklistsudhakarNo ratings yet

- Queueing Networks and Markov Chains: Modeling and Performance Evaluation with Computer Science ApplicationsFrom EverandQueueing Networks and Markov Chains: Modeling and Performance Evaluation with Computer Science ApplicationsRating: 5 out of 5 stars5/5 (1)

- 12 Elements of Firearms TrainingDocument6 pages12 Elements of Firearms TraininglildigitNo ratings yet

- 53 - 36765 - ME594 - 2014 - 1 - 2 - 1 - Homogeneous TransformationDocument21 pages53 - 36765 - ME594 - 2014 - 1 - 2 - 1 - Homogeneous TransformationHariharanNo ratings yet

- Physioex Ex 7 AnswersDocument5 pagesPhysioex Ex 7 AnswersTin-tinNo ratings yet

- Guidance, Navigation, and Control For Munitions PDFDocument138 pagesGuidance, Navigation, and Control For Munitions PDFlhomssiNo ratings yet

- Stream CipherDocument214 pagesStream CipherAyush TibrewalaNo ratings yet

- Shipping Agents in SGDocument3 pagesShipping Agents in SGeason insightsNo ratings yet

- Exam Materials ScienceDocument10 pagesExam Materials ScienceChimzoe CatalanNo ratings yet

- Collapse and Post-CollapseDocument222 pagesCollapse and Post-CollapseGiovanniStirelliNo ratings yet

- TextbookDocument409 pagesTextbookVrutang ShahNo ratings yet

- THESISDocument44 pagesTHESISRowena Shaira AbellarNo ratings yet

- Stochastic ProgrammingDocument315 pagesStochastic Programmingfeiying1980100% (1)

- La PDFDocument257 pagesLa PDFMaqsood 9682619146No ratings yet

- System Identification MatlabDocument167 pagesSystem Identification Matlabkarlg100% (1)

- Evans PDE Solution Chapter 5 Sobolev PDFDocument9 pagesEvans PDE Solution Chapter 5 Sobolev PDFPubavaNo ratings yet

- Basic Control System 1Document151 pagesBasic Control System 1idhoidoNo ratings yet

- Conversational Automatic Programming Function Ii For Lathe Operator's Manual (B-61804e-2 - 05) PDFDocument798 pagesConversational Automatic Programming Function Ii For Lathe Operator's Manual (B-61804e-2 - 05) PDFdmlukinyandex.ru0% (1)

- Print BookDocument214 pagesPrint BookSidarth VenkatesanNo ratings yet

- Time Series BookDocument435 pagesTime Series BookJosé Geraldo De Souza Silva100% (1)

- The Ayurvedic Vegan Kitchen PDFDocument203 pagesThe Ayurvedic Vegan Kitchen PDFRuvaly MzNo ratings yet

- Applied Nonparametric RegressionDocument426 pagesApplied Nonparametric RegressionIntan Purnomosari100% (1)

- Provisional Restorations in Fixed ProsthodonticsDocument4 pagesProvisional Restorations in Fixed ProsthodonticsPhoebe David100% (1)

- STAT613Document295 pagesSTAT613ansarixxxNo ratings yet

- Design of A Robotic Arm For Laboratory Simulations of Spacecraft Proximity Navigation and DockingDocument311 pagesDesign of A Robotic Arm For Laboratory Simulations of Spacecraft Proximity Navigation and DockingEmadaddi AlazzaniNo ratings yet

- Kantha Embroidery by Nanduri Asha, Shreya Gulati, Saloni PriyaDocument17 pagesKantha Embroidery by Nanduri Asha, Shreya Gulati, Saloni PriyaShreyaa Gulati100% (3)

- Stochastic ProgrammingDocument326 pagesStochastic ProgrammingFang TianNo ratings yet

- Time of Flight Cameras: Principles, Methods, and ApplicationsDocument103 pagesTime of Flight Cameras: Principles, Methods, and ApplicationsZhicheng1 YANGNo ratings yet

- BOOK2Document201 pagesBOOK2Chetan Satish PadoleNo ratings yet

- Seismic Reliability Analysis of Structures: Paolo E. Pinto, Renato Giannini, Paolo Franchin Press Release, May 2004Document378 pagesSeismic Reliability Analysis of Structures: Paolo E. Pinto, Renato Giannini, Paolo Franchin Press Release, May 2004RenatoNo ratings yet

- N - Kondipati - MScThesis RCCI Data AvailableDocument218 pagesN - Kondipati - MScThesis RCCI Data AvailableBagus NugrohoNo ratings yet

- Applied Nonparametric RegressionDocument433 pagesApplied Nonparametric RegressionasdfghjklqazokmNo ratings yet

- (eBook-PDF) - Statistics - Applied Nonparametric RegressionDocument433 pages(eBook-PDF) - Statistics - Applied Nonparametric RegressionCristiane TDNo ratings yet

- Analytical Workspace, Kinematics, and Foot Force Based Stability of Hexapod Walking RobotsDocument156 pagesAnalytical Workspace, Kinematics, and Foot Force Based Stability of Hexapod Walking RobotspancawawanNo ratings yet

