Professional Documents

Culture Documents

BP Jastrebac Clanak

Uploaded by

sexmanijakCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BP Jastrebac Clanak

Uploaded by

sexmanijakCopyright:

Available Formats

MINING AND METALLURGY INSTITUTE BOR ISSN: 2334-8836 (Štampano izdanje)

UDK: 622 ISSN: 2406-1395 (Online)

UDK: 621.65(045)=111 doi:10.5937/mmeb1802131R

Branislav Rajković*, Goran Angelov*, Radmilo Rajković*

VERIFICATION OF A DEEP WELL PUMP FOR

THE INDUSTRIAL WATER SUPPLY SYSTEM

Abstract

This paper gives a procedure of calculation verification the technical characteristics of the pump un-

der given operating conditions in an example of the existing installation of a deep well pump for the

technical water supply of the Nisal factory, The calculation was done analytically and graphically.

It also presents a scheme of industrial water supply, disposition of a deep well pump installa-

tion, as well as its technical characteristics.

Key words: deep well pump, calculation, disposition, technical characteristics

1 INTRODUCTION 2 TECHNICAL DESCRIPTION

Deep well pumps are used in the water Vertical deep well pump construction

supply facilities, industry, construction and consists of the discharge head, fixed dis-

mining to reduce or maintain the water le- charge pipe section, discharge pipe sec-

vels [1]. Three reservoirs R1, R2 and R3 tions, hydraulic sections and suction bell

are used for the needs of the technological [2]. The cross section drawing of the deep

process of the “Nisal” factory in Nis. The well pump is shown in Figure 2. A flanged

reservoirs are supplied with water from electromotor with electrically driven pumps

three artesian wells for the technical water is assembled on a discharge head, while a

B1, B2 and B3. The B1 well is Ø1600 mm discharge head itself contains the axial and

in diameter, about 20 m in depth, and water radial bearing, shaft, elastic coupling, ma-

is pumped from it by means of a deep well nometer, shaft sealing and discharge con-

pump made by the ”Jastrebac“ Nis, with nection. Fixed discharge pipe section

label BP-150-4. The B2 and B3 wells are serves as a connection of discharge head

Ø1200 mm in diameter, about 7 m in depth, with the discharge pipe sections. Discharge

and water is pumped from them by means pipe sections make the necessary pump

of a deep well pump made by the “Jastre- height. Hydraulic part of the pump consists

bac“ Nis, with label BP-100-2. All reser- of the suction and discharge cases, as well

voirs are connected in the “ring” in case of as a certain number of impellers with dif-

failure of individual deep well pump by the fusers through which the shaft on rubber

buried steel pipelines A case of supply o bearings passes. Suction bell consists of the

the reservoirs R1, R2 and R3 from the B2 suction strainer and check valve. Deep well

well will be analyzed in this paper. The pump BP-100-2 is a two-stage semi-axial

scheme of industrial water supply from the vertical deep well pump driven by electro-

B2 well with designated sections is shown motor made by the “Jastrebac“ Nis the with

in Figure 1. following technical characteristics:

*

Mining and Metallurgy Institute Bor, branislav.rajkovic@irmbor.co.rs

No. 1-2, 2018 131 Mining & Metallurgy Engineering Bor

- power: [ ] Disposition of deep well pump BP-100-

2 in the B2 well is shown in Figure 3.

- speed: [ ] Performance curve of the pump is

- discharge connection: DN100 PN10 shown in Figures 4 and 5.

Figure 1 Scheme of the industrial water supply from the B2 well

Figure 2 Cross section of the BP deep well pump

No. 1-2, 2018 132 Mining & Metallurgy Engineering Bor

Figure 3 Disposition of the deep well pump BP-100-2 in the B2 well

3 CALCULATION

Hydraulic calculation of the industrial 2. Maximum height difference between

water system of Nisal was done for the the water level in the B2 well and the reser-

