Professional Documents

Culture Documents

LimconJob RRRRR PDF

Uploaded by

Bavedi SanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LimconJob RRRRR PDF

Uploaded by

Bavedi SanCopyright:

Available Formats

Page 1 of 3

15/04/2019

09:16:13 p.

BAS

Job: LimconJob -- Connection: rrrrr

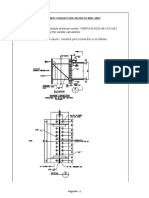

CONNECTION: rrrrr - AISC Moment End Plate Connection

Member: B1 410UB53.7 Gr.300

End plate: 200x25x610 Gr.250 Stiffener: 100x8x150 Gr.250

40

60

130

263

130

Flange weld: CJPGW/490 - Web weld: 6 FW/490140

Bolts: 8 x M20 8.8/S/N at 140 gauge

LIMCON V3.63.2.4 {0} 15-APR-19

21:15:28

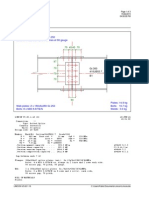

Connection: rrrrr

Type: AISC Moment End Plate Connection

Extended end plate - 2: 4 bolt stiffened (4ES)

Non-seismic

Country: Australia

Units: SI metric

Design code: ANSI/AISC 360 (LRFD)

Beam: Mark=B1 Section=410UB53.7 Grade=300

d = 403 mm Root rad. = 11 mm Fyf = 320 MPa

b = 178 mm Area = 6890 Fyw = 320 MPa

tf = 10.9 mm Sx = 933000 Fu = 440 MPa

tw = 7.6 mm Zx = 1060000

.Section moment strength . . . . 305.3 kN.m Note 1

.Section shear strength . . . . . 588.1 kN A360 (G2-1)

.Section tension strength . . . . 1984.3 kN A360-(D2-1)

.Section compression strength . . 1854.3 kN A360 E7

Column: Mark=C1 Section=310UC158 Grade=300

d = 327 mm Root rad. = 17 mm Fyf = 280 MPa

b = 311 mm Area = 2.0100E+04 Fyw = 300 MPa

tf = 25.0 mm Sx = 2370000 Fu = 440 MPa

tw = 15.7 mm Zx = 2680000

.Section moment strength . . . . 675.4 kN.m Note 1

.Section shear strength . . . . . 924.1 kN A360 (G2-1)

.Section compression strength . . 5065.2 kN A360 E7

Column terminates...

Top flange to end of column . . 200 mm

End plate:

610x200x25 Gr./Fy/Fu=250/25/410MPa

End plate welds:

CJPGW/490MPa flanges.

6 FW/490MPa web.

LIMCON V3.63.2.4 (TRIAL - days left: 7) C:\Users\Public\Documents\Limcon\LimconJob

Page 2 of 3

15/04/2019

09:16:13 p.

BAS

Job: LimconJob -- Connection: rrrrr

Bolts:

4 x M20 8.8/S/N top flange, 140 gauge at 130 spacing.

4 x M20 8.8/S/N btm. flange, 140 gauge.

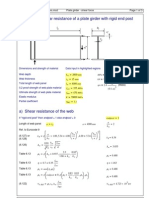

MINIMUM ACTION CHECK

(Minima are based on section capacity, not member capacity.)

Specified minimum design actions:

Bending 50% of øMs ( 305.3) = 152.6 kN.m

Shear 0% of øVs ( 588.1) = 0.0 kN

40.0 kN

Tension 0% of øNs ( 1984.3) = 0.0 kN

Compression 0% of øNc ( 1854.3) = 0.0 kN

NOTE: Input design actions are not automatically increased if they are less than

the specified minimum actions. Minimum actions may be set in any load case.

This check warns if any design action is less than the specified minimum

for all load cases.

WARNING: Design bending moment is less than specified minimum.

INPUT DESIGN ACTIONS

Moment, Mu . . . . . . . . . . . 10.0 kN.m

Shear, Vu . . . . . . . . . . . . 150.0 kN

Axial, Pu . . . . . . . . . . . . 0.0 kN

Using AISC 2002 model...

