Professional Documents

Culture Documents

R117 - 16 - Next Step in Offshore Maintenance Made Possible Through New JIP

Uploaded by

jobinhoeljoven0 ratings0% found this document useful (0 votes)

30 views1 pageR117_16_Next Step in Offshore Maintenance Made Possible Through New JIP

Original Title

R117_16_Next Step in Offshore Maintenance Made Possible Through New JIP

Copyright

© © All Rights Reserved

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentR117_16_Next Step in Offshore Maintenance Made Possible Through New JIP

Copyright:

© All Rights Reserved

0 ratings0% found this document useful (0 votes)

30 views1 pageR117 - 16 - Next Step in Offshore Maintenance Made Possible Through New JIP

Uploaded by

jobinhoeljovenR117_16_Next Step in Offshore Maintenance Made Possible Through New JIP

Copyright:

© All Rights Reserved

You are on page 1of 1

Next step in offshore

maintenance made

possible through new JIP

The Offshore Maintenance JIP aims to better quantify the O&M operability

and associated costs for maintenance operations by taking vessel

hydrodynamics and realistic operational limits into account in existing

Energy research Centre of the Netherlands (ECN) O&M cost models.

Erik-Jan de Ridder, e.d.ridder@marin.nl

The main aim of the OM JIP is to come up

with the most effective logistical scenario

for each maintenance operation. Present

O&M cost analysis models lack details about

hydrodynamic vessel response and human

response to vessel motions. Based on

discussions amongst partners and with

the industry it was concluded that there

was an urgent need for a realistic logistics

O&M model, which should include vessel

characteristics and operational (human)

criteria.

Furthermore, model tests with different CTV

The project was initiated by MARIN (hydro concepts were performed for the different

dynamics), ECN (operability and cost stages of the operation such as transit, and

prediction model) and TNO (human factors) approach and transfer All the data was then

and got underway in 2015. Research is validated with detailed, full- scale monitoring

performed in close cooperation with the of different CTVs in operation. The OM JIP

Carbon Trust from the UK, which represents can build even further on this large database,

most of the large energy companies in ensuring that there is no duplication of

Europe that are active in offshore wind. work. The research will now be extended to

larger DP accommodation vessels equipped

A considerable amount of research has been with access systems.

undertaken by the Carbon Trust which

mainly focuses on the smaller Crew Transfer The OM JIP consortium consists of 14 differ

Vessels (CTV) involved in offshore mainte ent participants including research institutes,

nance. Friction between the fender on the shipbuilders, OM operators, OM personnel,

bow of the CTV and the boat landing on the access system operators and utility compa

offshore wind turbine is an important para nies. Having such a diverse group involved

meter in the operation. Therefore, the work in the research makes it possible to take the

consisted of extended fender friction tests next step in offshore maintenance. New

both at model and full scale. companies are still invited to join.

16 report

You might also like

- A Maritime Inventory Routing Problem Discrete TimeDocument18 pagesA Maritime Inventory Routing Problem Discrete Timemajid yazdaniNo ratings yet

- Numerical Investigation On Ship EnergyDocument15 pagesNumerical Investigation On Ship Energygeng qinNo ratings yet

- Marine CFD 2005 - 4th International Conference On Marine Hydrodynamics (2005, The Royal Institution of Naval Architects)Document549 pagesMarine CFD 2005 - 4th International Conference On Marine Hydrodynamics (2005, The Royal Institution of Naval Architects)Rogerio GuahyNo ratings yet

- How Can Europeans Benefit From An Innovative Approach To Offshore Wind Farm Lifecycle and Supply ChainDocument23 pagesHow Can Europeans Benefit From An Innovative Approach To Offshore Wind Farm Lifecycle and Supply ChainAna Maria LaraNo ratings yet

- Simulation and Optimisation of Cargo Handling Operations of AFRAMAX TankersDocument11 pagesSimulation and Optimisation of Cargo Handling Operations of AFRAMAX TankersLaga PratamaNo ratings yet

- Vehicle RoutingDocument15 pagesVehicle RoutingmengistuNo ratings yet

- VIRTUE BPG Integrated Final PDFDocument233 pagesVIRTUE BPG Integrated Final PDFsplicosakiNo ratings yet

- Road Adland Et Al Ship Speed OptimizationDocument18 pagesRoad Adland Et Al Ship Speed OptimizationYihan ZhangNo ratings yet

