Professional Documents

Culture Documents

SOP - Welding

Uploaded by

AbhaySnghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP - Welding

Uploaded by

AbhaySnghCopyright:

Available Formats

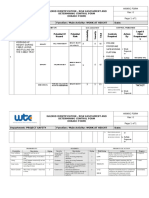

Environment, Health and Safety Execution Center India Environment, Health and Safety Execution Center India

SE-ECI-EHS-SOP-04

SAFE OPERATING PROCEDURE SAFE OPERATING PROCEDURE

Welding Welding

User must read this important information before

using the equipment PRE-OPERATIONAL SAFETY CHECKS

UNDERSTANDING THE Welding Machine 4. Defective connections at the electrode holder/torch or at the welding

current return clamp.

5. Cables and Plugs suitable for the intended use and performance.

Rated capacity of Welding Cables.Broken or thermally damaged plugs

and switches.

6. Metal frame and cases must be grounded to earth.

7. Ensure Welding machine is operated on ELCB/RCD operated circuit.

8. Power disconnection shall be routed thru MCB and must be provided

on the machine.

9. Before Welding, make sure that welding area is free of flammable and

combustible materials

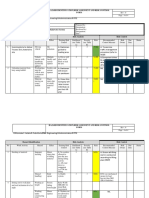

OPERATIONAL SAFETY CHECKS

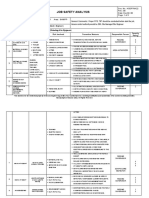

1. Carryout welding with proper work permit or job safety planning.

POTENTIAL HAZARDS AND RISKS

2. Connect to power source only after all adjustments have been made.

■ Non-Ionization Radiation ■ Electricity 3. Check that the power lead does not create a trip hazard and that it is

■ Eye injuries ■ Burns & Hot Spatters ■ Electric Shock well clear of the workpiece.

PERSONAL PROTECTIVE EQUIPMENTS 4. Insulate welder from workpiece and ground using dry insulation.

Rubber mat or dry wood.

Appropriate safety helmet must be worn at all 5. Connect the welding ground as close as possible to area where

times in all sites. welding is being performed.

6. Welding shall be carried out in ventilated area or proper ventilation

Appropriate safety footwear must be worn at all arrangements shall be made before start welding.

times in all sites. 7. Use welding shields to protect eye and face from radiation and

spatters. Guard eyes & face when chipping slag.

Approved reflective jacket must be worn at all

8. Use Welding screens to protect others from arc or glare.

times in all sites.

9. The work clamp must be securely attached to the work before the start

of the welding operation.

Approved face shield or welding goggles must be

worn when welding is carried. 10. Locate welding machines where they have adequate ventilation and

ventilation ports are not obstructed.

Appropriate safety hand gloves must be worn 11. Do not operate the rotary switch for current settings while the machine

when welding is carried. is operating under welding current load.

12. Disconnect the welding machines from the power supply when they

A mask must be worn when excessive airborne are left unattended.

metal fume is created. 13. A place will be provided to hang up or lay down the holder where it will

not come in contact with persons or conducting objects.

Suitable welding apron must be worn all times 14. Partially used electrodes should be removed from the holders when

when welding is carried. not in use.

15. Before making any machinery adjustments, bring the machine to

Cotton long sleeve shirt and long pant must be isolation by disconnecting from the power source.

worn. 16. Handle hot metal with pliers or tongs.

17. Do not allow the electrode to stick the metal. If this occurs, turn off the

Ring or Jewelry must not be worn. No loose welding, allow the electrode to cool, then break off with gloved hand.

clothing.

18. Prevent burns by cooling hot metal promptly, storing when not in use,

PRE-OPERATIONAL SAFETY CHECKS and never touch the electrode or electrode holder to bare skin.

1. Check workspace to ensure no slip-trip hazards are present. 19. Keep the Fire extinguisher and water bucket handy.

2. Examine the power lead and welding current return lead for obvious HOUSEKEEPING (AND CLEANING UP)

damage. 1. Remove electrode stubs, chipped slag after welding.

3. Missing or defective insulation at the welding holder/torch. 2. Remove all materials and equipments from the welding area.