GEOMETRY CHECKS

Bolts: M20

Bolt UTS . . . . . . . . . . . . 830 ≥ 800 Yes

Single bolt tension strength . . 146.1 kN A360-T:J3.2

Specified minimum tension . . . . 0.0 kN

Assumed tension . . . . . . . . . 68.2 kN SDG16 p.31

Table 4-7 - Tested parameter ranges:

Ref. 18: Steel Design Guide 16 (SDG16)

Flush and Extended Multiple Row Moment End Plate Connections

T.M. Murray & W.L. Shoemaker - AISC - 2002

pfo . . . . . . . . . . . . . . . 60 ≥ 25 Yes

60 ≤ 65 Yes

pfi . . . . . . . . . . . . . . . 59 ≥ 25 Yes

59 ≤ 65 Yes

pext . . . . . . . . . . . . . . 100 ≥ 60 Yes

100 ≤ 135 Yes

g . . . . . . . . . . . . . . . . 140 ≥ 65 Yes

140 ≤ 180 Yes

h . . . . . . . . . . . . . . . . 403 ≥ 400 Yes

403 ≤ 610 Yes

bp . . . . . . . . . . . . . . . 200 ≥ 150 Yes

200 ≤ 265 Yes

tf . . . . . . . . . . . . . . . 11 ≥ 9 Yes

11 ≤ 26 Yes

DESIGN STRENGTH CHECKS

Strength ratio JJJJJJJJJK

Required strength K M

┌JDesign strength M M Reference

M M M OOOOOOOOOOOOOO

Section Bending:

Section moment strength . . . . . . . . . . 305.3 ≥ Mu = 10.0 30.5 Pass

End plate yield line analysis:

Yield line parameter, Y . . . . . 3350 mm

Mpl . . . . . . . . . . . . . . . 523.5 kN.m

Mnp . . . . . . . . . . . . . . . 305.9 kN.m

» End plate no prying thickness . 18 mm SDG16 (2-7)

» Thick plate behaviour governs...

End plate yield strength, øMpl . . . . . . 471.2 ≥ Mueq = 10.0 47.1 Pass

Bolt rupture strength (no prying), øMnp . . 229.4 ≥ Mueq = 10.0 22.9 Pass

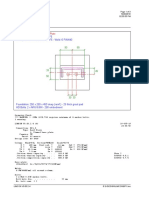

Flanges:

Flange tension strength . . . . . . . . . . 558.8 ≥ Puft = 25.5 21.9 Pass Informative

Flange compression strength . . . . . . . . 558.8 ≥ Pufc = 25.5 21.9 Pass Informative

Flange welds:

Maximum flange force . . . . . . 25.5 kN

Flange yield strength . . . . . . 558.8 kN

Flange utilization ratio . . . . 5%

Minimum weld design force (60%) . 335.3 kN

Flange width . . . . . . . . . . 178 mm

LIMCON V3.63.2.4 (TRIAL - days left: 7) C:\Users\Public\Documents\Limcon\LimconJob

Page 3 of 3

15/04/2019

09:16:13 p.

BAS

Job: LimconJob -- Connection: rrrrr

For complete penetration groove weld, fu= 49...

Flange CJPGW tension strength . . . . . . . 558.8 ≥ Puft = 335.3 1.67 Pass

Flange CJPGW compression strength . . . . . 558.8 ≥ Pufc = 335.3 1.67 Pass

Web shear:

Web depth between flanges . . . . 381 mm

Web depth for shear resistance . 191 mm SDG16 2.5.3(10

Beam web shear strength . . . . . . . . . . 278.1 ≥ Vu = 150.0 1.85 Pass

Web welds:

NOTE: This check uses method from AISC SDG 16 (Ref. 18).

Length of web weld . . . . . . . 381 mm

Length for shear resistance . . . 191 mm

For 6 FW/490MPa both sides...

