Professional Documents

Culture Documents

WPS106 6010 WPS 107 7024 Secondary and Post Secondary

Uploaded by

ahmedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS106 6010 WPS 107 7024 Secondary and Post Secondary

Uploaded by

ahmedCopyright:

Available Formats

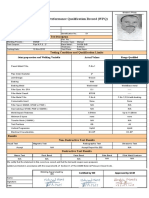

SkillsUSA Page 1 of 1 SkillsUSA Page 1 of 1

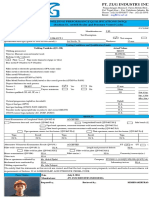

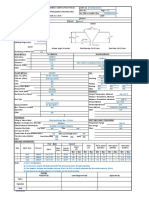

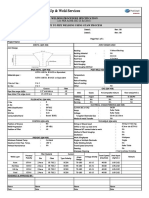

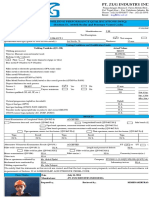

Welding Procedure Specification WPS 106 Welding Procedure Specification WPS 107

WPS No. WPS 106 Revision 2 Date 4/20/2012 By NP WPS No. WPS 107 Revision 2 Date 4/20/2012 By NP

Authorized By GH Date 5/15/2011 Prequalified Authorized By GH Date 5/15/2011 Prequalified

Welding Process(es) SMAW Type: Manual Machine Semi-Auto Auto Welding Process(es) SMAW Type: Manual Machine Semi-Auto Auto

Supporting PQR(s) Prequalified Supporting PQR(s) Prequalified

JOINT JOINT

Type T-Joint Type T-Joint

Backing Yes No Single Weld Double Weld Backing Yes No Single Weld Double Weld

Backing Material N/A 45° Backing Material N/A

Root Opening N/A Root Face Dimension N/A Root Opening N/A Root Face Dimension N/A

Groove Angle N/A Radius (J-U) N/A Groove Angle N/A Radius (J-U) N/A

1/8” ±1/16”

Back Gouge Yes No Back Gouge Yes No

Method N/A Method N/A

BASE METALS POSITION BASE METALS POSITION

Material Spec. A-36 to A-36 Position of Groove All Fillet All Material Spec. A-36 to A-36 Position of Groove Fillet 1F,2F

Type or Grade to Vertical Progression: Up Down Type or Grade to Vertical Progression: Up Down

Thickness: Groove ( in ) N/A - N/A ELECTRICAL CHARACTERISTICS Thickness: Groove ( in ) N/A - N/A ELECTRICAL CHARACTERISTICS

Fillet ( )Unlimited - Transfer Mode (GMAW): Fillet ( )Unlimited - Transfer Mode (GMAW):

Diameter (Pipe, in ) N/A - N/A Short-Circuiting Globular Spray Diameter (Pipe, in ) N/A - N/A Short-Circuiting Globular Spray

Current: AC DCEP DCEN Pulsed Current: AC DCEP DCEN Pulsed

FILLER METALS FILLER METALS

AWS Specification A5.1 Other N/A AWS Specification A5.1 Other N/A

AWS Classification E-6010 Tungsten Electrode (GTAW): AWS Classification E-7024 Tungsten Electrode (GTAW):

Size N/A Type N/A Size N/A Type N/A

TECHNIQUE TECHNIQUE

SHIELDING SHIELDING

Stringer or Weave Bead Both Stringer or Weave Bead Both

Flux Gas N/A Flux Gas N/A

N/A Composition N/A Multi-pass or Single Pass (per side) Multiple/Single N/A Composition N/A Multi-pass or Single Pass (per side) Multiple/Single

Electrode-Flux (Class) Flow Rate N/A Number of Electrodes 1 Electrode-Flux (Class) Flow Rate N/A Number of Electrodes 1

N/A Gas Cup Size N/A Electrode Spacing: Longitudinal N/A N/A Gas Cup Size N/A Electrode Spacing: Longitudinal N/A

Lateral N/A Lateral N/A

PREHEAT PREHEAT

Angle N/A Angle N/A

Preheat Temp., Min. 60 Deg.F Preheat Temp., Min. 60 Deg.F

Contact Tube to Work Distance N/A Contact Tube to Work Distance N/A

Thickness Up to 3/4" Temperature N/A Thickness Up to 3/4" Temperature N/A

Peening N/A Peening N/A

Over 3/4" to 1-1/2" N/A Over 3/4" to 1-1/2" N/A

Interpass Cleaning Chip slag and wire brush Interpass Cleaning Chip slag and wire brush

Over 1-1/2" to 2-1/2" N/A Over 1-1/2" to 2-1/2" N/A

Over 2-1/2" N/A POSTWELD HEAT TREATMENT PWHT Required Over 2-1/2" N/A POSTWELD HEAT TREATMENT PWHT Required

