Professional Documents

Culture Documents

Air Balancing: Application Guide

Uploaded by

vtin tinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Balancing: Application Guide

Uploaded by

vtin tinCopyright:

Available Formats

Air Balancing A P P L ICATIO N G U I D E

Redefine your comfort zone. ™ | www.titus-hvac.com

A PP LICAT ION G UIDE

A IR BALANC I N G

Table of Contents

Foreword....................................................................................................................................................................3

Introduction...............................................................................................................................................................3

Methodology..............................................................................................................................................................4

Flow and Pressure Requirements........................................................................................................................4

Example – Air Volume.....................................................................................................................................4

Example – Air Pressure ...................................................................................................................................4

Example – Fan Total Pressure.........................................................................................................................4

Example – Fan Volume....................................................................................................................................4

Definitions..................................................................................................................................................................5

Anemometer.........................................................................................................................................................5

Area Factor............................................................................................................................................................5

Velocity..................................................................................................................................................................5

Velometer..............................................................................................................................................................5

Instrumentation.........................................................................................................................................................6

Preliminary Balancing Steps......................................................................................................................................6

Proportional Balancing Steps....................................................................................................................................7

Grille Free Area..........................................................................................................................................................4

Cross Reference.........................................................................................................................................................5

System Balancing Worksheet...................................................................................................................................6

This document provides general information necessary to balance Titus HVAC equipment. Use this document

along with the specific product flow factors to balance air distribution equipment.

Additional information may be found at the Titus website, its address is www.titus-hvac.com.

Titus, the Titus Spiral, and are trademarks of Titus. All other trademarks, noted or not, are the property of their respective owners.

2 Application Guide - AIR BALANCING Redefine your comfort zone. ™ | www.titus-hvac.com

Foreword

The intention of an air conditioning engineer is to design an air distribution

system to deliver the required air volume to satisfy the space load. The duct

system components are sized to deliver air without excessive balancing.

Under ideal conditions, the pressure loss from the fan to the supply outlets

should be sufficient to overcome the pressure loss through the supply

outlet and distribute the air to the space. This ideal system would require

no further airflow adjustments. However, in reality this condition is usually

not met. Therefore, the system and component balancing is required to

achieve the engineer’s design criteria.

Introduction

When fans operate at a constant speed they have such characteristics

that for a given air flow rate a certain pressure will be developed at

the fan discharge. If the pressure requirement changes, the quantity

of air delivered will also change. It is important to note that each

downstream damper adjustment affects the fan pressure and airflow.

An individual outlet cannot be adjusted without affecting the rest of

the system. Therefore the system must be balanced in accordance with

some systematic procedure. The objective of the manual is to provide a

basic understanding of air conditioning system balancing. The balancing

method presented within this manual uses a velometer positioned by

hand at each grille. The method is generally referred to as the “Chicago

Proportional Balancing” method.

Redefine your comfort zone. ™ | www.titus-hvac.com Application Guide - AIR BALANCING 3

A PP LICAT ION G UIDE

A IR BALANC I N G

Methodology

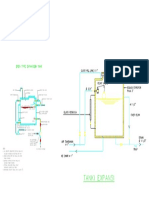

Figure 1 shows a typical example of a fan and duct system pressure EXAMPLE – AIR VOLUME

characteristic. The duct system has four supply outlets with a damper

in each outlet’s branch line. There is also a damper in the main duct At the “a” on the A curve; the required pressure is 1 for 8 units of air

between the fan and the first branch takeoff. Each part of the system has volume flow per unit time. When the flow is increased from 8 units at a “a”

the characteristic that the pressure required to overcome the resistance to 16 units at “b” then,

of that section of the system varies as the square of the volume of air

flowing through it. Curve A shows the pressure characteristic of the last 16 flow units

= 2 and (2)2 = 4

section of the duct from station 0 to 1, curve B represents the system 8 flow units

including the last two supply outlets and so on. The following numerical

Therefore, the required pressure at point “b” is

examples illustrate the relationship between the volume of air flowing

through a section of the system and the required pressure to overcome 1 pressure unit x 4 = 4 pressure units

the resistance of that section.

