Professional Documents

Culture Documents

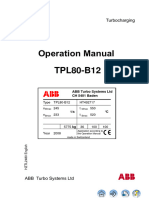

ABB Turbocharger Operations Manual PDF

Uploaded by

Abhinav KhullarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABB Turbocharger Operations Manual PDF

Uploaded by

Abhinav KhullarCopyright:

Available Formats

Operation Manual

List of contents Page 1

List of contents

January 2007

1 Preliminary remarks

1.1 Purpose of the manual

1.2 Layout and function

1.3 Correct use of the turbocharger

1.4 Essential information

1.5 Abbreviations and symbols

1.6 Turbocharger rating plate

2 Safety

HZTL2491_EN (TPL85-B14/-B15/-B16)

2.1 Basic safety instructions

2.2 General safety instructions

2.3 Special safety instructions

2.4 Safety instructions and hazard protection

2.5 Warnings on the turbocharger

3 Commissioning

3.1 Oil supply

3.2 Inspection work

3.3 Putting into operation after laying up

4 Operation

4.1 Servicing work

4.2 Monitoring

4.3 Surging of turbocharger

4.4 Contact with rotating parts

4.5 Shutting the engine down

Version 4

5 Maintenance

5.1 Foreword to Maintenance

5.2 Cleaning the filter silencer

5.3 Cleaning the compressor during operation

5.4 Cleaning turbine blades and nozzle ring in operation

5.5 Suppliers of materials for dry cleaning

ABB Turbo Systems Ltd

Operation Manual

List of contents Page 2

6 Troubleshooting

January 2007

6.1 Possible remedies for failures

7 Removal and installation

7.1 Turbocharger weights

7.2 Remove the turbocharger

7.3 Installing the turbocharger

8 Disassembly and assembly

8.1 Module weights

8.2 Removing and fitting the filter silencer or air suction branch

8.3 Axial clearance

8.4 Dismantling the internal part of the compressor casing

HZTL2491_EN (TPL85-B14/-B15/-B16)

8.5 Dismantling gas inlet casing

8.6 Fitting gas inlet casing

8.7 Fitting the internal part of the compressor casing

8.8 Table of tightening torques

9 Taking out of operation temporarily

9.1 Possibilities for emergency repair

9.2 Locking the rotor

9.3 Blocking the inlets and outlets

9.4 Bypass the turbocharger

10 Mothballing the turbocharger

10.1 Taking out of operation for up to 12 months

10.2 Taking out of operation for more than 12 months

11 Reserve and spare parts

11.1 Ordering spare parts

Version 4

11.2 Directory of part numbers

11.3 General view of turbocharger

11.4 General view of cartridge group

ABB Turbo Systems Ltd

Operation Manual

Preliminary remarks 1

Purpose of the manual 1.1 Page 1

1 Preliminary remarks

1.1 Purpose of the manual

January 2007

Operation manual This operation manual will help you to become familiar with your ABB

Turbo Systems Ltd turbocharger and to use it to full effect in its intended

application. You will find important instructions as to the safe, correct, and

economical operation of the turbocharger.

Target group The content of this operation manual is intended for persons such as en-

gineers, marine mechanics and service technicians who are responsible

for the running of the engine and the turbocharger installed thereon.

Content of operation ma- This operation manual includes helpful information on the following topics:

nual

Information on the operation of the turbocharger and ways to prolong

the turbocharger's service life.

HZTL2491_EN (TPL85-B14/-B15/-B16)

Early awareness and avoidance of hazards.

Minimising repair costs and failure times.

This operation manual is a complement to, and an extension of, existing

national regulations on accident protection and prevention.

An operation manual must be available at all times at the site where the

turbocharger is used. It is essential that this operation manual is read

before beginning work by all persons working with or on the turbo-

NOTE charger. Personnel who only work occasionally on the machine (e.g.

during installation and maintenance) must also have read and fully un-

derstood the operating manual before beginning work.

The instructions included in this operation manual must be followed under

all circumstances.

This applies especially to the general and special safety instructions

preceding and in the respective chapters. Ignoring hazards and the sa-

fety instructions can lead to serious personal injury and damage to e-

Version 4

WARNING quipment.

In the event of doubt, consult the officer for safety and accident protection

responsible for your area.

ABB Turbo Systems Ltd

Operation Manual

Preliminary remarks 1

Layout and function 1.2 Page 2

1.2 Layout and function

January 2007

HZTL2491_EN (TPL85-B14/-B15/-B16)

1.2.

1 Filter silencer 7 Nozzle ring

2 Radial plain bearing 8 Turbine wheel

3 Thrust bearing 9 Bearing casing

4 Radial plain bearing 10 Diffuser

5 Gas outlet casing 11 Compressor wheel

6 Gas inlet casing 12 Air outlet casing

Version 4

ABB Turbo Systems Ltd

Operation Manual

Preliminary remarks 1

Layout and function 1.2 Page 3

Mode of operation

January 2007

The turbocharger is a turbo-machine and consists of the following main

components:

Turbine

Compressor

These are both are mounted on a common shaft.

The exhaust gases from the diesel engine flow through the gas inlet cas-

ing (6) and nozzle ring (7) to the turbine wheel (8).

The turbine wheel (8) uses the energy contained in the exhaust gas to

drive the compressor wheel (11), whereby the compressor draws in fresh

HZTL2491_EN (TPL85-B14/-B15/-B16)

air, and the compressed air is forced into the cylinders.

The exhaust gases escape through the exhaust pipe which is connected

to the gas outlet casing (5).

The air which is necessary for the operation of the diesel engine and

which is compressed in the turbocharger is drawn through the suction

branch or the filter silencer (1) into the compressor wheel (11). It then

passes through the diffuser (10) and leaves the turbocharger through the

compressor outlet on the air outlet casing (12).

The rotor runs in two radial plain bearings (2/4), which are located in the

bearing casing (9) between the compressor and the turbine. The axial

thrust bearing (3) is on the compressor side.

The plain bearings are connected to a central lubricating oil feed which is

normally supplied by the oil lubrication circuit of the engine. The oil outlet

is always at the lowest point of the bearing casing (9).

The turbocharger is equipped with an emergency lubrication oil tank,

which is integrated in the bearing casing. With a failure of the lubrication

oil system, the bearings are supplied with oil with this emergency lubrica-

tion until the rotor comes to a standstill.

Version 4

ABB Turbo Systems Ltd

Operation Manual

Preliminary remarks 1

Correct use of the turbocharger 1.3 Page 4

1.3 Correct use of the turbocharger

January 2007

This turbocharger supplied by ABB Turbo Systems has been developed

for use on diesel engines to generate the volume of air and the charg-

ing pressure required to operate the engine.

NOTE The engine manufacturer has provided ABB Turbo Systems with infor-

mation regarding the intended purpose of the engine, from which the

operating parameters specific to the turbocharger (such as rotating

speeds, temperatures, replacement periods / exchange intervals) have

been derived and are indicated on the rating plate.

Any other usage shall be regarded as a special application which must

be discussed with ABB Turbo Systems. The manufacturer accepts no

liability for other applications. If it is used otherwise, ABB Turbo Sys-

tems reserves the right to reject all claims under the warranty.

HZTL2491_EN (TPL85-B14/-B15/-B16)

Latest technology This turbocharger was built according to state-of-the-art technology and is

operationally safe according to prevailing safety regulations.

Improper operation and maintenance of the turbocharger can result in

danger to life and limb of the user or third parties. In addition, improper

use may cause damage to the machine. The machine may only be ope-

WARNING rated by trained personnel.

Correct use of the turbocharger also includes observation of the assem-

bly, disassembly, operating, maintenance and repair conditions specified

by the manufacturer. Regulations set out by local authorities must be ob-

served when disposing of the turbine.

Perfect condition The turbocharger must only be installed in a technically perfect condition,

corresponding to its intended purpose and following the instructions in the

Engine Manufacturers' Manual, and must be operated and used in com-

pliance with the Operation Manual.

Version 4

X Defects which could affect safety must be eliminated immediately.

The manufacturer shall not accept liability for damages resulting from un-

authorised alterations to the turbocharger.