Interpass Temp., Min. N/A Max. N/A Temp. N/A Time N/A Interpass Temp., Min. N/A Max. N/A Temp. N/A Time N/A

WELDING PROCEDURE WELDING PROCEDURE

Layer/Pass Process Filler Metal Class Diameter Cur. Type Amps Volts Travel Speed Other Notes Layer/Pass Process Filler Metal Class Diameter Cur. Type Amps Volts Travel Speed Other Notes

All SMAW E-6010 1/8 DCEP 90-115 N/A 4-10 ipm All SMAW E-7024 1/8 DCEP 130-150 N/A 4-10 ipm

You might also like

- E-Studio 205L, 255, 305, 355, 455 MFP Service HandbookDocument732 pagesE-Studio 205L, 255, 305, 355, 455 MFP Service HandbookAnonymous gn8qxx66% (35)

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Welder Performance Qualification Record (WPQ) : Testing Condition and Qualification LimitsDocument9 pagesWelder Performance Qualification Record (WPQ) : Testing Condition and Qualification Limitsahmed mohamed100% (1)

- National Telecommunication Corporation (NTC)Document40 pagesNational Telecommunication Corporation (NTC)Faheem Sajid100% (1)

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- WPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless SteelDocument1 pageWPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless SteelAhmed Gomaa100% (1)

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- 180-Smaw-Zug-Asme (Andhika Rolando-3g) - WPQDocument4 pages180-Smaw-Zug-Asme (Andhika Rolando-3g) - WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Document2 pagesWelding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Edwin Romero100% (1)

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- Discover Haxeflixel FullDocument182 pagesDiscover Haxeflixel FullKristian Macanga100% (3)

- Welders Performance Qualification Record: Actual Values Range QualifiedDocument13 pagesWelders Performance Qualification Record: Actual Values Range QualifiedErick AguadoNo ratings yet

- Sembcorp Marine Integrated Yard PteDocument3 pagesSembcorp Marine Integrated Yard PteMd. Mizanur Rahaman100% (1)

- Mabel Engineers Pvt. LTD Priliminary Welding Procedure Specification (PWPS) EN ISO 15609-1 2004Document2 pagesMabel Engineers Pvt. LTD Priliminary Welding Procedure Specification (PWPS) EN ISO 15609-1 2004dayalram100% (1)

- WPS SMAW - PL en V Con GaugingDocument1 pageWPS SMAW - PL en V Con GaugingLuis MirandaNo ratings yet

- WDI-WPS-072 Rev.00 SMAW 2Document4 pagesWDI-WPS-072 Rev.00 SMAW 2MohamedNo ratings yet

- Aws 001Document1 pageAws 001akshay sarfareNo ratings yet

- Welders CertDocument11 pagesWelders CertAhmed GomaaNo ratings yet

- WPS PQR FormatDocument1 pageWPS PQR FormatJatin Kamdar100% (2)

- 5510 0004 04 - 18 1021 Basic Principles of Ship Propulsion - MAN PDFDocument68 pages5510 0004 04 - 18 1021 Basic Principles of Ship Propulsion - MAN PDFAlex FatecNo ratings yet

- 175 Smaw Zug Asme (Muhammad Wardi 3g) WPQDocument4 pages175 Smaw Zug Asme (Muhammad Wardi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- EWAD-CF EEDEN15-435 Data Books EnglishDocument42 pagesEWAD-CF EEDEN15-435 Data Books EnglishrpufitaNo ratings yet

- Cement EvaluationDocument19 pagesCement EvaluationDiego PalaciosNo ratings yet

- Alumana Welder IDDocument7 pagesAlumana Welder IDZuberYousufNo ratings yet

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Rejoy babyNo ratings yet

- WPQRDocument1 pageWPQRJBStringerNo ratings yet

- Procedure Qualification Record (PQR) : Filler Metals AWS Specification AWS ClassificationDocument3 pagesProcedure Qualification Record (PQR) : Filler Metals AWS Specification AWS ClassificationRejoy babyNo ratings yet

- Screenshot 2023-01-31 at 5.18.21 PMDocument9 pagesScreenshot 2023-01-31 at 5.18.21 PMisanNo ratings yet

- 6gr Smaw WQTR - F. Edilo (Sn-189)Document1 page6gr Smaw WQTR - F. Edilo (Sn-189)hanz bermejoNo ratings yet

- Annex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document2 pagesAnnex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Daniel ZapataNo ratings yet

- 3g Tar WPQTR Form Aws d1.1Document2 pages3g Tar WPQTR Form Aws d1.1Scott AdkinsNo ratings yet