- Optimization of O&MDocument9 pagesOptimization of O&MSHRUTIGONUNo ratings yet

- Ocean Engineering: D.G. Trodden, A.J. Murphy, K. Pazouki, James SargeantDocument10 pagesOcean Engineering: D.G. Trodden, A.J. Murphy, K. Pazouki, James SargeantMonica EllaNo ratings yet

- Approaching A Critical Review. An Assessment of Real World Crew Transfer Vessel Capabilities at Gwynt y MôrDocument17 pagesApproaching A Critical Review. An Assessment of Real World Crew Transfer Vessel Capabilities at Gwynt y MôrssnivashanNo ratings yet

- 1 s2.0 S2590174523000211 MainDocument19 pages1 s2.0 S2590174523000211 MainaminNo ratings yet

- Lessons Learned From Infrastructure Operation in The CUTE ProjectDocument11 pagesLessons Learned From Infrastructure Operation in The CUTE Projectmavroudisd3710No ratings yet

- Optimum CTV Fleet Selection For Offshore Wind Farm O M ActivitiesDocument9 pagesOptimum CTV Fleet Selection For Offshore Wind Farm O M ActivitiesWibowo ArieNo ratings yet

- Ship Performance IndicatorDocument10 pagesShip Performance Indicatorc rkNo ratings yet

- Transportation Research Part D: Kai Wang, Xinping Yan, Yupeng Yuan, Xiaoli Jiang, Xiao Lin, Rudy R. NegenbornDocument14 pagesTransportation Research Part D: Kai Wang, Xinping Yan, Yupeng Yuan, Xiaoli Jiang, Xiao Lin, Rudy R. NegenbornM Taufiq KhanNo ratings yet

- WER 2013 11 Marine EnergyDocument14 pagesWER 2013 11 Marine EnergyAshiq SheebanNo ratings yet

- Ecdis Enc 08 ReportDocument53 pagesEcdis Enc 08 ReportBinh Pham100% (1)

- GPRA15063 SubmittedDocument17 pagesGPRA15063 SubmittedTranspo MasterNo ratings yet

- 18-10-2016-Effect of Loading Conditions and Quay Crane Assignments On Container Terminal Performance PIANC COPEDEC 2016Document10 pages18-10-2016-Effect of Loading Conditions and Quay Crane Assignments On Container Terminal Performance PIANC COPEDEC 2016Al-Razzaq Al-WahhabNo ratings yet

- Offshore Facilities: Technology FocusDocument14 pagesOffshore Facilities: Technology FocusSarah MandasariNo ratings yet

- Design, Simulation, and Evaluation of Automated Container TerminalsDocument15 pagesDesign, Simulation, and Evaluation of Automated Container TerminalsHậu PhạmNo ratings yet

- Assessment of ESD Benefit Voermans2017Document27 pagesAssessment of ESD Benefit Voermans2017장영훈No ratings yet

- Improvement in Ship Powering Using Hull Vane: Chapter 1: IntroductionDocument10 pagesImprovement in Ship Powering Using Hull Vane: Chapter 1: IntroductionMuhamad Nazren Mohamed ZaidiNo ratings yet

- A Hybrid Estimation of Distribution Algorithm For The Quay Crane Scheduling ProblemDocument26 pagesA Hybrid Estimation of Distribution Algorithm For The Quay Crane Scheduling ProblemImane TorbiNo ratings yet

- A New Formulation Based On Customer Delivery Patterns For A Maritime Inventory Routing Problem2015transportation ScienceDocument19 pagesA New Formulation Based On Customer Delivery Patterns For A Maritime Inventory Routing Problem2015transportation Sciencemajid yazdaniNo ratings yet

- Jmse 09 01450 v3Document20 pagesJmse 09 01450 v3sorenvinNo ratings yet

- Single Liner Shipping Service DesignDocument6 pagesSingle Liner Shipping Service Designmajid yazdaniNo ratings yet

- Valencia ConfDocument6 pagesValencia Confvran77100% (1)

- Omae2015 41020 2Document8 pagesOmae2015 41020 2Arun Kumar PancharajNo ratings yet

- A Transnational Approach of Research Developments in Maritime TransportDocument9 pagesA Transnational Approach of Research Developments in Maritime Transportcristina.cristinaNo ratings yet

- Simulation and Optimisation of Cargo Han PDFDocument10 pagesSimulation and Optimisation of Cargo Han PDFkadaNo ratings yet

