Professional Documents

Culture Documents

Runner Blocks Slimline, Steel Version: Runner Block SNS R1622

Uploaded by

Leonardo AlexOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Runner Blocks Slimline, Steel Version: Runner Block SNS R1622

Uploaded by

Leonardo AlexCopyright:

Available Formats

Runner Blocks Slimline, Steel Version

Runner Block SNS

R1622

Slimline Standard

Versions:

– Runner block without ball chain:

for part numbers, see table

– Runner block with low friction seal

without ball chain**:

Part numbers R1622 xxx 21

– Runner block with ball chain:

part numbers R1622 xxx 21

– Runner block with low friction seal

with ball chain**:

Part numbers R1622 xxx 22

Dynamic Characteristics

Speed vmax = 5 m/s

Acceleration amax = 500 m/s2 Size Accuracy Part numbers for runner blocks for preload class

Class C0 C1 C2

Precision Runner Block 15 N R1622 194 20 R1622 114 20 R1622 124 20

H R1622 193 20 R1622 113 20 R1622 123 20

– Pre-lubricated P R1622 112 20 R1622 122 20

20 N R1622 894 20 R1622 814 20 R1622 824 20

Corrosion resistant version H R1622 893 20 R1622 813 20 R1622 823 20

P R1622 812 20 R1622 822 20

– Pre-lubricated 25 N R1622 294 20 R1622 214 20 R1622 224 20

For Resist NR corrosion-resistant Steel H R1622 293 20 R1622 213 20 R1622 223 20

P R1622 212 20 R1622 222 20

runner block, see appropriate section. 30 N R1622 794 20 R1622 714 20 R1622 724 20

For Resist NR II - All corrosion-resistant H R1622 793 20 R1622 713 20 R1622 723 20

steel parts, see appropriate section. P R1622 712 20 R1622 722 20

35 N R1622 394 20 R1622 314 20 R1622 324 20

H R1622 393 20 R1622 313 20 R1622 323 20

P R1622 312 20 R1622 322 20

45* N R1622 494 20 R1622 414 20 R1622 424 20

High Precision Runner Blocks

H R1622 493 20 R1622 413 20 R1622 423 20

– Further improved movement accuracy P R1622 412 20 R1622 422 20

– Superior quality

– Highest precision

– Pre-lubricated Size Accuracy Part numbers for runner blocks for preload class

Class C1 C2 C3

– Minimal oil preservation

15 XP R1622 118 20 R1622 128 20 R1622 138 20

20 XP R1622 818 20 R1622 828 20 R1622 838 20

25 XP R1622 218 20 R1622 228 20 R1622 238 20

30 XP R1622 718 20 R1622 728 20 R1622 738 20

35 XP R1622 318 20 R1622 328 20 R1622 338 20

45* XP R1622 418 20 R1622 428 20 R1622 438 20

Preload Class * No delivery with low friction seal ** Low friction seal available for preload C0 and C1

C0 = without Preload (only for precision classes N, H, XP)

C1 = Preload 2% C

C2 = Preload 8% C

C3 = Preload 13% C

For further technical information, please

see chapter on "General Technical Data

and Calculations".

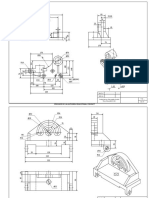

A

E8 B

S9

S2 K2 B2

V1 K3 K4

E9 N3

H1

H

H2

N6

A3 A2

S5

A1

a) For O-ring b) Lube nipple sizes 15 and 20:

Size 15: dia. 4 · 1.0 (mm) funnel-type nipple

a) Size 20-45: dia. 5 · 1.0 (mm) Type A – M3 x 5, DIN 3405

Open lube bore as required. B2 = 1.6 mm

See Accessories: If another lube nipple is used:

K1 Mounting lubrication adapter. observe the screw-in depth of 5 mm!

Size 25 to 45: M6 x 8,

DIN 71412

B1 E2 B2 = 9.5 mm

If another lube nipple is used:

observe the screw-in depth of 8 mm!

