Professional Documents

Culture Documents

RC Beam Multi Layer T

Uploaded by

YHK3001Original Title

Copyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRC Beam Multi Layer T

Uploaded by

YHK3001Project Job no.

Calcs for Start page no./Revision

1

Calcs by Calcs date Checked by Checked date Approved by Approved date

11/4/2019

RC MEMBER DESIGN

In accordance with EN1992-1-1:2004 incorporating Corrigenda January 2008 and the UK national annex

Tedds calculation version 3.2.02

Concrete details - Table 3.1. Strength and deformation characteristics for concrete

Concrete strength class; C35/45

Aggregate type; Quartzite

Aggregate adjustment factor - cl.3.1.3(2); AAF = 1.0

Characteristic compressive cylinder strength; fck = 35 N/mm2

Mean value of compressive cylinder strength; fcm = fck + 8 N/mm2 = 43 N/mm2

Mean value of axial tensile strength; fctm = 0.3 N/mm2 (fck/ 1 N/mm2)2/3 = 3.2 N/mm2

Secant modulus of elasticity of concrete; Ecm = 22 kN/mm2[fcm/10 N/mm2]0.3 AAF = 34077 N/mm2

Ultimate strain - Table 3.1; cu2 = 0.0035

Shortening strain - Table 3.1; cu3 = 0.0035

Effective compression zone height factor; = 0.80

Effective strength factor; = 1.00

Coefficient k1; k1 = 0.40

Coefficient k2; k2 = 1.0 (0.6 + 0.0014 / cu2) = 1.00

Coefficient k3; k3 = 0.40

Coefficient k4; k4 = 1.0 (0.6 + 0.0014 / cu2) = 1.00

Partial factor for concrete -Table 2.1N; C = 1.50

Compressive strength coefficient - cl.3.1.6(1); cc = 0.85

Design compressive concrete strength - exp.3.15; fcd = cc fck / C = 19.8 N/mm2

Compressive strength coefficient - cl.3.1.6(1); ccw = 1.00

Design compressive concrete strength - exp.3.15; fcwd = ccw fck / C = 23.3 N/mm2

Maximum aggregate size; hagg = 20 mm

Monolithic simple support moment factor; 1 = 0.25

Reinforcement details

Characteristic yield strength of reinforcement; fyk = 500 N/mm2

Partial factor for reinforcing steel - Table 2.1N; S = 1.15

Design yield strength of reinforcement; fyd = fyk / S = 435 N/mm2

Nominal cover to reinforcement

Nominal cover to top reinforcement; cnom_t = 35 mm

Nominal cover to bottom reinforcement; cnom_b = 35 mm

Nominal cover to side reinforcement; cnom_s = 35 mm

Fire resistance

Standard fire resistance period; R = 60 min

Number of sides exposed to fire; 3

Minimum width of beam - EN1992-1-2 Table 5.5; bmin = 120 mm

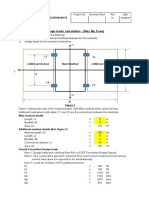

Section 1 - Multiple layers

Flanged section details

Section width; b = 300 mm

Section depth; h = 500 mm

Maximum available flange width; bf = 1250 mm

Flange depth; hf = 200 mm

Allowance for holes; bhole = 0 mm

Project Job no.

Calcs for Start page no./Revision

2

Calcs by Calcs date Checked by Checked date Approved by Approved date

11/4/2019

PASS - Minimum dimensions for fire resistance met

1250

2 × 16f

200

2 × 8 legs @ 300 c/c

300

2 × 20f

3 × 20f

300

Positive moment - section 6.1

Design bending moment; M = Mpos_s1 = 250.0 kNm

Distance between points of zero moment; L0 = L0 = 1000 mm

Maximum flange outstand; b1 = (bf - b) / 2 = 475 mm

Effective flange outstand; beff,1 = min(0.2 b1 + 0.1 L0, 0.2 L0, b1) = 195 mm

Effective flange width; beff = 2 beff,1 + b = 690 mm

Effective depth of tension reinforcement; d = 429 mm

Redistribution ratio; = min(pos_s1, 1) = 1.000

K = M / (beff d2 fck) = 0.056

K' = (2 cc / C) (1 - ( - k1) / (2 k2)) ( ( - k1) / (2 k2))

= 0.207

Lever arm; z = min(0.5 d [1 + (1 - 2 K / ( cc / C))0.5], 0.95 d) = 407 mm

Depth of neutral axis; x = 2 (d - z) / = 56 mm

x <= hf - Compression block wholly within the depth of flange

K' > K - No compression reinforcement is required

Area of tension reinforcement required; As,req = max(M / (fyd z), As,min) = 1414 mm2

Tension reinforcement provided; Layer 1 - 3 20f, Spacing - 25mm, Layer 2 - 2 20f

Area of tension reinforcement provided; As,prov = 1571 mm2

Minimum area of reinforcement - exp.9.1N; As,min = max(0.26 fctm / fyk, 0.0013) b d = 215 mm2

Maximum area of reinforcement - cl.9.2.1.1(3); As,max = 0.04 b h = 6000 mm2

PASS - Area of reinforcement provided is greater than area of reinforcement required

