Professional Documents

Culture Documents

Pre-Evaluation Before Maintenance

Uploaded by

ultraspeedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pre-Evaluation Before Maintenance

Uploaded by

ultraspeedCopyright:

Available Formats

COLUMN

Pre-evaluating before maintenance

O

When performing ne must evaluate the media: Is it a

clean gas, or is it heavy hydrocarbons

maintenance on a with a lot of pollution? Is there an

leaky ball valve, aggressive or sour media, or is it soft?

Then the construction of the valve: Is it self-

there is a lot of relief or double piston? Is the valve soft seated

information that with soft PTFE or is it a harder material such as

PEEK? Or is it metal to metal with a tungsten

must be evaluated carbide layer on the ball and seats? What type

before the actual of radial seals are there on the seats? Are they

O-rings, chevrons or lip seals? How is the valve

maintenance is operated? Is it opened with differential pressure,

carried out. Part 12 or fully equalized?

Is the cavity equalized or not? Has the valve

in a series on the been closed with full flow through the valve?

how (and why) of How often is the valve operated – once a week

or once a year? How fast is the valve operated?

maintenance. Then the two most important questions; is the

valve equipped with lubrication fittings to the

By Ingolf Fra Holmslet seat, if so, how many to each seat? Is the valve

equipped with an auxiliary valve to the cavity?

If the valve is equipped with fittings and an

auxiliary valve there are (as we have seen from

previous articles) a lot of possibilities for main-

tenance, and in many cases the valve may be

100% cured, but in other cases it may be worse

after cleaning, it is not the maintenance that has

damaged the valve, but the maintenance has

uncovered the state of the valve.

Jumping to conclusions

In this article, I will discuss two cases occurring

on two large valves, one where I was misled Figure 64

by my own assessment and one where I was

lucky when performing the fix. I am using those

cases to illustrate how one can be fooled into first barrier and should have been 100% sealed,

jumping to conclusions, or how one can be but the valve was leaking too much. The valve

lucky when doing the right assessment. The first information was as follows: Self-relief construc-

example involved a top entry trunnion ball valve tion on the seats which sealed on the upstream

containing 140 bar clean sales gas with conden- seat only. As illustrated in Figure 65 the valve

sate. In this case the valve was needed as a was equipped with soft-seated seats with PEEK

About the expert

Ingolf Fra Holmslet is a

Norwegian consultant and valve

iinstructor through

hhis company Klyde

CConsultants AS.

IIngolf can be

ccontacted at

IIngolf@valve.no

wwww.valve.no.

Figure 65

1 Valve World March 2018 www.valve-world.net

C OLUMN

Figure 66 Figure 67

“

inserts. As also illustrated in Figure 65 the had tricked me as the O-rings were in

radial seals on the seats were O-rings. The perfect condition. But, as illustrated in

Don’t jump to

valve was normally in the open position, Figure 66, the seal area on the seats was conclusions, the devil

operated only one or two times a year and full of hard particles that were stuck on is in the detail

had been in service for about 10 years. The the seat. The particles were some 10th of

valve was never closed in flowing condition a millimetre high and prevented the seat

or opened with differential pressure. from coming into contact with the ball. We seats sideways in the seat pocket, increas-

At the assessment phase there seemed to found the same black stuff in the spring ing the gap between the seat and seat

be a simple solution on the problem. My pockets and on the coil springs, illustrated pocket at 3 o´clock and reducing the gap at

argumentation was as follows: not opened in Figure 64. 9 o´clock. If the tolerance between the seat

with differential pressure, not closed at As the media was clean gas and conden- and the seat pocket were in the maximum

a flowing condition and maximum opera- sate I was quite puzzled. I did clean the and minimum area, one could get a lack of

tions 20 closures and 20 openings equals seats with valve cleaner and, as illustrated contact between the lip seal and the seat

40 of 90 degrees movement. With so few in Figure 67, the particles on the seal area pocket at 3 o´clock, creating a leak path,

operations in a clean media and operating were dissolved. It was decided to replace and subsequently a leaky valve.