Web fillet weld shear strength (2 sides) . 356.6 ≥ Vu = 150.0 2.38 Pass

End plate design moment, Mueq . . 10.0 kN.m

Section moment strength . . . . . 305.3 kN.m

Beam moment utilization ratio . . 3%

Beam web axial strength . . . . . 2.189 kN/mm

Minimum weld design force (60%) . 1.313 kN/mm

NOTE: Using 50% directional strength increase. A360 (J2-5)

Fillet weld strength . . . . . . 1.403 kN/mm

Web fillet weld axial strength (2 sides) . 2.807 ≥ puw = 1.313 2.14 Pass

Bolts:

Shear strength of compression bolts . . . . 350.6 ≥ Vu = 150.0 2.34 Pass

End plate bearing strength . . . . . . . . 1476.0 ≥ Vu = 150.0 9.84 Pass

NOTE: Column-side checks omitted.

NOTES:

1. Flexural yield capacity ignoring section slenderness.

CRITICAL LIMIT STATE . . . Flange CJPGW compression strength

UTILIZATION RATIO . . . . 60%

STRENGTH RATIO . . . . . . 1.667 Pass

LIMCON V3.63.2.4 (TRIAL - days left: 7) C:\Users\Public\Documents\Limcon\LimconJob

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- HP Job: PA IWAN -- Connection Design and ChecksDocument3 pagesHP Job: PA IWAN -- Connection Design and Checksnofrizar nofriNo ratings yet

- Unnamed Gornja GredaDocument7 pagesUnnamed Gornja GredasehmediaNo ratings yet

- Plate shear rupture strength limitDocument6 pagesPlate shear rupture strength limitflacocNo ratings yet

- LIMCOM SPLICE 1 - Bracing3 OKDocument3 pagesLIMCOM SPLICE 1 - Bracing3 OKmascalzoneNo ratings yet

- CONNECTION: DETAIL-D8 - Bolted Moment End Plate: UB406X178X54 Gr.S275 UB406X178X54 B1 B2Document6 pagesCONNECTION: DETAIL-D8 - Bolted Moment End Plate: UB406X178X54 Gr.S275 UB406X178X54 B1 B2Akhil VNNo ratings yet

- CONNECTION: DETAIL-D9 - Bolted Moment End PlateDocument4 pagesCONNECTION: DETAIL-D9 - Bolted Moment End PlateAkhil VNNo ratings yet

- Bolted splice design of HEA280 beam connectionDocument3 pagesBolted splice design of HEA280 beam connectionSerkanAydoğduNo ratings yet

- Sambungan Apx-Wf150Document5 pagesSambungan Apx-Wf150Puji KurniawanNo ratings yet

- PlacabaseccrDocument2 pagesPlacabaseccrcorneliortizNo ratings yet

- HP Job D1 Connection DetailDocument6 pagesHP Job D1 Connection DetailAkhil VNNo ratings yet

- Steel ConnectionDocument6 pagesSteel ConnectionAly Arquillano JrNo ratings yet

- Rafi - PDF Base PlateDocument3 pagesRafi - PDF Base PlatemohamedNo ratings yet

- Design of Bolts Carrying Crane BeamDocument12 pagesDesign of Bolts Carrying Crane BeamOmar SalahNo ratings yet

- CONNECTION: UB305X165X40BS5950 - Base Plate: AdminDocument3 pagesCONNECTION: UB305X165X40BS5950 - Base Plate: AdminPNo ratings yet

- LimconJob G2Document2 pagesLimconJob G2mascalzoneNo ratings yet

- CONNECTION: G2 - Bolt Group: Gusset Plate (Min.) : 163x25x250 Gr.A36 Bolts: 6 X 1" A325ST/N in 2 ColsDocument2 pagesCONNECTION: G2 - Bolt Group: Gusset Plate (Min.) : 163x25x250 Gr.A36 Bolts: 6 X 1" A325ST/N in 2 ColsmascalzoneNo ratings yet

- Fin Plate Connection DesignDocument3 pagesFin Plate Connection DesignihpeterNo ratings yet

- SIMPLIFIED RC DESIGN FORMULA FOR BEAMS AND SLABSDocument3 pagesSIMPLIFIED RC DESIGN FORMULA FOR BEAMS AND SLABSnap_carinoNo ratings yet

- Appendix 4 Material Sheet and Test CertificateDocument3 pagesAppendix 4 Material Sheet and Test Certificate4romi89No ratings yet

- MC12X14 beam to column connection designDocument4 pagesMC12X14 beam to column connection designVinoth KumarNo ratings yet

