Professional Documents

Culture Documents

CNSB Bypass Separator Commissioning and Maintenance Guide: Conder® Tanks Covered by This Guide

Uploaded by

sterlingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CNSB Bypass Separator Commissioning and Maintenance Guide: Conder® Tanks Covered by This Guide

Uploaded by

sterlingCopyright:

Available Formats

CNSB Bypass Separator

Commissioning and

Maintenance Guide

CONDER® TANKS

COVERED BY THIS

GUIDE:

INTRODUCTION

CNSB Bypass The primary function of oil/water separators is to separate oil, petrol,

Separators diesel and other hydrocarbon contaminants from waste water and

retain the separated liquids. These separated liquids must be

removed regularly, using a licensed effluent disposal contractor

To BS EN 858 (your contracted service provider), to ensure that the separator

Class One & operates as efficiently as possible.

Class two

All CNSB separators include for silt storage and hydrocarbon

seperation within the unit.

The process of hydrocarbon separation is achieved by flow of the

contaminated liquid through the coalescing filter, which is housed in

the main body of the separator. The passage of hydrocarbons

Environment through the coalescing filter causes the formation of large

Agency* hydrocarbon ‘bubbles’. Theses ‘bubbles’ then ‘break away’ from the

filter and rise to the top of the main chamber. The treated water

outlet is from the base of the main chamber, hence causing the

“Use and Design of separated hydrocarbons to be retained within the unit untill they are

Oil Separators in removed during maintenance.

Surface Water

Drainage Systems:

PPG3” REGULAR MAINTENANCE OF SEPARATOR EQUIPMENT WILL

ENSURE IT OPERATES AS INTENDED WITH MINIMUM RISK OF

POLLUTION TO THE ENVIRONMENT.

MAINTENANCE INSPECTIONS

Separators are used in widely varying circumstances where some

will require frequent maintenance and others will have substantially

longer intervals before any maintenance (emptying) is required.

However, for every separator regular maintenance inspections

CNSB should be carried out to determine whether or not there is a need to

Commissioning remove the accumulated oil, petrol, diesel, etc., or sediment. The

owner of the Conder® separator is responsible for its operation and

and Maintenance ensuring that the effluent quality does not breach any Discharge

Guide Consent Standards. It is advisable to set up a ‘Service Agreement’

Rev 3 with an effluent disposal contractor who can provide ‘automatic’ and

regular maintenance and advise you if any problems with the system

occur. The owner is reminded that the existence of a ‘Service

Agreement’ does not necessarily transfer responsibility for general

maintenance which must be conducted in accordance with this

guide.

Mar. 2010 Sheet 1 of 4

The Environment Agency* has determined that separators shall be Sheet 2 of 4

inspected at least every six months to establish whether or not

emptying is necessary, and a log shall be maintained. Additional

equipment for separators provided by Premier Tech Aqua Ltd such as

an Alarm System which will give warning of the accumulation of oil,

petrol, diesel, etc., but should not be used to replace regular CNSB

inspections. Commissioning

To keep your Conder® CNSB Separator in top condition, we

and Maintenance

recommend regular servicing by Premier Tech Aqua’s service Guide

partners. Rev

MAINTENANCE PROCEDURES

1.0 Health and Safety

Section 6(a) of the United Kingdom Health and Safety at Work

Act 1974 requires manufacturers to advise their customers on

the safety and handling precautions to be observed when

installing, operating, maintaining and servicing their products.

The maintenance procedures described here should be read

and fully understood by the operator (competant person) before

commencing work. Appropriate personal protective equipment

should be used (gloves, goggles, waterproof clothing etc.,)

particularly when handling filters which have been in contact

with oil and oily sediment.

Before any work commences always identify the separator and

its associated manhole covers, and cone off or erect barriers

around the entire area.

DO NOT ENTER THE TANK

2.0 Commissioning the Separator following Installation

2.1 Sediment and other construction debris can accumulate in the

separator during its installation and whilst associated works are

in progess. If this has ocurred, isolate the separator from the 2 Whitehouse Way

drainage system remove the sediment as follows. South West Ind Est

Peterlee

Co Durham

2.2 Slowly lift out the coalescing filter asembly. This should be lifted SR8 2RA

at a rate of 20mm per second (1.2m per minute), until clear of

the water, ensuring that most of the residual water is drained TEL: 0870 264 0004

from the coalescing filter. This will reduce the weight of the FAX: 0870 264 0005

assembly.