Connection possible at all sides.

b)

E1

Dimensions (mm)

Size A A1 A2 A3 B B1 H H1 H21) H22) V1 E1 E2 E8 E9 K1 K2 K3 K4

15 34 17 15 9.5 58.2 39.2 24 19.90 16.30 16.20 5.0 26 26 24.55 6.70 10.00 11.60 3.20 3.20

20 44 22 20 12.0 75.0 49.6 30 25.35 20.75 20.55 6.0 32 36 32.50 7.30 13.80 13.80 3.35 3.35

25 48 24 23 12.5 86.2 57.8 36 29.90 24.45 24.25 7.5 35 35 38.30 11.50 17.45 18.60 5.50 5.50

30 60 30 28 16.0 97.7 67.4 42 35.35 28.55 28.35 7.0 40 40 48.40 14.60 20.00 21.70 6.05 6.05

35 70 35 34 18.0 110.5 77.0 48 40.40 32.15 31.85 8.0 50 50 58.00 17.35 20.50 22.00 6.90 6.90

45 86 43 45 20.5 137.6 97.0 60 50.30 40.15 39.85 10.0 60 60 69.80 20.90 27.30 29.30 8.20 8.20

1) Dimension H2 with rail seal cover strip 2) Dimension H2 without rail seal cover strip

Load Capacities (N)3) Moments (Nm)

Dimensions (mm) Mass C C0 Mt Mt0 ML ML0

Size N3 N6±0.5 S2 S5 S9 (kg) dyn. stat. dyn. stat. dyn. stat.

15 6.0 10.3 M4 4.4 M2.5-3.5 deep 0.15 7 800 13 500 74 130 40 71

20 7.5 13.2 M5 6.0 M3-5 deep 0.35 18 800 24 400 240 310 130 165

25 9.0 15.2 M6 7.0 M3-5 deep 0.50 22 800 30 400 320 430 180 240

30 12.0 17.0 M8 9.0 M3-5 deep 0.85 31 700 41 300 540 720 290 380

35 13.0 20.5 M8 9.0 M3-5 deep 1.25 41 900 54 000 890 1 160 440 565

45 18.0 23.5 M10 14.0 M4-7 deep 2.40 68 100 85 700 1 830 2 310 890 1 130

3) Load capacities for version without ball chain. Load capacities for version with ball chain, see Product Overview with Load Capacities.

Determination of the dynamic of the load capacities and moments is based on 100,000 m of stroke travel. Often only 50,000 m are actually

stipulated. Comparison: Value C, Mt und ML per table multiplied by 1.26.

You might also like

- DX Blame Mkii Supercharged SchematicDocument1 pageDX Blame Mkii Supercharged SchematicRodrigo Negrelli100% (1)

- UNI-750-1 Schematic Control - G PDFDocument2 pagesUNI-750-1 Schematic Control - G PDFhigttech solution100% (1)

- Krankosa Ver3.1Document4 pagesKrankosa Ver3.1Vina PropertyNo ratings yet

- Contoh Exposition TextDocument1 pageContoh Exposition TextKristin SeranNo ratings yet

- Borges, The SouthDocument4 pagesBorges, The Southdanielg233100% (1)

- HUMSS - Introduction To World Religions & Belief Systems CGDocument13 pagesHUMSS - Introduction To World Religions & Belief Systems CGAliuqus SirJasper89% (18)

- Ej. 1 Fin CorpDocument3 pagesEj. 1 Fin CorpChantal AvilesNo ratings yet

- Bosch Rexroth Runner Blocks Type 1622 CatalogDocument4 pagesBosch Rexroth Runner Blocks Type 1622 CatalogBudy GedhaBlackNo ratings yet

- 12V Simple Single Supply Amp - BindDocument14 pages12V Simple Single Supply Amp - BindArlene B. NoceteNo ratings yet

- Crown Xls x6ftDocument1 pageCrown Xls x6ftHiển Amplier100% (4)

- 2x Gain BTL With 2 Pcs Transistor: Main Supply 1x GAIN R13 18K 2x GAIN R13 4K7Document2 pages2x Gain BTL With 2 Pcs Transistor: Main Supply 1x GAIN R13 18K 2x GAIN R13 4K7mdeky20No ratings yet