ABB Turbo Systems Ltd

Operation Manual

Preliminary remarks 1

Essential information 1.4 Page 5

1.4 Essential information

January 2007

Organisational measures

In addition to this manual, the general, statutory regulations applicable in

the respective country for the prevention of accidents and the protection of

the environment must be observed.

This also applies to the provision and wearing of personnel protection e-

quipment.

The safety and risk consciousness of the personnel working on and

with the turbocharger must be checked regularly with reference to this

manual.

NOTE

HZTL2491_EN (TPL85-B14/-B15/-B16)

X The turbocharger must be shut down immediately in the event of al-

terations affecting safety or of corresponding operating behaviour. The

fault should be reported to the person or department responsible.

Additions and alterations to, and conversions of the turbocharger that

could compromise safety require the prior approval of ABB Turbo Sys-

tems.

NOTE

Version 4

ABB Turbo Systems Ltd

Operation Manual

Preliminary remarks 1

Essential information 1.4 Page 6

Original parts and safety

January 2007

Original parts and accessories are especially designed for the turbo-

charger supplied by ABB Turbo Systems Ltd.

We herewith expressly state that parts and accessories not supplied by

us have also not been tested and approved by us.

NOTE

If components and assemblies not manufactured and tested by ABB

Turbo Systems are used, this may have a negative effect on the techni-

cal design specifications of the turbocharger.

HZTL2491_EN (TPL85-B14/-B15/-B16)

WARNING Moreover, the active and/or passive safety of the turbocharger may be

compromised by the use of non-original parts. Note that such improper

use may endanger personnel and the machine.

ABB Turbo Systems shall not be liable for any damage caused by using

non-original parts and accessories.

Qualification of personnel

The turbocharger must only be operated and maintained by trained and

authorised personnel.

Work on mechanical components, such as bearings or rotors, must only

be performed by qualified fitters from an official service station of ABB

Turbo Systems Ltd.!

CAUTION

It must be ensured that only authorised personnel work on the turbo-

Version 4

charger.

ABB Turbo Systems Ltd

Operation Manual

Preliminary remarks 1

Essential information 1.4 Page 7

After-sales service

January 2007

The Contact Information brochure contains an overview of official ABB

Turbo Systems Ltd. service stations worldwide.

Design variants

This operating manual is valid for various turbocharger design variants.

This means that some sections and component descriptions in this oper-

ating manual do not apply to your turbocharger.

Our service stations and agencies will gladly answer your questions relat-

ing specifically to your model.

HZTL2491_EN (TPL85-B14/-B15/-B16)

Accuracy of illustrations

The graphics and images shown in this manual are of a general nature

and are intended to assist understanding of the work steps and instruc-

tions. Differences may exist in certain details.

Storage of new turbochargers

New turbochargers supplied by ABB Turbo Systems Ltd. can be stored

without additional safeguarding measures for a period of 6 months after

the delivery date.

Ensure that the storage area is dry with humidity of 40-70% and free of

condensation.

X After 6 months, rust-proofing oil should be sprayed on exposed sur-

faces and all accessible areas of the turbocharger.

X To do this, the insulating materials must be removed.

Version 4

Repeat the steps described for rust-proofing your turbocharger every 6

months.

NOTE

ABB Turbo Systems Ltd

Operation Manual

Preliminary remarks 1

Abbreviations and symbols 1.5 Page 8

1.5 Abbreviations and symbols

The following abbreviations are used in this document:

January 2007

Z Prerequisite

X Work step

D Result

9 Positive checkpoint (activity that must be carried out without fail)

U Negative checkpoint (activity that must not be carried out under any

circumstances)

Basic Instructions

HZTL2491_EN (TPL85-B14/-B15/-B16)

The following symbol is used for notes in this manual:

This note provides suggestions and tips to make work on the turbo-

charger easier.

The note provides further essential information.

NOTE

ABB Turbo Systems

The term ABB Turbo Systems used in this manual signifies ABB Turbo

Systems Ltd.

Official ABB Turbo Systems service station

Version 4

The term used in this manual Official ABB Turbo Systems service station

signifies ABB Turbocharger service stations, that have been tested and

certified by ABB Turbo Systems Ltd.

ABB Turbo Systems Ltd

Operation Manual

Preliminary remarks 1

Turbocharger rating plate 1.6 Page 9

1.6 Turbocharger rating plate

January 2007

HZTL2491_EN (TPL85-B14/-B15/-B16)

L_00012

Operational limits 1 Turbocharger operational limits at engine overload (110 %).

In test rig operation only, unless otherwise agreed with the

engine manufacturer.

2 Turbocharger operational limits in service.

Recommended replace- 3 Replacement interval for the plain bearings in 1000 h

Version 4

ment periods / exchange

4 Exchange interval for the compressor in 1000 h (no data for

intervals for turbocharger

100,000 h)

components

5 Exchange interval for the turbine in 1000 h (no data for

100,000 h)

ABB Turbo Systems Ltd

Operation Manual

Preliminary remarks 1

Turbocharger rating plate 1.6 Page 10

Additional specifications: 6 Customer part number

7 Field for special design designation

8 Weight of the turbocharger in kg

January 2007

9 CE = Conformité Européenne

10 Turbocharger type

11 Series number

12 Year of construction of the turbocharger

Explanations of the rating plate

The recommended exchange intervals and the corresponding operation

limits are defined together with the engine builder. These specifications

are system-specific.

HZTL2491_EN (TPL85-B14/-B15/-B16)

Continuous running above the indicated nBmax, tBmax values may consid-

erably reduce the recommended exchange intervals. In such cases, we

recommend you contact the nearest official service station of ABB

CAUTION Turbo Systems Ltd.

nMmax , tMmax normally apply only when running at overload (110 %) dur-

ing trials on the engine test bed. These limits may also be permitted in

service for special applications. The operation over nMmax , tMmax is not

permitted.

Non-compliance with the recommended exchange intervals may in-

crease the risk of unpredictable component failure.

Version 4

ABB Turbo Systems Ltd

Operation Manual

Safety 2

Basic safety instructions 2.1 Page 1

2 Safety

2.1 Basic safety instructions

January 2007

The following symbols and terms are used for the safety instructions in

this manual:

Failure to follow work steps and operating instructions marked with this

symbol completely and rigorously may result in serious personal injury

or even fatal accidents.

WARNING Warning signs must be strictly observed at all times.

HZTL2491_EN (TPL85-B14/-B15/-B16)

Serious damage to the machine or to other property may result if the

working and operation instructions marked with this symbol are not, or

only partly, observed.

CAUTION Caution signs must be strictly observed at all times.

Version 4

ABB Turbo Systems Ltd

Operation Manual

Safety 2

General safety instructions 2.2 Page 2

2.2 General safety instructions

The instructions listed here are designed to ensure your safety and to

January 2007

promote safe handling of the turbocharger and its associated operating

materials.

The following safety instructions must be followed when operating and

when working on the turbocharger.

WARNING

Do not work on the turbocharger if you are under physical or mental

stress.

Wear protective clothing at all times.

Helmet

Ear protection

HZTL2491_EN (TPL85-B14/-B15/-B16)

Protective glasses

Protective suit

Oil and petrol resistant gloves

Protective shoes

Attach individual parts and larger component modules carefully to suit-

able hoists/lifting devices which are in technically perfect condition and

which have adequate load-bearing capacity.

Do not stand under suspended loads.

If welding work is to be carried out above the turbocharger, the air filter

must be covered to prevent damage to the filter mat.

When working on the turbocharger, be aware of the risk of it falling.

For overhead assembly work, use the steps and platforms provided for

this purpose.

Version 4

ABB Turbo Systems Ltd

Operation Manual

Safety 2

Special safety instructions 2.3 Page 3

2.3 Special safety instructions

January 2007

Safety when connecting

Work only on those connections for which you are qualified.

Safety when commissioning and during operation

Before starting work, make a visual inspection of the working area.

Remove obstacles and any objects lying around from the work area.

Before commissioning check the turbocharger for damage and leaks.

Refrain from any activity which could compromise safety while working

with the turbocharger.