NOTE: This assembly could weigh up to 55kgs and should be

handled by two persons unless a mechanical hoist

(recommended) is being used.

2.3 Remove this coalescing filter pod assembly to a place of safe

keeping.

2.4 Fill the separator with clean water up to the outlet invert level. Sheet 3 of 4

2.5 Slowly lower the filter assembly into the separator until it is

firmly located inside the tank.

3.0 Maintenance CNSB

Commissioning

3.1 If, following maintenance inspections, the separator is found to and Maintenance

be storing the maximum volume of oil, petrol, diesel etc,. or the

maximum volume of sediment, inform your licensed effluent Guide

disposal contractor who will arrange emptying. Before making Rev

arrangements, check that you are registered with the

Environment Agency, as required under the new Hazardous

Waste Regulations 2005, where hazardous waste producers

must be registeder before any waste can be removed.

The following are guidelines only for determining the maximum

storage volumes of oil and sediment.

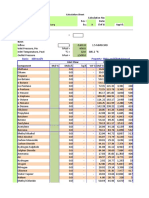

a) Multiply the maximum flowrate for which the separator has

been designed (l/sec) by 15. This will be the maximum

storage volume of hydrocarbonss in litres e.g. a CNSB15

separator is designed for a 15 l/sec flowrate, therefore, can

store 225 litres.

b) Where no specific sediment volumes have been

determined for the separator, or where no sediment has

been expected to accumulate in the system, the maximum

stored depth of sediment should not exceed 20% of the

depth of the separator barrel e.g. a 1.8m diameter

separator should not store more than 360mm depth of

sediment.

3.2 Apply the Health and Safety requirements detailed in Section 1

before commencing any work.

3.3 Isolate the separator from the drainage system either by closing

closing pre-installed valves in the upstream and downstream

manholes or by securely fitting proprietry pipeline stoppers.

3.4 Slowly lift out the coalescing filter pod assembly.This should be

lifted at a rate of 20mm per second (1.2m per minute), until

clear of the water, ensuring that most of the residual water is

drained from the coalescing filter. This will also reduce the

combined overall weight of the assembly.

NOTE: This assembly could weigh up to 55kgs and should be

handled by two persons unless a mechanical hoist

(recommended) is being used. 2 Whitehouse Way

South West Ind Est

Peterlee

3.5 Remove the coalescing Filter Pod assembly to a place of safe

Co Durham

keeping. SR8 2RA

TEL: 0870 264 0004

FAX: 0870 264 0005

3.6 Using a licensed effluent disposal contractor (your contracted

service provider) carry out the following: Sheet 4 of 4

Remove the oil, petrol, diesel etc., from the surface of the liquid,

leaving as much of the cleaner water as possible in the

separator. Remove the sediment from the bottom of the

separator taking great care in and around the filter outlet CNSB

housing on the base to ensure that it does not become Commissioning

damaged, again leaving as much of the cleaner water as

possible in the separator and Maintenance

Guide

3.7 Move the filter pod assembly to a convenient position upstream Rev 3

of the separator so that any polluted water washed from the

filter will be directed back to the separator.

Wash the filter using a low pressure hose.If the Coalescing

Filter has become ‘blinded’ with sediment or it is too dirty to

clean or has become damaged, replace it by contacting Pims

(Service) Ltd. Tel: 0870 405 0902.

3.8 Fill the separator with clean water up to the outlet invert level

3.9 Slowly lower the filter pod assembly into the separator and

push home to ensure it is fully seated and sealed.

3.10 Check that the Alarm probe has not been damaged and that the

alarm system is working.

3.11 Replace the manhole covers and remove the cones and/or

barriers from the worksite.

REMEMBER - if the alarm system activates due to the accumulation

of oil, petrol, diesel etc., do not delay in contacting your licensed

effluent disposal contractor.