with a fully equalized valve I could not see all internal parts, and the particles were My suggestion was: Operate the valve

any reason why the PEEK seal on the seats sent to a laboratory for analysis. The result around 5 mm towards the open position,

should leak. As the media was clean sales was: Under certain conditions (temperature and stop. This trying to centre the seat

gas I did not think that deposits could be and pressure drop) the gas molecules will in the seat pocket and creating lip seal

formed on the ball or seats. That argument bind in chains and transfer from gas to contact all around the seat. Not every-

was also based upon the fact that the con- solid carbon and bind to the seal. body in the production agreed, but they

densate should actually work as a cleaner I have never seen this before, but it humoured me.

on the seal surfaces. My conclusion to this taught me an important lesson: If the valve We set it up with the instrument person-

problem was that the O-ring on the radial has been without maintenance, always nel, me on the top of the actuator ready

seal of the seats may have suffered explo- clean it. It doesn’t matter if the media has to scream out at the first movement of

sive decompression, or RGD, and the leak been clean. If we had cleaned the valve the valve; an instrument technician at the

path was not between the ball and the seat it would have been fixed and probably panel, bypassing the system, moving the

but between the seat and the seat pocket, sealed 100%. valve and stopping at my command. I made

as illustrated in Figure 65. This could be a line across the position plate and waited

fixed by injecting sealing component into Valve got fooled for any movement.

the O-ring groove. In the second case it was the opposite – At the first mm movement of the indicator,

I fooled the valve. I yelled and he stopped the valve with

Fooled by the valve The case involved a 42” ESD valve, less then 5 mm movement and locked the

Because the conclusion in the pre-assess- class 1500 metal sealed (TC on ball and valve. When testing the valve after the

ment was RGD in the radial O-ring we did seats) top entry, trunnion ball valve, a movement, you may have guessed it, the

not clean the valve with valve cleaner, but monster of a valve. The media was valve sealed 100% and I was the hero of

regarded that as a waste of time and valve “clean” sales gas. The valve was one of the day.

cleaner. To the seal of the O-ring we in- the outer barriers towards the installation.

jected a fair amount of sealing component, When the valve was closed it was leaking My point being: Don´t jump to conclusions!

I even thought it was too much required to too much to set a barrier, and we knew Remember, “The devil is in the detail”.

seal off the valve. We were unable to seal the rotation of the ball was correct. I must

the valve 100% but we managed to get the add that the valve was equipped with lip

valve nearly sealed off and kept the cavity seals as the radial seal on the seat, which

without pressure by opening the auxiliary was important.

valve in the cavity. We managed to do the The valve was without lubrication fittings

required job, but because of the relatively to the seats, and no cavity port for bleed-

large leak rate passing the valve it was ing of the cavity. The valve had been in

decided to repair the valve in the line (top service around 6 years, operated only

entry valve). The whole system was shut for setting a barrier 5 to 6 times. I could The two books: Cheater bar for valves

down and depressurised to dismantle the not see any reason why this valve should with rotating spindle and Cheater bar for

ball and seats. leak. valves with rising spindles are written by

Ingolf Fra Holmslet and can be ordered

When the seats came out, I could see that The only thing I could come up with was

from his web page www.valve.no

this time I had been fooled by a valve. It that when the ball rotated it dragged the

www.valve-world.net Valve World March 2018 2

You might also like

- Cylinder Valves: Safetygram 23Document12 pagesCylinder Valves: Safetygram 23Gore JiangNo ratings yet

- Valve Failure Analysis: Read the CluesDocument5 pagesValve Failure Analysis: Read the CluesahmedalgaloNo ratings yet

- Repairing Leaky Gate Valves: MarkDocument2 pagesRepairing Leaky Gate Valves: MarkAlfred PabloNo ratings yet

- Valves General For DummiesDocument42 pagesValves General For Dummiesdito100% (7)

- 50 Question Related To ValvesDocument24 pages50 Question Related To ValvesNjat HakimNo ratings yet

- Valve MaintenanceDocument28 pagesValve MaintenanceAdrianne Cook50% (2)

- Marine engineering: Fuel injector o'haul, pump gland packing, SDNR valve, globe valve overhaulDocument24 pagesMarine engineering: Fuel injector o'haul, pump gland packing, SDNR valve, globe valve overhaulVijay PrakashNo ratings yet

- Installation & Operation Manual for ECON Gate ValvesDocument4 pagesInstallation & Operation Manual for ECON Gate Valveslinh phamNo ratings yet