- Beam-Column Moment ConnectionDocument10 pagesBeam-Column Moment Connectionrammohan100% (3)

- Pinned base plate connection analysisDocument2 pagesPinned base plate connection analysisAllan Bautista100% (1)

- AKASH InputDocument3 pagesAKASH InputJitendra PatelNo ratings yet

- 1.-Planilla Rbs w24x76 - w14x211 A250espDocument14 pages1.-Planilla Rbs w24x76 - w14x211 A250espGabriel Contreras AlfaroNo ratings yet

- Bolted splice design of 410UB53.7 beamDocument3 pagesBolted splice design of 410UB53.7 beamconorkellysligoNo ratings yet

- Ec9 Ex61 Shear No StiffenersDocument3 pagesEc9 Ex61 Shear No StiffenersimotalpNo ratings yet

- Whalen Uy Residences 2S-2 125.00 125.00 3.00 Ksi 40 Ksi 10 12.00 1.90 MDocument1 pageWhalen Uy Residences 2S-2 125.00 125.00 3.00 Ksi 40 Ksi 10 12.00 1.90 MWilliam ProvidoNo ratings yet

- 11.2 Lifting Lug Cal Rev 1Document17 pages11.2 Lifting Lug Cal Rev 1Astle DsouzaNo ratings yet

- 69kV Disconnector Foundation Calculation: AR-DOC-003-0011-00Document6 pages69kV Disconnector Foundation Calculation: AR-DOC-003-0011-00Amol ChavanNo ratings yet

- DIA - Calcul Grinzi Din Beton ArmatDocument12 pagesDIA - Calcul Grinzi Din Beton ArmatCristina DumitriuNo ratings yet

- CONNECTION: BENTANG6.4 - 2 - Haunched BMEPDocument5 pagesCONNECTION: BENTANG6.4 - 2 - Haunched BMEPnofrizar nofriNo ratings yet

- Anchor Bolt Design of Channel Pinned ConnectionDocument42 pagesAnchor Bolt Design of Channel Pinned Connectionprasanth bhadranNo ratings yet

- Tutorial 7 - Connections - Part ADocument28 pagesTutorial 7 - Connections - Part ACyrus HongNo ratings yet

- Triangle Beam B1Document6 pagesTriangle Beam B1sallysel90No ratings yet

- 3 Design of I5 As RCDocument12 pages3 Design of I5 As RCRaphael KennethNo ratings yet

- Whalen Uy Residences 2CS-1 125.00 125.00 3.00 Ksi 40 Ksi 10 12.00 0.50 MDocument1 pageWhalen Uy Residences 2CS-1 125.00 125.00 3.00 Ksi 40 Ksi 10 12.00 0.50 MWilliam ProvidoNo ratings yet

- Spacing of Bolts in Built-Up BeamsDocument7 pagesSpacing of Bolts in Built-Up BeamsDAN MARK OPONDANo ratings yet

- Beam Design OptimizationDocument4 pagesBeam Design OptimizationAlma M. LaraNo ratings yet

- Vivek Kumar 2nd RA BillDocument8 pagesVivek Kumar 2nd RA Billborkarsd007No ratings yet

- Extremely torsionally stiff trailing cablesDocument1 pageExtremely torsionally stiff trailing cablesLuis AguilarNo ratings yet

- Concrete Column DesignDocument2 pagesConcrete Column DesignGandhi HammoudNo ratings yet

- Sample PrestressDocument4 pagesSample PrestressHilton D. CalawenNo ratings yet

- Design singly reinforced beam and column using limit state methodDocument14 pagesDesign singly reinforced beam and column using limit state methodAbrar AhmadNo ratings yet

- Beryl (Radial Thru-Hole) RF SeriesDocument2 pagesBeryl (Radial Thru-Hole) RF Seriesester853No ratings yet

- Design of Stair Case With Central Stringer BeamDocument45 pagesDesign of Stair Case With Central Stringer BeamCONSTHURAG2012No ratings yet