Crack control - Section 7.3

Maximum crack width; wk = 0.3 mm

Design value modulus of elasticity reinf – 3.2.7(4); Es = 200000 N/mm2

Mean value of concrete tensile strength; fct,eff = fctm = 3.2 N/mm2

Stress distribution coefficient; kc = 0.4

Non-uniform self-equilibrating stress coefficient; k = min(max(1 + (300 mm - min(h, b)) 0.35 / 500 mm, 0.65), 1) =

1.00

Actual tension bar spacing; sbar = (b - (2 (cnom_s + fs1_v) + fs1_b_L1 Ns1_b_L1)) / (Ns1_b_L1 - 1) +

fs1_b_L1 = 97 mm

Maximum stress permitted - Table 7.3N; s = 322 N/mm2

Steel to concrete modulus of elast. ratio; cr = Es / Ecm = 5.87

Distance of the Elastic NA from bottom of beam; y = (b h2 / 2 + As,prov (cr - 1) (h - d) + (beff - b) hf (h - hf/2)) / (b

h + As,prov (cr - 1) + (beff - b) hf) = 294 mm

Area of concrete in the tensile zone; Act = b y = 88152 mm2

Minimum area of reinforcement required - exp.7.1; Asc,min = kc k fct,eff Act / s = 351 mm2

PASS - Area of tension reinforcement provided exceeds minimum required for crack control

Quasi-permanent moment; MQP = Mpos_QP_s1 = 160.0kNm

Project Job no.

Calcs for Start page no./Revision

3

Calcs by Calcs date Checked by Checked date Approved by Approved date

11/4/2019

Permanent load ratio; RPL = MQP / M = 0.64

Service stress in reinforcement; sr = fyd As,req / As,prov RPL = 251 N/mm2

Maximum bar spacing - Tables 7.3N; sbar,max = 186.8 mm

PASS - Maximum bar spacing exceeds actual bar spacing for crack control

Minimum bar spacing (Section 8.2)

Top bar spacing; stop = (b - (2 (cnom_s + fs1_v) + fs1_t_L1 Ns1_t_L1)) / (Ns1_t_L1 - 1) = 182.0

mm

Minimum allowable top bar spacing; stop,min = max(fs1_t_L1 ks1, hagg + ks2, 20mm) = 25.0 mm

PASS - Actual bar spacing exceeds minimum allowable

Bottom bar spacing; sbot = (b - (2 (cnom_s + fs1_v) + fs1_b_L1 Ns1_b_L1)) / (Ns1_b_L1 - 1) = 77.0

mm

Minimum allowable bottom bar spacing; sbot,min = max(fs1_b_L1 ks1, hagg + ks2, 20mm) = 25.0 mm

PASS - Actual bar spacing exceeds minimum allowable

Section in shear (section 6.2)

Angle of comp. shear strut for maximum shear; max = 45 deg

Strength reduction factor - cl.6.2.3(3); v1 = 0.6 (1 - fck / 250 N/mm2) = 0.516

Compression chord coefficient - cl.6.2.3(3); cw = 1.00

Minimum area of shear reinforcement - exp.9.5N; Asv,min = 0.08 N/mm2 b (fck / 1 N/mm2)0.5 / fyk = 284 mm2/m

Design shear force at support ; VEd,max = VEd,max_s1 = 120 kN

Min lever arm in shear zone; z = 407 mm

Maximum design shear resistance - exp.6.9; VRd,max = cw b z v1 fcwd / (cot(max) + tan(max)) = 734 kN

PASS - Design shear force at support is less than maximum design shear resistance

Design shear force ; VEd = 105 kN

Design shear stress; vEd = VEd / (b z) = 0.861 N/mm2

Angle of concrete compression strut - cl.6.2.3; = min(max(0.5 Asin(min(2 vEd / (cw fcwd v1),1)), 21.8 deg),

45deg) = 21.8 deg

Area of shear reinforcement required - exp.6.8; Asv,des = vEd b / (fyd cot()) = 238 mm2/m

Area of shear reinforcement required; Asv,req = max(Asv,min, Asv,des) = 284 mm2/m

Shear reinforcement provided; 2 8 legs @ 300 c/c

Area of shear reinforcement provided; Asv,prov = 335 mm2/m

PASS - Area of shear reinforcement provided exceeds minimum required

Maximum longitudinal spacing - exp.9.6N; svl,max = 0.75 d = 322 mm

PASS - Longitudinal spacing of shear reinforcement provided is less than maximum

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AS 4773.1-2010 Masonry in Small BDG (Amdt 1-2011) PDFDocument108 pagesAS 4773.1-2010 Masonry in Small BDG (Amdt 1-2011) PDFYHK3001100% (7)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Steel Truss Bridge Design ExampleDocument63 pagesSteel Truss Bridge Design ExampleCarlos Silva Castillo75% (4)

- Column Base PlateDocument4 pagesColumn Base PlateYHK3001No ratings yet

- Design RCC Over Head TankDocument82 pagesDesign RCC Over Head TankVikram SinghNo ratings yet