- Module 1 - Basics of Bioprocess Technology: ValvesDocument5 pagesModule 1 - Basics of Bioprocess Technology: ValvesnavneetNo ratings yet

- Marine Engineering PracticeDocument19 pagesMarine Engineering PracticeAnoop Vijayakumar100% (1)

- Ball ValveDocument4 pagesBall ValveArbaz KhanNo ratings yet

- Compressor Valves - Questions and Answers How and Why Compressor Valves FailDocument8 pagesCompressor Valves - Questions and Answers How and Why Compressor Valves Failbinu vaNo ratings yet

- HPTroubleshootingEbookV1 PDFDocument12 pagesHPTroubleshootingEbookV1 PDFJesseNo ratings yet

- Land Cruiser 2F Head Replacement: DiagnosisDocument4 pagesLand Cruiser 2F Head Replacement: DiagnosisWawan SetyawanNo ratings yet

- Valve Live Loading Using Belleville SpringsDocument6 pagesValve Live Loading Using Belleville SpringsBruno ManzettiNo ratings yet

- Ramel LP FinalDocument7 pagesRamel LP FinalRamel RaymousNo ratings yet

- Wom ValvesDocument11 pagesWom ValvesRio IndokniveziaNo ratings yet

- Learning For Oil and Gas PlantDocument93 pagesLearning For Oil and Gas Plantlucky yadavNo ratings yet

- Manual Foil Controls Simplify Rave SailingDocument4 pagesManual Foil Controls Simplify Rave SailingBillKayNo ratings yet

- WNCO Valve's WN-1 Valve MaintenanceDocument5 pagesWNCO Valve's WN-1 Valve MaintenancethritaNo ratings yet

- Inside This Issue: Faq'S TechtipsDocument6 pagesInside This Issue: Faq'S TechtipscarmaNo ratings yet

- ASCO Solenoid Valve Troubleshooting GuideDocument2 pagesASCO Solenoid Valve Troubleshooting GuideNeeraj JangidNo ratings yet

- GhareebDocument17 pagesGhareebMohamed OthmanNo ratings yet

- 215 Instructor GuideDocument46 pages215 Instructor Guidesispot2009No ratings yet

- ValveDocument26 pagesValvetiantaufik100% (1)

- B&G Hydronics Manual - How System Components Really WorkDocument36 pagesB&G Hydronics Manual - How System Components Really WorkrjcantwellNo ratings yet

- Safety Concerns: Relief Valves, Corrosion, and Safety TripsDocument12 pagesSafety Concerns: Relief Valves, Corrosion, and Safety TripsAbhimanyu SharmaNo ratings yet

- Chemical Reactor PDF and ImagesDocument35 pagesChemical Reactor PDF and Imagesdurgaprasad.mNo ratings yet

- Servicing Guide To British Motor V EhiclesDocument1 pageServicing Guide To British Motor V EhiclesStephen CarterNo ratings yet

- Bonetti Piston Valve FactsheetDocument2 pagesBonetti Piston Valve FactsheetRajivharolikarNo ratings yet

- Carb - Nikki StrippingDocument23 pagesCarb - Nikki StrippingLiam FNo ratings yet

- TransmissionDocument2 pagesTransmissionlee washingtonNo ratings yet

- A B C D E F G H I J: The Industrial WikiDocument54 pagesA B C D E F G H I J: The Industrial WikiRashmi SinghNo ratings yet

- Shuttle Review 1BADocument10 pagesShuttle Review 1BAoulitNo ratings yet

- Checking Valves Design and TypesDocument7 pagesChecking Valves Design and Typesmister pogiNo ratings yet

- Preliminary Troubleshooting Guide OutlandDocument15 pagesPreliminary Troubleshooting Guide OutlandMax MarcelinoNo ratings yet

- Installation, Operation and Maintenance Manual For AIL Cast Steel Gate, Globe and Gheck ValvesDocument17 pagesInstallation, Operation and Maintenance Manual For AIL Cast Steel Gate, Globe and Gheck ValvesKarthigeyan R Rkg100% (1)

- Operations and Maintenance ManualDocument18 pagesOperations and Maintenance ManualSupakanit LimsowanNo ratings yet