Inspect the turbocharger after about 12 hours of operation or at least

HZTL2491_EN (TPL85-B14/-B15/-B16)

once a day for visible damage and defects.

Report any damage or changes in operational performance to the per-

son/department responsible immediately.

In the event of damage, shut down the turbocharger immediately and

secure it against inadvertent or unauthorized use.

Safety when cleaning

When handling detergents, solvents, acids and alkalis be sure to observe

the respective safety directions on the manufacturers' labels.

Follow directions regarding the environmentally compatible collection, sto-

rage and disposal of these liquids.

Explosion hazard

Cleaning work should be carried out outdoors due to explosion hazard.

If this is not possible, ensure that there is adequate ventilation and air

WARNING circulation. Before beginning cleaning work in confined spaces, extin-

guish naked flames (including cigarettes!) due to the risk of explosion.

Version 4

ABB Turbo Systems Ltd

Operation Manual

Safety 2

Special safety instructions 2.3 Page 4

Before cleaning, protect the floor against unintended leaks of oil and

operation materials.

January 2007

You must wear protective clothing (see section General safety instruc-

tions).

Handle operation materials and detergents with utmost caution.

When handling solvents, wear protective clothing and observe the fol-

lowing rules:

Avoid skin contact with solvents.

Avoid inhaling vapours under all circumstances.

Do not allow solvents to soak protective clothing.

After cleaning, check electric cables for signs of wear or damage.

Safety during disassembly, assembly, maintenance and troubleshooting

HZTL2491_EN (TPL85-B14/-B15/-B16)

Follow the prescribed maintenance and inspection schedules for all ad-

justment, maintenance and inspection work.

Inform operating personnel about special work and repairs before start-

ing.

Ensure that absorbent materials are available to clean up any opera-

tion materials that escape accidentally.

Ensure safe and environmentally-friendly drainage, collection and dis-

posal of operating and auxiliary materials.

Before opening a cover or removing a protective component on the

turbocharger, the engine must have been switched off and must not be

started up again until all parts have been properly re-assembled.

Assembly and disassembly work must only be performed by trained

personnel. Work on mechanical components, such as bearings or ro-

tors, must only be performed by qualified fitters from an official service

CAUTION station of ABB Turbo Systems. Version 4

ABB Turbo Systems Ltd

Operation Manual

Safety 2

Special safety instructions 2.3 Page 5

Safety when taking out of operation or putting into storage

January 2007

Secure the rotor against turning.

Clean the turbocharger before mothballing.

Wear protective clothing when mothballing the turbocharger.

Keep the work area clean and free of oil and operating materials.

Remove any obstacles lying around on the floor.

HZTL2491_EN (TPL85-B14/-B15/-B16)

Version 4

ABB Turbo Systems Ltd

Operation Manual

Safety 2

Safety instructions and hazard 2.4 Page 6

protection

2.4 Safety instructions and hazard protection

Associated hazards may arise during operation of and work on the turbo-

January 2007

charger:

from the turbocharger and its accessories.

from the operating materials used.

due to failure to comply with the safety instructions.

from inadequate performance of maintenance and inspection work.

Mechanical influences

Mechanical influences can cause serious injury or even fatal injury.

HZTL2491_EN (TPL85-B14/-B15/-B16)

WARNING

Personal injury Unconsciousness and injury due to:

crushing

shearing

cutting

winding

smashing

drawing in

knocking

stabbing

rubbing

Escape of liquids under high pressure and / or at high temperature

slipping

tripping

falling

Version 4

ABB Turbo Systems Ltd

Operation Manual

Safety 2

Safety instructions and hazard 2.4 Page 7

protection

Causes sharp edges, pointed parts

crush, shear and winding areas

fragmentation / ejection of parts

January 2007

fracture or rupture of parts due to overload

Elastic elements (springs), liquids and / or gases under pressure/in a

vacuum

slippery, oily work area, obstacles on the floor

Protective measures 9 Wear leather protective gloves

9 Wear close-fitting protective clothing

9 Tie up long hair and beards (wear hair protection)

9 Wear face and eye protection

9 Wear protective shoes

9 Keep floor, equipment and the turbocharger clean

9 Ensure the availability of oil absorbing materials and have oil collector

basins ready or in position

9 Eliminate leaks

HZTL2491_EN (TPL85-B14/-B15/-B16)

Operation and process materials

Operation and process materials refer to chemical and hazardous sub-

stances:

Oils

Grease

Coolants

Detergents and solvents

Acids

Note that operation and process materials are harmful to the environ-

ment if they penetrate soil or water.

CAUTION

Version 4

ABB Turbo Systems Ltd

Operation Manual

Safety 2

Safety instructions and hazard 2.4 Page 8

protection

Personal injury The following injuries can be caused by operation and process materials:

Allergies

January 2007

Skin disease

Loss of consciousness

Poisoning or nausea after inhalation

Causes Inhalation of toxic gases, smoke and vapours

Skin contact with aggressive fluids

Clothing wet or soaked with hazardous substances

Spilling and tipping over of vessels containing substances used during

operation

Escape due to leakage

Tanks and collectors which are not gas-tight and which do not comply

with the regulations on hazardous substances

Burning cigarettes or open flame in the proximity of operation materials

HZTL2491_EN (TPL85-B14/-B15/-B16)

Protective measures 9 Utmost caution when handling process and operation materials

9 Protective clothing must be worn

9 Avoid skin contact and inhalation under all circumstances

9 Ensure that the workroom is properly ventilated

9 Observe the hazard indications on the containers for operation and

process materials

9 Immediately after use, seal the hazardous substance container tight

9 Used operation materials must be collected safely in accordance with

the legal provisions, stored separately in suitable containers as pre-

scribed, and disposed of as special waste in a technically and envi-

ronmentally compatible manner

9 Ensure that containers for new / used operation materials are sealed

tight

9 In the event of leaks or spills immediately apply a suitable absorbent

material and dispose of this in a technically and environmentally com-

patible manner as special waste

Version 4

ABB Turbo Systems Ltd

Operation Manual

Safety 2

Safety instructions and hazard 2.4 Page 9

protection

Handling insulating materials

January 2007

9 Ensure that the work area is well ventilated

9 Keep the work area clean

9 Avoid disturbing dust

9 Dust-suppressing tools and processing steps

9 Remove from packaging only in the work area

9 Exercise particular care when removing old insulating materials

9 Dispose of insulating materials in a technically and environmentally

compatible manner

9 If large quantities of dust are created, wear protective glasses

9 Use half or quarter masks

9 Wear suitable work clothing and gloves

9 For sensitive skin, apply moisturising, protective barrier cream

Noise

HZTL2491_EN (TPL85-B14/-B15/-B16)

The effects of noise above a legally permitted level can cause personal in-

jury.

Personal injury Loss of hearing

Deafness

Impaired hearing

Health disorders such as loss of balance or of consciousness

Cardiac and circulatory disturbances

Causes Machine noise level above 85 dB (A)

Protective measures 9 Wear ear protection

Heat hazard

When the turbocharger is operated, surfaces become very hot.

Personal injury Burns

Version 4

Causes Missing or incorrectly fitted insulation.

Protective measures 9 Wear leather protective gloves.

ABB Turbo Systems Ltd

Operation Manual

Safety 2

Warnings on the turbocharger 2.5 Page 10

2.5 Warnings on the turbocharger

January 2007

Warnings that have been applied to turbochargers by ABB Turbo Systems

must not be removed, painted over or obscured with other stickers. Miss-

ing or illegible warnings must be replaced by new warnings.

HZTL2491_EN (TPL85-B14/-B15/-B16)

L_00227

Apply warnings so that they are clearly visible in the positions intended

for that purpose. Please contact an official ABB Turbo Systems service

station for further information.

NOTE

Version 4

ABB Turbo Systems Ltd

Operation Manual

Commissioning 3

Oil supply 3.1 Page 1

3 Commissioning

3.1 Oil supply

January 2007

A carefully designed oil supply, which functions under all operating condi-

tions, is an important precondition for trouble-free operation of the turbo-

charger.

Lubrication of the turbocharger is normally carried out with oil from the

engine oil circuit.