- Drawing3 ModelDocument1 pageDrawing3 Modeldibyendum013No ratings yet

- Machin Drawing With CADDocument29 pagesMachin Drawing With CADBerihu GirmayNo ratings yet

- 2t FRQDocument1 page2t FRQMamad SoheNo ratings yet

- Drawing3 ModelDocument1 pageDrawing3 Modeldibyendum013No ratings yet

- 11ak57 CRT Board 004.sht: TV R&D Group Vestel ElectronicsDocument4 pages11ak57 CRT Board 004.sht: TV R&D Group Vestel ElectronicsdasdNo ratings yet

- UcD 10w NoB v1Document1 pageUcD 10w NoB v1Leegh Lungset MbesesetNo ratings yet

- Universal Complete Book (With Assembly)Document37 pagesUniversal Complete Book (With Assembly)herohai8881No ratings yet

- 50 2d Cad Exercises PDFDocument50 pages50 2d Cad Exercises PDFrichardkwofieNo ratings yet

- Autobahn: FX Type: Auto-WahDocument3 pagesAutobahn: FX Type: Auto-WahFooNo ratings yet

- PS 001Document1 pagePS 001Harun ARIKNo ratings yet

- Decimator G String ENGDocument6 pagesDecimator G String ENGАлексей КурниковNo ratings yet

- Amp Expandible PDFDocument21 pagesAmp Expandible PDFCarlos VasquezNo ratings yet

- V-F / F-V Convertor: General Description Package OutlineDocument14 pagesV-F / F-V Convertor: General Description Package OutlineIlyes KHOUILDINo ratings yet

- PDF 2Document1 pagePDF 2Tyson GamingNo ratings yet

- Tabulasi Rev AriDocument8 pagesTabulasi Rev AriAriNo ratings yet

- 国际39M混凝土泵车卖点介绍Specification & Advantages of SYG39Document30 pages国际39M混凝土泵车卖点介绍Specification & Advantages of SYG39Alex MazaNo ratings yet

- GE 7 Graphic Equalizer ENGDocument4 pagesGE 7 Graphic Equalizer ENGBabarNo ratings yet

- Australian-Monitor Amis120p cd6338-2 Rev.e PWR Amplifier SCHDocument1 pageAustralian-Monitor Amis120p cd6338-2 Rev.e PWR Amplifier SCHal hakimNo ratings yet

- Iii-Ii Final PDFDocument44 pagesIii-Ii Final PDFChinsdazz KumarNo ratings yet

- Spain 1500 Diagrama DriverDocument1 pageSpain 1500 Diagrama DriverManoj JainNo ratings yet

- Bal Card Schematic PDFDocument1 pageBal Card Schematic PDFHelder Fernandes FonsecaNo ratings yet

- Apex Ax14 SCH (Et)Document2 pagesApex Ax14 SCH (Et)Astom KumarNo ratings yet

- Apex Ax14 SCHDocument2 pagesApex Ax14 SCHHamass ShofwanuddinNo ratings yet

- Apex Ax14 SCH PDFDocument2 pagesApex Ax14 SCH PDFNam TàoNo ratings yet

- Apex Ax14 SCH PDFDocument2 pagesApex Ax14 SCH PDFOnesimus Tozeyana100% (1)

- APEX AXffffffffff PDFDocument2 pagesAPEX AXffffffffff PDFAurelio Moreno100% (1)

- User Manual - Panel LVMDP PT - YGIDocument20 pagesUser Manual - Panel LVMDP PT - YGIAhmad Hasby SyahirNo ratings yet

- Mad Prof Snow White Autowah PCB Layout 1Document1 pageMad Prof Snow White Autowah PCB Layout 1sugenkNo ratings yet

- Small Clone Chorus ENGDocument3 pagesSmall Clone Chorus ENGtofu157No ratings yet