- Types: List of ValvesDocument9 pagesTypes: List of ValvesJordan MosesNo ratings yet

- Installation Considerations / TroubleshootingDocument22 pagesInstallation Considerations / TroubleshootingSangmin KimNo ratings yet

- LCMS Trouble ShootingDocument68 pagesLCMS Trouble ShootingLuis VilchezNo ratings yet

- Non-Return Valves: An IntroductionDocument23 pagesNon-Return Valves: An IntroductionAli OsmanNo ratings yet

- Valve QuestionnaireDocument5 pagesValve Questionnaireprnsh_k100% (1)

- Troubleshooting Rub Marks in A Centrifugal PumpDocument4 pagesTroubleshooting Rub Marks in A Centrifugal Pumpابو المعالي الهمامNo ratings yet

- Well Completion & Reservoir StimulationDocument14 pagesWell Completion & Reservoir StimulationPhước LêNo ratings yet

- Piping Interview QuestionnaireDocument7 pagesPiping Interview Questionnaireanas060100% (1)

- Tilt CylinderDocument7 pagesTilt Cylinderluis tocoraNo ratings yet

- Valve: These Water Valves Are Operated by HandlesDocument11 pagesValve: These Water Valves Are Operated by Handlesrishangsingh92No ratings yet

- Rocess Afety Eacon: It's A Bird, It's A Plane, It's A PUMP!Document1 pageRocess Afety Eacon: It's A Bird, It's A Plane, It's A PUMP!Alejandro HernandezNo ratings yet

- External Casing Packers ECPDocument1 pageExternal Casing Packers ECPKevin MuellerNo ratings yet

- Basics of ValvesDocument8 pagesBasics of ValvesIsmael KhalilNo ratings yet

- ةرازو يممعلا ثحبلاو يلاعلا ميمعتلا ةيمك رافلا ا عماجلا يب ة ةمحرملا ةيناثلا: Fluid flow2 ةداملا ريرقت ناونعب Butterfly valve نم بلاطلا لبق باهيا دامح ديلو فارشأب ذاتسلاا: ريملاادبع ةزمحDocument18 pagesةرازو يممعلا ثحبلاو يلاعلا ميمعتلا ةيمك رافلا ا عماجلا يب ة ةمحرملا ةيناثلا: Fluid flow2 ةداملا ريرقت ناونعب Butterfly valve نم بلاطلا لبق باهيا دامح ديلو فارشأب ذاتسلاا: ريملاادبع ةزمحHamzah A. LaftaNo ratings yet

- Coleman Vacu PrintDocument2 pagesColeman Vacu PrintAlejandra Vera LopezNo ratings yet

- One Way ValveDocument2 pagesOne Way ValveOzan EGEMENNo ratings yet

- Globe & Gate ValvesDocument6 pagesGlobe & Gate Valvessumit kumarNo ratings yet

- How To Fix A Washing Machine: 9 Common Problems: Attempting RepairsDocument6 pagesHow To Fix A Washing Machine: 9 Common Problems: Attempting RepairsLouieGonzalesNo ratings yet

- Edward Vacuum Pump Rebuild Guide: July 2019Document41 pagesEdward Vacuum Pump Rebuild Guide: July 2019Srikanth GedelaNo ratings yet

- Lt Valves Trunnion Mounted Ball ValvesDocument48 pagesLt Valves Trunnion Mounted Ball ValvesXioamiWangWertNo ratings yet

- Crap, The Shitter Is Broke! -Or- How To Fix Common Problems With Your ToiletFrom EverandCrap, The Shitter Is Broke! -Or- How To Fix Common Problems With Your ToiletNo ratings yet

- C1e 001Document44 pagesC1e 001ultraspeedNo ratings yet

- Valve Leakage Rates Test STDDocument9 pagesValve Leakage Rates Test STDultraspeedNo ratings yet

- VICTREX CT200 Flyer Digital 2018 11Document2 pagesVICTREX CT200 Flyer Digital 2018 11ultraspeedNo ratings yet

- Single Direction Thrust Ball Bearing: Dimensions PerformanceDocument4 pagesSingle Direction Thrust Ball Bearing: Dimensions PerformanceultraspeedNo ratings yet