Regarding the oil supply, follow the engine manufacturer's instructions

concerning selection of lubricating oil, oil change intervals, oil filtration,

and oil pressure and temperature.

NOTE

HZTL2491_EN (TPL85-B14/-B15/-B16)

Oil filtration

A lubrication oil filter system with a mesh size ≤ 0.050 mm is adequate for

TPL ..-B turbochargers.

Oil pressure

The oil pressure before the bearings must be maintained precisely to en-

sure fault-free operation.

The permissible oil pressures are specified in the following tables de-

pendent on the lubrication (engine lubrication or separate lubricating sys-

tem).

Engine lubrication Kinetic viscosity 45 - 170 cST Oil pressure [bar]

Impermissible oil-pressure range -> 0.0 - 0.6

Engine Shut Down (without delay)

Short-term (<1h) permissible oil-pressure range -> 0.6 - 0.8

Version 4

Alarm

Permissible oil-pressure range for normal operation 0.8 - 2.5

Permissible oil-pressure range during engine warm- 0.8 - 4.0

up phase

ABB Turbo Systems Ltd

Operation Manual

Commissioning 3

Oil supply 3.1 Page 2

Separate lubrication sys- Kinetic viscosity 12 - 170 cST Oil pressure [bar]

tem

Impermissible oil-pressure range -> 0.0 - 0.9

Engine Shut Down (without delay)

January 2007

Short-term (<1h) permissible oil-pressure range -> 0.9 - 1.1

Alarm

Permissible oil-pressure range for normal operation 1.1 - 2.5

Permissible oil-pressure range during engine warm- 1.1 - 4.0

up phase

Oil temperature during normal operation

Engine lubrication Oil inlet Engine load Oil inlet pressure Oil outlet

HZTL2491_EN (TPL85-B14/-B15/-B16)

temperature [%] [ bar ] temperature

[ °C ] [ °C ]

45 100 1.5 - 2 70 - 90

70 100 1.5 - 2 90 - 110

Version 4

ABB Turbo Systems Ltd

Operation Manual

Commissioning 3

Inspection work 3.2 Page 3

3.2 Inspection work

This inspection work includes preventive visual controls, as well as moni-

January 2007

toring and measurement to ensure the correct functioning of the turbo-

charger. These serve as an aid to detecting anomalies before and during

commissioning, thus preventing possible damage to the machine.

The safety instructions must be followed before and during all inspec-

tion work.

3.2.1 Inspection before commissioning

Monitoring equipment X To be checked for correct functioning.

HZTL2491_EN (TPL85-B14/-B15/-B16)

Air filter mat X Inspect for damage.

Lubricating system X Check oil filter for cleanliness before commissioning.

It is urgently recommended that the entire lubrication system be flushed

thoroughly with warm oil using a bypass pipe before commissioning and

after every servicing operation on the lubrication system.

CAUTION We strongly recommend the use of a starting filter when running the

engine in and after every servicing operation on the lubrication system.

X Check oil pressure in oil supply lines.

Version 4

ABB Turbo Systems Ltd

Operation Manual

Commissioning 3

Inspection work 3.2 Page 4

3.2.2 Inspection after commissioning

January 2007

Lubricating system X Check oil pressure in oil supply lines.

Charger speed X Measuring

Charger pressure X Measuring

Temperatures X Measure upstream/downstream from turbine, compressor and oil feed

for various engine speeds

HZTL2491_EN (TPL85-B14/-B15/-B16)

Gas, air, and oil lines X After the engine has been started up, check all gas, air and oil lines for

leaks.

Further must be observed:

Lubricants and pastes are liquefied or vaporised during assembly of the

turbocharger and may escape as an oily liquid in the first few hours af-

ter commissioning. If oily liquid continues to escape after this period,

NOTE the cause must be treated as an oil leak and located. The first step in

this process is to check the oil supply to the turbocharger for leaks. If

this is not in order, contact an official ABB Turbo Systems service sta-

tion.

X Measure the speed, oil pressure, charging pressure and temperatures

Version 4

before and after the turbine and the compressor at various engine

speeds.

X Compare the measured values with those of the inspection report, tak-

ing into account the different operating conditions.

3.2.3 Inspection after 100 service hours

Clean or replace lubricating oil filters after the first 100 service hours.

ABB Turbo Systems Ltd

Operation Manual

Commissioning 3

Putting into operation after laying up 3.3 Page 5

3.3 Putting into operation after laying up

If provided X Remove the cover plates (blind flanges) between the compressor cas-

January 2007

ing outlet and charge-air receiver, upstream of the gas inlet, down-

stream of the gas outlet.

X Inspect the exhaust pipe before and after the turbine for any combus-

tion residue, clean / remove foreign bodies or residual water.

X Inspect air supply line or filter silencer for any foreign bodies, clean /

remove.

X Start up the turbocharger's engine end oil circulation system.

X Prepare the turbocharger for operation as instructed in the section In-

spection work before commissioning in the chapter entitled Commis-

sioning.

X Start up the turbocharger.

HZTL2491_EN (TPL85-B14/-B15/-B16)

Version 4

ABB Turbo Systems Ltd

Operation Manual

Operation 4

Servicing work 4.1 Page 1

4 Operation

4.1 Servicing work

January 2007

Servicing work during operation includes visual checks, monitoring and

measuring as well as inspection and function checks in order to ensure

correct functioning of the turbocharger. It serves as an aid to detecting

anomalies during operation, thus preventing damage to the machine.

The inspection, measurement and servicing operations listed must be car-

ried out at the intervals indicated.

The pertinent safety instructions must be observed during all servicing

work.

WARNING

HZTL2491_EN (TPL85-B14/-B15/-B16)

Servicing work must be carried out at the prescribed intervals in order

to avoid damage to and malfunctioning of the turbocharger.

CAUTION

4.1.1 Servicing work every 25 to 50 hours

Operation data X must be recorded

X Enter in the machine logbook

X In the event of significant anomalies, establish the cause

If you are unable to establish the cause of the anomalies, contact an

official ABB Turbo Systems service station.

CAUTION

Version 4

ABB Turbo Systems Ltd

Operation Manual

Operation 4

Servicing work 4.1 Page 2

4.1.2 Entries in the machine logbook

January 2007

Monitoring of the machine plant provides information about the perform-

ance of the turbocharger.

The following operation data and measurement values must be entered

regularly in the engine manufacturer's machine log book:

Output and speed of the engine

Air intake temperature

Exhaust temperature before and after the turbine

Pressure of the charge-air

Pressure drop in the charge-air cooler

Lubricating oil pressure, lubricating oil temperature

HZTL2491_EN (TPL85-B14/-B15/-B16)

If provided Air temperature after compressor and after the charge-air cooler

Speed of the turbocharger

Pressure loss in the air filter

4.1.3 Servicing work according to the engine manufacturer's instructions

Oil filters X With the engine at standstill clean or replace oil filters

Version 4

ABB Turbo Systems Ltd

Operation Manual

Operation 4

Servicing work 4.1 Page 3

4.1.4 Inspection work every 18,000 hours

January 2007

X Remove filter silencer or air suction branch

X Clean filter silencer as far as accessible, and inspect for damage

X Remove the internal part of the compressor casing

X Check clearance A (axial bearing clearance)

X Clean accessible parts (compressor wheel, diffuser, wall insert), and

inspect for damage

X Visual inspection of the turbine parts (nozzle ring, turbine diffuser/cover

ring, turbine blades) without dismantling, using the endoscope, for pos-

sible soiling and damage. As an option, this inspection can also be per-

formed after the disassembly of the gas inlet casing.

X Refit the internal part of the compressor casing

X Re-install the filter silencer or air suction branch.

HZTL2491_EN (TPL85-B14/-B15/-B16)

This inspection work and the checks are to be carried out by an official

service station of ABB Turbo Systems Ltd.

NOTE

Version 4

ABB Turbo Systems Ltd

Operation Manual

Operation 4

Servicing work 4.1 Page 4

4.1.5 Servicing work every 36,000 hours

January 2007

X Remove filter silencer or air suction branch

X Clean filter silencer as far as accessible, and inspect for damage

X Remove the internal part of the compressor casing

X Check clearance A (axial bearing clearance)

X Clean accessible parts (diffuser, wall insert), and inspect for damage

X Remove gas inlet casing, and dismantle nozzle ring

X Clean nozzle ring, and check for damage/wear

X Clean turbine diffuser/cover ring, and check for damage/wear

X Replacement of the radial bearing and axial bearing with original parts

from ABB Turbo Systems Ltd.