- Franch in ThesisDocument147 pagesFranch in ThesisRobert ColbanNo ratings yet

- Rao (2022) - A Course in Time Series AnalysisDocument527 pagesRao (2022) - A Course in Time Series AnalysisEduardo Schirmer FinnNo ratings yet

- CS502 HandoutsDocument184 pagesCS502 HandoutssarwatqamarNo ratings yet

- Materialdeestudioparteidiap1-74Document202 pagesMaterialdeestudioparteidiap1-74pechan07No ratings yet

- Strategi Optimasi CMMDocument132 pagesStrategi Optimasi CMMFadel RahmanNo ratings yet

- Drilling Optimization of Petr... On of Artificial - BarbosaDocument3 pagesDrilling Optimization of Petr... On of Artificial - BarbosaChinedu NwabuezeNo ratings yet

- 02 WholeDocument260 pages02 Wholemymadi2009No ratings yet

- Draft: Lecture Notes On Discrete MathematicsDocument195 pagesDraft: Lecture Notes On Discrete MathematicsexamschedulersNo ratings yet

- Time SeriesDocument327 pagesTime SeriesPairri RaajshekharNo ratings yet

- Dot TurbineDocument144 pagesDot TurbineJérômeNo ratings yet

- Logical EffortDocument223 pagesLogical Effortgmahajan0100% (6)

- Principles of Digital CommunicationDocument222 pagesPrinciples of Digital CommunicationTed TolmanNo ratings yet

- Digital CommunicationsDocument325 pagesDigital CommunicationsNavdeep GoelNo ratings yet

- Nuri ETH CalculationDocument73 pagesNuri ETH CalculationJiri JetmarNo ratings yet

- La PDFDocument208 pagesLa PDFDurga 333No ratings yet

- Tesis - Juan Carlos MorenoDocument67 pagesTesis - Juan Carlos MorenolikufaneleNo ratings yet

- STAT 520 Forecasting and Time Series: Lecture NotesDocument311 pagesSTAT 520 Forecasting and Time Series: Lecture NotesGeorge Van KykNo ratings yet

- BurgerBurgeUticsVol2 ContentsDocument7 pagesBurgerBurgeUticsVol2 ContentsVaibhav MathurNo ratings yet

- Smoothness Priors Analysis of Economic and Financial Time SeriesDocument193 pagesSmoothness Priors Analysis of Economic and Financial Time SeriesMary BojanNo ratings yet

- Con AlgoritmosDocument100 pagesCon AlgoritmosFreddy AguirreNo ratings yet

- Calcul Stochastique Et Finance: Peter Tankov Peter - Tankov@ensae - FR Nizar Touzi Nizar - Touzi@polytechnique - EduDocument293 pagesCalcul Stochastique Et Finance: Peter Tankov Peter - Tankov@ensae - FR Nizar Touzi Nizar - Touzi@polytechnique - EduVictor VermèsNo ratings yet

- ComboNoteswSolutions11 6 04Document358 pagesComboNoteswSolutions11 6 04Jorge ChavesNo ratings yet

- Design Models For Corrugated Board Packaging-Mottola PHD ThesisDocument245 pagesDesign Models For Corrugated Board Packaging-Mottola PHD Thesisdwarak nathNo ratings yet

- Hardle - Applied Nonparametric RegressionDocument433 pagesHardle - Applied Nonparametric Regressionapi-3837435No ratings yet

- KathirgamanathanpDocument201 pagesKathirgamanathanpronald_edinsonNo ratings yet

- 664 Optimal ControlDocument184 pages664 Optimal ControlrodenderonNo ratings yet

- Algorithms For The Matrix Exponential and Frechet DerivativeDocument116 pagesAlgorithms For The Matrix Exponential and Frechet DerivativeJulio Cesar Barraza BernaolaNo ratings yet

- MDFA LegacyDocument278 pagesMDFA Legacysamadozoure120No ratings yet

- Turbomole Manual 7-5Document547 pagesTurbomole Manual 7-5Shekhar HansdaNo ratings yet

- Math562 ContinuousOptimizationDocument126 pagesMath562 ContinuousOptimizationDSP111No ratings yet

- Simulation Statistical Foundations and MethodologyFrom EverandSimulation Statistical Foundations and MethodologyNo ratings yet

- The Einstein-Klein-Gordon Coupled System: Global Stability of the Minkowski Solution: (AMS-213)From EverandThe Einstein-Klein-Gordon Coupled System: Global Stability of the Minkowski Solution: (AMS-213)No ratings yet

- Rigid Part Mating: - Goals of This ClassDocument51 pagesRigid Part Mating: - Goals of This ClassHariharanNo ratings yet

- Computers Ind. EngngDocument4 pagesComputers Ind. EngngHariharanNo ratings yet

- Classroom: Study CourseDocument2 pagesClassroom: Study CourseHariharanNo ratings yet