- 2022 Steel PlatesDocument41 pages2022 Steel PlatesultraspeedNo ratings yet

- Champak Steel & Engineering Co - Champak Steel & Engineering Co - Champak Steel & Engineering CoDocument54 pagesChampak Steel & Engineering Co - Champak Steel & Engineering Co - Champak Steel & Engineering CoHabli MawardiNo ratings yet

- Full Port 2 Piece Ball Valve DN200 - Valve Performance ReportDocument27 pagesFull Port 2 Piece Ball Valve DN200 - Valve Performance ReportSneha ShettyNo ratings yet

- Axk 0619 TN - 20220815Document3 pagesAxk 0619 TN - 20220815Islam MagdyNo ratings yet

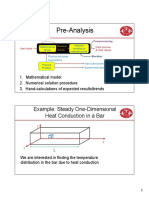

- Pre-Analysis: Example: Steady One-Dimensional Heat Conduction in A BarDocument12 pagesPre-Analysis: Example: Steady One-Dimensional Heat Conduction in A BarultraspeedNo ratings yet

- Chart MultiStartThreadsDocument6 pagesChart MultiStartThreadsultraspeedNo ratings yet

- TAbla Resumen de Calculo de Tanq EsfericoDocument26 pagesTAbla Resumen de Calculo de Tanq EsfericoGuillerm Prudent BaldeonNo ratings yet

- Pre-Analysis: Example: Steady One-Dimensional Heat Conduction in A BarDocument12 pagesPre-Analysis: Example: Steady One-Dimensional Heat Conduction in A BarultraspeedNo ratings yet

- Friction WedgesrtDocument29 pagesFriction WedgesrtShawakAuraNo ratings yet

- TAbla Resumen de Calculo de Tanq EsfericoDocument26 pagesTAbla Resumen de Calculo de Tanq EsfericoGuillerm Prudent BaldeonNo ratings yet

- Torque Curve PDFDocument12 pagesTorque Curve PDFultraspeedNo ratings yet

- Numerical Analysis 323Document161 pagesNumerical Analysis 323maths203No ratings yet

- Sambo Mechanical Advantage BevelDocument3 pagesSambo Mechanical Advantage BevelultraspeedNo ratings yet

- Catalog Di N Tho I Panasonic KX t2375Document2 pagesCatalog Di N Tho I Panasonic KX t2375ultraspeedNo ratings yet

- Tolerance TableDocument2 pagesTolerance TablePrabhanjan BhatNo ratings yet

- Iso 8062Document1 pageIso 8062Asrar Ahmed100% (2)

- Design Standards: Steel Construction ManualDocument1 pageDesign Standards: Steel Construction ManualMiguel Alfonso Ruiz MendezNo ratings yet

- General Tolerances DIN ISO 2768Document2 pagesGeneral Tolerances DIN ISO 2768Vasil Gospodinov83% (23)

- NRI/CIWGC/FN Admission - 2015 Announcement: Centre For International AffairsDocument1 pageNRI/CIWGC/FN Admission - 2015 Announcement: Centre For International AffairsultraspeedNo ratings yet

- Engineering MathematicsDocument234 pagesEngineering Mathematicssangeethsreeni60% (5)

- Iso GD&TDocument39 pagesIso GD&TSanjay Kumar SinghNo ratings yet

- 7158 Windchill QSG enDocument16 pages7158 Windchill QSG enfpmike2870No ratings yet

- Tax Planning Guide 2014 EditionDocument53 pagesTax Planning Guide 2014 EditionKabad SinghNo ratings yet

- 08 Ugauc 2008 Am 14Document6 pages08 Ugauc 2008 Am 14ultraspeedNo ratings yet

- L ProfileDocument20 pagesL Profilemthpcluj9126No ratings yet

- Chemistry Practical Class XDocument11 pagesChemistry Practical Class XAditya PandeyNo ratings yet

- Polyflex 448: High Build EpoxyDocument2 pagesPolyflex 448: High Build EpoxycesarNo ratings yet

- Erba Total Protein PDFDocument2 pagesErba Total Protein PDFAniket dubey100% (1)

