Professional Documents

Culture Documents

Interstiffener Collapse en 13445-3 - 8.6.3

Uploaded by

met-calc0 ratings0% found this document useful (0 votes)

60 views4 pagesInterstiffener Collapse en 13445-3

Original Title

Interstiffener Collapse en 13445-3_8.6.3

Copyright

© © All Rights Reserved

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document0 ratings0% found this document useful (0 votes)

60 views4 pagesInterstiffener Collapse en 13445-3 - 8.6.3

Uploaded by

met-calcYou are on page 1of 4

8.6.

3 Interstiffener collapse

The minimum yield strength or 0,2% proof strength at

calculation temperature: Rp0,2T 345 [Mpa]

The nominal elastic limits for shell:

Ferritic material

𝜎 =𝑅 , /

Austenitic material

𝑅 , /

𝜎 =

1,25

Fer

σe 345 [Mpa]

The nominal thickness: en 35 [mm]

The corrosion allowance: c 2 [mm]

The absolute value of the possible negative tolerance

on the nominal thickness (EN 10029): quality C

de1 0 [mm]

Limit values of weld joint defects (EN ISO 5817): quality D

Linear offset between plates (EN 5817):

𝐵 → 𝛿 = 𝑚𝑖𝑛 0,2 + 0,1𝑒 ; 3

𝐶 → 𝛿 = 𝑚𝑖𝑛 0,2 + 0,15𝑒 ; 4

𝐷 → 𝛿 = 𝑚𝑖𝑛 0,2 + 0,25𝑒 ; 5

de2 5 [mm]

Defects of welds:

𝐵 → 𝛿 = 0,2𝑒 ∗ 0,04

𝐶 → 𝛿 = 0,3𝑒 ∗ 0,08

𝐷 → 𝛿 = 0,4𝑒 ∗ 0,16

de3 2,2 [mm]

The analysis thickness:

𝑒 =𝑒 −𝛿 −𝛿 −𝛿 −𝑐

ea 25,8 [mm]

The maximum radius of conical shell: Rmax 1000 [mm]

The mean radius of conical shell: Rn 567 [mm]

The semi angle of come at apex: α 30 [°]

The elastic modulus: E 210000 [MPa]

The unsupported length of the shell: L 1000 [mm]

The pressure at which mean circumferential stress in a

conical shell, reaches yield point:

𝑒 ∗ 𝜎 ∗ cos 𝛼

𝑃 =

𝑅

Py 7,7 [MPa]

L/2R=L/2Rncosα 1,0

ea/2R=ea/2Rncosα 0,026

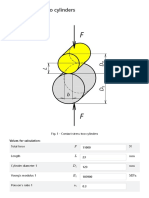

The number of circumferential waves for an

unstiffened part of a conical shell: ncyl 3 []

Parameter:

𝜋 ∗ 𝑅 ∗ cos ∝

𝑍=

𝐿

Z 1,5 []

Poisson's ratio: ν 0,3 []

The mean elastic circumferential strain at collapse:

1 1 𝑒 ∗ cos ∝

𝜀= + 𝑛 −1+𝑍

𝑍 𝑛 12 𝑅 ∗ 𝑐𝑜𝑠 ∝ 1 − 𝜈

𝑛 −1+

2 +1

𝑍

ε 0,008 []

The theoretical elastic instability pressure for collapse

of a perfect conical shell:

𝐸 ∗ 𝑒 ∗ 𝜀 ∗ 𝑐𝑜𝑠 ∝

𝑃 =

𝑅

Pm 47,8 [MPa]

Pm/Py 6,2 [MPa]

Pr/Py 0,935 [MPa]

The calculated lower bound collapse pressure:

𝑃

𝑃 = ∗𝑃

𝑃

Pr 7,2 [MPa]

The calculation pressure: P 2,5 [Mpa]

The test pressure: Ptest 4 [Mpa]

𝑃 < 𝑃 /1,5 Pr/1,5 4,8 [Mpa]

