Professional Documents

Culture Documents

Domestic Construction - Timber Framing - Completion Checklist

Uploaded by

alee00070 ratings0% found this document useful (0 votes)

347 views3 pagesWall framea

Original Title

Wall Frames Text Part 2

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWall framea

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

347 views3 pagesDomestic Construction - Timber Framing - Completion Checklist

Uploaded by

alee0007Wall framea

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 3

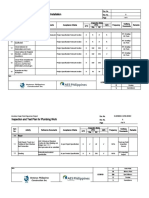

Domestic Construction – Timber Framing –

Completion Checklist

Owner:

Builder: QBCC Licence:

Project:

Site Address:

Supervisor: Phone No:

Date: Job No:

Component / Action/Comment

Check plans and contract

documents for any variations

Room set outs and wall locations

consistent with approved plans

Wall frame plumb and straight

sufficient to receive wall finishes

Tie down fixings to slab at least

50mm from slab edge

Bottom plate not overhanging

slab edge by more than 10mm.

All wall bracing in position as

required on approved plans and

properly fixed including tie-down

rods. Nails not overdriven

Roof and truss point loads

supported and blocked if required

Truss layout consistent with truss

plan and fixed at correct centres

Trusses plumb (max allowable

50mm or height/50) and not

bowed (max allowable 50mm or

bowed section/200)

Saddle trusses properly fixed to

supporting truss top chord

Roof tie down in accordance with

approved plans and truss

manufacturers requirements

Strengthening for installation of

solar hot water system installed

Roof steel bracing properly

installed in accordance with truss

plan. Where fixed to wall frame

bracing nailed flat to avoid

interfering with wall sheet or

cornice

Truss bottom chord bracing

This example is a guide

only and not a QBCC

recommendation

Current as at: May 2011

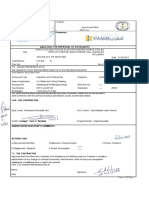

Domestic Construction – Timber Framing –

Completion Checklist

Owner:

Builder: QBCC Licence:

Project:

Site Address:

Supervisor: Phone No:

Date: Job No:

Component / Action/Comment

installed where suspended

ceilings or metal furring channel

ceiling battens used.

Binders installed

Transfer noggings installed

connecting bracing walls to

trussed roof frame

Non load bearing walls set down a

minimum of ceiling batten depth

+ 10mm from the level of

external load bearing walls.

Non load bearing walls connected

to trusses with slotted wall

brackets where required.

Entry bulkheads straight and level

Ceilings nogged for plaster sheet

joins and at change of direction

Internal door opening sizes

consistent with plans

Bottom plate removed from all

internal doorways

Internal bulkheads installed

plumb and straight

Plumbing duct and vent pipe

framing plumb and straight

Lintel sizes as shown on approved

plan

Windows fixed in accordance with

window manufacturers

requirements or Aust Window

Assoc. recommendations

Windows plumb and level

Bath properly framed up and

supported with appropriate

clearance for tiles and sheeting

Nogging installed for WC cistern

and toilet roll holder

Nogging installed for ensuite

cistern and toilet roll holder

Nogging installed for bathroom

towel rails

This example is a guide

only and not a QBCC

recommendation

Current as at: May 2011

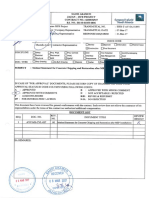

Domestic Construction – Timber Framing –

Completion Checklist

Owner:

Builder: QBCC Licence:

Project:

Site Address:

Supervisor: Phone No:

Date: Job No:

Component / Action/Comment

Nogging installed for ensuite

towel rail

Noggings installed for panel lift

door

Noggings installed for clothes

dryer

Other noggings required and

installed

Manhole correctly positioned &

framed.