3. Clean the area and leave it in a safe & tidy condition.

You might also like

- Lathe Machine Risk AssessmentDocument4 pagesLathe Machine Risk AssessmentChethan88% (8)

- Manual Tig Welding (RRC) - Job ProcedureDocument3 pagesManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- JSA For Cutting, Grinding and Welding in AtmosphereDocument21 pagesJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- Risk Ass - TK-4742-WELDING ACTVITIES FOR REST AREA PREPARATIONDocument6 pagesRisk Ass - TK-4742-WELDING ACTVITIES FOR REST AREA PREPARATIONnsadnanNo ratings yet

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDocument2 pagesJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- Skillbuild Risk Assessment: Competition Organising Partner: Citb /skillbuild Competition Skills: BricklayingDocument6 pagesSkillbuild Risk Assessment: Competition Organising Partner: Citb /skillbuild Competition Skills: BricklayinguknandiNo ratings yet

- Safety Operating ProcedureDocument15 pagesSafety Operating ProcedureJinky L. Lavega100% (1)

- Risk Assesment-Rebar Loading & UnloadingDocument1 pageRisk Assesment-Rebar Loading & Unloadingmainraj rajNo ratings yet

- Hirarc CRDocument76 pagesHirarc CRNazri100% (1)

- SOP Gas Cutting and Heating .Document1 pageSOP Gas Cutting and Heating .aarunsnairNo ratings yet

- Welding and Cutting S.O.P. 3FDocument14 pagesWelding and Cutting S.O.P. 3FAlnurhakim Hebat100% (1)

- 6-Steel Work Risk Assessment ReportDocument7 pages6-Steel Work Risk Assessment ReportSyed Ali Hassan67% (3)

- Risk Assessment in A Welding and Construction SiteDocument3 pagesRisk Assessment in A Welding and Construction SiteFad Tobi75% (8)

- Pha ExcavationDocument13 pagesPha ExcavationirshadNo ratings yet

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- Jsa For Civil Confined Space EntryDocument11 pagesJsa For Civil Confined Space EntryKhuda BukshNo ratings yet

- Working at Height: Activity-Based Risk Assessment FormDocument7 pagesWorking at Height: Activity-Based Risk Assessment Formfredo100% (4)

- QP Painting JSADocument6 pagesQP Painting JSAMohammed Mujahid100% (2)

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 pagesJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- JSA For BM - To Dry Up at Site, Remove Motor To Workshop For Repair, Re-Install & Perform Run Test-CRMDocument10 pagesJSA For BM - To Dry Up at Site, Remove Motor To Workshop For Repair, Re-Install & Perform Run Test-CRMChung TrịnhNo ratings yet

- Risk Assessment - Lifting OperationsDocument3 pagesRisk Assessment - Lifting Operationsdnmule100% (2)

- JHA Cutting of Asphalt Road For Replacement of Protection SlabsDocument5 pagesJHA Cutting of Asphalt Road For Replacement of Protection SlabsNasrullah JanNo ratings yet

- Portable Power Tools - Risk Assessment2Document3 pagesPortable Power Tools - Risk Assessment2Basit Nawaz100% (1)

- Lim Meng Heck (SR - Operation Manager) : ISK Ssessment ORMDocument2 pagesLim Meng Heck (SR - Operation Manager) : ISK Ssessment ORMVaradaraju ThirunavukkarasanNo ratings yet

- RA - 018 01 Scaffolding Erection and DismantlingDocument14 pagesRA - 018 01 Scaffolding Erection and DismantlingVuong Bui95% (63)

- JSA WeldingDocument2 pagesJSA WeldingSigint Sides0% (3)

- Operation of CNC Machine JSA PDFDocument2 pagesOperation of CNC Machine JSA PDFashok Kumar100% (1)

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEDocument12 pagesRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- JHA # 009 - Hot WorkDocument7 pagesJHA # 009 - Hot WorkkumarNo ratings yet

- JSA For Material ShiftingDocument3 pagesJSA For Material ShiftingMohammed Minhaj100% (1)

- 007 - Risk Ass. - CE-0994-MEP WorksDocument9 pages007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- Jsa Radiography ActivitiesDocument4 pagesJsa Radiography Activitiesnasar_mahsood80% (15)

- Welding and Gas CuttingDocument2 pagesWelding and Gas CuttingKrishna Patil100% (2)

- Job Safety Analysis Form HydrotestDocument3 pagesJob Safety Analysis Form Hydrotestyayongjcs100% (4)

- Hirarc Form Rev. 0 Page 1 of 1: Hazard Identification Control MeasuresDocument2 pagesHirarc Form Rev. 0 Page 1 of 1: Hazard Identification Control Measuressyafiq ishak100% (1)

- Job Hazard Analysis Welding Operations: Job Title: Work Place LocationDocument18 pagesJob Hazard Analysis Welding Operations: Job Title: Work Place Locationmuhammad imtiaz100% (1)

- SWP Welder Gas Metal Arc AS560Document2 pagesSWP Welder Gas Metal Arc AS560Kamal ShaariNo ratings yet

- Safe Work Procedure (Drill Press)Document2 pagesSafe Work Procedure (Drill Press)SURJIT SINGH100% (1)