𝑃 < 𝑃 /1,1 Pr/1,1 6,5 [Mpa]

You might also like

- Unstiffened Cylinders EN 13445-3 - 8.5.2 PDFDocument4 pagesUnstiffened Cylinders EN 13445-3 - 8.5.2 PDFfrlamontNo ratings yet

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Rating: 4.5 out of 5 stars4.5/5 (5)

- Design of Stairs Design of Stairs From Ground To Landing Material PropertiesDocument3 pagesDesign of Stairs Design of Stairs From Ground To Landing Material PropertiesJohn Paul Hilary EspejoNo ratings yet

- Principles of HydrotherapyDocument21 pagesPrinciples of Hydrotherapyvaishali jagtap100% (6)

- Figure 9.4-9 Cylindrical Shell With Isolated Opening, Increased Wall Thickness and Set-In Nozzle en 13445-3 - Figure 9.4-9Document4 pagesFigure 9.4-9 Cylindrical Shell With Isolated Opening, Increased Wall Thickness and Set-In Nozzle en 13445-3 - Figure 9.4-9met-calcNo ratings yet

- Overview of GRP PipesDocument14 pagesOverview of GRP PipesMD IBRARNo ratings yet

- Figure 9.5-1 Cylindrical Shell With Nozzle Oblique in The Longitudinal Cross Section en 13445-3 - Figure 9.5-1Document5 pagesFigure 9.5-1 Cylindrical Shell With Nozzle Oblique in The Longitudinal Cross Section en 13445-3 - Figure 9.5-1met-calcNo ratings yet

- Power ScrewsDocument4 pagesPower Screwsmet-calcNo ratings yet

- Circulatum MinusDocument2 pagesCirculatum MinusJoshua Arent100% (1)

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Figure 9.5-2 Cylindrical Shell With Nozzle Oblique in The Transverse Cross Section en 13445-3 - Figure 9.5-2Document5 pagesFigure 9.5-2 Cylindrical Shell With Nozzle Oblique in The Transverse Cross Section en 13445-3 - Figure 9.5-2met-calcNo ratings yet

- Hydrodynamic Calculation Needle ValveDocument23 pagesHydrodynamic Calculation Needle Valvemet-calcNo ratings yet

- Nuts (11.4.3.2) EN 13445-3Document1 pageNuts (11.4.3.2) EN 13445-3met-calcNo ratings yet

- Crochet Your Christmas Ornaments: 25 Christmas Decorations to MakeFrom EverandCrochet Your Christmas Ornaments: 25 Christmas Decorations to MakeRating: 5 out of 5 stars5/5 (2)

- Hydrodynamic Calculation Butterfly Valve (Lattice Disc)Document18 pagesHydrodynamic Calculation Butterfly Valve (Lattice Disc)met-calcNo ratings yet

- Figure 9.4-13 Conical Shell With Isolated Opening. Combined Reinforcement From Shell and Nozzle en 13445-3 - Figure 9.4-13Document4 pagesFigure 9.4-13 Conical Shell With Isolated Opening. Combined Reinforcement From Shell and Nozzle en 13445-3 - Figure 9.4-13met-calcNo ratings yet

- Figure 9.5-3 Spherical Shell With A Non Radial Nozzle en 13445-3 - Figure 9.5-3Document5 pagesFigure 9.5-3 Spherical Shell With A Non Radial Nozzle en 13445-3 - Figure 9.5-3met-calcNo ratings yet

- Conical Shells (7.6.4) EN 13445-3Document3 pagesConical Shells (7.6.4) EN 13445-3met-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document18 pagesHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNo ratings yet

- Allowable Stress: R Mpa C SDocument1 pageAllowable Stress: R Mpa C Smet-calcNo ratings yet

- Spherical Shells (7.4.3) EN 13445-3Document3 pagesSpherical Shells (7.4.3) EN 13445-3met-calcNo ratings yet