- Hea160 Ebsp 1Document4 pagesHea160 Ebsp 1Bùi Trọng QuỳnhNo ratings yet

- General Data Pk3L P34 Pk4L P35 Pk5LDocument22 pagesGeneral Data Pk3L P34 Pk4L P35 Pk5LAnonymous 24MCFJXNo ratings yet

- Eurobeam Steel Beam CalculationDocument3 pagesEurobeam Steel Beam CalculationnsureshbabuNo ratings yet

- Reinforcement Bar Arrangement and Stress: Normal ConditionDocument2 pagesReinforcement Bar Arrangement and Stress: Normal Conditionanon_857185869No ratings yet

- Strap Footing Design: ASDIP Foundation 3.2.2Document4 pagesStrap Footing Design: ASDIP Foundation 3.2.2Mainali IshuNo ratings yet

- Stability Calculation - Ship - Pro Bang Doyo: Loadcase - Loadcase 1 Damage Case - IntactDocument2 pagesStability Calculation - Ship - Pro Bang Doyo: Loadcase - Loadcase 1 Damage Case - IntactFirdania AmeliaNo ratings yet

- PepsiCo India Design Calculation ReportDocument7 pagesPepsiCo India Design Calculation ReportsprasannaaNo ratings yet

- Compression & Biaxial Bending IS 800 2007Document22 pagesCompression & Biaxial Bending IS 800 2007Anirban BhattacharjeeNo ratings yet

- CONNECTION: G1 - Bolt Group: Gusset Plate (Min.) : 152,2x25x342,7 Gr.A36 Bolts: 8 X 1" A325ST/N in 2 ColsDocument2 pagesCONNECTION: G1 - Bolt Group: Gusset Plate (Min.) : 152,2x25x342,7 Gr.A36 Bolts: 8 X 1" A325ST/N in 2 ColsmascalzoneNo ratings yet

- Stiffened Plate Buckling DNV-RP-C201 Rev02-December-2011Document9 pagesStiffened Plate Buckling DNV-RP-C201 Rev02-December-2011Farid TataNo ratings yet

- Pipe Guide and Welding Connection - h150x125x14x8.5Document13 pagesPipe Guide and Welding Connection - h150x125x14x8.5BenchNo ratings yet

- MECHANDocument21 pagesMECHANOsamaNo ratings yet

- 2015.12.09 - Vibration of Reinforced Concrete Floor Systems - Part 1Document77 pages2015.12.09 - Vibration of Reinforced Concrete Floor Systems - Part 1Bavedi SanNo ratings yet

- 2016.02.10 - Ethics For Structural Engineers - Part 2Document29 pages2016.02.10 - Ethics For Structural Engineers - Part 2Bavedi SanNo ratings yet

- DWG TrueView DWG Convert Conversion ReportDocument1 pageDWG TrueView DWG Convert Conversion ReportCosmin CinciNo ratings yet

- Iag0420 020Document1 pageIag0420 020Bavedi SanNo ratings yet

- Ética en La Ingeniería EstructuralDocument29 pagesÉtica en La Ingeniería EstructuralBavedi SanNo ratings yet

- Iag0420 070Document1 pageIag0420 070Bavedi SanNo ratings yet

- Asbuilt t2 PDFDocument1 pageAsbuilt t2 PDFBavedi SanNo ratings yet

- Deflexion A Largo Plazo VigasDocument3 pagesDeflexion A Largo Plazo VigasBavedi SanNo ratings yet

- Iag0420 033Document1 pageIag0420 033Bavedi SanNo ratings yet

- Iag0420 039Document1 pageIag0420 039Bavedi SanNo ratings yet

- Iag0420 002Document1 pageIag0420 002Bavedi SanNo ratings yet

- Iag0420 037Document1 pageIag0420 037Bavedi SanNo ratings yet

- Joist Loading Diagram (SL) ScheduleDocument1 pageJoist Loading Diagram (SL) ScheduleBavedi SanNo ratings yet

- Tension Development PDFDocument0 pagesTension Development PDFAjay SinghNo ratings yet

- Manual ProConcreteDocument1,036 pagesManual ProConcreteBavedi San75% (4)

- Dia GridDocument12 pagesDia GridBavedi SanNo ratings yet

- Critical Values For The Dickey-Fuller Unit Root T-Test StatisticsDocument1 pageCritical Values For The Dickey-Fuller Unit Root T-Test Statisticswjimenez1938No ratings yet