EXAMPLE – AIR PRESSURE

At the “C” on the B curve, the required pressure is 2 for 8 units of airflow.

When the flow is increased from 8 units at “c” to 12 units at “d” then,

12 flow units =1.5 and (1.5)2 = 2.25

8 flow units

Therefore, the required pressure at point “d” is

2 pressure units x 2.25 = 4.5 pressure units

Example – Fan Total Pressure

The following general equation may be used to perform fan pressure

calculations.

Therefore, based upon this basic fan law, a 20 percent increase in fan

volume requires

(1 + 0.2)2 = 1.44 or 44% higher fan total pressure

EXAMPLE – FAN VOLUME

Another useful basic fan law is as follows:

x (Fan RPM2)

Fan Vol. Flow2 = Fan Vol. Flow1

Figure 1. Fan and System Characteristics (Fan RPM1)

Such that a 10 percent increase in fan volume requires a 10 percent

increase in fan speed.

FLOW AND PRESSURE REQUIREMENTS

The following are examples of flow and pressure requirements occurring

in an air distribution system.

4 Application Guide - AIR BALANCING Redefine your comfort zone. ™ | www.titus-hvac.com

Definitions

Anemometer

Instrument used for determining the force or speed of air. Two

anemometer types are as follows:

•• Vane: Used to measure sidewalls, grilles, registers, and ceiling

diffusers. The vane anemometers are commonly depicted with

balancing Titus air system equipment.

•• Rotating vane: Used to measure linear feet of air passing

through it. Generally used for measuring air velocity through

supply, return and exhaust air grilles, registers, or openings. Do

not use a rotating vane anemometer as an averaging instrument.

Area Factor

The area factor, AK, is the effective area of the outlet at the point of

outlet velocity, the VK measurement is such that the volume flow is

equal to AK times VK.

The area factors are based on equalized airflow 12 flow units in the

outlet neck.

Note: Severe damper throttling or takeoffs without air turning devices

or control grids can affect the indicated airflow accuracy of these

factors dramatically.

Velocity

The measurement of air speed as it exits the grille, register, or diffuser.

Velocity is averaged by number of readings taken at grille, register,

or diffuser. Velocity is measured with instruments and depending

on application, the velocity being measured can be either supply or

return air.

Velometer

Instrument used for HVAC balancing, static pressure measurements,

energy audits.

Redefine your comfort zone. ™ | www.titus-hvac.com Application Guide - AIR BALANCING 5

A PP LICAT ION G UIDE

A IR BALANC I N G

Instrumentation

We recommend all system balancing instruments calibrated annually

with the manufacturer’s furnished calibration curve. Also, it is strongly

recommended these instruments be used within their specified accuracy

range. The appropriate usage and accurate instrument calibration ensures

ongoing credibility and accuracy for the air balancing technician.

For return grille balancing, the position of the velometer probe must be

as shown in the diagrams for each diffuser shown. Based on the vane

anemometer use, the attachment of the tubing to the anemometer

requires a reversing movement on the instrument. Alternative methods

may use a flow hood in a similar manner. Consult organizations such as

NEBB and AADC for more information on those methods that use the flow

hood to measure volume flow directly.

Preliminary Balancing Steps

Use the following information to balancing preparation.

1. Open all system air valves and dampers in both supply and return ducts.

2. Set all other dampers to normal operating position.

3. Check all filters and coils to ensure they are clear of dirt and debris.

4. Start all fans.

5. Check rotation of all fans and ensure the direction is correct.

6. Copy the balancing worksheet provided in this manual to record readings.

7. Number the outlets on the worksheet.

Note: The furthest branch and the furthest outlet on the branch

away from the fan will be outlet one on the branch number one.