- Contact Stress of The Cylinder in The Cylindrical SocketDocument3 pagesContact Stress of The Cylinder in The Cylindrical Socketmet-calcNo ratings yet

- Contact Stress of Cylinder On Flat SurfaceDocument3 pagesContact Stress of Cylinder On Flat Surfacemet-calcNo ratings yet

- Threaded Holes (11.4.3.3) EN 13445-3Document1 pageThreaded Holes (11.4.3.3) EN 13445-3met-calcNo ratings yet

- Unstiffened Cylinders en 13445-3 - 8.5.2Document4 pagesUnstiffened Cylinders en 13445-3 - 8.5.2met-calcNo ratings yet

- Hydrodynamic Calculation Howell-Bunger ValveDocument34 pagesHydrodynamic Calculation Howell-Bunger Valvemet-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Lenticular Disc)Document28 pagesHydrodynamic Calculation Butterfly Valve (Lenticular Disc)met-calcNo ratings yet

- Hydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The PistonDocument23 pagesHydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The Pistonmet-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Document24 pagesHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNo ratings yet

- Spherical Shells en 13445-3 - 7.4.3Document3 pagesSpherical Shells en 13445-3 - 7.4.3met-calc100% (1)

- Rolled Shells (7.4.2) According To Standards EN 13445-3: Values For CalculationDocument3 pagesRolled Shells (7.4.2) According To Standards EN 13445-3: Values For Calculationmet-calcNo ratings yet

- U-Shaped Unreinforced Bellows (Austenitic Steel)Document9 pagesU-Shaped Unreinforced Bellows (Austenitic Steel)met-calc100% (1)

- Full Face Flange With Metal To Metal Contact (11.10) EN 13445-3Document5 pagesFull Face Flange With Metal To Metal Contact (11.10) EN 13445-3met-calcNo ratings yet

- The Flow Characteristic On The Position of The DriveDocument7 pagesThe Flow Characteristic On The Position of The Drivemet-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Lattice Disc)Document31 pagesHydrodynamic Calculation Butterfly Valve (Lattice Disc)met-calcNo ratings yet

- BucklingDocument2 pagesBucklingmet-calcNo ratings yet

- Hydrodynamic Calculation Gate Valve (Through Conduit)Document14 pagesHydrodynamic Calculation Gate Valve (Through Conduit)met-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document31 pagesHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNo ratings yet

- Hydrodynamic Calculation Gate Valve (Through-Conduit)Document23 pagesHydrodynamic Calculation Gate Valve (Through-Conduit)met-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Document19 pagesHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNo ratings yet

- Articulated Trunnion in The RodDocument5 pagesArticulated Trunnion in The Rodmet-calc100% (1)

- Contact Stress Two CylindersDocument3 pagesContact Stress Two Cylindersmet-calcNo ratings yet

- Hydrodynamic Calculation Spherical ValveDocument40 pagesHydrodynamic Calculation Spherical Valvemet-calcNo ratings yet

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Document4 pagesFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcNo ratings yet

- Hydrodynamic Calculation Howell-Jet ValveDocument17 pagesHydrodynamic Calculation Howell-Jet Valvemet-calcNo ratings yet

- Multi-Stage ValveDocument2 pagesMulti-Stage Valvemet-calcNo ratings yet

- Ellipsoidal Ends en 13445-3 - 8.8.3Document2 pagesEllipsoidal Ends en 13445-3 - 8.8.3met-calcNo ratings yet

- Junction Between The Large End of A Cone and A Cylinder With A Knuckle en 13445-3 - 7.6.7Document4 pagesJunction Between The Large End of A Cone and A Cylinder With A Knuckle en 13445-3 - 7.6.7met-calcNo ratings yet

- Junction Between The Large End of A Cone and A Cylinder Without A Knuckle en 13445-3 - 7.6.6Document3 pagesJunction Between The Large End of A Cone and A Cylinder Without A Knuckle en 13445-3 - 7.6.6met-calcNo ratings yet