Fascia fixed and aligned properly

Fascia properly aligned for

external cladding or brickwork

where there is no eaves overhang

Trimmers and battens installed to

eaves to properly fix eaves lining

Temporary bracing removed

Windows checked to ensure they

are not damaged

House swept and clear of debris

Site clear of rubbish

Frame inspection passed

Sub-Contractor: QBCC Licence:

This example is a guide

only and not a QBCC

recommendation

Current as at: May 2011

You might also like

- Understanding the NDIS (BOOKLET 1 OF 3Document12 pagesUnderstanding the NDIS (BOOKLET 1 OF 3alee0007No ratings yet

- Understanding the NDIS (BOOKLET 1 OF 3Document12 pagesUnderstanding the NDIS (BOOKLET 1 OF 3alee0007No ratings yet

- Documents Checklist For Foundation Plan Submission Typical Items RequirementsDocument10 pagesDocuments Checklist For Foundation Plan Submission Typical Items RequirementsChan Kin CheungNo ratings yet

- Victoria Police Codes and Abbervations For RadioDocument3 pagesVictoria Police Codes and Abbervations For Radioalee00070% (1)

- Technical Specification: External CladdingDocument36 pagesTechnical Specification: External Claddingalee0007No ratings yet

- Saudi Oger Ltd. (Project Name) : PlasteringDocument1 pageSaudi Oger Ltd. (Project Name) : PlasteringAnthony AngelesNo ratings yet

- Itp Package UnitDocument2 pagesItp Package UnitWasim AhmedNo ratings yet

- Inspection ChecklistDocument1 pageInspection ChecklistMohammad Hadoumi Saldan100% (1)

- Construction MethodologyDocument15 pagesConstruction MethodologyLorens RiezaNo ratings yet

- Itp Lot 28Document94 pagesItp Lot 28Wahyu Rohmad DiantoNo ratings yet

- C4M Mivan FormworkDocument3 pagesC4M Mivan Formworkmanohar reddyNo ratings yet

- Inspection & Test Plan Project Name: Coring and Concrete Cutting of R/C WallsDocument1 pageInspection & Test Plan Project Name: Coring and Concrete Cutting of R/C WallsA S80% (5)

- Method Statement for Slab Ground Floor ConstructionDocument11 pagesMethod Statement for Slab Ground Floor ConstructiondeviesrigatiNo ratings yet

- Quality Systems Manual Method Statement: Tiling Work (Floors and Walls)Document8 pagesQuality Systems Manual Method Statement: Tiling Work (Floors and Walls)Lloyd MariNo ratings yet

- Inspection & Test Plan (Itp) : Gypsum Board False CeilingDocument1 pageInspection & Test Plan (Itp) : Gypsum Board False CeilingLOPA THANDARNo ratings yet

- Demolition 4 PDFDocument19 pagesDemolition 4 PDFazrulNo ratings yet

- Furniture Making, Advanced Projects in Woodwork - 1917Document72 pagesFurniture Making, Advanced Projects in Woodwork - 1917workshopcarpintaria100% (7)

- 007 MS - Kerb & Interlocking Tiles InstallationDocument3 pages007 MS - Kerb & Interlocking Tiles InstallationAnonymous iI88LtNo ratings yet

- Erection Method StatementDocument8 pagesErection Method Statementjones100% (1)

- Building Estimation Excel Sheet 1Document16 pagesBuilding Estimation Excel Sheet 1Jheremae DeypalubosNo ratings yet

- Method Statement & Itp For Waterproofing WorkDocument7 pagesMethod Statement & Itp For Waterproofing WorkRumi ZamNo ratings yet

- MS-CVL-009 Erection of Hollowcore Slabs 1Document12 pagesMS-CVL-009 Erection of Hollowcore Slabs 1Suju RajanNo ratings yet

- Check List For Backfilling WorksDocument2 pagesCheck List For Backfilling WorksYash SharmaNo ratings yet

- Building InspectionsDocument2 pagesBuilding InspectionsSuresh DevarajanNo ratings yet

- ITP For Handrail WeldingDocument2 pagesITP For Handrail WeldingKumar AbhishekNo ratings yet

- Cat Ladder Details3Document36 pagesCat Ladder Details3Shoaib KhanNo ratings yet

- MS # 00 Method Statement For Waterproofing MembraneDocument9 pagesMS # 00 Method Statement For Waterproofing MembraneMGNo ratings yet

- Cost AnalysisDocument12 pagesCost AnalysisAzmi Suhardi100% (2)

- Method Statement For False Ceiling WorksDocument8 pagesMethod Statement For False Ceiling WorkscdnaveenNo ratings yet