The outlets are numbered consecutively working back toward the

fan. Figure 2 shows the numbering arrangement.

It is very important the outlets be numbered, tested, and adjusted

in the described sequence. If the sequence is not followed, the Figure 2. Schematic Diagram of the Duct System

procedure will not be valid.

8. Spot-check outlets along the branch to determine if enough air is

being delivered to give measurable readings.

6 Application Guide - AIR BALANCING Redefine your comfort zone. ™ | www.titus-hvac.com

Proportional Balancing

The following balancing information is specific to low pressure ventilating 11. Adjust Outlet 4 so its R value matches Outlet 3’s R value. Proceed

and air conditioning systems. in same manner to each outlet in the branch until out outlets are

balanced proportionally to each other.

1. Measure velocities at Outlet 1, the furthest outlet on the branch.

It is essential that once an outlet is proportionally balanced with

2. Determine the average velocity and use the System Balancing the preceding outlet, no further adjustments be made to that or a

Worksheet to record the value in the column VM (measured velocity) preceding outlet.

under Adjustments I heading. This indicates the first reading of

that outlet. 12. Balance each branch in a similar manner.

3. Determine the ratio of VD (measure to design velocity) and record 13. Measure airflow at a selected outlet in each of the two branches

R (ratio) under Adjustment I and 1B. Use the following equation to farthest from the fan. Adjust branch dampers until the R values

determine ratios. for the selected outlets are equal. The two branch ducts are not

proportionally balanced.

Measured Velocity VM

R= = VD 14. Adjust each branch to balance it proportionally with the preceding

AK (flow factor)

branch in the same manner that the outlets were balanced.

4. Proceed to the second outlet. Determine the average velocity (VM)

and ratio (R) and record these values under Adjustment I and 2A.

5. Compare R values from 1B and 2A under Adjustment I. If the R values

are not equal, adjust Outlet 2 so R2 will approach R1. Do not adjust

Outlet 1.

6. After adjustment, record VM and R values for Outlet 2 under II and 2A.

7. Go back to Outlet 1 and measure VM. Record VM and R values under

Adjustment II, 1B. If R values shown under adjustment II, 1B and

2A vary more than 0.1, they are not proportionally balanced one to

another and further adjustment to Outlet 2 is required. After each

adjustment of outlet number, record the new VM and R values

under 1B and 2A in each successive adjustment column. Once the

prescribed limits are achieved, proceed to the next step.

8. After Outlets 1 and 2 are satisfactorily balanced one to another, the

final adjustment values of R and VM from row 2A should be rewritten

under column Adjustment I, row 2B.

9. Proceed to Outlet 3 and measure VM and record VM and R values

under Adjustment I, 3A.

10. Compare 3A and 2B readings under Adjustment I. If necessary adjust

Outlet 3 to achieve the same R values as shown for number 2.

Note: Do not adjust Outlets 2 or 1.

Any adjustments to Outlet 3 will change the flow through Outlets 2

and 1; however, as long as Outlet 2 or 1 are adjusted they will remain

proportionally balanced to each other. The R value determined

for Outlets 2 and 3 will also apply to Outlet 1 and they will be

proportionally balanced to each other.

Redefine your comfort zone. ™ | www.titus-hvac.com Application Guide - AIR BALANCING 7

A PP LICAT ION G UIDE

A IR BALANC I N G

Grille Free Area

Grille free area (AF/AC) is the area free of obstruction in a grille face.