- Light Stiffeners EN 13445-3 - 8.6.4.1.2Document10 pagesLight Stiffeners EN 13445-3 - 8.6.4.1.2met-calcNo ratings yet

- U-Shaped Reinforced Bellows (Austenitic Steel)Document10 pagesU-Shaped Reinforced Bellows (Austenitic Steel)met-calcNo ratings yet

- Figure 9.4-5 Cylindrical Shell With Isolated Opening and Reinforcing Ring, With External Blind Flange B en 13445-3 - Figure 9.4-5Document4 pagesFigure 9.4-5 Cylindrical Shell With Isolated Opening and Reinforcing Ring, With External Blind Flange B en 13445-3 - Figure 9.4-5met-calcNo ratings yet

- Nozzles Which Encroach Into The Knuckle Region (Kloepper) en 13445-3 - 7.7Document6 pagesNozzles Which Encroach Into The Knuckle Region (Kloepper) en 13445-3 - 7.7met-calcNo ratings yet

- Longitudinal Pin For Shaft-Hub ConnectionDocument6 pagesLongitudinal Pin For Shaft-Hub Connectionmet-calcNo ratings yet

- Component DesignDocument32 pagesComponent Designdaniel hambissaNo ratings yet

- 08 Practical Application Press FitDocument6 pages08 Practical Application Press Fitenrico.michelatoNo ratings yet

- Example 2 To Start ExplainationDocument8 pagesExample 2 To Start ExplainationsamehNo ratings yet

- BEARING STRESS CALCULATIONDocument21 pagesBEARING STRESS CALCULATIONDenver NieverasNo ratings yet

- Beams: (Frame 2)Document54 pagesBeams: (Frame 2)John Rafael R. CanoosNo ratings yet

- Coupling and Its TypesDocument22 pagesCoupling and Its TypesAnantha BhatNo ratings yet

- Two-Way Slab Design AnalysisDocument12 pagesTwo-Way Slab Design AnalysisMin Min IINo ratings yet

- Design Test 1 - (With Memo)Document5 pagesDesign Test 1 - (With Memo)Tukisho MacheteNo ratings yet

- 06 Practical Application Bolted Cylindrical VesselDocument12 pages06 Practical Application Bolted Cylindrical Vesselenrico.michelatoNo ratings yet

- Composite AssDocument13 pagesComposite AssBelay BayuNo ratings yet

- Barrier Connector CalculationDocument2 pagesBarrier Connector CalculationSaifan RizaldyNo ratings yet

- IC Engines Design Book PDFDocument19 pagesIC Engines Design Book PDFRohith FernandoNo ratings yet

- Double Action Lifting Jack Design CalculationsDocument26 pagesDouble Action Lifting Jack Design CalculationsGabriel AkNo ratings yet

- Sample SolutionsDocument10 pagesSample SolutionsRishabh JainNo ratings yet

- CE199-2L Deesuyn-MergedDocument67 pagesCE199-2L Deesuyn-MergedMark Kenneth BaldoqueNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Allowable Hertz PressureDocument1 pageAllowable Hertz Pressuremet-calcNo ratings yet

- Multi-Hole CageDocument7 pagesMulti-Hole Cagemet-calcNo ratings yet

- Fat Digestion and Metabolism in RuminantsDocument23 pagesFat Digestion and Metabolism in Ruminantsshahbaz zafarNo ratings yet

- Weld Design-GrDocument58 pagesWeld Design-Grvenky100% (1)

- Scope and Sequence - ChemistryDocument2 pagesScope and Sequence - Chemistryapi-232424041No ratings yet

- Abrasive-A ReviewDocument43 pagesAbrasive-A ReviewA.YusoffNo ratings yet

- Nanotechnology v1.0Document43 pagesNanotechnology v1.0Faizan AhmedNo ratings yet