- Vessel Eet Optimization For Maintenance Operations at Offshore Wind Farms Under UncertaintyDocument10 pagesVessel Eet Optimization For Maintenance Operations at Offshore Wind Farms Under UncertaintyVipal ChoudharyNo ratings yet

- Determinants of Port Performance - Case Study of FDocument9 pagesDeterminants of Port Performance - Case Study of FWai PhyopaingNo ratings yet

- Systems Modelling For Energy-Efficient ShippingDocument40 pagesSystems Modelling For Energy-Efficient Shippingali trrafNo ratings yet

- WaveNet Full ReportDocument502 pagesWaveNet Full ReportpanicoscribdNo ratings yet

- A Branchandprice Guided Search Approach To Maritime Inventory Routing2013computers and Operations ResearchDocument10 pagesA Branchandprice Guided Search Approach To Maritime Inventory Routing2013computers and Operations Researchmajid yazdaniNo ratings yet

- Jmse 09 00720 v3Document20 pagesJmse 09 00720 v3Roxana Ortega CarrascoNo ratings yet

- Alternative Mixed-Integer Linear Programming Models of A MaritimeDocument26 pagesAlternative Mixed-Integer Linear Programming Models of A Maritimemajid yazdaniNo ratings yet

- 16 SC Performance of Ships in Service 28th ITTC 2017Document55 pages16 SC Performance of Ships in Service 28th ITTC 2017Edson MesquitaNo ratings yet

- DEXTREMEL Final ReportDocument75 pagesDEXTREMEL Final ReportalfavectorNo ratings yet

- Resumo Alargado - Final Version - BUSNARDODocument10 pagesResumo Alargado - Final Version - BUSNARDOKL SimNo ratings yet

- Energy Efficiency MeasuresDocument5 pagesEnergy Efficiency MeasuresHarryNo ratings yet

- Ocean Engineering: J. Calleya, R. Pawling, A. GreigDocument8 pagesOcean Engineering: J. Calleya, R. Pawling, A. GreigMaruf MuhammadNo ratings yet

- Access and EgressDocument13 pagesAccess and EgressVan LianNo ratings yet

- FulltextDocument174 pagesFulltextDavid Omar Torres GutierrezNo ratings yet

- ECDIS ArticleDocument4 pagesECDIS ArticleConrad ManacapNo ratings yet

- Seaside Operations in Container Terminals Literature Overview Trends and Research DirectionsDocument46 pagesSeaside Operations in Container Terminals Literature Overview Trends and Research DirectionsHậu PhạmNo ratings yet

- Ocean Engineering: Malte Riesner, Ould El MoctarDocument14 pagesOcean Engineering: Malte Riesner, Ould El MoctarSahil JawaNo ratings yet

- Velocity and DragDocument12 pagesVelocity and DragAnh NgoNo ratings yet

- Jmse 10 00760Document11 pagesJmse 10 00760abbasNo ratings yet

- Shopera Eedi RinaDocument15 pagesShopera Eedi RinagodfreyreggioNo ratings yet

- Systematic Simulation Methodology - LNG Ship Operations in Port Waters - Meizhou BayDocument33 pagesSystematic Simulation Methodology - LNG Ship Operations in Port Waters - Meizhou Bayjbloggs2007No ratings yet

- Handbook of Ocean Container Transport Logistics - Making Global Supply Chains Effective PDFDriveDocument556 pagesHandbook of Ocean Container Transport Logistics - Making Global Supply Chains Effective PDFDriveMigle Bloom100% (1)

- A New Combined Seakeeping and Manoeuvring BasinDocument12 pagesA New Combined Seakeeping and Manoeuvring BasinibadurrahmanNo ratings yet

- 2021 Fuel Bunker Management Strategies Within Sustainable Container Shipping Operation Considering Disruption and Recovery PoliciesDocument23 pages2021 Fuel Bunker Management Strategies Within Sustainable Container Shipping Operation Considering Disruption and Recovery PoliciesQingji ZhouNo ratings yet

- SPE-38513-MS The Subsea Well Decommissioning ProjectDocument9 pagesSPE-38513-MS The Subsea Well Decommissioning ProjectÓscar MedinaNo ratings yet

- Sustainability 12 03202 v2Document24 pagesSustainability 12 03202 v2tambahahahNo ratings yet

- Green Ports: Inland and Seaside Sustainable Transportation StrategiesFrom EverandGreen Ports: Inland and Seaside Sustainable Transportation StrategiesRating: 5 out of 5 stars5/5 (1)