2 Whitehouse Way

South West Ind Est

Peterlee

Co Durham

SR8 2RA

TEL: 0870 264 0004

FAX: 0870 264 0005

You might also like

- Separator (Grs-10eb 100eb) Manual (Rev4)Document16 pagesSeparator (Grs-10eb 100eb) Manual (Rev4)voinea ionut75% (4)

- The Bloodless GospelDocument7 pagesThe Bloodless GospelKJVNo ratings yet

- EMMS SpecificationsDocument18 pagesEMMS SpecificationsAnonymous dJtVwACc100% (2)

- O-W Separator LiteratureDocument8 pagesO-W Separator Literatureernesto_sugiharto100% (1)

- Tech PDFDocument3 pagesTech PDFAwais JalaliNo ratings yet

- Material Balance NotesDocument108 pagesMaterial Balance Notesapi-3709413100% (4)

- Separation Systems Chapter from Computer Assisted Petroleum Production Engineering BookDocument16 pagesSeparation Systems Chapter from Computer Assisted Petroleum Production Engineering BookHaziq YussofNo ratings yet

- AES Oil Separator MaintenanceDocument3 pagesAES Oil Separator MaintenanceHatta YasinNo ratings yet

- Aircraft ChecksDocument10 pagesAircraft ChecksAshirbad RathaNo ratings yet

- Pump sizing spreadsheet calculates performanceDocument26 pagesPump sizing spreadsheet calculates performancesterling100% (1)

- Global 6000 SystemsDocument157 pagesGlobal 6000 SystemsJosé Rezende100% (1)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Equipment TroubleshootDocument13 pagesEquipment TroubleshootManel Montesinos100% (1)

- On-Board Machine FiltrationDocument4 pagesOn-Board Machine FiltrationCarlos LoboNo ratings yet

- Operation and Maintenance Manual: Effluent Treatment PlantDocument49 pagesOperation and Maintenance Manual: Effluent Treatment PlantOmkar BharankarNo ratings yet

- Conder Separator Brochure NewDocument8 pagesConder Separator Brochure Newednavilod100% (1)

- Water Washing of Steam Turbine RotorsDocument4 pagesWater Washing of Steam Turbine Rotorssarsan nedumkuzhiNo ratings yet

- Applications of Multiphase Desander TechnologyDocument19 pagesApplications of Multiphase Desander TechnologyanisNo ratings yet

- Hazop Training GuideDocument9 pagesHazop Training GuideAdyBorsosNo ratings yet

- 4 4 7 Oil Grit Separator - Page6pdfDocument18 pages4 4 7 Oil Grit Separator - Page6pdfchaker05No ratings yet

- Reverse Osmosis R24-SERIES Installation InstructionsDocument44 pagesReverse Osmosis R24-SERIES Installation InstructionsWattsNo ratings yet

- Joyful Living: (Based On Chapter 13: Advaitananda Prakaranam of Panchadashi of Sri Vidyaranya Swami)Document11 pagesJoyful Living: (Based On Chapter 13: Advaitananda Prakaranam of Panchadashi of Sri Vidyaranya Swami)Raja Subramaniyan100% (1)

- MysepDocument16 pagesMysepsterlingNo ratings yet

- INSTRUCTION MANUAL (Bilge Separator-E (USH-03 50) (2012.12.5)Document32 pagesINSTRUCTION MANUAL (Bilge Separator-E (USH-03 50) (2012.12.5)Naman Bajpai100% (1)

- Temporarypermanent Pipe Repair - GuidelinesDocument70 pagesTemporarypermanent Pipe Repair - Guidelinesqinaip100% (1)

- Basis: Basis: 100 Mol/h Property: GPSA and Elliott ManualDocument6 pagesBasis: Basis: 100 Mol/h Property: GPSA and Elliott ManualsterlingNo ratings yet

- API Separator and Waste WaterDocument5 pagesAPI Separator and Waste Waterbctian2004No ratings yet

- Reverse Osmosis Model #R44 Installation InstructionsDocument40 pagesReverse Osmosis Model #R44 Installation InstructionsWatts100% (1)

- Cakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DataDocument6 pagesCakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DatasterlingNo ratings yet

- CARTRIDGE FILTER TECHNICAL MANUALDocument30 pagesCARTRIDGE FILTER TECHNICAL MANUALabessiNo ratings yet

- O & M - Pidilite EtpDocument51 pagesO & M - Pidilite EtpOmkar BharankarNo ratings yet

- Oil-Fuel SeparatorDocument24 pagesOil-Fuel SeparatorSiva SubramaniyanNo ratings yet