purpose of verifying the BP-100-2 deep voirs R1, R2 and R3 amounts H=14 m at

well pump that transports water from the the equal water level in all reservoirs

well B2 into the reservoirs R1, R2 and R3 3. [ ] - absolute roughness

for the needs of the technological process, of the steel pipe

and it is given according to [3]. The calcu-

4. [ ] - kinematic

lation results are the flow rates for every

section, and afterwards comparison with viscosity of water

the required flow rates for each reservoir 5. Local losses amounts 20% from

is done. friction losses

The input data: 6. [ ] - length of section

1. Minimum height difference between 7. [ ] - internal diameter of section

the water level in the B2 well and the re- 8. [ ] - water velocity in section

servoirs R1, R2 and R3 amounts H=7 m at 9. [ ] - coefficient of local losses

the equal water level in all reservoirs

No. 1-2, 2018 133 Mining & Metallurgy Engineering Bor

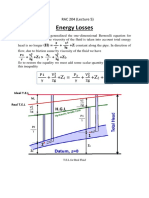

The following calculation formulae are tion of the pressure loss curves of sec-

used in the calculation: tions, taking into account whether the sec-

tions are connected in series or parallel the

1. - Reynolds number

cumulative pipeline pressure loss curve is

2. ( ) - friction co- determined. At the intersection of this

curve and pump performance curve in Y-

efficient of a section according to the

Q diagram, the operating point of pump is

Altsule

⁄ placed which simultaneously determines

3. ( ∑ )[ ] - re- the flow rate through the section 1. Then

⁄

sistance coefficient of a section the flow rates for all other sections are

4. [ ] - pressure determined based on the known pressure

loss curves. The calculation is carried out

loss curve of a section iteratively which means that at first the

where velocities in sections are assumed, and the

[ ] - gravitational constant calculation is repeated until the calculated

velocities match the ones in the previous

[ ] - flow rate in section iteration. The results of the calculation are

tabulated in Tables 1 and 2, while the op-

5. [ ] - pump performance curve

erating points of the pump are shown in

given by a pump supplier Figures 4 and 5 for both cases of adopted

On the basis of resistance coefficients height differences between the water level

of each section and the scheme of pipe in the well B2 and the reservoirs R1, R2

network (see Fig. 1) by appropriate addi- and R3.

Table 1 Flow rates and velocities at height difference of Hmin=7[m]

INTERNAL PIPE

COEFFICIENT

COEFFICIENT

RESISTANCE

FLOW RATE

REYNOLDS

DIAMETER

VELOCITY

VELOCITY

FRICTION

SECTION

SECTION

NUMBER

NUMBER

LENGTH

ACTUAL

ACTUAL

- L D v Re λ m Q v

3

- m mm m/s - - (J/kg)/(m /s) l/s m/s

1 138 182.9 0.61 85428 0.023 15040 16.00 0.61

2 202 182.9 0.36 50417 0.024 23474 9.34 0.36

3 119 182.9 0.25 35011 0.026 14602 6.66 0.25

4 46 150 0.38 43645 0.026 15029 6.66 0.38

5 30 107.1 0.4 32802 0.028 57072 3.59 0.40

6 40 107.1 0.34 27882 0.028 77804 3.07 0.34

No. 1-2, 2018 134 Mining & Metallurgy Engineering Bor

Table 2 Flow rates and velocities at height difference of Hmax=14[m]

COEFFICIENT

COEFFICIENT

RESISTANCE

FLOW RATE

REYNOLDS

DIAMETER

VELOCITY

VELOCITY

INTERNAL

FRICTION

SECTION

SECTION

NUMBER

NUMBER

LENGTH

ACTUAL

ACTUAL

PIPE

- L D v Re λ m Q v

- m mm m/s - - (J/kg)/(m3/s) l/s m/s

1 138 182.9 0.45 62365 0.024 15595 11.60 0.44

2 202 182.9 0.26 36582 0.026 24614 6.87 0.26

3 119 182.9 0.19 26249 0.027 15326 4.90 0.19

4 46 150 0.28 32006 0.027 15717 4.90 0.28

5 30 107.1 0.29 24022 0.029 59637 2.64 0.29

6 40 107.1 0.25 20804 0.029 81308 2.26 0.25

300

250

Head in J/kg

200

150

100

50

0

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

Flow rate in l/s

Figure 4 Operating point of the pump at height difference of Hmin=7 [m]

300

250

Head in J/kg

200

150

100

50

0

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

Flow rate in l/s

Figure 5 Operating point of the pump at height difference of Hmax=14 [m]

No. 1-2, 2018 135 Mining & Metallurgy Engineering Bor

4 DISCUSSION OF CALCULATION

As it can be seen from the calculation, ting of 6 sections when the pump operates

when operating the pump in the most unfa- in section 1 with a given performance char-

vorable variant, which means that the deep acteristic. Alternatively, it is possible to

well pump B2 itself supplies all three reser- solve the problem of pump verification in

voirs at the maximum height difference such a way that, based on the values of the

between the water level in the well and the required inflows in the reservoirs, the values

reservoirs, the flow rate in each of the reser- of the required flow rates in all sections are

voirs will be greater than the required min- determined and for them the value of the

imum flow rate. Corresponding values are total pressure drop for the most unfavorable

circuit is calculated. This value represents

given in Tables 3 and 4. The problem that

the required pump head. If the available

has been solved here is to determine the

pump head is greater than the required

flow rates through the sections for the given

pump head for the given total flow rate the

geometry of the complex pipeline consis- pump may be verified.