X Inspection and assessment of the rotor

HZTL2491_EN (TPL85-B14/-B15/-B16)

The replacement of the bearing parts as well as the inspection and as-

sessment of the rotor must be carried out by an official ABB Turbo Sys-

tems service station.

NOTE

Version 4

ABB Turbo Systems Ltd

Operation Manual

Operation 4

Monitoring 4.2 Page 5

4.2 Monitoring

January 2007

4.2.1 Speed measurement

HZTL2491_EN (TPL85-B14/-B15/-B16)

86505_001

1 Bearing casing 6 Connecting cable

2 Axial bearing 7 Line amplifier (option)

3 Guide in the axial bearing 8 Speed transmitter

4 Gasket ring 9 Installation variant of the

speed transmitter

5 Screw plug

Version 4

The speed transmitter system for the measurement of the turbocharger

speed also permits, in conjunction with the corresponding measuring in-

struments and/or monitoring systems (not included in the scope of deliv-

ery), a constant remote monitoring of the turbocharger speed. With con-

tinuous monitoring of the machine installation, the turbocharger speed can

be used as a suitable control parameter. The line amplifier can be pur-

chased as an optional addition to the described speed measuring system.

ABB Turbo Systems Ltd

Operation Manual

Operation 4

Monitoring 4.2 Page 6

Possible reasons for failure of the speed indicator:

Defects in the speed transmitter, the connecting cable and plug to the

measuring unit, in the measuring unit itself or the power supply.

January 2007

Turbocharger damage.

Failure of the speed indicator

If the speed indication fails, it is recommended that the engine output

be reduced to idling speed and the engine stopped. The cause of the

CAUTION failure should then be determined.

We recommend that subsequent assembly or replacement of the speed

transmitter system should be carried out only by an official ABB Turbo

Systems service station.

HZTL2491_EN (TPL85-B14/-B15/-B16)

NOTE

A reduction in speed of a charger can signify:

Damaged turbine or bearing

Severe soiling of the turbine

Version 4

ABB Turbo Systems Ltd

Operation Manual

Operation 4

Monitoring 4.2 Page 7

4.2.2 Underpressure measurement on filter silencer

January 2007

A U-tube manometer can be ordered from ABB Turbo Systems Ltd. for

measuring the underpressure at the filter silencer.

The measurement can be used for the following purposes:

To measure the correction factor for calculating the efficiency of the

turbocharger when accepting the engine

The use of a filter mat on the filter silencer can cause a loss of pres-

sure. More significant pressure loss is an indication of increased soiling

of the filter material.

U-tube manometer

HZTL2491_EN (TPL85-B14/-B15/-B16)

Version 4

L_00003

L_00004

1 Felt discs

A [mm H2O] Pressure differential / pressure loss

ABB Turbo Systems Ltd

Operation Manual

Operation 4

Monitoring 4.2 Page 8

All parts required for assembly are supplied in a separate package.

Mechanical vibration of the U-tube manometer is reduced by the installa-

tion of additional felt discs (1).

January 2007

The U-tube manometer must be exposed to minimum possible me-

chanical shock or vibration.

NOTE

X Fit the U-tube manometer to the filter silencer as shown in the preced-

ing description.

X For best readability, the U-tube manometer can be filled with slightly

coloured water.

Under as-new conditions (new or clean filter silencer and filter mat), the

maximum pressure loss (A) is 120 mm H2O under full loading.

HZTL2491_EN (TPL85-B14/-B15/-B16)

X Clean the filter as soon as the loss of pressure (A) reaches a value of

200 mm H2O if not before.

For better readability of the pressure differential (A) on the U-tube ma-

nometer, the measuring rod can be withdrawn to the level of the lower

water level indicators.

NOTE

Version 4

ABB Turbo Systems Ltd

Operation Manual

Operation 4

Surging of turbocharger 4.3 Page 9

4.3 Surging of turbocharger

Surging of the turbocharger can occur with certain engine operating sta-

January 2007

tes, such as rapid load removal or while manoeuvring. The direction of

flow in the compressor is then briefly reversed. However, sporadic surging

of this kind does not generally affect the safe operation of the turbo-

charger.

Prolonged or periodic surging

If surging is prolonged or occurs periodically, the following components

may be damaged:

CAUTION - Compressor wheel (vibration fractures, ...)

- Turbine blades (cracks)

- Bearing (overheating)

- Filter silencer

HZTL2491_EN (TPL85-B14/-B15/-B16)

Action to be taken:

The operating safety of the turbocharger is no longer ensured with con-

tinuous or periodically recurring surging. The operator must take immedi-

ate steps to correct the surging together with the closest official ABB

Turbo Systems service station.

The components listed above must be inspected for damage by an official

ABB Turbo Systems service station, and replaced in cases of doubt.

Version 4

ABB Turbo Systems Ltd

Operation Manual

Operation 4

Contact with rotating parts 4.4 Page 10

4.4 Contact with rotating parts

Mild, uniform wear around the circumference of rotor components, caused

January 2007

by slight local grazing against adjacent components, is non-hazardous

and permissible. This slightly reduces the length of the blades in the com-

pressor and/or the turbine. Certain tolerances must be observed to avoid

significant loss of efficiency.

X A check on dimensions must be carried out by an official ABB Turbo

Systems service station.

HZTL2491_EN (TPL85-B14/-B15/-B16)

Version 4

ABB Turbo Systems Ltd

Operation Manual

Operation 4

Shutting the engine down 4.5 Page 11

4.5 Shutting the engine down

January 2007

Before shutting the engine down, it must be allowed to idle for about 3

minutes longer so that the circulating lubricating oil can dissipate the

heat in the turbocharger bearings.

CAUTION

HZTL2491_EN (TPL85-B14/-B15/-B16)

Version 4

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Foreword to Maintenance 5.1 Page 1

5 Maintenance

5.1 Foreword to Maintenance

January 2007

Cleaning work includes regular visual checks and washing to ensure the

correct functioning of the turbocharger and its auxiliary appliances.

The external condition and the degree of contamination of the cleaning

points specified in this chapter must be established by visual checks at

the intervals indicated.

The safety instructions must be observed during all cleaning work.

The cleaning points described in the following are:

HZTL2491_EN (TPL85-B14/-B15/-B16)

Filter silencer

Compressor

Turbine and nozzle ring

Version 4

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning the filter silencer 5.2 Page 2

5.2 Cleaning the filter silencer

January 2007

5.2.1 Filter silencer with tension band

HZTL2491_EN (TPL85-B14/-B15/-B16)

L_00210

Version 4

81265 Filter ring (if provided) 81266 Cover grids

81270 Tension ring 81136 Fleece segment

38271 Trap cover 81137 Cover panel

81268 Connecting strip 81135 Filter silencer body

E Slide-in module = fleece segment + cover panel installed

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning the filter silencer 5.2 Page 3

Disassembling and cleaning the filter silencer

If provided X Remove filter ring (81265).

January 2007

X Rinse filter ring (81265) with water using detergent or, if very dirty, so-

ak it. Squeeze out carefully. Rinse in cold water. Avoid high mechani-

cal stress (water jet).

The dirt in the filter ring (81265) depends on the cleanness of the air

drawn in. Wash or replace the filter ring as necessary or every 500 ser-

vice hours.

NOTE

X Loosen tension bands (81270) on trap covers (81271) and carefully

remove cover grid (81266) from connecting strips (81268).

HZTL2491_EN (TPL85-B14/-B15/-B16)

In the case of a slide-in module (E), with a cleaning container attached

to the filter silencer (available as option depending on turbocharger ty-

pe) the water injection line must first be removed (see also following

NOTE section Disassembling the cleaning line).

X Pull the slide-in modules (E) out, bend the cover panels (81137) open,

and then take out the fleece segments (81136).

X Clean fleece segments (81136).