The more free space, the more unobstructed airflow. The following table

provides the average percentage of free grille area, deflection degree, and

grille model number

Table 1. Grille Free Area (AF/AC)

Model Deflection (Degrees) Free Area (%)

3F 45 52%

4F 45 62%

13R 0 86%

15R 0 83%

23R 45 44%

25R 30 62%

30R 0 75%

33R 38 61%

50F N/A 90%

60 FL 0 42%

63 FL 30 38%

0 82%

271 & 272 45 63%

22.5 76%

300 see 271 & 272

350 35 58%

355 35 46%

355 ZRL 0 80%

1700 N/A 68%

CT-480 N/A 47%

CT-481 N/A 42%

CT-540 N/A 56%

CT-541 N/A 51%

CT-580 N/A 69%

CT-581 N/A 65%

CT-700 N/A 56%

T-700 N/A 56%

8 Application Guide - AIR BALANCING Redefine your comfort zone. ™ | www.titus-hvac.com

Cross Reference

Table 2 provides a listing of products and their respective flow factor document.

Table 2. Product Cross Reference of Flow Factors

Product See Flow Factor… Product See Flow Factor…

30 272-FF CT-580 CT-FF

111 272-FF CT-581 CT-FF

112 272-FF CT-700 T700-FF

121 272-FF CT-700 Core 272-FF

122 272-FF DL DL-FF

131 272-FF FlowBar FB-FF

132 272-FF FR-1, -2, -3, -4 FR-FF

271 272-FF LL-1 LL1-FF

272 272-FF LL-2 LL2-FF

1700 1700-FF ML-37 ML-FF

23 - Core 272-FF ML-38 ML-FF

25 - Core 272-FF ML-39 ML-FF

250 1-way 250-FF N-1 N1-FF

250 2-way 250-FF N-1-DR N1DR-FF

250 3-way 250-FF OMNI OMNI-FF

250 4-way 250-FF F PAR PAR-F

3 - Core 272-FF PAS PAS-FF

30 - Core 272-FF PDR PAR-FF

300FL 272-FF PDS PAS-FF

300FS 272-FF PFR PFS-FF

300HD 300HD-FF PFS PFS-FF

300RL 272-FF PSS PSS-FF

300RS 272-FF R-OMNI R-OMNI-FF

301FL F 272-FF SG-SD SGSD-F

301FS 272-FF T700 T700-F

301RL 272-FF T700 - Core 272-FF

301RS 272-FF TBD-10 TBD-10-F

33 - Core 272-FF TBD-30 TBD-30-FF

34 - Core 272-FF TBD-80 TBD-80-FF

350FL Core 272-FF TBDI-10 TBD-10-F

350FS Core 272-FF TBDI-30 TBD-30-FF

350RL Core 272-FF TBDI-80 TBD-80-FF

350RS Core 272-FF TDC TDC-FF

355 272-FF TBF TBF-FF

4 - Core 272-FF TLF TLF-FF

50 - Core 272-FF TMR TMR-FF

50F 50-FF TMRA TMRA-FF

8 - Core 272-FF TMR-AA TMR-FF

CT-480 CT-FF TMRA-AA TMRA-FF

CT-481 CT-FF TMS TMS-FF

CT-540 CT-FF TMSA TMSA-FF

CT-541 CT-FF XC-310 XC310-FF

Redefine your comfort zone. ™ | www.titus-hvac.com Application Guide - AIR BALANCING 9

A PP LICAT ION G UIDE

A IR BALANC I N G

System Balancing Worksheet

Adjustments

Outlet Product Information

I II III iv

Outlet Design VM R VM R VM R VM R

Outlet

K-Factor 1A

No.

Type Size CFM VD

1B

2A

1

2B

3A

2

3B

3 4A

4B

4 5A

5B

5 6A

6B

6 7A

7B

7 8A

8B

8

9A

9B

9

10A

10 10B

11A

11 11B

12A

12 12B

13A

13 13B

14A

14 14B

15A

15

15B

10 Application Guide - AIR BALANCING Redefine your comfort zone. ™ | www.titus-hvac.com

Notes

Redefine your comfort zone. ™ | www.titus-hvac.com Application Guide - AIR BALANCING 11