Table 3 Flow rates at height difference of Hmin=7 [m]

TECHNICAL WATER SUPPLY OF RESERVOIRS R1, R2 AND R3

FROM WELL B2 AT Hmin=7m

Pump operating point: head Y=74,57 J/kg; flow rate Q=16 l/s

Reservoir Calculated inflow in l/s Required inflow in l/s

R1 3.07 2.15

R2 3.59 0.116

R3 9.34 5.56

Table 4 Flow rates at height difference of Hmax=14[m]

TECHNICAL WATER SUPPLY OF RESERVOIRS R1, R2 AND R3

FROM WELL B2 AT Hmax=14m

Pump operating point: head Y=140,6 J/kg; flow rate Q=11,6 l/s

Reservoir Calculated inflow in l/s Required inflow in l/s

R1 2.26 2.15

R2 2.64 0.116

R3 6.87 5.56

CONCLUSION REFERENCES

The exposed methodology of the hy- [1] R. Rajković, B. Rajković, R. Lekovski:

draulic calculation of the complex pipeline is „Selection of ,FLYGT’ pumps for

a grapho-analytical method for determining dewatering of copper open pit ,Veliki

the operating point of the pump which, as Krivelj’“; Journal mining Works No.

can be seen, is not simple even when it 1; 2007.

comes to the complex pipelines with only a [2] Catalogue: “Deep Well Pumps BP“;

few sections, and when certain simplifica- “Jastrebac“ Pumps Factory Nis

tions are used. Although it can be imple- [3] Z. Protić, M. Nedeljković: Pumps and

mented for simpler cases of complex pipe- Fans-Problems, Solutions, Theory;

lines, a perspective is certainly in the appli- Faculty of Mechanical Engineering,

cation of specialized software. Belgrade; 1992.

No. 1-2, 2018 136 Mining & Metallurgy Engineering Bor

You might also like

- Special Purpose Transformer For Industrial ApplicationDocument5 pagesSpecial Purpose Transformer For Industrial Applicationsubodh_7No ratings yet

- Numerical Calculation of The Flow in A Centrifugal Pump Impeller Using Cartesian GridDocument6 pagesNumerical Calculation of The Flow in A Centrifugal Pump Impeller Using Cartesian Gridkrishna sharmaNo ratings yet

- Introduction To Cavitation in Hydraulic MachineryDocument14 pagesIntroduction To Cavitation in Hydraulic Machineryclaudio.ferreirademoNo ratings yet

- Optimal Design of Water Supply Networks in Buildings: SÂRBU, IoanDocument8 pagesOptimal Design of Water Supply Networks in Buildings: SÂRBU, Ioanarpit1121No ratings yet

- Design and Analysis of Small Hydroelectric Power For Rural ElectrificationDocument23 pagesDesign and Analysis of Small Hydroelectric Power For Rural Electrificationjethro ganeloNo ratings yet

- Hydraulic EngineeringDocument4 pagesHydraulic Engineeringmmfauzi78No ratings yet

- Total Head CalculationDocument16 pagesTotal Head CalculationZaid Al RayesNo ratings yet

- Water: Coupled Electric and Hydraulic Control of A PRS Turbine in A Real Transport Water NetworkDocument12 pagesWater: Coupled Electric and Hydraulic Control of A PRS Turbine in A Real Transport Water Networksaliyarumesh2292No ratings yet

- Chapter 2 Natural Gas Production Transportation V2Document71 pagesChapter 2 Natural Gas Production Transportation V2hugoNo ratings yet

- Analysis On Centrifugal Pump Performance in Single, Serial, and ParallelDocument8 pagesAnalysis On Centrifugal Pump Performance in Single, Serial, and ParallelFaiz AkbarsyahNo ratings yet

- Design and Analysis of Centrifugal Pump Impeller Using Ansys FluentDocument4 pagesDesign and Analysis of Centrifugal Pump Impeller Using Ansys FluentAmpera marzelaNo ratings yet