- Ref: M.R. Riazi, Characterization and Properties of Petroleum Fractions, ASTM, 2005Document42 pagesRef: M.R. Riazi, Characterization and Properties of Petroleum Fractions, ASTM, 2005sterling100% (1)

- The Rich Hues of Purple Murex DyeDocument44 pagesThe Rich Hues of Purple Murex DyeYiğit KılıçNo ratings yet

- Mba Project GuidelinesDocument8 pagesMba Project GuidelinesKrishnamohan VaddadiNo ratings yet

- ThesisDocument250 pagesThesislax mediaNo ratings yet

- Oil Water Separators GreenStamp Environmental Information GuideDocument3 pagesOil Water Separators GreenStamp Environmental Information GuideJessicaNo ratings yet

- Z1170 EngineeredDocument4 pagesZ1170 EngineeredMahmoud GwailyNo ratings yet

- SD10Document4 pagesSD10samer tirhiNo ratings yet

- Geoceptor DatasheetDocument2 pagesGeoceptor DatasheetWilliam MurrayNo ratings yet

- Condensate Drain Scavenge Air Cooler RTA-74Document5 pagesCondensate Drain Scavenge Air Cooler RTA-74rafaelNo ratings yet

- Ref N° 24 - PRODUCED WATER HANDLING - PHILOSOPHYDocument11 pagesRef N° 24 - PRODUCED WATER HANDLING - PHILOSOPHYlxz861020No ratings yet

- Requirements For Gravity Oil-Water SeperatorsDocument4 pagesRequirements For Gravity Oil-Water SeperatorssamehNo ratings yet

- WV92Q282 01gbDocument4 pagesWV92Q282 01gbRuwan Susantha PelawattaNo ratings yet

- Grease Trap - Interceptor Specification - R0 - Nov-2023Document9 pagesGrease Trap - Interceptor Specification - R0 - Nov-2023NAJIM NAZERNo ratings yet

- Install and Maintain DEOIL3 & DEOIL5 Oil SeparatorsDocument42 pagesInstall and Maintain DEOIL3 & DEOIL5 Oil SeparatorsSaifulAzuanNo ratings yet

- Oil/Water Separation BMP Fact SheetDocument8 pagesOil/Water Separation BMP Fact SheetbadelitamariusNo ratings yet

- USEPA Hydrodynamic SeparatorsDocument6 pagesUSEPA Hydrodynamic SeparatorsJp TreacyNo ratings yet

- CertiFicate For Water - NEWDocument6 pagesCertiFicate For Water - NEWMohan RajNo ratings yet

- Fuel System Filter-ReplaceDocument3 pagesFuel System Filter-ReplaceFiza IlmiNo ratings yet

- CVP Series & CNN-6000, 9000 Models: Installation, Operation, and Maintenance ManualDocument28 pagesCVP Series & CNN-6000, 9000 Models: Installation, Operation, and Maintenance ManualRodriguezNo ratings yet

- EcoTop o M Ecotechnic EnglishDocument8 pagesEcoTop o M Ecotechnic EnglishmartinNo ratings yet

- Boss 11T-107 Installation Manual A 0Document54 pagesBoss 11T-107 Installation Manual A 0Ardi WiranataNo ratings yet

- Rev D 900FH and 1000FH Turbine FiltersDocument12 pagesRev D 900FH and 1000FH Turbine FiltersJan AhmedNo ratings yet

- Section 02750 Sewage Treatment Plant Performance SpecificationDocument18 pagesSection 02750 Sewage Treatment Plant Performance SpecificationOlivas L. Baguec JrNo ratings yet

- CUTES Liquid Ring Vacuum Pump ManualDocument28 pagesCUTES Liquid Ring Vacuum Pump ManualGabenkNo ratings yet

- AP Guidelines For The Design and Operation of Washdown BaysDocument6 pagesAP Guidelines For The Design and Operation of Washdown BaysFarzin ShahabNo ratings yet

- Multimediaws Rev 2Document17 pagesMultimediaws Rev 2Manager Sales and ServiceNo ratings yet

- 10 Oily Water Separator (OWS) Maintenance Tips Every Ship Engineer Must Kn222248Document10 pages10 Oily Water Separator (OWS) Maintenance Tips Every Ship Engineer Must Kn222248Bagas Abhimanyu100% (1)