When cleaning, ensure that the fleece segments (81136) are cleaned

only with a mild jet of compressed air, a soft brush or damp cloth. Oth-

erwise the segments may be damaged or lose their shape.

Heavily soiled fleece segments and filter ring as well as damaged con-

necting strips should be replaced with original parts from ABB Turbo

Systems.

Version 4

NOTE

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning the filter silencer 5.2 Page 4

Assembling the filter silencer

January 2007

X Assemble the slide-in modules (E) by inserting fleece segments

(81136) in the cover panels (81137).

X Bend the cover panels back to their original shape.

X Insert slide-in modules (E) in the grooves in the filter silencer body

(81135).

With a cleaning container fitted to the filter silencer (available as option

depending on turbocharger type) the water injection line must now be

re-installed (see also following section Assembling the cleaning line).

NOTE

HZTL2491_EN (TPL85-B14/-B15/-B16)

X When fitting, insert the cover grid (81266) into the connecting strips

(81268).

X Fit the tension bands (81270) and tighten on the trap covers (81271).

If provided X Fit filter ring (81265).

Version 4

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning the filter silencer 5.2 Page 5

5.2.2 Removing / installing the cleaning line

January 2007

HZTL2491_EN (TPL85-B14/-B15/-B16)

L_00192

1 Injection pipe 2 Pipe

3 Guide tube

Version 4

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning the filter silencer 5.2 Page 6

Removing the cleaning line

January 2007

X Disconnect the line (2) at the injection pipe (1) and remove the screw

coupling from the pipe.

X Withdraw the pipe (2) from the guide tube (3).

Punch out the guide tube

HZTL2491_EN (TPL85-B14/-B15/-B16)

L_00193

X Punch the guide tube (3) out of the caulking with a bolt (diameter = 16

mm) and withdraw it.

Heavily soiled components of the cleaning line must be replaced with

original parts from ABB Turbo Systems.

Version 4

NOTE

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning the filter silencer 5.2 Page 7

Installing the cleaning line

January 2007

HZTL2491_EN (TPL85-B14/-B15/-B16)

L_00194

X After fitting the slide-in modules (E), re-fit the guide tube (3) and re-

caulk it.

X Fit the pipe (2) and screw to the injection pipe (1).

Version 4

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning the compressor during 5.3 Page 8

operation

5.3 Cleaning the compressor during operation

January 2007

These guidelines for wet cleaning apply exclusively for cleaning with

clean water and are subject to permission for the procedure being ob-

tained from the engine manufacturer.

NOTE

The dirt in the compressor stage (compressor wheel and diffuser) de-

pends on the cleanness of the air drawn in and the operating point.

A deposit of dirt in the flow ducts will be formed if the following substances

are present in the intake air:

Oil or saline mist

HZTL2491_EN (TPL85-B14/-B15/-B16)

Solid combustion residues

Dust of various kinds

Soiling of the compressor stage has a negative effect on compressor effi-

ciency and charging pressure, particularly for smaller turbochargers.

This results in higher exhaust temperatures and increased fuel consump-

tion by the engine. Contamination of the compressor also increases the

rotor imbalance.

Periodic cleaning of the compressor in operation prevents or retards a se-

vere increase in soiling, but in no way replaces the regular servicing work,

during which the turbocharger is completely dismantled.

Interval between clea- The interval between periodic cleaning depends in large measure on the

nings operating conditions. In general, cleaning should be carried out every 25

to 100 operating hours.

Should the prescribed cleaning intervals prove incompatible with the

Version 4

operation of the ship, please contact ABB Turbo Systems.

NOTE

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning the compressor during 5.3 Page 9

operation

Cleaning method

The compressor is cleaned while operating using the cleaning method de-

January 2007

scribed in the following. This method has been tested and is approved by

ABB Turbo Systems:

Wet cleaning

Principle of wet cleaning Water is injected before the compressor wheel via an injection pipe fitted

in the filter silencer or the suction branch in order to clean the compressor

stage in operation.

The water does not act as a solvent in the process, but the deposit is re-

moved by the mechanical impact of the drops. The process is ideal, pro-

vided the soiling is not too advanced.

HZTL2491_EN (TPL85-B14/-B15/-B16)

Due to the danger of corrosion, only clean water may be used, and on

no account salt water. The water should also contain no cooling addi-

tives, which could form deposits in the flow ducts.

CAUTION

Cleaning more than one If several turbochargers are installed on one engine, we recommend clea-

turbocharger compressor ning the turbocharger compressors one after the other.

Version 4

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning the compressor during 5.3 Page 10

operation

5.3.1 Wet cleaning the compressor with external pressurised water con-

January 2007

tainer (XC3)

The water feed with the externally mounted dosing vessel is only suit-

able for applications with underpressure upstream of the compressor

wheel (cannot be used for: Blower connected upstream of the com-

NOTE pressor or high-pressure compressor stage in the case of two-stage

charging).

Operating state preconditions for cleaning compressors with XC3

HZTL2491_EN (TPL85-B14/-B15/-B16)

In order to carry out a successful cleaning procedure that has been

tested and is recommended by ABB Turbo Systems, the following pre-

conditions must be met:

NOTE

Z Engine warm from running (engine under full loading as far as possi-

ble)

Z High turbocharger speed

X Cleaning cycle started according to the following description in Pro-

cedure for wet cleaning with XC3.

Version 4

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning the compressor during 5.3 Page 11

operation

Procedure for compressor wet cleaning with XC3

January 2007

HZTL2491_EN (TPL85-B14/-B15/-B16)

L_00198

X Screw plug

Y Valve lever

Operating the pressure X The Operating state preconditions for cleaning compressors with XC3

water vessel must be met before cleaning can begin.

X Remove the screw plug (X).

X Fill the vessel with pure water.

Version 4

X Tighten screw plug (X).

X Actuate valve lever (Y) against the spring and hold it for 10 to 15 sec-

onds until all the water has been injected.

X After cleaning, a waiting time of at least 5 minutes is necessary to allow

the turbocharger to dry.

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning the compressor during 5.3 Page 12

operation

If the cleaning operation is unsuccessful, it can be repeated up to 2 ti-

mes.

January 2007

If cleaning is still unsuccessful after three attempts and the engine op-

NOTE erating values are unsatisfactory, we recommend that the turbocharger

be checked and cleaned by an official ABB Turbo Systems service sta-

tion.

Cleaning parameters for each turbocharger compressor

Turbocharger type Turbocharger Contents of the Water injection

speed dosing vessel time

[dm3] t1 [s]

TPL 69BA Possible 0.4 4 ... 15

HZTL2491_EN (TPL85-B14/-B15/-B16)

TPL 73-B nBmax 1

TPL 77-B

TPL 80-B 2

TPL 85-B

TPL 91-B

Version 4

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning the compressor during 5.3 Page 13

operation

5.3.2 Wet cleaning compressors with water vessel (XC4)

January 2007

Operating state preconditions for cleaning compressors with XC4

In order to carry out a successful cleaning procedure that has been

tested and is recommended by ABB Turbo Systems, the following pre-

conditions must be met:

NOTE

Z Engine warm from running (engine under full loading as far as possi-

ble)

Z High turbocharger speed

X Cleaning cycle started according to the following description in Pro-

cedure for wet cleaning with XC4.

HZTL2491_EN (TPL85-B14/-B15/-B16)

Procedure for compressor wet cleaning with XC4

Version 4

L_00197

1 Cleaning container 2 Pipe

3 Injection pipe 4 Cleaning instructions

5 Cover 6 Valve

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning the compressor during 5.3 Page 14

operation

If the cleaning container on the filter silencer is used, the detailed clean-

ing instructions provided on the plate (4) fitted to the filter silencer

January 2007

should be followed.

NOTE

Use of cleaning container X The Operating state preconditions for cleaning compressors with XC4

must be met before cleaning can begin.

X Open filling cap (5) on cleaning container (1).

X Fill with clean water.

X Screw filling cap (5) back into place.

X Open valve (6) for about 3 minutes.

X Close valve (6) and check that all the water has been sucked out.