- WQT Form (AWS D1.1) 04-23Document1 pageWQT Form (AWS D1.1) 04-23hanz bermejoNo ratings yet

- Welder CertificateDocument1 pageWelder CertificatePaul H TampubolonNo ratings yet

- Gtaw - Inox - 6g Julio Arriagada Gallegos Constructora Laja Mayo 2023Document1 pageGtaw - Inox - 6g Julio Arriagada Gallegos Constructora Laja Mayo 2023elevacerchileNo ratings yet

- Welder'S Qualification Test Certificate: Plate TO Plate Plate and Pipe Dia 500Document3 pagesWelder'S Qualification Test Certificate: Plate TO Plate Plate and Pipe Dia 500Er Pralabh ShahNo ratings yet

- Welder Peformance Qualification Record: Pearl GTL Project - Liquid Processing Unit (C5)Document3 pagesWelder Peformance Qualification Record: Pearl GTL Project - Liquid Processing Unit (C5)SANUNo ratings yet

- WPQRDocument1 pageWPQRangelito bernalNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- NYX Ndustries ZC: Welder Performance Qualification RecordDocument1 pageNYX Ndustries ZC: Welder Performance Qualification RecordanoopkumarNo ratings yet

- Petroleum Equipment Assembly & Metal Structure JSC: N/A N/ADocument2 pagesPetroleum Equipment Assembly & Metal Structure JSC: N/A N/AKhôi ĐàoNo ratings yet

- BGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Document1 pageBGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Eswar Enterprises QcNo ratings yet

- Preliminary - Welding Procedure Specification (WPS)Document1 pagePreliminary - Welding Procedure Specification (WPS)Rudi DaNo ratings yet

- Procedure Qualification Record (PQR) Form: JointsDocument12 pagesProcedure Qualification Record (PQR) Form: JointsAl Fatih Darussalam YasfiNo ratings yet

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- Mathew Associates Hook Up & Weld Services: Welding Procedure SpecificationDocument1 pageMathew Associates Hook Up & Weld Services: Welding Procedure SpecificationHimanshu SinghNo ratings yet

- WPQ 006Document1 pageWPQ 006vinuNo ratings yet

- PWPS DonpyDocument1 pagePWPS DonpyANDINTA MUDA YUSUFNo ratings yet

- Welding Procedure Specification (WPS) : Joint Design PositionDocument9 pagesWelding Procedure Specification (WPS) : Joint Design PositionpetermanroelibraryNo ratings yet

- PWPS 005Document2 pagesPWPS 005Mehrdad RezaeiNo ratings yet

- 181-Smaw-Zug-Asme (Rinovianda-3g) - WPQDocument4 pages181-Smaw-Zug-Asme (Rinovianda-3g) - WPQMuhammad Fitransyah Syamsuar Putra100% (2)

- 174 Smaw Zug Asme (Asep Wahyudi 3g) WPQDocument4 pages174 Smaw Zug Asme (Asep Wahyudi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- WPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0Document1 pageWPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0คุณพ่อน้อง บิ๊กบอส100% (1)

- (Automatic, Manual, Machine, or Semi-Auto) : 3-4 MM 1-5 MMDocument2 pages(Automatic, Manual, Machine, or Semi-Auto) : 3-4 MM 1-5 MMpraveesh qc2023No ratings yet

- JFORMDocument2 pagesJFORMMohd Effiezool YaserNo ratings yet

- WPQR SampleDocument1 pageWPQR SampleccbmitNo ratings yet

- Welding Procedure Specifiction: JOINTS (QW-402)Document3 pagesWelding Procedure Specifiction: JOINTS (QW-402)Ahmad MohammadNo ratings yet

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PNo ratings yet

- ZATCA E-Invoicing Report 2022 2Document22 pagesZATCA E-Invoicing Report 2022 2ahmedNo ratings yet

- MCET226 - Workshop Report - SampleDocument3 pagesMCET226 - Workshop Report - SampleahmedNo ratings yet

- Course Plan MCET105Document1 pageCourse Plan MCET105ahmedNo ratings yet

- ST ® T Pipe Root Pass Synergic Weld ProcessDocument2 pagesST ® T Pipe Root Pass Synergic Weld ProcessahmedNo ratings yet

- Surface Tension Transfer (STT) Pipe WeldingDocument3 pagesSurface Tension Transfer (STT) Pipe WeldingahmedNo ratings yet

- What Is PreheatDocument4 pagesWhat Is PreheatahmedNo ratings yet

- Welding Variables - Heats School of Welding Technology Inc. - Tarlac CityDocument14 pagesWelding Variables - Heats School of Welding Technology Inc. - Tarlac CityahmedNo ratings yet