- Banki Blade Turbine Calculations 19153Document23 pagesBanki Blade Turbine Calculations 19153Juan FernándezNo ratings yet

- Design of High Efficiency Cross-Flow Turbine For Hydro-Power PlantDocument4 pagesDesign of High Efficiency Cross-Flow Turbine For Hydro-Power PlantChristopher VergaraNo ratings yet

- Efficiency of Pumps in Parallel Operation On Long-Distance Water PipelinesDocument12 pagesEfficiency of Pumps in Parallel Operation On Long-Distance Water Pipelinessimu84No ratings yet

- CH2 Introduction IBL BDocument44 pagesCH2 Introduction IBL Bnoorr66No ratings yet

- Lab 5 - Operating Characteristics of A Centrifugal PumpDocument9 pagesLab 5 - Operating Characteristics of A Centrifugal PumpGianne Nigelle DoriaNo ratings yet

- AECH3222 Lab 3 W22Document18 pagesAECH3222 Lab 3 W22GharamNo ratings yet

- Guidelines For Selection of Turbines, Preliminary Dimensioning and Layout of Surface Hydroelectric Power HousesDocument17 pagesGuidelines For Selection of Turbines, Preliminary Dimensioning and Layout of Surface Hydroelectric Power HousessubasratnaNo ratings yet

- ịchDocument5 pagesịchTran LuanNo ratings yet

- Flow Measurement (Compatibility Mode)Document11 pagesFlow Measurement (Compatibility Mode)NRNiloyNo ratings yet

- HL Losse in Diff Pipes-1Document13 pagesHL Losse in Diff Pipes-1Tadesse AyalewNo ratings yet

- Axial VentilationDocument4 pagesAxial VentilationVincent RogNo ratings yet

- Calculation MethodDocument12 pagesCalculation Methodspalaniyandi100% (1)

- 4 2-D Vertical Piping Span Stress Analysis in Tmin: Shear and Moment AnalysisDocument22 pages4 2-D Vertical Piping Span Stress Analysis in Tmin: Shear and Moment AnalysisPrashant AgrawalNo ratings yet

- SN - Design Report - Enjera Production Building - Rev-00Document10 pagesSN - Design Report - Enjera Production Building - Rev-00Nuhamin Zablon100% (1)

- Design of High Efficiency Cross-Flow Turbine For Hydro-Power PlantDocument4 pagesDesign of High Efficiency Cross-Flow Turbine For Hydro-Power PlantAdson JuniorNo ratings yet

- SL - No Item Name Unit (Metre) Rate/mt. Total AmountDocument1 pageSL - No Item Name Unit (Metre) Rate/mt. Total AmountMD Badra AlamNo ratings yet

- Dimensioning of Branching Irrigation Networks by Means of Linear ProgrammingDocument9 pagesDimensioning of Branching Irrigation Networks by Means of Linear ProgrammingjhdmssNo ratings yet

- Fire Sprinkler DesignDocument19 pagesFire Sprinkler DesignViswanathan Krish0% (1)

- Monitoring of Cheragh-Veis Dam During Construction Using Instrumentation DataDocument7 pagesMonitoring of Cheragh-Veis Dam During Construction Using Instrumentation DataSamNo ratings yet

- CFD Simulation Ofat T-JunctionDocument11 pagesCFD Simulation Ofat T-JunctionSam BanNo ratings yet

- Computational and Experimental Study of A Gas/Steam Turbine Derivative Axial Flow Impulse-Type Hydraulic TurbineDocument6 pagesComputational and Experimental Study of A Gas/Steam Turbine Derivative Axial Flow Impulse-Type Hydraulic TurbineKailas NimbalkarNo ratings yet

- Computation Stiling BasinDocument13 pagesComputation Stiling BasinFareena FatimaNo ratings yet

- NewGenerationRadialPistonPumps TechpaperDocument12 pagesNewGenerationRadialPistonPumps TechpaperEbrahim AhmariNo ratings yet

- Improvement of A Francis Runner Design: Nicola VISCANTIDocument8 pagesImprovement of A Francis Runner Design: Nicola VISCANTIFolpoNo ratings yet

- Design of Impeller Blade by Varying Blades and Type of Blades Using Analytical PDFDocument11 pagesDesign of Impeller Blade by Varying Blades and Type of Blades Using Analytical PDFasrikalyanNo ratings yet

- CFD Analysis and Design ImpellerDocument8 pagesCFD Analysis and Design ImpellerFarooqNo ratings yet