- Robust Tolerance Synthesis With The Design of Experiments ApproachDocument9 pagesRobust Tolerance Synthesis With The Design of Experiments ApproachHariharanNo ratings yet

- IMECE2005-79945: Functional Interface-Based Assembly ModelingDocument6 pagesIMECE2005-79945: Functional Interface-Based Assembly ModelingHariharanNo ratings yet

- Helmhotz TheoremDocument18 pagesHelmhotz TheoremHariharanNo ratings yet

- Elementary Numerical AnalysisDocument1 pageElementary Numerical AnalysisHariharanNo ratings yet

- Paper 2Document12 pagesPaper 2HariharanNo ratings yet

- Abstract of Composites and Smart MaterialsDocument1 pageAbstract of Composites and Smart MaterialsHariharanNo ratings yet

- GGGGDocument6 pagesGGGGHariharanNo ratings yet

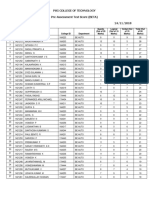

- S. No Y: PSG College of Technology: Coimbatore - 641004Document2 pagesS. No Y: PSG College of Technology: Coimbatore - 641004HariharanNo ratings yet

- Pre-Assessment BETA 2020Document32 pagesPre-Assessment BETA 2020HariharanNo ratings yet

- Deb Nath Miku SinskiDocument1 pageDeb Nath Miku SinskiHariharanNo ratings yet

- Professional and Open Electives NPTELDocument2 pagesProfessional and Open Electives NPTELHariharanNo ratings yet

- Distributions and OperatorsDocument3 pagesDistributions and OperatorsHariharanNo ratings yet

- M 2 L 7Document6 pagesM 2 L 7HariharanNo ratings yet

- Coursetitle PDFDocument1 pageCoursetitle PDFHariharanNo ratings yet

- I H S A: Ntroduction To Ilbert Paces With PplicationsDocument19 pagesI H S A: Ntroduction To Ilbert Paces With PplicationsHariharanNo ratings yet

- MiniNova GuideDocument41 pagesMiniNova GuideBob FredNo ratings yet

- Deep Carbon ObservatoryDocument90 pagesDeep Carbon ObservatorygoblinNo ratings yet

- Sea Shanty PrintDocument3 pagesSea Shanty PrintDiego DracvsNo ratings yet

- MCQs Saudia Pharmacy Registration ExamDocument7 pagesMCQs Saudia Pharmacy Registration ExamAli ButtNo ratings yet

- Plugs, Fuses and Household ElectricityDocument4 pagesPlugs, Fuses and Household ElectricityRonald HuynhNo ratings yet

- Buongiorno - Etal - 2009 The Big Experimental CheckDocument15 pagesBuongiorno - Etal - 2009 The Big Experimental CheckMikhail TarabrinNo ratings yet

- Comsol ProfileDocument4 pagesComsol ProfilePrashant KumarNo ratings yet

- Origami - Playing CardsDocument6 pagesOrigami - Playing Cardsapi-3709851No ratings yet

- Weirs: 2. Open Channel Flow 4. Flumes IndexDocument25 pagesWeirs: 2. Open Channel Flow 4. Flumes IndexlordsethdarknessNo ratings yet

- Subject: Using Emergency Power With DSD Elevator DrivesDocument4 pagesSubject: Using Emergency Power With DSD Elevator DrivesmehariiNo ratings yet

- Geometry CheatsheetDocument5 pagesGeometry CheatsheetMarilyn CitadelNo ratings yet

- Astm E1975 - 1 (En)Document17 pagesAstm E1975 - 1 (En)Dinesh Sai100% (1)

- Salvado de Arroz Fermentado: Una Alternativa de Ingrediente para PanificaciónDocument10 pagesSalvado de Arroz Fermentado: Una Alternativa de Ingrediente para PanificaciónAnelise RibeiroNo ratings yet

- The Beginningof The Church.R.E.brownDocument4 pagesThe Beginningof The Church.R.E.brownnoquierodarinforNo ratings yet

- Rossmann Repair Training Guide - Google SlidesDocument167 pagesRossmann Repair Training Guide - Google Slidesmirza baigNo ratings yet

- British Vs American English - CrosswordDocument3 pagesBritish Vs American English - Crosswordlkham enkhsaikhanNo ratings yet

- Curicullum Vitae Hendri Zand Franxiscus LahaguDocument3 pagesCuricullum Vitae Hendri Zand Franxiscus LahaguSepta Yudistira Inggil PambudiNo ratings yet

- CE-401CE 2.0 Network Diagrams 2015Document83 pagesCE-401CE 2.0 Network Diagrams 2015Shubham BansalNo ratings yet

- Cess 172Document30 pagesCess 172MaryadiNo ratings yet

- Poems by Cawein, Madison Julius, 1865-1914Document126 pagesPoems by Cawein, Madison Julius, 1865-1914Gutenberg.orgNo ratings yet

- Unit 1Document175 pagesUnit 1Karthikeya SharmaNo ratings yet