- 2-2 Internal MarksDocument85 pages2-2 Internal Marksbalu56kvNo ratings yet

- DX Blame ST LayoutDocument1 pageDX Blame ST LayoutAntonio C C manzano100% (1)

- Medidor Esr A Transistores: Title: Rev: Date: Sheet: Easyeda V4.11.9 Drawn byDocument1 pageMedidor Esr A Transistores: Title: Rev: Date: Sheet: Easyeda V4.11.9 Drawn byMemoPalacioNo ratings yet

- Medidor Esr A Transistores: Title: Rev: Date: Sheet: Easyeda V4.11.9 Drawn byDocument1 pageMedidor Esr A Transistores: Title: Rev: Date: Sheet: Easyeda V4.11.9 Drawn byManos MagicasNo ratings yet

- Medidor Esr A Transistores: Title: Rev: Date: Sheet: Easyeda V4.11.9 Drawn byDocument1 pageMedidor Esr A Transistores: Title: Rev: Date: Sheet: Easyeda V4.11.9 Drawn byMemoPalacioNo ratings yet

- VinothDocument1 pageVinothminions kumarNo ratings yet

- Tone Control Sansui AU5500Document1 pageTone Control Sansui AU5500chliez07No ratings yet

- 18Y10-B-300 T1 18Y10-A-300 T1: Software Consultants (Pty) LTDDocument1 page18Y10-B-300 T1 18Y10-A-300 T1: Software Consultants (Pty) LTDnadher albaghdadiNo ratings yet

- Amplificador Atlanta: Title: Rev: Sheet: Drawn By: CompanyDocument1 pageAmplificador Atlanta: Title: Rev: Sheet: Drawn By: CompanyRoberto DiazNo ratings yet

- Lista de Materiales Del Entrenador V12Document3 pagesLista de Materiales Del Entrenador V12Urdaneta J. ManuelNo ratings yet

- Portable SCR106PD-SCR126PDDocument1 pagePortable SCR106PD-SCR126PDkwstdbjp5fNo ratings yet

- Katalog Aksesoris 2021 ROCKY D 55 Rev.2Document3 pagesKatalog Aksesoris 2021 ROCKY D 55 Rev.2Jose GuardiolaNo ratings yet

- Crescendo - Improved VersionDocument1 pageCrescendo - Improved VersionFanOfDanNo ratings yet

- Conversao Racor Filtro Separador AguaDocument3 pagesConversao Racor Filtro Separador AguaRICHARD RONALD SchneiderNo ratings yet

- NHT Nokian Logger King LS-2 ENDocument2 pagesNHT Nokian Logger King LS-2 ENmauricio1barrientos1No ratings yet

- 6b. Rib - Shell - Hole (Homework)Document4 pages6b. Rib - Shell - Hole (Homework)Tấn ngọc TriệuNo ratings yet

- Small StoneDocument2 pagesSmall StoneAlvaro MesquitaNo ratings yet

- IndroidDocument197 pagesIndroidAuto LED Light VSNo ratings yet

- SOCL-504 Modded Ver.1Document2 pagesSOCL-504 Modded Ver.1gjy56pbgr8No ratings yet

- Exdc Solution: Ganeshkumar Me Engine Er SCALE-1:1 S He Et-A2 Mat Erial-Cast Iron G Rade - A1 AlldinmmDocument1 pageExdc Solution: Ganeshkumar Me Engine Er SCALE-1:1 S He Et-A2 Mat Erial-Cast Iron G Rade - A1 AlldinmmGanesh kumarNo ratings yet

- 20170710100925-Lubricating Oil Purifier NAKINDocument8 pages20170710100925-Lubricating Oil Purifier NAKINAntonioAriasNo ratings yet

- Manitowoc Cff-90 PartsDocument13 pagesManitowoc Cff-90 PartsDaren FerreiraNo ratings yet

- 6200 Series Deep Groove Radial Ball BearingsDocument3 pages6200 Series Deep Groove Radial Ball BearingsJulian Patricio OrtegaNo ratings yet