- User-Centered Website Development: A Human-Computer Interaction ApproachDocument24 pagesUser-Centered Website Development: A Human-Computer Interaction ApproachKulis KreuznachNo ratings yet

- ABN AMRO Holding N.V. 2009 Annual ReportDocument243 pagesABN AMRO Holding N.V. 2009 Annual ReportF.N. HeinsiusNo ratings yet

- Iso 4624Document15 pagesIso 4624klkopopoonetdrghjktl100% (2)

- VBScriptDocument120 pagesVBScriptdhanaji jondhaleNo ratings yet

- For-tea Tea Parlour Marketing Strategy Targets 40+ DemographicDocument7 pagesFor-tea Tea Parlour Marketing Strategy Targets 40+ Demographicprynk_cool2702No ratings yet

- 3000W InverterDocument2 pages3000W InverterSeda Armand AllaNo ratings yet

- Maximizing Revenue of IT Project DevelopmentDocument4 pagesMaximizing Revenue of IT Project DevelopmentJulius Mark CerrudoNo ratings yet

- FilesDocument12 pagesFilesRajesh TuticorinNo ratings yet

- Whats The Average 100 M Time For An Olympics - Google SearchDocument1 pageWhats The Average 100 M Time For An Olympics - Google SearchMalaya KnightonNo ratings yet

- United States Court of Appeals, Third CircuitDocument3 pagesUnited States Court of Appeals, Third CircuitScribd Government DocsNo ratings yet

- Vallance - Sistema Do VolvoDocument15 pagesVallance - Sistema Do VolvoNuno PachecoNo ratings yet

- Itec 3100 Student Response Lesson PlanDocument3 pagesItec 3100 Student Response Lesson Planapi-346174835No ratings yet

- Accident Causation Theories and ConceptDocument4 pagesAccident Causation Theories and ConceptShayne Aira AnggongNo ratings yet

- Broschuere Unternehmen Screen PDFDocument16 pagesBroschuere Unternehmen Screen PDFAnonymous rAFSAGDAEJNo ratings yet

- BC Specialty Foods DirectoryDocument249 pagesBC Specialty Foods Directoryjcl_da_costa6894No ratings yet

- AB InBev Code of Business Conduct PDFDocument10 pagesAB InBev Code of Business Conduct PDFcristian quelmis vilca huarachiNo ratings yet

- Cantilever Retaining Wall AnalysisDocument7 pagesCantilever Retaining Wall AnalysisChub BokingoNo ratings yet

- Building A Computer AssignmentDocument3 pagesBuilding A Computer AssignmentRajaughn GunterNo ratings yet

- Cagayan Electric Company v. CIRDocument2 pagesCagayan Electric Company v. CIRCocoyPangilinanNo ratings yet

- Congress Policy Brief - CoCoLevyFundsDocument10 pagesCongress Policy Brief - CoCoLevyFundsKat DinglasanNo ratings yet

- Illustrator CourseDocument101 pagesIllustrator CourseGreivanNo ratings yet

- Triblender Wet Savoury F3218Document32 pagesTriblender Wet Savoury F3218danielagomezga_45545100% (1)

- BCM Risk Management and Compliance Training in JakartaDocument2 pagesBCM Risk Management and Compliance Training in Jakartaindra gNo ratings yet

- Central BankDocument65 pagesCentral BankFarazNaseer100% (1)

- SQL-Problems Solutions PDFDocument11 pagesSQL-Problems Solutions PDFManpreet Singh100% (1)

- UNIT: 01 Housekeeping SupervisionDocument91 pagesUNIT: 01 Housekeeping SupervisionRamkumar RamkumarNo ratings yet

- Market Participants in Securities MarketDocument11 pagesMarket Participants in Securities MarketSandra PhilipNo ratings yet

- Amos Code SystemDocument17 pagesAmos Code SystemViktor KarlashevychNo ratings yet

- Philippines Taxation Scope and ReformsDocument4 pagesPhilippines Taxation Scope and ReformsAngie Olpos Boreros BaritugoNo ratings yet