- RMS 6th 2019Document14 pagesRMS 6th 2019angelgupta2303No ratings yet

- Hazard AnalysisDocument39 pagesHazard AnalysisvishnuNo ratings yet

- Mineral PropertiesDocument3 pagesMineral PropertiesAji SuhadiNo ratings yet

- Operating Manual SIRIUS 1000-2000 LIN Storage Vessel Art. No 78211329 Da...Document29 pagesOperating Manual SIRIUS 1000-2000 LIN Storage Vessel Art. No 78211329 Da...Bogdan CorbescuNo ratings yet

- Dale Beggs 1 - Production Optimization Using Nodal Analysis (010-016)Document7 pagesDale Beggs 1 - Production Optimization Using Nodal Analysis (010-016)Luz Mary OrtegaNo ratings yet

- Acom 3 2015Document13 pagesAcom 3 2015Joshua WalkerNo ratings yet

- Why SKF - SKF Explorer Spherical Roller Bearings For Vibratory Applications - 06551 - 1 EN PDFDocument2 pagesWhy SKF - SKF Explorer Spherical Roller Bearings For Vibratory Applications - 06551 - 1 EN PDFWildan PriatnaNo ratings yet

- 管径计算表Document11 pages管径计算表Ascend032No ratings yet

- Contamination Control Requirements: Space ShuttleDocument34 pagesContamination Control Requirements: Space ShuttlectrubasNo ratings yet

- Pravara Rural College Pharmacy Industrial Training ReportDocument28 pagesPravara Rural College Pharmacy Industrial Training ReportSudarshan GhogareNo ratings yet

- Turbichem D-Dimer Test OverviewDocument2 pagesTurbichem D-Dimer Test OverviewDharmesh PatelNo ratings yet

- Cascade Aeration Lecture 6 Environmental Engineering Unit Operations Spring 2014Document16 pagesCascade Aeration Lecture 6 Environmental Engineering Unit Operations Spring 2014Song Nguyen NguyenNo ratings yet

- Lead Acid Batteries in Critical ApplicationsDocument24 pagesLead Acid Batteries in Critical Applicationsger80100% (1)

- By Niranjan S. L.N College of Engineering, Raichur.Document29 pagesBy Niranjan S. L.N College of Engineering, Raichur.alistuguiNo ratings yet

- Niosh SHO Exam Notes - Module 3 Question and Answer PDFDocument19 pagesNiosh SHO Exam Notes - Module 3 Question and Answer PDFExcellentdeals4all94% (51)

- 25X5 GI Strip - Data SheetDocument1 page25X5 GI Strip - Data SheetSandeep VijayakumarNo ratings yet

- OzonolysisDocument1 pageOzonolysisThu NguyenNo ratings yet

- Electric Breakdown in Gases GuideDocument80 pagesElectric Breakdown in Gases GuideHafsa Ijaz50% (2)

- Summary of Scigress Commands Practical 1: Task Scigress Command Shortcut Comments/notesDocument4 pagesSummary of Scigress Commands Practical 1: Task Scigress Command Shortcut Comments/notesnoorNo ratings yet

- Standard M Ethods of Test For: Weight of Coating On Zinc-Coated (Galvanized) ) Iron or Steel ArticlesDocument6 pagesStandard M Ethods of Test For: Weight of Coating On Zinc-Coated (Galvanized) ) Iron or Steel ArticlesRichard PalaciosNo ratings yet

- GSI SLV SFI Whitepaper EN PDFDocument9 pagesGSI SLV SFI Whitepaper EN PDFjayahasanNo ratings yet

- Astm A29Document16 pagesAstm A29Nacer KisyNo ratings yet

- Chemset Chemical AnchoringDocument4 pagesChemset Chemical Anchoringthorik achsanNo ratings yet

- Test Bank For Essentials of Genetics 8th Edition by KlugDocument9 pagesTest Bank For Essentials of Genetics 8th Edition by Klugminhkhoit8cua3No ratings yet

- SMAW LessonDocument8 pagesSMAW LessonOJ DogplaceNo ratings yet

- Chemical Reactors and Reactor Sizing: Lecturer: Dr. Ayoola A.ADocument14 pagesChemical Reactors and Reactor Sizing: Lecturer: Dr. Ayoola A.AChuka OmeneNo ratings yet

- Expressing Concentration of Solutions in Different UnitsDocument4 pagesExpressing Concentration of Solutions in Different UnitsKunal Kishor100% (5)