- Risk Assesment For Sand Blasting and PaintingDocument6 pagesRisk Assesment For Sand Blasting and PaintingRochdi Bahiri100% (10)

- Safety Operating Procedure Angle GrinderDocument1 pageSafety Operating Procedure Angle GrinderSURJIT SINGHNo ratings yet

- JSA-for Lifting Activity by Crane. (11-01-2016)Document3 pagesJSA-for Lifting Activity by Crane. (11-01-2016)Mohammed Minhaj100% (2)

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: Facilitywahyu nugrohoNo ratings yet

- HIRARCDocument34 pagesHIRARCLeal Safety100% (3)

- JSA Machinal PipingDocument7 pagesJSA Machinal PipingNaitik Desai48100% (1)

- Job Safety Analysis - 100 Ton Hyd Press 14.8.07Document1 pageJob Safety Analysis - 100 Ton Hyd Press 14.8.07IB IsmadyNo ratings yet

- JSA Welding Confined SpaceDocument2 pagesJSA Welding Confined Spacegkmlal100% (4)

- HIRARC Work at HeightDocument2 pagesHIRARC Work at HeightPanchdev KumarNo ratings yet

- 13.2.4 RA SWP For Cable Installation Glanding Terminating Testing To Site Cabins at DCLDocument13 pages13.2.4 RA SWP For Cable Installation Glanding Terminating Testing To Site Cabins at DCLMARIAN100% (1)

- JSA For Working at HeightDocument2 pagesJSA For Working at HeightXUE JIANNo ratings yet

- Job Safety Analysis (Rolling For MS Plates)Document1 pageJob Safety Analysis (Rolling For MS Plates)Muhammad Ali100% (2)

- 002 Working at Height Risk AssessmentDocument4 pages002 Working at Height Risk Assessmentgangadharan000100% (14)

- Roof Work HIRARCDocument4 pagesRoof Work HIRARCSarah Liyana86% (7)

- Refueling JSA 4 08 2019 Rev.03 Near WaterDocument9 pagesRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariNo ratings yet

- HIRARCDocument34 pagesHIRARCNaga Rajan100% (1)

- OCP 12 - Working at HeightDocument2 pagesOCP 12 - Working at HeightVipin Kumar Parashar100% (1)

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: Facilitysanjeev kumar100% (1)

- JSA Installation of GearboxDocument2 pagesJSA Installation of Gearboxprasong100% (1)

- Nelson NCD 1000T 1600T Operating ManualDocument35 pagesNelson NCD 1000T 1600T Operating ManualSagar KumarNo ratings yet

- E3000 enDocument22 pagesE3000 enasilka68No ratings yet

- Wire Feeder UnitDocument26 pagesWire Feeder UnitXicotencatl DelgadilloNo ratings yet

- Byproduct Operations and ProcessDocument8 pagesByproduct Operations and ProcessAbhaySnghNo ratings yet

- Guide To The NEBOSH Award in Health and Safety at Work: July 2016Document46 pagesGuide To The NEBOSH Award in Health and Safety at Work: July 2016IrfanNo ratings yet

- Guidelines For Standardization of Colour Code Scheme On OHE MasDocument27 pagesGuidelines For Standardization of Colour Code Scheme On OHE MasAbhaySnghNo ratings yet

- Nebosh Open Book Examination Learner GuideDocument12 pagesNebosh Open Book Examination Learner GuideAbhaySngh100% (1)

- Vertigo Test ModelDocument1 pageVertigo Test ModelAbhaySngh100% (1)

- SG Mandatory Sign Poster Wear Your Helmets A4 PDFDocument1 pageSG Mandatory Sign Poster Wear Your Helmets A4 PDFAbhaySnghNo ratings yet

- IGC3 GuidanceDocument21 pagesIGC3 GuidanceAmitPatroNo ratings yet

- Safe Load IndicatorDocument8 pagesSafe Load IndicatorAbhaySnghNo ratings yet

- Working at Height Recue Plan PDFDocument2 pagesWorking at Height Recue Plan PDFAmit Singh ChauhanNo ratings yet

- Job Safety Analysis FormDocument2 pagesJob Safety Analysis FormAbhaySngh100% (1)

- Green Cascade PDFDocument1 pageGreen Cascade PDFAbhaySnghNo ratings yet

- SG Mandatory Sign Poster Wear Your Helmets A4 PDFDocument1 pageSG Mandatory Sign Poster Wear Your Helmets A4 PDFAbhaySnghNo ratings yet

- Job Safety Analysis FormDocument2 pagesJob Safety Analysis FormAbhaySngh100% (1)

- Root Cause Analysis and Critical Thought: July 19, 2012Document24 pagesRoot Cause Analysis and Critical Thought: July 19, 2012KushNo ratings yet