605 Shiloh Rd

Plano TX 75074

ofc: 972.212.4800

fax: 972.212.4884

Redefine your comfort zone. ™ | www.titus-hvac.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Displacement App Guide - 2013Document14 pagesDisplacement App Guide - 2013Santiago J. ramos jrNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- SEC & iEC Series: Maximum Energy Efficiency and Optimum Air Conduction Air Cooled / Water Cooled / Dual Fluid UnitsDocument8 pagesSEC & iEC Series: Maximum Energy Efficiency and Optimum Air Conduction Air Cooled / Water Cooled / Dual Fluid Unitsvtin tinNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- LEED™ & Green Buildings: Application GuideDocument10 pagesLEED™ & Green Buildings: Application Guidevtin tinNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- E20s BLK416 STD 183 PDFDocument4 pagesE20s BLK416 STD 183 PDFvtin tinNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Carrier Hap 4 8 Manual PDFDocument140 pagesCarrier Hap 4 8 Manual PDFmendoncasegundoNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- SWRSC Hap491xDocument2 pagesSWRSC Hap491xEr JoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- ToxLogic Comments Submitted To ACGIH - May 2016Document8 pagesToxLogic Comments Submitted To ACGIH - May 2016vtin tinNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Natural Draft Chart PDFDocument1 pageNatural Draft Chart PDFvtin tinNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Vibration Isolation - SimmonsDocument12 pagesVibration Isolation - SimmonsJoão Cavalcanti100% (1)

- Air Distribution System Design: Good Duct Design Increases EfficiencyDocument6 pagesAir Distribution System Design: Good Duct Design Increases Efficiencyharoub_nasNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Duct DesignDocument67 pagesDuct DesignShahrukh Ansari100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Duct DesignDocument67 pagesDuct DesignShahrukh Ansari100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- E L A F A-64 F+116 : File: EMF/ghf3 - 2031 - SI - EmfDocument1 pageE L A F A-64 F+116 : File: EMF/ghf3 - 2031 - SI - Emfvtin tinNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Pages From (VRV IV Co Edmt341410c)Document1 pagePages From (VRV IV Co Edmt341410c)vtin tinNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Design-Guides-Set (Sample) PDFDocument28 pagesDesign-Guides-Set (Sample) PDFLloyd SamaniegoNo ratings yet

- Expansion Tank With Insulation-ModelDocument1 pageExpansion Tank With Insulation-Modelvtin tinNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Hazen Williams EquationDocument1 pageHazen Williams Equationanil4u29No ratings yet

- FT25,35DVMDocument59 pagesFT25,35DVMvtin tinNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Inverter Split FTKE25-35Document81 pagesInverter Split FTKE25-35vtin tinNo ratings yet

- Installation Details Model 2Document1 pageInstallation Details Model 2vtin tinNo ratings yet

- EvaporatorDocument2 pagesEvaporatorvtin tinNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- FT50,60FVMDocument56 pagesFT50,60FVMvtin tinNo ratings yet

- PUMP Model PDFDocument1 pagePUMP Model PDFvtin tinNo ratings yet

- 45° Lateral Saddle TapDocument1 page45° Lateral Saddle Tapvtin tinNo ratings yet

- 90° Tee With OvalDocument1 page90° Tee With Ovalvtin tinNo ratings yet

- Installation Details Model 1 - 2 PDFDocument1 pageInstallation Details Model 1 - 2 PDFvtin tinNo ratings yet

- Installation Details Model 1Document1 pageInstallation Details Model 1vtin tinNo ratings yet

- Alternate ArrangementDocument1 pageAlternate Arrangementvtin tinNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Wye FittingDocument1 pageWye Fittingvtin tinNo ratings yet

- Coulomb's Law and Electric Field Intensity: Engineering ElectromagneticsDocument24 pagesCoulomb's Law and Electric Field Intensity: Engineering ElectromagneticsKenn SenadosNo ratings yet

- Final Cor 011 Reviewer PDFDocument104 pagesFinal Cor 011 Reviewer PDFMary JuneNo ratings yet