- 01 ITP TemplateDocument6 pages01 ITP TemplateHelsy FuentesNo ratings yet

- ITP Temporary HoardingDocument1 pageITP Temporary HoardingMohd Azrin100% (1)

- Quotation and Invoice TemplateDocument10 pagesQuotation and Invoice TemplateMcDonald WesleyNo ratings yet

- Small Double Oor House Plan With 3 Bedroom and Stunning ExteriorDocument3 pagesSmall Double Oor House Plan With 3 Bedroom and Stunning Exteriorsaneesh81No ratings yet

- Method Statement For Stone WorksDocument10 pagesMethod Statement For Stone WorksRangamal DahanayakeNo ratings yet

- Demolition Permit Application GuidelinesDocument2 pagesDemolition Permit Application Guidelinesalee0007No ratings yet

- Demolition Permit Application GuidelinesDocument2 pagesDemolition Permit Application Guidelinesalee0007No ratings yet

- Importing From China EbookDocument103 pagesImporting From China Ebookalee0007No ratings yet

- SWMS DemolitionDocument18 pagesSWMS Demolitionalee0007100% (1)

- Method of Statement (Open Cut)Document14 pagesMethod of Statement (Open Cut)Syed FaizNo ratings yet

- Installation of Steel Doors Method StatementDocument5 pagesInstallation of Steel Doors Method StatementEmadHassanNo ratings yet

- Tiling WorksDocument21 pagesTiling WorksGhayas JawedNo ratings yet

- Method Statement For Casting of Cement Based ScreedDocument8 pagesMethod Statement For Casting of Cement Based Screedmd_rehan_2No ratings yet

- Tamil Nadu Fire Rescue Licence AppDocument3 pagesTamil Nadu Fire Rescue Licence AppViswanathan Krish0% (1)

- Cable Containment ITPDocument1 pageCable Containment ITPwagwahkiabatheNo ratings yet

- Inspection & Test Plan For DrywallDocument2 pagesInspection & Test Plan For Drywallexia1992100% (1)

- ITP Check List For Metal Deck InstallationDocument2 pagesITP Check List For Metal Deck InstallationLeo PascualNo ratings yet

- ITP For Caprentry & Joinery WorksDocument2 pagesITP For Caprentry & Joinery Worksexia19920% (2)

- Inspection & Test Plan (Itp) :plasteringDocument1 pageInspection & Test Plan (Itp) :plasteringLOPA THANDAR100% (1)

- Method Statement InstallationDocument22 pagesMethod Statement InstallationrayNo ratings yet

- 044 ITP For Installation of Gypsum Board Buildings PDFDocument10 pages044 ITP For Installation of Gypsum Board Buildings PDFHarshvardhan PathakNo ratings yet

- Inspection Checklist Masonry WallDocument3 pagesInspection Checklist Masonry WallJonatan LopezNo ratings yet

- Demolition ProcedureDocument3 pagesDemolition Procedurealee0007100% (1)

- Block Work CHK ListDocument1 pageBlock Work CHK Listhafis100% (1)

- Triveni Kala Sangam India International Center Case StudyDocument1 pageTriveni Kala Sangam India International Center Case StudyHamzah AbdullahNo ratings yet

- Method Statement Trial TrenchDocument6 pagesMethod Statement Trial TrenchSasi KumarNo ratings yet

- 6.method Statement Steel Erection and CladdingDocument4 pages6.method Statement Steel Erection and Claddingشاز إياسNo ratings yet

- Method Statement and SpecificationDocument17 pagesMethod Statement and SpecificationApai MfarNo ratings yet

- Inspection Checklist For Precast Gully Installation: Form No: C851/6-CLT-QMT-0002 Rev.00Document1 pageInspection Checklist For Precast Gully Installation: Form No: C851/6-CLT-QMT-0002 Rev.00JabinNo ratings yet

- Comparative Analysis of B.P. 220, P.D. 1096, P.D. 957 and Fire CodeDocument8 pagesComparative Analysis of B.P. 220, P.D. 1096, P.D. 957 and Fire CodeyllaNo ratings yet

- Inspection Test Plan ITP Painting WorksDocument4 pagesInspection Test Plan ITP Painting WorksMichael AntipuestoNo ratings yet