- Proceedings of the 6th International Workshop on Hydro Scheduling in Competitive Electricity MarketsFrom EverandProceedings of the 6th International Workshop on Hydro Scheduling in Competitive Electricity MarketsArild HelsethNo ratings yet

- Foreword 1991 Dynamics of Fixed Marine StructuresDocument2 pagesForeword 1991 Dynamics of Fixed Marine StructuresjobinhoeljovenNo ratings yet

- Ods 2017 FischDocument34 pagesOds 2017 FischjobinhoeljovenNo ratings yet

- INNWIND Deliverable D5 21Document55 pagesINNWIND Deliverable D5 21jobinhoeljovenNo ratings yet

- Upending of A Monopile For An Offshore Wind Turbine FoundationDocument94 pagesUpending of A Monopile For An Offshore Wind Turbine FoundationjobinhoeljovenNo ratings yet

- Non Linear WavesDocument41 pagesNon Linear WavesjobinhoeljovenNo ratings yet

- Non Linear WavesDocument41 pagesNon Linear WavesjobinhoeljovenNo ratings yet

- Beb TM 69 PDFDocument22 pagesBeb TM 69 PDFjobinhoeljovenNo ratings yet

- Msc. & Mba in Food & Agribusiness Management: Learn - Create - SucceedDocument2 pagesMsc. & Mba in Food & Agribusiness Management: Learn - Create - SucceedjobinhoeljovenNo ratings yet

- 0031 1 FloatoverDocument36 pages0031 1 FloatoverjobinhoeljovenNo ratings yet

- EWEA European Offshore Statistics 2015Document24 pagesEWEA European Offshore Statistics 2015jobinhoeljovenNo ratings yet

- 3 2 03 NorthHoyleWindFarmDocument2 pages3 2 03 NorthHoyleWindFarmjobinhoeljovenNo ratings yet

- EY Offshore Wind in Europe PDFDocument16 pagesEY Offshore Wind in Europe PDFjobinhoeljovenNo ratings yet

- EWEA Wind Energy Scenarios 2030 PDFDocument16 pagesEWEA Wind Energy Scenarios 2030 PDFjobinhoeljovenNo ratings yet

- Floating Offshore Wind Market Technology ReviewDocument168 pagesFloating Offshore Wind Market Technology ReviewjobinhoeljovenNo ratings yet

- Boat Landing Systems-2Document6 pagesBoat Landing Systems-2Guilherme LealNo ratings yet

- GL Iv-6-4 eDocument214 pagesGL Iv-6-4 ejobinhoeljovenNo ratings yet

- Update: DNV Enhances Offshore Class RulesDocument36 pagesUpdate: DNV Enhances Offshore Class RulesjobinhoeljovenNo ratings yet

- Amp2 Impact Loads Without Anti-Surge SystemDocument6 pagesAmp2 Impact Loads Without Anti-Surge SystemjobinhoeljovenNo ratings yet

- Marine FenderDocument56 pagesMarine Fenderjobinhoeljoven100% (1)

- Oil and Gas Update 0113 Tcm4-549016Document36 pagesOil and Gas Update 0113 Tcm4-549016jobinhoeljovenNo ratings yet

- Fenton88 The Numerical Solution of Steady Water Wave ProblemsDocument12 pagesFenton88 The Numerical Solution of Steady Water Wave ProblemsjobinhoeljovenNo ratings yet

- 0028 5 JacketsDocument41 pages0028 5 JacketsjobinhoeljovenNo ratings yet

- Material Coefficients of Structural SteelDocument1 pageMaterial Coefficients of Structural SteelMurat KızılarslanNo ratings yet

- CIVIL 703 - Assignment 1Document2 pagesCIVIL 703 - Assignment 1jobinhoeljovenNo ratings yet

- Oto 99022Document157 pagesOto 99022jobinhoeljovenNo ratings yet

- Oto 99022Document157 pagesOto 99022jobinhoeljovenNo ratings yet

- PolyplexDocument27 pagesPolyplexkunalkakkadNo ratings yet

- Features Description: LTC3608 18V, 8A Monolithic Synchronous Step-Down DC/DC ConverterDocument26 pagesFeatures Description: LTC3608 18V, 8A Monolithic Synchronous Step-Down DC/DC ConverterAhmad SubkhanNo ratings yet

