Professional Documents

Culture Documents

Hemispherical Ends en 13445-3 - 8.8.1

Uploaded by

met-calc0 ratings0% found this document useful (0 votes)

14 views2 pagesHemispherical Ends en 13445-3

Original Title

Hemispherical Ends en 13445-3_8.8.1

Copyright

© © All Rights Reserved

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document0 ratings0% found this document useful (0 votes)

14 views2 pagesHemispherical Ends en 13445-3 - 8.8.1

Uploaded by

met-calcYou are on page 1of 2

8.8.

1 Hemispherical ends

The minimum yield strength or 0,2% proof strength at

calculation temperature: Rp0,2T 355 [Mpa]

The nominal elastic limits for shell:

Ferritic material

𝜎 =𝑅 , /

Austenitic material

𝑅 , /

𝜎 =

1,25

Fer

σe 355 [Mpa]

The nominal thickness: en 10 [mm]

The corrosion allowance: c 2 [mm]

The absolute value of the possible negative tolerance

on the nominal thickness (EN 10029): quality C

de1 0 [mm]

Limit values of weld joint defects (EN ISO 5817): quality C

Linear offset between plates (EN 5817):

𝐵 → 𝛿 = 𝑚𝑖𝑛 0,2 + 0,1𝑒 ; 3

𝐶 → 𝛿 = 𝑚𝑖𝑛 0,2 + 0,15𝑒 ; 4

𝐷 → 𝛿 = 𝑚𝑖𝑛 0,2 + 0,25𝑒 ; 5

de2 1,7 [mm]

Defects of welds:

𝐵 → 𝛿 = 0,2𝑒 ∗ 0,04

𝐶 → 𝛿 = 0,3𝑒 ∗ 0,08

𝐷 → 𝛿 = 0,4𝑒 ∗ 0,16

de3 0,2 [mm]

The analysis thickness:

𝑒 =𝑒 −𝛿 −𝛿 −𝛿 −𝑐

ea 6,1 [mm]

The mean radius of a hemispherical ends: R 304 [mm]

The elastic modulus: E 210000 [MPa]

The pressure at which mean circumferential stress in a

hemispherical ends, reaches yield point:

2𝜎 ∗ 𝑒

𝑃 =

𝑅

Py 14,2 [MPa]

The theoretical elastic instability pressure for collapse

of a perfect hemispherical ends:

1,21𝐸 ∗ 𝑒

𝑃 =

𝑅

Pm 101,0 [MPa]

Pm/Py 7,1 [MPa]

Pr/Py 0,57 [MPa]

The calculated lower bound collapse pressure:

𝑃

𝑃 = ∗𝑃

𝑃

Pr 8,1 [MPa]

The calculation pressure: P 4 [Mpa]

The test pressure: Ptest 6 [Mpa]

𝑃 < 𝑃 /1.5 Pr/1.5 5,4 [Mpa]

𝑃 < 𝑃 /1.1 Pr/1.1 7,3 [Mpa]

The circularity tolerance:

𝑇𝑜𝑙𝑒𝑟𝑎𝑛𝑐𝑒 = 0,01𝑅

tolerance 3,0 [mm]

The length of the arc to which the nominal tolerance

may not exceed by more than 30%

𝑒

𝑎𝑟𝑐 𝑙𝑒𝑛𝑔𝑡ℎ = 2,4 𝑒 ∗ 𝑅 +

2

the length of the arc 103,5 [mm]

30% tolerance 0,9 [mm]

You might also like

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Document19 pagesHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Lattice Disc)Document31 pagesHydrodynamic Calculation Butterfly Valve (Lattice Disc)met-calcNo ratings yet

- Hydrodynamic Calculation Howell-Jet ValveDocument17 pagesHydrodynamic Calculation Howell-Jet Valvemet-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Document24 pagesHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document31 pagesHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNo ratings yet

- Hydrodynamic Calculation Needle ValveDocument23 pagesHydrodynamic Calculation Needle Valvemet-calcNo ratings yet