- 8 No. 25 MM Diameter Longitudinal Bars Max Link Spacing 400 MM Generally, 240 MM For 500 MM Above and Below Slab/beam and at LapsDocument7 pages8 No. 25 MM Diameter Longitudinal Bars Max Link Spacing 400 MM Generally, 240 MM For 500 MM Above and Below Slab/beam and at LapsYHK3001100% (1)

- Pile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesDocument3 pagesPile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesYHK3001No ratings yet

- Pile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesDocument3 pagesPile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesYHK3001No ratings yet

- Soil Structure Interaction in A Combined Pile RaftDocument22 pagesSoil Structure Interaction in A Combined Pile RaftHunny VermaNo ratings yet

- Question Text: One Sack of RiceDocument102 pagesQuestion Text: One Sack of RiceJelyn Ramirez67% (3)

- Concept of Silo DesignDocument6 pagesConcept of Silo Designv2299No ratings yet

- Calcs for steel beam designDocument3 pagesCalcs for steel beam designYHK3001No ratings yet

- ISA - 750101 - SPBD Sizing Control ValvesDocument72 pagesISA - 750101 - SPBD Sizing Control ValvesJosh FlynnNo ratings yet

- Unsteady Flow in Open ChannelsDocument12 pagesUnsteady Flow in Open Channelskasandra010% (1)

- Mudmat Structural Design Loads Calculation - (Max My Case)Document14 pagesMudmat Structural Design Loads Calculation - (Max My Case)sreekx0073916100% (1)

- Laser Physics Chapter 1Document49 pagesLaser Physics Chapter 1Alexander MintsNo ratings yet

- Timber Fitch Beam PDFDocument4 pagesTimber Fitch Beam PDFYHK3001No ratings yet

- Calcs for steel masonry supportDocument2 pagesCalcs for steel masonry supportYHK3001No ratings yet

- Design of Single-Pitched Roof Truss: Structural FormDocument10 pagesDesign of Single-Pitched Roof Truss: Structural FormRoshan KejariwalNo ratings yet

- Punching Shear EdgeDocument3 pagesPunching Shear EdgeYHK3001No ratings yet

- W15 QDocument6 pagesW15 QRajeshNo ratings yet

- Amali 3 First LawDocument7 pagesAmali 3 First LawNur ShazzyNo ratings yet

- BB Session - Me132p - Lecture 2 KD and DofDocument31 pagesBB Session - Me132p - Lecture 2 KD and Dofkris garciaNo ratings yet

- MR FluidDocument5 pagesMR FluidNithin GowdaNo ratings yet

- 0lecture 6 - Flexural Analysis and Design of Doubly Reinforced SectionsDocument33 pages0lecture 6 - Flexural Analysis and Design of Doubly Reinforced SectionsMazen KhaledNo ratings yet

- Flow Through AnnulusDocument7 pagesFlow Through Annulusamir_hayfaNo ratings yet

- IRS Steel Bridge CodeDocument25 pagesIRS Steel Bridge Codeviv99844No ratings yet

- 024 Review of Methods of Analysis of Test Results From Bi-Directional Static Load TestsDocument5 pages024 Review of Methods of Analysis of Test Results From Bi-Directional Static Load TestsShehabNo ratings yet

- (14-Bands) Application of Analytical K.P Model With Envelope FunctionDocument12 pages(14-Bands) Application of Analytical K.P Model With Envelope FunctiontransfinitumNo ratings yet

- Questions Bank On ELECTROSTATICSDocument3 pagesQuestions Bank On ELECTROSTATICSAlok ShawNo ratings yet

- Static Equilibrium and ElasticityDocument26 pagesStatic Equilibrium and ElasticitydeeparNo ratings yet

- Charlie'S Rss Feed: Liberal Allowable Stress RangeDocument3 pagesCharlie'S Rss Feed: Liberal Allowable Stress RangekparthypanNo ratings yet

- FOUNDADocument22 pagesFOUNDAShaina Mariz PanaliganNo ratings yet

- Speed, Distance WKSTDocument3 pagesSpeed, Distance WKSTBryanne MiethNo ratings yet

- Kinematics of Machinery (Me35) - 1 PDFDocument15 pagesKinematics of Machinery (Me35) - 1 PDFPraveen RajaNo ratings yet

- Engineering MechanicsqpDocument14 pagesEngineering MechanicsqpKrishna MurthyNo ratings yet

- 1-Deformed and Plain Billet-Steel Bars For ConcreteDocument4 pages1-Deformed and Plain Billet-Steel Bars For ConcreteMJKHT100% (1)

- DampedDocument11 pagesDampedAnkitNo ratings yet

- Experimental Investigation of Solid Bed Depth at The Discharge End of Rotary Kilns (Muy Importante Lo Que Voy Hacer) (Impreso)Document8 pagesExperimental Investigation of Solid Bed Depth at The Discharge End of Rotary Kilns (Muy Importante Lo Que Voy Hacer) (Impreso)maanmeroNo ratings yet

- Gasdynamics PDFDocument465 pagesGasdynamics PDFPeri Pitriadi CaralozNo ratings yet