- Material Safety Data Sheet: 1. Product and Company IdentificationDocument10 pagesMaterial Safety Data Sheet: 1. Product and Company IdentificationahmedNo ratings yet

- Four Steps To Proper Nozzle SelectionDocument2 pagesFour Steps To Proper Nozzle SelectionahmedNo ratings yet

- Handling of AcetyleneDocument2 pagesHandling of AcetyleneahmedNo ratings yet

- Facts About AcetyleneDocument7 pagesFacts About AcetyleneahmedNo ratings yet

- Fundamentals of Professional WeldingDocument3 pagesFundamentals of Professional WeldingahmedNo ratings yet

- The US Customary System of Measurement AND Conversions: MSJC San Jacinto CampusDocument25 pagesThe US Customary System of Measurement AND Conversions: MSJC San Jacinto CampusahmedNo ratings yet

- 1SC0 2PF Exam-Paper 20180616Document20 pages1SC0 2PF Exam-Paper 20180616Thasanya AlgamaNo ratings yet

- Netxknx Opc 3 - 5 - 4 EngDocument93 pagesNetxknx Opc 3 - 5 - 4 Engtai_sao_khong_1307No ratings yet

- Ubd Planning Template With QuestionsDocument3 pagesUbd Planning Template With Questionsapi-217297849No ratings yet

- Structure Lab Manual FullDocument318 pagesStructure Lab Manual FullRodrigo Requelme BorjaNo ratings yet

- Inform: Extending PhoenicsDocument42 pagesInform: Extending PhoenicsrsigorNo ratings yet

- Mac Keyboard ShortcutsDocument16 pagesMac Keyboard ShortcutsSaira FazalNo ratings yet

- Oral Histology & Embryology-FikreDocument240 pagesOral Histology & Embryology-FikreHeran A AlhadiNo ratings yet

- Section 3 Quiz, Database Design ORACLEDocument8 pagesSection 3 Quiz, Database Design ORACLEMostragNo ratings yet

- Sheet Pile Analysis Sheet v1.07-18.1Document2 pagesSheet Pile Analysis Sheet v1.07-18.1SES DESIGN100% (1)

- IP03 Loops-4slides PDFDocument10 pagesIP03 Loops-4slides PDFRamesh GNo ratings yet

- Python ProgramDocument3 pagesPython ProgramGOKUL BNo ratings yet

- TM4320 PDFDocument85 pagesTM4320 PDFandres cortezNo ratings yet

- SolutionsDocument8 pagesSolutionsJavid BalakishiyevNo ratings yet

- 29 - CHAPTER 3 Intermolecular Forces and Potential Enegy SurfacesDocument9 pages29 - CHAPTER 3 Intermolecular Forces and Potential Enegy SurfacesMohit Kamboj100% (2)

- Calculation Sheet Boiler Control BuildingDocument35 pagesCalculation Sheet Boiler Control BuildingKhamal Rachmanda AdamNo ratings yet

- Microstructure Characteristics and Performance of Dissimilar Welds Between Magnesium Alloy and Aluminum Formed by Friction StirringDocument5 pagesMicrostructure Characteristics and Performance of Dissimilar Welds Between Magnesium Alloy and Aluminum Formed by Friction StirringLeidy Silvana Chacón VelascoNo ratings yet

- Electrosurgical Text HandboockDocument94 pagesElectrosurgical Text HandboockThéu Castro100% (1)

- Lecture-V Reaction and Separation SystemDocument54 pagesLecture-V Reaction and Separation SystemErmias AbelnehNo ratings yet

- Nested LoopsDocument11 pagesNested LoopssivaabhilashNo ratings yet

- Unit Iv Ce 6405Document13 pagesUnit Iv Ce 6405HanafiahHamzahNo ratings yet

- Operating and Maintenance Manual 322375H01 Rev CDocument82 pagesOperating and Maintenance Manual 322375H01 Rev CGustavo BarbosaNo ratings yet

- Deductive ReasoningDocument2 pagesDeductive ReasoningMariel C. BombitaNo ratings yet

- Hide Answer Notebook Notebook Discuss: Here Is The Answer and ExplanationDocument16 pagesHide Answer Notebook Notebook Discuss: Here Is The Answer and ExplanationPayashwini KulkarniNo ratings yet

- The Relationship Between Emotional Maturity and Psychosocial Adjustment Among First-Year Undergraduate Students in Amhara Region Public Universities, EthiopiaDocument11 pagesThe Relationship Between Emotional Maturity and Psychosocial Adjustment Among First-Year Undergraduate Students in Amhara Region Public Universities, EthiopiaYared FentawNo ratings yet

- MCAT Uhs Past Paper (2008-2016)Document180 pagesMCAT Uhs Past Paper (2008-2016)Abdullah SheikhNo ratings yet