- CommentsDocument10 pagesCommentsVarun GuptaNo ratings yet

- Toolbox 7Document24 pagesToolbox 7LidijaSpaseskaNo ratings yet

- Cover Page & Basis of DesignDocument8 pagesCover Page & Basis of DesignJonery NabablitNo ratings yet

- P-G-007 - COWBP01 Pump Head CAlculationsDocument66 pagesP-G-007 - COWBP01 Pump Head CAlculationsJonery NabablitNo ratings yet

- Full 64256 Ok OkDocument8 pagesFull 64256 Ok OkmghgolNo ratings yet

- Coordination of Fuse Links With Oil Circuit Reclosers: Cooper PowerDocument20 pagesCoordination of Fuse Links With Oil Circuit Reclosers: Cooper PowerannymagoNo ratings yet

- P-G-0101 - CWBP01 Pump Head CAlculationsDocument54 pagesP-G-0101 - CWBP01 Pump Head CAlculationsJonery NabablitNo ratings yet

- Analysis of Performance of V-Cone Meter - Experimental & CFDDocument7 pagesAnalysis of Performance of V-Cone Meter - Experimental & CFDpratheesh91No ratings yet

- Exp F4 - System and Pump CharacteristicsDocument6 pagesExp F4 - System and Pump CharacteristicsMohamad IkhwanNo ratings yet

- Patel2018 PDFDocument45 pagesPatel2018 PDFLeidy Katherine Suarez GNo ratings yet

- Klemm - Application of A Cross Flow Fan As Wind TurbineDocument11 pagesKlemm - Application of A Cross Flow Fan As Wind TurbineDanang JoyoeNo ratings yet

- Hydraulic Control - Exam - 2022Document2 pagesHydraulic Control - Exam - 2022mohamed AlashriNo ratings yet

- CFD Analysis of Mixed Flow Impeller: Neelambika, VeerbhadrappaDocument7 pagesCFD Analysis of Mixed Flow Impeller: Neelambika, VeerbhadrappaAnilNo ratings yet

- Paper 3Document6 pagesPaper 3Srinivasan VairamanickamNo ratings yet

- Radial-Inflow Turbines: Vavra, M. HDocument65 pagesRadial-Inflow Turbines: Vavra, M. HSiraj MohammedNo ratings yet

- Flow Measurement and Fluid Machinery Lab - 18MEL67Document63 pagesFlow Measurement and Fluid Machinery Lab - 18MEL67Madhu KNNo ratings yet

- Introduction To Cavitation in Hydraulic MachineryDocument12 pagesIntroduction To Cavitation in Hydraulic MachineryBen100% (1)

- Fulltext PDFDocument15 pagesFulltext PDFAbhijeeth NagarajNo ratings yet

- Project Spec-Irrigation PumpDocument14 pagesProject Spec-Irrigation PumpKoshy MathewNo ratings yet

- 908design of High Efficiency Cross-Flow TurbineDocument4 pages908design of High Efficiency Cross-Flow TurbineAdi Setiadi100% (1)

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlFrom EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo ratings yet

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- IX H 727 10 Photo Atlas of Weld Appearance FiguresDocument21 pagesIX H 727 10 Photo Atlas of Weld Appearance FiguressexmanijakNo ratings yet

- Teguflex®: Expansion JointsDocument8 pagesTeguflex®: Expansion JointssexmanijakNo ratings yet

- 6series F12-F13Document16 pages6series F12-F13sexmanijakNo ratings yet

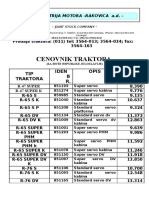

- Cenovnik Traktora: TIP Traktora Iden B R. Opis Cena/Eu RDocument2 pagesCenovnik Traktora: TIP Traktora Iden B R. Opis Cena/Eu RsexmanijakNo ratings yet

- Solenoid SIN45V To VDE 0580 Plug Plate To ISO 4400 / DIN 43650 Protection Class IP65Document2 pagesSolenoid SIN45V To VDE 0580 Plug Plate To ISO 4400 / DIN 43650 Protection Class IP65sexmanijakNo ratings yet

- AVK Dam Reservoir Applications Glenfield PDFDocument16 pagesAVK Dam Reservoir Applications Glenfield PDFsexmanijakNo ratings yet

- Portable Boring MachineDocument2 pagesPortable Boring Machinesexmanijak100% (1)