- Site Quality File-Test and Inspection Plan: Activity Curtain WallDocument3 pagesSite Quality File-Test and Inspection Plan: Activity Curtain WallFernando Burgos0% (1)

- Method Statement For Coring On Hollow Core Slab To Provide Holes For MEP Service Line OpeningsDocument6 pagesMethod Statement For Coring On Hollow Core Slab To Provide Holes For MEP Service Line Openingsmd_rehan_2No ratings yet

- Method Statement For Block Works - Rev01Document19 pagesMethod Statement For Block Works - Rev01rayNo ratings yet

- Masteremaco S 422Document3 pagesMasteremaco S 422shahidNo ratings yet

- Progress Report No. 2-Dhangadhi PDFDocument6 pagesProgress Report No. 2-Dhangadhi PDFIrah IrakihdaNo ratings yet

- Method Statement: Al Andalus Trdg. & Elect. Cont. Co. L.L.CDocument32 pagesMethod Statement: Al Andalus Trdg. & Elect. Cont. Co. L.L.CAva GhaziNo ratings yet

- Ms - Chipping and Restoration On Mep InstallationsDocument8 pagesMs - Chipping and Restoration On Mep Installationsmoytabura9667% (3)

- Ayala Triangle Gardens: Roughing Installation (Drop-Off Landscape Lightings)Document6 pagesAyala Triangle Gardens: Roughing Installation (Drop-Off Landscape Lightings)james alfarasNo ratings yet

- Concreting WorksDocument42 pagesConcreting WorkscdnaveenNo ratings yet

- Annual building checklist for safety and maintenanceDocument9 pagesAnnual building checklist for safety and maintenanceNur MajNo ratings yet

- BRT-Peshawer-Package-I-Reach-I - METHOD STATEMENTDocument66 pagesBRT-Peshawer-Package-I-Reach-I - METHOD STATEMENTRizwanNo ratings yet

- MOS Civil EngineeringDocument19 pagesMOS Civil EngineeringSahar GulNo ratings yet

- Inspection & Test Plan: Stone Works As Shown in The DrawingsDocument2 pagesInspection & Test Plan: Stone Works As Shown in The DrawingsharikrishnaNo ratings yet

- Checklist Mechanical Block-Outs and Pipe SleevesDocument2 pagesChecklist Mechanical Block-Outs and Pipe SleevesImho Tep100% (1)

- Section 03 Site Clearance N Demolition PDFDocument11 pagesSection 03 Site Clearance N Demolition PDFlakmalperera1986100% (1)

- DSR 2013Document472 pagesDSR 2013Anjaneyulu BodhanapuNo ratings yet

- Qual Checklist Construction V 120140721Document10 pagesQual Checklist Construction V 120140721Anonymous ZWfHOdSNo ratings yet

- Demolition Specification BCA Building Classes 1 and 10Document8 pagesDemolition Specification BCA Building Classes 1 and 10alee0007No ratings yet

- Demolition Building Work ProcedureDocument8 pagesDemolition Building Work ProcedureMersi BukuNo ratings yet

- Examples of Image Analysis Using ImageJDocument2 pagesExamples of Image Analysis Using ImageJMarcela Morales GeddaNo ratings yet

- The Nature of Psychological Thresholds: Theoretical NoteDocument6 pagesThe Nature of Psychological Thresholds: Theoretical Notealee0007No ratings yet

- Dp80 7. Seriousness and Proof of DamageDocument10 pagesDp80 7. Seriousness and Proof of Damagealee0007No ratings yet

- Victorian Local Government Best Practice Procurement Guidelines 2013Document147 pagesVictorian Local Government Best Practice Procurement Guidelines 2013alee0007No ratings yet

- VT TestingDocument5 pagesVT Testinggogo36No ratings yet

- NDIS014 Participant Pathwa y Book2 16pp A4 Accessible PDFDocument16 pagesNDIS014 Participant Pathwa y Book2 16pp A4 Accessible PDFNgaire TaylorNo ratings yet

- Fortnightly Tax Table 2017 18Document10 pagesFortnightly Tax Table 2017 18nirpatel2No ratings yet