X After cleaning, a waiting time of at least 5 minutes with the engine run-

HZTL2491_EN (TPL85-B14/-B15/-B16)

ning must be allowed so that the turbocharger can dry.

If the cleaning operation is unsuccessful, it can be repeated up to 2 ti-

mes.

If cleaning is still unsuccessful after three attempts and the engine op-

NOTE erating values are unsatisfactory, we recommend that the turbocharger

be checked and cleaned by an official ABB Turbo Systems service sta-

tion.

Cleaning parameters for each turbocharger compressor

Turbocharger type Turbocharger Contents of the Water injection

speed dosing vessel time

[dm3] t1 [s]

TPL 69BA Possible 2 4 ... 15

TPL 73-B nBmax

TPL 77-B

Version 4

TPL 80-B 3

TPL 85-B

TPL 91-B

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning turbine blades and nozzle ring 5.4 Page 15

in operation

5.4 Cleaning turbine blades and nozzle ring in

operation

January 2007

Combustion of heavy fuel oil in diesel engines causes soiling of the tur-

bine blades and nozzle rings of the turbochargers.

Soiling increases with time, so that regular and properly performed clean-

ing is important to remove the accumulated deposits.

The exhaust gas temperature downstream of the cylinders can rise and

the charging pressure at the air receiver can fall if turbine components be-

come soiled.

A soiled turbine also results in rotor unbalance. Severe soiling can lead to

impermissibly high rotor imbalance.

Experience in operation has shown that despite periodic cleaning during

HZTL2491_EN (TPL85-B14/-B15/-B16)

operation, it is impossible to dispense with overhauls during which the tur-

bine and nozzle ring are mechanically cleaned. However, if cleaning is

performed correctly and the cleaning system is properly dimensioned, the

intervals between overhauls can be extended.

Wet cleaning interval The interval between periodic cleaning depends in large measure on the

operating conditions. In general, cleaning should be carried out every 50

to 500 operating hours.

Interval for dry cleaning The interval between periodic cleaning depends in large measure on the

operating conditions. In general, cleaning should be carried out every 20

to 50 operating hours.

Version 4

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning turbine blades and nozzle ring 5.4 Page 16

in operation

Cleaning methods

January 2007

Several methods are possible for cleaning the turbine and nozzle ring dur-

ing operation. The cleaning methods described in the following have been

tested and are recommended by ABB Turbo Systems:

Wet cleaning

Dry cleaning

Principle of wet cleaning During wet cleaning using droplets of water, the water does not act as a

solvent. Instead, the deposit is removed by the mechanical impact of the

drops.

HZTL2491_EN (TPL85-B14/-B15/-B16)

Due to the danger of corrosion, only clean water may be used, and on

no account salt water. The water should also contain no cooling addi-

tives, which could form deposits in the flow ducts.

CAUTION

Principle of dry cleaning During dry cleaning using dry solid particles in granulate form, the deposit

is removed by the mechanical impact of the grains hitting the surface.

Wet and dry cleaning are equally effective. However, it may be useful to

apply both methods together.

NOTE

Version 4

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning turbine blades and nozzle ring 5.4 Page 17

in operation

January 2007

Stabilising and drying time

Cleaning of the turbine-side components begins after engine start or

reduction of engine load. The exhaust temperature must not exceed the

value specified in the corresponding cleaning instructions (see the re-

NOTE spective section Operating state preconditions).

Failure to maintain the prescribed exhaust temperature upstream of the

turbine, and to allow the minimum stabilising time before and between

cleaning procedures and the drying time after cleaning in accordance

HZTL2491_EN (TPL85-B14/-B15/-B16)

CAUTION with the pertinent cleaning instructions will shorten the expected service

life of the components significantly.

Cleaning more than one If several turbochargers are installed on one engine, we recommend clea-

turbocharger turbine ning the turbocharger turbines with nozzle rings one after the other.

Version 4

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning turbine blades and nozzle ring 5.4 Page 18

in operation

5.4.1 Wet cleaning the turbine and nozzle ring during operation at partial

January 2007

power

The maximum exhaust gas temperature specified by the engine manufac-

turer and the TMmax temperature as shown on the turbocharger rating plate

must not be exceeded under any circumstances. During wet cleaning, the

turbine is braked and the turbocharger operates at reduced speed. As a

result, less air is supplied to the engine and the temperature after the en-

gine cylinder and exhaust valve rises.

Operating state precondition for wet cleaning

HZTL2491_EN (TPL85-B14/-B15/-B16)

In order to carry out a successful cleaning procedure that has been

tested and is recommended by ABB Turbo Systems, the following pre-

conditions must be met:

NOTE

Z After the engine has been started or during operation, the engine

output must be adjusted until the scavenging air pressure pscav is

within the range of 0.3 – 0.6 bar (gauge pressure).

Z Wait 10 to 15 minutes (stabilising time), until the exhaust tempera-

ture at the turbine inlet is stable and below 430°C, the auxiliary

blower must also be operating.

X Cleaning cycle started according to the following description in Pro-

cedure for wet cleaning.

Version 4

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning turbine blades and nozzle ring 5.4 Page 19

in operation

Procedure for wet cleaning

January 2007

HZTL2491_EN (TPL85-B14/-B15/-B16)

L_00394

1 Water supply (fresh water 8 Drainage line

only) at least 6.0 bar

2 Regulating valve 9 Drain cock

3 Manometer 10 Outflow

4 Air supply with 3-way-valve 11 Orifice (integrated in turbo-

charger)

5 Stainless steel piping 21 Air duct from compressor cas-

ing

6 Other turbochargers A Position 1

7 Injection pipe B Position 2

Version 4

Operating the wet clea- Z The Operating state preconditions for wet cleaning must be satisfied

ning system before cleaning is begun.

X Check that the water supply (1) is open and ensured, and also con-

nected to the regulating value (2) in front of the turbocharger.

X Set the shut-off valve (9) of the drain pipe (8) on the gas outlet casing

to Position 1 and check whether exhaust gas escapes.

X Firstly, slowly open the 3-way-valve (4) (if fitted), then the regulating

valve (2) until the manometer (3) shows a pressure of 1 ∓ 0.2 bar.

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning turbine blades and nozzle ring 5.4 Page 20

in operation

X Inject water for 5 minutes at constant engine output.

X Check whether the exhaust-gas temperature after the turbine drops.

X Close the regulating valve (2) and the 3-way-valve (4).

January 2007

X Set drain cock (9) of the drain pipe (8) on the gas outlet casing to Posi-

tion 2, in order to keep the drain pipe clean with air from the compres-

sor casing (21).

X The water supply connection (1) to the regulating valve (2) must be

disconnected.

X After cleaning, a waiting time of at least 10 minutes with the engine

running must be allowed so that the turbocharger can dry.

If the cleaning operation is unsuccessful, it can be repeated up to 2 ti-

mes.

If cleaning is still unsuccessful after three attempts and the engine op-

NOTE erating values are unsatisfactory, we recommend that the turbocharger

be checked and cleaned by an official ABB Turbo Systems service sta-

HZTL2491_EN (TPL85-B14/-B15/-B16)

tion.

Points to remember when The gas outlet casing must be drained of water via the drain pipe (8)

cleaning when cleaning.

The exhaust-gas temperature after the turbocharger falls significantly

during cleaning (by 50 to 150°C).

Outflow can (but need not) take place through the drain-pipe, depend-

ing on the engine load. This outflow might not start for 2 - 3 minutes, or

it may not occur at all.

If draining is not carried out, the turbocharger speed and / or gas inlet

temperature must be monitored closely during the washing operation. If

the load is too low, water can collect in the gas outlet casing. Signs of

this are a sudden fall in the turbocharger speed or very rapid increase

in the gas inlet temperature. In either of these cases, the washing op-

eration must be terminated and the washing cycle begun again with a

lower water pressure or higher engine loading.

Version 4

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning turbine blades and nozzle ring 5.4 Page 21

in operation

5.4.2 Integrated dry cleaning of the turbine and nozzle ring during opera-

January 2007

tion

This cleaning method is not suitable for removing thick dirt deposits and

must therefore be carried out more often (see chapter Cleaning turbine

blades and nozzle ring in operation).