- CDCCL PresentationDocument41 pagesCDCCL Presentationrizcst9759100% (5)

- SI Units and Dimensions: by Prof M BasannaDocument4 pagesSI Units and Dimensions: by Prof M Basannaembi76No ratings yet

- Last Name, First CHE426Document3 pagesLast Name, First CHE426sumitNo ratings yet

- Example Risk Assessment For Motor Vehicle Repair WorkshopDocument11 pagesExample Risk Assessment For Motor Vehicle Repair Workshopaymenmoataz100% (1)

- Kiln Emergency Conditions OkDocument30 pagesKiln Emergency Conditions OkmustafNo ratings yet

- Thermogravimetric Analysis: W. J. P. RedfernDocument19 pagesThermogravimetric Analysis: W. J. P. RedfernKpam SokpoNo ratings yet

- Instrument Transformer.: Y. K. PandharipandeDocument19 pagesInstrument Transformer.: Y. K. Pandharipandeupt vadodaraNo ratings yet

- #5 With Answer RecoverDocument9 pages#5 With Answer Recoverkan limNo ratings yet

- Welding Level C Practice ExamDocument0 pagesWelding Level C Practice ExamStarLink1100% (2)

- 2a - Packed ColumnsDocument55 pages2a - Packed ColumnsDoaa Badarneh100% (1)

- BR Prepump A4 Eng 201106Document12 pagesBR Prepump A4 Eng 201106GrundfosEgyptNo ratings yet

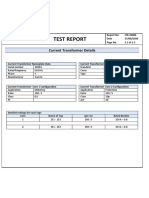

- Test Report: Current Transformer DetailsDocument3 pagesTest Report: Current Transformer DetailsJRC TestingNo ratings yet

- Xlpe CableDocument18 pagesXlpe Cablesopan saNo ratings yet

- Kul-24.3200 Lecture PropII 01aDocument27 pagesKul-24.3200 Lecture PropII 01aLong NguyenNo ratings yet

- Classical Physics Prof. V. Balakrishnan Department of Physics Indian Institute of Technology, Madras Lecture No. # 38Document27 pagesClassical Physics Prof. V. Balakrishnan Department of Physics Indian Institute of Technology, Madras Lecture No. # 38Anonymous 8f2veZfNo ratings yet

- ECE Bubble Power PDFDocument15 pagesECE Bubble Power PDFsachinsdurgadNo ratings yet

- Handbook of Coil Winding: Jürgen Hagedorn Florian Sell-Le Blanc Jürgen FleischerDocument30 pagesHandbook of Coil Winding: Jürgen Hagedorn Florian Sell-Le Blanc Jürgen FleischerAdeebaShaheenNo ratings yet

- Electrical Submersible Pumps DesigningDocument17 pagesElectrical Submersible Pumps Designingdhulfikarfadhil100% (1)

- Mitigation of Internal Corrosion in Sour Gas Gathering SystemsDocument34 pagesMitigation of Internal Corrosion in Sour Gas Gathering SystemsMohamed Wael Zakhama100% (1)

- 2000 4Runner-ECUDocument8 pages2000 4Runner-ECURay67% (3)

- Final Paper Gas Hydrates Around Makassar StraitsDocument6 pagesFinal Paper Gas Hydrates Around Makassar StraitsriowicaksonoNo ratings yet

- GravityLight Description of The Concept and Its RealizationDocument4 pagesGravityLight Description of The Concept and Its RealizationAhmad Fajar HumaidiNo ratings yet

- Exam Survival Guide (Voigt) PDFDocument388 pagesExam Survival Guide (Voigt) PDFJenYerroNo ratings yet

- Solving Overheating: By: Henry P. OlsenDocument9 pagesSolving Overheating: By: Henry P. OlsenAhmed TorkyNo ratings yet

- Centrifugal Pump Training ManualDocument28 pagesCentrifugal Pump Training ManualVegeta saiyanNo ratings yet

- Hukum Stoke - Transport Phenomena Bird Stewart Lightfoot PDFDocument4 pagesHukum Stoke - Transport Phenomena Bird Stewart Lightfoot PDFMAI_AAN_KURNIAWANNo ratings yet

- 998-21327565 DVR Ebro GMADocument24 pages998-21327565 DVR Ebro GMACata CatalinNo ratings yet

- From Lec.1 To Lec.26Document114 pagesFrom Lec.1 To Lec.26Youssry Elsayed MohamedNo ratings yet