- Cleanawater DEOIL3 - 5 - 10 Hydrocyclone Oil Separators BrochureDocument5 pagesCleanawater DEOIL3 - 5 - 10 Hydrocyclone Oil Separators BrochureAnonymous a4Jwz14WNo ratings yet

- Assemble Aquatron Water Still A4000 A4000D A8000Document28 pagesAssemble Aquatron Water Still A4000 A4000D A8000Diệp Long HồNo ratings yet

- Avon UTC 1535c8Document19 pagesAvon UTC 1535c8juanaNo ratings yet

- MILEST1Document17 pagesMILEST1ruyNo ratings yet

- SPE 77891 The Future of Three Phase Separator ControlDocument8 pagesSPE 77891 The Future of Three Phase Separator ControlRidwan Al-KhandiNo ratings yet

- Grease Operation ManualDocument13 pagesGrease Operation ManualJohn Cartagena CondorNo ratings yet

- Bilge Water SeparatorDocument121 pagesBilge Water SeparatorКостяNo ratings yet

- Vacu Flush 500 Plus Series-1000 Series-Model 706Document24 pagesVacu Flush 500 Plus Series-1000 Series-Model 706Roberto CapoteNo ratings yet

- Domnick Hunter ES2000 Series Oil Water Separators ManualDocument8 pagesDomnick Hunter ES2000 Series Oil Water Separators ManualMark CarterNo ratings yet

- 11.1 Purpose of Oil and Water SeparatorsDocument10 pages11.1 Purpose of Oil and Water SeparatorstesteNo ratings yet

- Pollution Reduction: The Boat Safety Scheme Essential GuideDocument6 pagesPollution Reduction: The Boat Safety Scheme Essential GuideCostin RotaruNo ratings yet

- Application of Multiphase Desander TechnologyDocument19 pagesApplication of Multiphase Desander TechnologyJose Rodrigo Salguero DuranNo ratings yet

- Series 4000 Cyclosep Centrifugal SeparatorDocument7 pagesSeries 4000 Cyclosep Centrifugal SeparatorValiNo ratings yet

- Hamworthy St2aDocument4 pagesHamworthy St2aAdnanNo ratings yet

- Installation, Commissioning and Maintenance of Servo and High-Response Control ValvesDocument4 pagesInstallation, Commissioning and Maintenance of Servo and High-Response Control ValvesEmrah BinayNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Report For The Design and Simulation of Benzene Recovery PlantDocument32 pagesReport For The Design and Simulation of Benzene Recovery PlantsterlingNo ratings yet

- Optimal Production Planning and Scheduling in Breweries: Journal Pre-ProofDocument61 pagesOptimal Production Planning and Scheduling in Breweries: Journal Pre-ProofsterlingNo ratings yet

- H&MBDocument1 pageH&MBsterlingNo ratings yet

- Control Valve Specification SheetDocument1 pageControl Valve Specification SheetsterlingNo ratings yet

- Serck Audco Valves: Sealants and Injection EquipmentDocument21 pagesSerck Audco Valves: Sealants and Injection EquipmentsterlingNo ratings yet

- Chapter 3&4&5Document24 pagesChapter 3&4&5sterlingNo ratings yet

- Chapter Three: 3.1 MaterialsDocument24 pagesChapter Three: 3.1 MaterialssterlingNo ratings yet

- Two Phase Line Sizing Calculation - Case ADocument1 pageTwo Phase Line Sizing Calculation - Case AsterlingNo ratings yet

- Chapter 3&4&5Document24 pagesChapter 3&4&5sterlingNo ratings yet

- NVABR1014-Sealant SealantEquipment PDFDocument8 pagesNVABR1014-Sealant SealantEquipment PDFsterlingNo ratings yet

- Higher Institutions in Rivers State and Their Locations - Ekky BlogDocument7 pagesHigher Institutions in Rivers State and Their Locations - Ekky BlogsterlingNo ratings yet

- Sample Conf LetterDocument2 pagesSample Conf LettersterlingNo ratings yet

- Orbit Valves Brochure PDFDocument28 pagesOrbit Valves Brochure PDFHendi RofiansyahNo ratings yet

- Consumption of Cooking GasDocument5 pagesConsumption of Cooking GassterlingNo ratings yet