- Bending RadiusDocument16 pagesBending RadiussexmanijakNo ratings yet

- AntonPaar White PaperDocument4 pagesAntonPaar White PaperPablo AntezanaNo ratings yet

- Wave CalculatorDocument15 pagesWave CalculatorwidyaaNo ratings yet

- ISA RP3.2-1960 Flange Mounted Sharp Edged Orifice Plate For Flow MeasurementDocument8 pagesISA RP3.2-1960 Flange Mounted Sharp Edged Orifice Plate For Flow MeasurementLalit MohanNo ratings yet

- Debottlenecking A Distillation ColumnDocument12 pagesDebottlenecking A Distillation Columnrasik.kirane100% (1)

- Triple Deck TheoryDocument18 pagesTriple Deck TheorykrishnamurthyVishNo ratings yet

- Engenering Agriculture PerryDocument423 pagesEngenering Agriculture PerryDaniel López100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document19 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Henrique100% (1)

- 2510.practical Aspects of Finite Element Modelling of Polymer Processing by Vahid NassehiDocument282 pages2510.practical Aspects of Finite Element Modelling of Polymer Processing by Vahid Nassehihalukg26No ratings yet

- Flow Separation or Boundary Layer Separation IsDocument4 pagesFlow Separation or Boundary Layer Separation Isengineer bilalNo ratings yet

- HW#3 - New 01Document2 pagesHW#3 - New 01Gaga852No ratings yet

- Chapter 5Document76 pagesChapter 5esra kadriye akgülNo ratings yet

- Water Supply CalculationsDocument8 pagesWater Supply CalculationsAshiq NishmaNo ratings yet

- Inhouse Trbfgfaning Report OnDocument13 pagesInhouse Trbfgfaning Report OnmustafahNo ratings yet

- Muhammad Haikal Daniel Bin Jamal - 2020890508Document23 pagesMuhammad Haikal Daniel Bin Jamal - 2020890508Muhd Haikal DanielNo ratings yet

- Lecture 5 2Document15 pagesLecture 5 2IbrahimDewaliNo ratings yet

- Pumps Head Loss Calculation (Colbrook Formula) : Local Factors of FittingsDocument22 pagesPumps Head Loss Calculation (Colbrook Formula) : Local Factors of FittingsAhmed EbrahimNo ratings yet

- Is Iec 60534 2 1 1998Document48 pagesIs Iec 60534 2 1 1998Sreeram PanigrahiNo ratings yet

- Adv of VenturimeterDocument1 pageAdv of Venturimetersujeet.jha.311No ratings yet

- Fire Hydraulic CalculationDocument2 pagesFire Hydraulic CalculationShubhajit ChakrabortyNo ratings yet

- Fundamentals of Thermal Fluid Sciences 6Th Edition Yunus A Cengel Full ChapterDocument51 pagesFundamentals of Thermal Fluid Sciences 6Th Edition Yunus A Cengel Full Chaptergloria.toher494100% (12)

- Inspection of PenstockDocument9 pagesInspection of PenstockDangol RupeshNo ratings yet

- Kfe e 1229r DG MergedDocument17 pagesKfe e 1229r DG MergedNagi ReddyNo ratings yet

- Annexure XXX - Stilling BasinDocument1 pageAnnexure XXX - Stilling BasinMd Ghani HaiderNo ratings yet

- Formulation of Wave and Current Forces Acting On A Body and ResistanceDocument9 pagesFormulation of Wave and Current Forces Acting On A Body and ResistanceTùng Nguyễn DuyNo ratings yet

- Hydrodynamic LubricationDocument87 pagesHydrodynamic LubricationHashem Mohamed HashemNo ratings yet

- Series & Parallel PumpDocument14 pagesSeries & Parallel PumpDivaan Raj Karunakaran100% (3)

- Pressure Safety Valve Sizing Calculation Rev.01 APUDocument10 pagesPressure Safety Valve Sizing Calculation Rev.01 APUAlvin SmithNo ratings yet

- Me 321: Fluid Mechanics-I: Dr. A.B.M. Toufique HasanDocument4 pagesMe 321: Fluid Mechanics-I: Dr. A.B.M. Toufique HasanankitaNo ratings yet

- 10 - OPEN CHANNELS Sample ProblemsDocument13 pages10 - OPEN CHANNELS Sample ProblemsGray Fiore FullbusterNo ratings yet

- Heat 4e Chap09 LectureDocument33 pagesHeat 4e Chap09 Lecturemsiembab17No ratings yet