- Physico-chemical Water Treatment Processes AssignmentDocument6 pagesPhysico-chemical Water Treatment Processes AssignmentAbir HasanNo ratings yet

- Folder ILF Upstream Facilities enDocument4 pagesFolder ILF Upstream Facilities enSterling GordianNo ratings yet

- 12.co Ordination CompoundsExerciseDocument34 pages12.co Ordination CompoundsExerciseMaster Of HakingNo ratings yet

- Ts 1 5 Specific Feed Safety LimitsDocument87 pagesTs 1 5 Specific Feed Safety Limitsraed abujoudehNo ratings yet

- M.E.Forge Tech: Customer:M/s L & T Valves LimitedDocument1 pageM.E.Forge Tech: Customer:M/s L & T Valves LimitedK.s. Raghavendra KumarNo ratings yet

- Notice IchloreDocument228 pagesNotice IchloreHervé MunozNo ratings yet

- Study of Gas-Condensate Well Productivity in Santa Barbara Field, Venezuela, by Well Test AnalysisDocument9 pagesStudy of Gas-Condensate Well Productivity in Santa Barbara Field, Venezuela, by Well Test AnalysisWaleed Barakat MariaNo ratings yet

- Newton HydroSeal 107F Elastic 2K TDS 4.0Document8 pagesNewton HydroSeal 107F Elastic 2K TDS 4.0Дмитрий СаламатовNo ratings yet

- Analytical Chemistry Volume 28 Issue 10 1956 (Doi 10.1021/ac60118a012) Pflaum, R. T. Howick, L. C. - Spectrophotometric Determination of Potassium With Sodium TetraphenylborateDocument3 pagesAnalytical Chemistry Volume 28 Issue 10 1956 (Doi 10.1021/ac60118a012) Pflaum, R. T. Howick, L. C. - Spectrophotometric Determination of Potassium With Sodium TetraphenylboratekhqqxyzNo ratings yet

- Allelopathic Potential of Tagetes Minuta Terpenes by A ChemicalDocument9 pagesAllelopathic Potential of Tagetes Minuta Terpenes by A ChemicalbiologiaufbaNo ratings yet

- WS3Document2 pagesWS3dextercitomanNo ratings yet

- As Chemistry Practical Booklet 2020-2021: NAME: - CLASS - TEACHERDocument9 pagesAs Chemistry Practical Booklet 2020-2021: NAME: - CLASS - TEACHERPaul MurrayNo ratings yet

- Chapter 3 2Document41 pagesChapter 3 2jerrica thomasNo ratings yet

- Zahid Husain M.Pharm (Pharmaceutics) Faculty of Pharmacy, IU, LucknowDocument24 pagesZahid Husain M.Pharm (Pharmaceutics) Faculty of Pharmacy, IU, LucknowQA Dhq OkaraNo ratings yet

- Spectrex UV IR 20 20LBDocument2 pagesSpectrex UV IR 20 20LBGustavo Alejandro Flores GarriNo ratings yet

- T06002.006 Viva E System Onsite Training Workbook Eff Date 09-13-21Document66 pagesT06002.006 Viva E System Onsite Training Workbook Eff Date 09-13-21Zitouni LamineNo ratings yet

- A 826 - A826m - 95 Qtgyni05nqDocument5 pagesA 826 - A826m - 95 Qtgyni05nqsachinguptachdNo ratings yet

- Panduan Troli EmergencyDocument3 pagesPanduan Troli EmergencyTukiyemNo ratings yet

- CVDocument2 pagesCVyadse100% (1)

- Small STNTechnical ManualDocument8 pagesSmall STNTechnical ManualMajid KhanNo ratings yet

- Energy and FluctuationDocument10 pagesEnergy and Fluctuationwalid Ait MazouzNo ratings yet

- Interpretation of Batch Reactor Data: Chapter ThreeDocument45 pagesInterpretation of Batch Reactor Data: Chapter ThreeAnnisa RizqiaNo ratings yet