- NDIS014 Participant Pathwa y Book2 16pp A4 Accessible PDFDocument16 pagesNDIS014 Participant Pathwa y Book2 16pp A4 Accessible PDFNgaire TaylorNo ratings yet

- Cost Sheet Framing - BlankDocument1 pageCost Sheet Framing - Blankalee0007No ratings yet

- Demolition Building Work ProcedureDocument8 pagesDemolition Building Work ProcedureMersi BukuNo ratings yet

- Wall Frames Text Part 2Document16 pagesWall Frames Text Part 2charlie20377240No ratings yet

- Concrete Panels Making DesignDocument30 pagesConcrete Panels Making Designalee0007No ratings yet

- F-OPN-05-08b Drawing Control Log (Construction) (Rev. 00)Document4 pagesF-OPN-05-08b Drawing Control Log (Construction) (Rev. 00)diane laine loretoNo ratings yet

- Prestige Willow Tree BrochureDocument42 pagesPrestige Willow Tree BrochurePanama TechnologiesNo ratings yet

- Schedule of DilapidationsDocument6 pagesSchedule of DilapidationsarlekynosNo ratings yet

- Topic - Medical College: Ground Floor Third FloorDocument1 pageTopic - Medical College: Ground Floor Third FloorAr Jitendra KumarNo ratings yet

- Ground Floor Plan: Dated: Client: Project: Sheet Title: Area: ArchitectDocument1 pageGround Floor Plan: Dated: Client: Project: Sheet Title: Area: ArchitectSarmad QureshiNo ratings yet

- Claveria House Plan-5Document19 pagesClaveria House Plan-5Rioma OmarNo ratings yet

- Vip Room 1: Ground FloorDocument1 pageVip Room 1: Ground FloorSKYLERNo ratings yet

- VERMICOMPOST PRODUCTION FACILITY Layout1Document1 pageVERMICOMPOST PRODUCTION FACILITY Layout1Eric Coluban AlipanNo ratings yet

- Symons Street Precinct CitationDocument36 pagesSymons Street Precinct Citationapi-250485405No ratings yet

- HERITAGE INFO SHEET 20 Armidale To RollingstoneDocument2 pagesHERITAGE INFO SHEET 20 Armidale To RollingstoneNgaire TaylorNo ratings yet

- French Embassy Staff Quarters: LOCATION: Chanakyapuri, New Delhi, India ARCHITECT: Raj Rewal Construction Period: 1968-69Document9 pagesFrench Embassy Staff Quarters: LOCATION: Chanakyapuri, New Delhi, India ARCHITECT: Raj Rewal Construction Period: 1968-69Ahnaf Nafim ShirajNo ratings yet

- PMı MS Office Project Dubai Mall PDFDocument2 pagesPMı MS Office Project Dubai Mall PDFXozanNo ratings yet

- Erdman Hall DormitoriesDocument26 pagesErdman Hall DormitoriesQuratul Ain MalickNo ratings yet

- Abhijit Auditorium Elective Sem 09Document3 pagesAbhijit Auditorium Elective Sem 09Abhijit Kumar AroraNo ratings yet

- Door Drawings & DetailsDocument1 pageDoor Drawings & DetailsHusain Al-AsfoorNo ratings yet

- Ground Floor Plan of Residence by Jankal ArchitectsDocument5 pagesGround Floor Plan of Residence by Jankal ArchitectsNaveen Kumar T SNo ratings yet

- Esherick House DrawingsDocument1 pageEsherick House DrawingsFbli FistikNo ratings yet

- Defect ReportDocument45 pagesDefect ReportMunie ZainonNo ratings yet

- All Labor Rates 2023Document4 pagesAll Labor Rates 2023ashish SinghNo ratings yet

- M.harut ModelDocument1 pageM.harut Modelfa4382246No ratings yet

- 40X60 East DuplexDocument1 page40X60 East DuplexPhaniraj RamachandrulaNo ratings yet

- 14 - Desain Konstruksi Tempat Penyimpanan (Tampak Atas, Samping Depan)Document1 page14 - Desain Konstruksi Tempat Penyimpanan (Tampak Atas, Samping Depan)Joe GrosirNo ratings yet

- 119 Madison EIG Application FINALDocument12 pages119 Madison EIG Application FINALcinemapprenticeNo ratings yet