- Rolled Shells (7.4.2) According To Standards EN 13445-3: Values For CalculationDocument3 pagesRolled Shells (7.4.2) According To Standards EN 13445-3: Values For Calculationmet-calcNo ratings yet

- Threaded Holes (11.4.3.3) EN 13445-3Document1 pageThreaded Holes (11.4.3.3) EN 13445-3met-calcNo ratings yet

- Spherical Shells (7.4.3) EN 13445-3Document3 pagesSpherical Shells (7.4.3) EN 13445-3met-calcNo ratings yet

- Hydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The PistonDocument23 pagesHydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The Pistonmet-calcNo ratings yet

- Hydrodynamic Calculation Spherical ValveDocument40 pagesHydrodynamic Calculation Spherical Valvemet-calcNo ratings yet

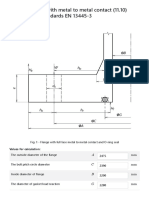

- Full Face Flange With Metal To Metal Contact (11.10) EN 13445-3Document5 pagesFull Face Flange With Metal To Metal Contact (11.10) EN 13445-3met-calcNo ratings yet

- Nuts (11.4.3.2) EN 13445-3Document1 pageNuts (11.4.3.2) EN 13445-3met-calcNo ratings yet

- Multi-Stage ValveDocument2 pagesMulti-Stage Valvemet-calcNo ratings yet

- Hydrodynamic Calculation Howell-Bunger ValveDocument34 pagesHydrodynamic Calculation Howell-Bunger Valvemet-calcNo ratings yet

- Hydrodynamic Calculation Gate Valve (Through-Conduit)Document23 pagesHydrodynamic Calculation Gate Valve (Through-Conduit)met-calcNo ratings yet

- Contact Stress of Cylinder On Flat SurfaceDocument3 pagesContact Stress of Cylinder On Flat Surfacemet-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Lenticular Disc)Document28 pagesHydrodynamic Calculation Butterfly Valve (Lenticular Disc)met-calcNo ratings yet

- BucklingDocument2 pagesBucklingmet-calcNo ratings yet

- Conical Shells (7.6.4) EN 13445-3Document3 pagesConical Shells (7.6.4) EN 13445-3met-calcNo ratings yet

- Contact Stress Two CylindersDocument3 pagesContact Stress Two Cylindersmet-calcNo ratings yet

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Document4 pagesFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcNo ratings yet

- Contact Stress of The Cylinder in The Cylindrical SocketDocument3 pagesContact Stress of The Cylinder in The Cylindrical Socketmet-calcNo ratings yet

- Allowable Stress: R Mpa C SDocument1 pageAllowable Stress: R Mpa C Smet-calcNo ratings yet

- Hydrodynamic Calculation Gate Valve (Through Conduit)Document14 pagesHydrodynamic Calculation Gate Valve (Through Conduit)met-calcNo ratings yet

- Allowable Hertz PressureDocument1 pageAllowable Hertz Pressuremet-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document18 pagesHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNo ratings yet

- Multi-Hole CageDocument7 pagesMulti-Hole Cagemet-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Lattice Disc)Document18 pagesHydrodynamic Calculation Butterfly Valve (Lattice Disc)met-calcNo ratings yet

- The Flow Characteristic On The Position of The DriveDocument7 pagesThe Flow Characteristic On The Position of The Drivemet-calcNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Cold-Formed Steel Flexural Member With Edge Stiffened Holes Behavior, Optimization, and DesignDocument9 pagesCold-Formed Steel Flexural Member With Edge Stiffened Holes Behavior, Optimization, and Designchristos032No ratings yet

- Design of Rectangular Reinforced Concrete BeamDocument7 pagesDesign of Rectangular Reinforced Concrete BeamsaadNo ratings yet

- Crushing Strain of Concrete - Google SearchDocument3 pagesCrushing Strain of Concrete - Google SearchUtkarsh YadavNo ratings yet