- Ealant EquipmentDocument1 pageEalant EquipmentsterlingNo ratings yet

- Consumption of Cooking GasDocument5 pagesConsumption of Cooking GassterlingNo ratings yet

- 4662022Document40 pages4662022sterlingNo ratings yet

- Level MeasurementDocument31 pagesLevel MeasurementMalik MuchamadNo ratings yet

- Gas Chromatographic Analysis ResultsDocument3 pagesGas Chromatographic Analysis ResultssterlingNo ratings yet

- MySep Vessel Motion - White Paper PDFDocument12 pagesMySep Vessel Motion - White Paper PDFsterlingNo ratings yet

- Energy BalanceDocument29 pagesEnergy BalancesterlingNo ratings yet

- Plant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirDocument20 pagesPlant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirSharad KokateNo ratings yet

- Design and Analysis of Algorithms Prof. Madhavan Mukund Chennai Mathematical Institute Week - 01 Module - 01 Lecture - 01Document8 pagesDesign and Analysis of Algorithms Prof. Madhavan Mukund Chennai Mathematical Institute Week - 01 Module - 01 Lecture - 01SwatiNo ratings yet

- Khaton Prayer BookDocument47 pagesKhaton Prayer BookKarma TsheringNo ratings yet

- About Version ControlDocument6 pagesAbout Version ControlMaria Kristina Cassandra HeukshorstNo ratings yet

- Panasonic TC-P42X5 Service ManualDocument74 pagesPanasonic TC-P42X5 Service ManualManager iDClaimNo ratings yet

- HU675FE ManualDocument44 pagesHU675FE ManualMar VeroNo ratings yet

- VARCDocument52 pagesVARCCharlie GoyalNo ratings yet

- Daughters of The Storm by Kim Wilkins - Chapter SamplerDocument32 pagesDaughters of The Storm by Kim Wilkins - Chapter SamplerHarlequinAustraliaNo ratings yet

- T23 Field Weld Guidelines Rev 01Document4 pagesT23 Field Weld Guidelines Rev 01tek_surinderNo ratings yet

- ArtigoPublicado ABR 14360Document14 pagesArtigoPublicado ABR 14360Sultonmurod ZokhidovNo ratings yet

- Principles of Cost Accounting 1Document6 pagesPrinciples of Cost Accounting 1Alimamy KamaraNo ratings yet

- Prof. Michael Murray - Some Differential Geometry ExercisesDocument4 pagesProf. Michael Murray - Some Differential Geometry ExercisesAnonymous 9rJe2lOskxNo ratings yet

- A Systematic Scoping Review of Sustainable Tourism Indicators in Relation To The Sustainable Development GoalsDocument22 pagesA Systematic Scoping Review of Sustainable Tourism Indicators in Relation To The Sustainable Development GoalsNathy Slq AstudilloNo ratings yet

- 01 Design of Flexible Pavement Using Coir GeotextilesDocument126 pages01 Design of Flexible Pavement Using Coir GeotextilesSreeja Sadanandan100% (1)

- Turbine 1st Stage Nozzle - DPTDocument15 pagesTurbine 1st Stage Nozzle - DPTAnonymous gWKgdUBNo ratings yet

- SIM5320 - EVB Kit - User Guide - V1.01 PDFDocument24 pagesSIM5320 - EVB Kit - User Guide - V1.01 PDFmarkissmuzzoNo ratings yet

- Assessing Eyes NCM 103 ChecklistDocument7 pagesAssessing Eyes NCM 103 ChecklistNicole NipasNo ratings yet

- VNC Function Operation InstructionDocument11 pagesVNC Function Operation InstructionArnaldo OliveiraNo ratings yet

- Research Paper Theory of Mind 2Document15 pagesResearch Paper Theory of Mind 2api-529331295No ratings yet

- SOP for Troubleshooting LT ACB IssuesDocument9 pagesSOP for Troubleshooting LT ACB IssuesAkhilesh Kumar SinghNo ratings yet

- Hotel and Restaurant at Blue Nile FallsDocument26 pagesHotel and Restaurant at Blue Nile Fallsbig johnNo ratings yet

- Lesson Plan 2018-2019 Term 1Document205 pagesLesson Plan 2018-2019 Term 1Athlyn DurandNo ratings yet