NOTE

Operating state preconditions for integrated dry cleaning device

In order to carry out a successful cleaning procedure that has been

HZTL2491_EN (TPL85-B14/-B15/-B16)

tested and is recommended by ABB Turbo Systems, the following pre-

conditions must be met:

NOTE

Z High engine output (50 to 100%) and high turbocharger speed.

Z Gas inlet temperature upstream of the turbine must be below 590°C.

Otherwise, there is considerable danger that the dry cleaning agent

will be burnt off.

X Start the cleaning cycle with reference to the following description

Operating procedure for integrated dry cleaning device.

Version 4

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning turbine blades and nozzle ring 5.4 Page 22

in operation

Operation of integrated dry cleaning device

January 2007

HZTL2491_EN (TPL85-B14/-B15/-B16)

L_00094

1 Container for granulated mate- 5 ON/OFF valve

rial

Version 4

2 Trap-cover 6 Safety valve

3 Compressed air supply [4 to 10 7 Combined air valve/pressure

bar] relief valve

4 Pipe made from stainless steel 8 Cleaning instructions

The air system must be protected against overpressure (> 10 bar).

CAUTION

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning turbine blades and nozzle ring 5.4 Page 23

in operation

Operation of the dry Z The Operating state preconditions for integrated dry cleaning must be

satisfied before cleaning is begun.

January 2007

cleaning device

X Ensure that the ON/OFF valve (5) is closed.

X Check that the combined air valve/pressure relief valve (7) is in the

pressure relief position.

X Open the trap-cover (2) carefully.

X Fill the container (1) with the prescribed amount of granulate.

X Close and seal the trap-cover (2).

X Open the air valve (7).

X Open the safety valve (6).

X Whilst cleaning the turbine, open the ON/OFF valve (5) and leave it

open for approx. 1 minute.

X Close the ON/OFF valve (5).

X Close the safety valve (6).

HZTL2491_EN (TPL85-B14/-B15/-B16)

X Set the combined air valve/pressure relief valve (7) to the pressure re-

lief position.

X Check whether the exhaust gas temperature has dropped downstream

of the turbine.

In order to obtain the best possible cleaning effect, it is essential that

the prescribed quantity of granulate is blown in.

The drain openings in the gas outlet casing must remain closed while

NOTE the turbine is being cleaned. Careless handling can cause incompletely

combusted soot particles to escape.

If the cleaning operation is unsuccessful, it can be repeated up to 2 ti-

mes.

If cleaning is still unsuccessful after three attempts and the engine op-

Version 4

NOTE erating values are unsatisfactory, we recommend that the turbocharger

be checked and cleaned by an official ABB Turbo Systems service sta-

tion.

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning turbine blades and nozzle ring 5.4 Page 24

in operation

Cleaning parameters for integrated dry cleaning device

January 2007

Selection of materials The following materials are suitable for use in dry cleaning:

Hard, granulated materials (such as natural core granulates)

Softblast media

Activated carbon particles

The average grain size of the cleaning granulate must be between 1.2

and 2.0 mm.

HZTL2491_EN (TPL85-B14/-B15/-B16)

The specific weight of the cleaning granulate must not exceed 1.2 kg/dm3.

Granulate quantity per TPL 69BA TPL 73-B TPL 77-B TPL 80-B TPL 85-B TPL 91-B

turbocharger [litres]

1.0 1.0 1.5 2.0 3.0 3.5

The cleaning granulate must be stored in a dry, clean place in order to

avoid clogging the pipes during cleaning.

The table in chapter Suppliers of dry cleaning agents lists possible sup-

NOTE pliers of dry cleaning agents.

Version 4

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning turbine blades and nozzle ring 5.4 Page 25

in operation

5.4.3 Non-integrated dry cleaning device for the turbine and nozzle ring

January 2007

during opration

As an alternative to the built-in dry cleaning system, a non-integrated dry

cleaning device can be installed upstream of the gas inlet casing by the

engine manufacturer.

Operating state preconditions for non-integrated dry cleaning device

In order to carry out a successful cleaning procedure that has been

tested and is recommended by ABB Turbo Systems, the following pre-

conditions must be met:

HZTL2491_EN (TPL85-B14/-B15/-B16)

NOTE

Z High engine output (50 to 100%) and high turbocharger speed.

Z Gas inlet temperature upstream of the turbine must be below 590°C.

Otherwise, there is considerable danger that the dry cleaning agent

will be burnt off.

X Start the cleaning cycle with reference to the following description

Operating procedure for non-integrated dry cleaning device.

Version 4

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning turbine blades and nozzle ring 5.4 Page 26

in operation

Operation of non-integrated dry cleaning device

January 2007

HZTL2491_EN (TPL85-B14/-B15/-B16)

Version 4

L_00208

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning turbine blades and nozzle ring 5.4 Page 27

in operation

1 Trap-cover G2“ 6 Strap for securing the container

2 Poss. copper gasket 7 Safety valve with ventilation

3 Double nipple G2“ 8 Compressed air shut-off valve

January 2007

4 Copper gasket 9 Compressed air pipe

(internal diameter 8mm)

5 Friction cock or slide controller 10 Compressed air max. 6 bar

G1''

The air system must be protected against overpressure (> 6 bar).

CAUTION

HZTL2491_EN (TPL85-B14/-B15/-B16)

Operation of the dry Z The Operating state preconditions for non-integrated dry cleaning de-

cleaning device vice must be satisfied before cleaning is begun.

Z Friction cock or slide controller (5) closed and safety valve with ventila-

tion (7) open.

X Close the safety valve with ventilation (7).

X Tighten the trap-cover (1).

X Open the compressed air shut-off valve (8) so that deposits and any

condensation are blown off.

X Close the compressed air shut-off valve (8) again after about 3 min-

utes.

X Close the friction cock / slide controller (5).

X Open the safety valve with ventilation (7) to blow out the exhaust ga-

ses.

X Open the trap-cover (1) on the granulate container carefully.

X Fill the granulate container with the prescribed quantity of granulate.

X Close and seal the trap-cover (1).

X Close the safety valve with ventilation (7).

X Open the compressed air shut-off valve (8).

X Open the friction cock or slide controller (5) for approx. 1 minute.

X Close the friction cock or slide controller (5).

Version 4

X Close the compressed air shut-off valve (8).

X Open the safety valve with ventilation (7).

X Check whether the exhaust gas temperature has dropped downstream

of the turbine.

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Cleaning turbine blades and nozzle ring 5.4 Page 28

in operation

In order to obtain the best possible cleaning effect, it is essential that

the prescribed quantity of granulate is blown in.

January 2007

The drain openings in the gas outlet casing must remain closed while

NOTE the turbine is being cleaned. Careless handling can cause incompletely

combusted soot particles to escape.

If the cleaning operation is unsuccessful, it can be repeated up to 2 ti-

mes.

If cleaning is still unsuccessful after three attempts and the engine op-

NOTE erating values are unsatisfactory, we recommend that the turbocharger

be checked and cleaned by an official ABB Turbo Systems service sta-

tion.

HZTL2491_EN (TPL85-B14/-B15/-B16)

Cleaning parameters for the non-integrated dry cleaning device

The choice of material takes place according to chapter Integrated dry

cleaning of the turbine and nozzle ring during operation.

NOTE

Granulate quantity per Turbocharger type Amount of granulate Container size

turbocharger [dm3]

TPL 69BA 1.0 II

TPL 73-B 1.0 II

TPL 77-B 1.5 II

TPL 80-B 2.0 II

TPL 85-B 3.0 III

Version 4

TPL 91-B 3.5 III

ABB Turbo Systems Ltd

Operation Manual

Maintenance 5

Suppliers of materials for dry cleaning 5.5 Page 29

5.5 Suppliers of materials for dry cleaning

Manufacturer Country Address Number for contact

January 2007

ABB Service Australia 20 Queen Street Tel. +61 2 9795310

Revesby Sydney Fax. +61 2 9773 8855

NSW 2212

Paul Auer GmbH Germany Bad Kreuznacher Str. 81 Tel. +49,621,727 69 -0

68309 Mannheim-Käfertal Fax. +49 621 717 6988