- Definitions AISI 2007Document20 pagesDefinitions AISI 2007sergiob0107SBANo ratings yet

- JSPL Insdag BookDocument291 pagesJSPL Insdag Bookshrikant waghNo ratings yet

- Thermal Stresses in a Metal Rod Encased in AluminaDocument8 pagesThermal Stresses in a Metal Rod Encased in AluminaamnajamNo ratings yet

- Machine Design-AC09Document7 pagesMachine Design-AC09Ashutosh RajawatNo ratings yet

- Locating Earthquake Epicenters Using Seismic Wave DataDocument8 pagesLocating Earthquake Epicenters Using Seismic Wave DataMira VeranoNo ratings yet

- 02.06 Chapter 6 - Ship StructuresDocument25 pages02.06 Chapter 6 - Ship StructuresMogie TalampasNo ratings yet

- Shear Reinforcement Design of Beam Column JointsDocument35 pagesShear Reinforcement Design of Beam Column JointsAnggi Novi AndriNo ratings yet

- Faliures in Steel StructuresDocument15 pagesFaliures in Steel StructuresVindula RanawakaNo ratings yet

- Stresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsDocument12 pagesStresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsAlexander BlackNo ratings yet

- IES OBJ Civil Engineering 2002 Paper IDocument17 pagesIES OBJ Civil Engineering 2002 Paper ISudharsananPRSNo ratings yet

- Material Characterisation - Low Cost Housing - Dr. V Singhal - H.bashaDocument45 pagesMaterial Characterisation - Low Cost Housing - Dr. V Singhal - H.bashaRatihYustinaputriNo ratings yet

- ReWaRD 2.5 Reference ManualDocument110 pagesReWaRD 2.5 Reference ManualaselabambarandageNo ratings yet

- Deformation of Ceramics and PolymersDocument41 pagesDeformation of Ceramics and PolymersJane Erestain BuenaobraNo ratings yet

- CH 13Document15 pagesCH 13xperia30100% (1)

- Mini Project SteelDocument9 pagesMini Project SteelMuhammad NaqibNo ratings yet

- YieldingDocument2 pagesYieldingtyjmtyjmNo ratings yet

- Exit Exam Temesgen.DDocument83 pagesExit Exam Temesgen.DFira tubeNo ratings yet

- Calculation of Pipe SupportDocument6 pagesCalculation of Pipe Supportnaveen_86No ratings yet

- Snap Fit DesignDocument22 pagesSnap Fit Designsachinrawool100% (1)

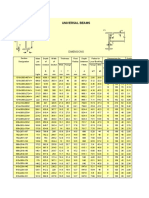

- UNIVERSAL BEAM DIMENSIONSDocument241 pagesUNIVERSAL BEAM DIMENSIONSeng_muhammad88No ratings yet

- Compressive Strength of WoodDocument6 pagesCompressive Strength of Woodatreu747100% (2)

- Plastic Analysis and Design MethodsDocument18 pagesPlastic Analysis and Design MethodsShita Alemie100% (2)

- Mechanical Behavior of Inconel 625 at Elevated TempDocument13 pagesMechanical Behavior of Inconel 625 at Elevated Tempgacm98No ratings yet

- Calculation For IPE360Document12 pagesCalculation For IPE360HaymanAHMEDNo ratings yet

- KA20903 - Lecture 1 Introduction To Mechanics of SolidsDocument6 pagesKA20903 - Lecture 1 Introduction To Mechanics of SolidsKit Meng LimNo ratings yet

- Buckling of Tubulars Inside Wellbores: A Review On Recent Theoretical and Experimental WorksDocument7 pagesBuckling of Tubulars Inside Wellbores: A Review On Recent Theoretical and Experimental WorksmsmsoftNo ratings yet

- SeismicGuidelines WaterPipelinesDocument265 pagesSeismicGuidelines WaterPipelinesanon_839792731No ratings yet