- Rohan Builders (India) PVT - LTD: Concreting Rbipl MR - Vilas Kadam / MR - Sunil Shinde Main Plant and Road WorkDocument3 pagesRohan Builders (India) PVT - LTD: Concreting Rbipl MR - Vilas Kadam / MR - Sunil Shinde Main Plant and Road WorkAbhaySngh100% (1)

- ISO 45001.docx Check ListDocument18 pagesISO 45001.docx Check ListKrishna Vacha100% (1)

- Safety Training PassportDocument2 pagesSafety Training PassportAbhaySnghNo ratings yet

- Safety CheckDocument2 pagesSafety CheckAbhaySngh100% (1)

- 019.full Face & Escape Mask - Rev.0 PDFDocument21 pages019.full Face & Escape Mask - Rev.0 PDFnarasimhamurthy414No ratings yet

- Health and Safety Policy: Rev No: 03 Dr. Vinod Nowal Date: 1 June 2017 Deputy Managing DirectorDocument1 pageHealth and Safety Policy: Rev No: 03 Dr. Vinod Nowal Date: 1 June 2017 Deputy Managing DirectorAbhaySnghNo ratings yet

- OSHA Slings 1910.184Document15 pagesOSHA Slings 1910.184Binoy GopinathanNo ratings yet

- Project PresentationDocument17 pagesProject PresentationSaran M KumarNo ratings yet

- 14DICIDocument450 pages14DICIDanBarberaNo ratings yet

- Thermomix Instruction ManualDocument68 pagesThermomix Instruction ManualKarren_M888100% (1)

- The WEEKENDERDocument4 pagesThe WEEKENDERasafoabe4065No ratings yet

- Vasanth & CoDocument3 pagesVasanth & CoJegan Joseph0% (1)

- Ashok Griha Udyog Kendra (P) LimitedDocument9 pagesAshok Griha Udyog Kendra (P) LimitedAmit BhattacherjiNo ratings yet

- Oasis: by Emily ReichDocument5 pagesOasis: by Emily ReichcannibithobbalNo ratings yet

- Walmart Business ModuleDocument21 pagesWalmart Business ModulewarlockNo ratings yet

- Shivan&Narresh PresentationDocument16 pagesShivan&Narresh PresentationAyush Khanna100% (3)

- PorterSM05final FinAccDocument67 pagesPorterSM05final FinAccGemini_0804100% (2)

- Bissell Powerforce Bagless Turbo ManualDocument16 pagesBissell Powerforce Bagless Turbo ManualdennisborcherNo ratings yet

- Sony Company ProfileDocument7 pagesSony Company ProfileAmruta TerdalNo ratings yet

- Non Wovens - FinalDocument43 pagesNon Wovens - FinalBijal DedhianGosarNo ratings yet

- ScaniaDocument60 pagesScaniaCarlos100% (1)

- Engine 114 - 2 Series KomatsuDocument444 pagesEngine 114 - 2 Series KomatsuLuis Mendez100% (5)

- Create Jewelry PearlsDocument8 pagesCreate Jewelry PearlsInterweave80% (5)

- Anglicism FashionDocument22 pagesAnglicism Fashionlukalu100% (1)

- Marketing Plan FinalDocument7 pagesMarketing Plan FinalSerial Sleeper100% (1)

- Washmachine Manual IWDE126Document20 pagesWashmachine Manual IWDE126Ana AnaNo ratings yet

- Classified: Your Local MarketplaceDocument4 pagesClassified: Your Local MarketplaceDigital MediaNo ratings yet

- Manual Kenmore 385.17928Document73 pagesManual Kenmore 385.17928Angel SandovalNo ratings yet

- Idhiyaan Catalog 2Document73 pagesIdhiyaan Catalog 2Geeta BhavanNo ratings yet

- TextDocument43 pagesTextshockwave1665No ratings yet

- Tutorial Martha DahligDocument3 pagesTutorial Martha DahligalfredovidyNo ratings yet

- IKEA Case StudyDocument4 pagesIKEA Case StudyMaya Bharti100% (3)

- Different Kinds of Tools and Equipments in The Kitchen LaboratoryDocument8 pagesDifferent Kinds of Tools and Equipments in The Kitchen LaboratoryMaria ComonNo ratings yet

- ConsumerDocument1 pageConsumerLucian NutaNo ratings yet

- 01 - Competing With OperationsDocument34 pages01 - Competing With OperationsJai SundriyalNo ratings yet

- Class-good-Designing Distribution Network and Application To E-BusinessDocument37 pagesClass-good-Designing Distribution Network and Application To E-BusinessReshma Mariya TomyNo ratings yet