- Report On RoboticsDocument40 pagesReport On Roboticsangelcrystl4774No ratings yet

- STAN Statistika 12 PDFDocument25 pagesSTAN Statistika 12 PDFPembelajaran Jarak JauhNo ratings yet

- Nfpa 13d 2007 IndexDocument3 pagesNfpa 13d 2007 Indexsaladin1977No ratings yet

- J. Agric. Food Chem. 2005, 53, 9010-9016Document8 pagesJ. Agric. Food Chem. 2005, 53, 9010-9016Jatyr OliveiraNo ratings yet

- CEBUANO ERNESTO CODINA (Astonaut Hardware Designer)Document1 pageCEBUANO ERNESTO CODINA (Astonaut Hardware Designer)Dessirea FurigayNo ratings yet

- Brunei 2Document16 pagesBrunei 2Eva PurnamasariNo ratings yet

- Aspen Tutorial #4: Design Specs & Sensitivity Analysis: OutlineDocument11 pagesAspen Tutorial #4: Design Specs & Sensitivity Analysis: OutlineWonda 005No ratings yet

- Topic 2 P2: MarkschemeDocument58 pagesTopic 2 P2: MarkschemeZihil ShahNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Full Site PDFDocument23 pagesFull Site PDFpursuwNo ratings yet

- CN 235 Aircraft DefinitionDocument22 pagesCN 235 Aircraft DefinitionMoch Dedy100% (4)

- Okumas Guide To Gaijin 1Document90 pagesOkumas Guide To Gaijin 1Diogo Monteiro Costa de Oliveira SilvaNo ratings yet

- Pathoftherosesyllabus2015 1 PDFDocument12 pagesPathoftherosesyllabus2015 1 PDFsperm100% (7)

- Kingspan 30 GSNDocument1 pageKingspan 30 GSNNoella AguiarNo ratings yet

- SuctioningDocument58 pagesSuctioningAyusa PradhanNo ratings yet

- Crimin Q and A Set 1Document6 pagesCrimin Q and A Set 1Marc angelo RegnerNo ratings yet

- Buk Uuuuuu UuuuuuuDocument92 pagesBuk Uuuuuu UuuuuuuJanaliyaNo ratings yet

- Methodology of Static Pile Load TestDocument33 pagesMethodology of Static Pile Load Testraju_420034520100% (1)

- 1Document3 pages1Pradeep PunterNo ratings yet

- Advanced Automatic ControlDocument26 pagesAdvanced Automatic Controlabdullah 3mar abou reashaNo ratings yet

- Cambridge IGCSE: MATHEMATICS 0580/41Document20 pagesCambridge IGCSE: MATHEMATICS 0580/41TatiannahNo ratings yet

- Rig 166 Data SheetDocument2 pagesRig 166 Data SheetEstuardo OlanNo ratings yet

- Dobdsm 304Document39 pagesDobdsm 304LuisangelDueñasNo ratings yet

- Street Design Manual NYCDocument312 pagesStreet Design Manual NYCgonleoNo ratings yet

- XVI - Magneticpropertiesofmanganese ContainingsolidsolutionsofbismuthorthoniobateBiNiO4Document7 pagesXVI - Magneticpropertiesofmanganese ContainingsolidsolutionsofbismuthorthoniobateBiNiO4Chukwuebuka UgochukwuNo ratings yet

- Corrosion Resistant Steels: Stainless Steel AlloysDocument11 pagesCorrosion Resistant Steels: Stainless Steel AlloysPraveen SamarthiNo ratings yet

- S934 - Instruction ManualDocument36 pagesS934 - Instruction ManualTony MarascaNo ratings yet

- Introduction To Food Analysis2020Document2 pagesIntroduction To Food Analysis2020Ĝĭdęŷ KîřöşNo ratings yet

- Roland RS-5 Manual Del UsuarioDocument180 pagesRoland RS-5 Manual Del Usuariodavevad12345No ratings yet