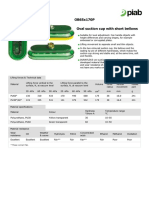

- OB65 X 170 PDocument2 pagesOB65 X 170 PLeonardo AlexNo ratings yet

- Detailed Drawing Exercises: Solidworks EducationDocument51 pagesDetailed Drawing Exercises: Solidworks EducationLeonardo AlexNo ratings yet

- R1651Document4 pagesR1651Leonardo AlexNo ratings yet

- Bosch PDFDocument2 pagesBosch PDFLeonardo AlexNo ratings yet

- Life of Festo Products BrochureDocument7 pagesLife of Festo Products BrochureLeonardo AlexNo ratings yet

- 172 Kg. 379 LBS.: Dowels Ø 10 MM Depth 20 MM by The Customer Dowels Ø 12 MM Depth 25 MM by The CustomerDocument1 page172 Kg. 379 LBS.: Dowels Ø 10 MM Depth 20 MM by The Customer Dowels Ø 12 MM Depth 25 MM by The CustomerLeonardo AlexNo ratings yet

- C1225-125-5000-M: Round WireDocument1 pageC1225-125-5000-M: Round WireLeonardo AlexNo ratings yet

- C1225-125-5000-M: Round WireDocument1 pageC1225-125-5000-M: Round WireLeonardo AlexNo ratings yet

- Series: SpecificationsDocument1 pageSeries: SpecificationsLeonardo AlexNo ratings yet

- Positioning Bushings: With Collar EH 23112Document3 pagesPositioning Bushings: With Collar EH 23112Leonardo AlexNo ratings yet

- Crossed Roller Bearings: For High Precision ApplicationsDocument67 pagesCrossed Roller Bearings: For High Precision ApplicationsLeonardo AlexNo ratings yet

- Fanuc M 900ia SeriesDocument4 pagesFanuc M 900ia SeriesLeonardo AlexNo ratings yet

- BoschDocument2 pagesBoschLeonardo AlexNo ratings yet

- Series: ISO/VDMA CylinderDocument50 pagesSeries: ISO/VDMA CylinderLeonardo AlexNo ratings yet

- 3HAC026876-001 Revc enDocument443 pages3HAC026876-001 Revc enLeonardo AlexNo ratings yet

- (Example: CSP02-C) : Thread WDocument2 pages(Example: CSP02-C) : Thread WLeonardo AlexNo ratings yet

- Project - Scarab - A Collector RobotDocument16 pagesProject - Scarab - A Collector RobotLeonardo AlexNo ratings yet

- Project - Introduction Robotics Project #2Document2 pagesProject - Introduction Robotics Project #2Leonardo AlexNo ratings yet

- Tangerine - Breakfast Set Menu Wef 16 Dec UpdatedDocument3 pagesTangerine - Breakfast Set Menu Wef 16 Dec Updateddeveloper louNo ratings yet

- ABARI-Volunteer Guide BookDocument10 pagesABARI-Volunteer Guide BookEla Mercado0% (1)

- D&D 5.0 Combat Reference Sheet Move Action: Interact With One Object Do Other Simple ActivtiesDocument2 pagesD&D 5.0 Combat Reference Sheet Move Action: Interact With One Object Do Other Simple ActivtiesJason ParsonsNo ratings yet

- 11.3.1 Some Special CasesDocument10 pages11.3.1 Some Special CasesSiddharth KishanNo ratings yet

- 18-MCE-49 Lab Session 01Document5 pages18-MCE-49 Lab Session 01Waqar IbrahimNo ratings yet

- 02 Object Modeling TechniqueDocument50 pages02 Object Modeling TechniqueMuhammad Romadhon Batukarang EsdNo ratings yet

- Mathmatcs Joint Form TwoDocument11 pagesMathmatcs Joint Form TwoNurudi jumaNo ratings yet

- Caring For Women Experiencing Breast Engorgement A Case ReportDocument6 pagesCaring For Women Experiencing Breast Engorgement A Case ReportHENINo ratings yet

- SP-Chapter 14 PresentationDocument83 pagesSP-Chapter 14 PresentationLoiDa FloresNo ratings yet

- Plastic Properties HandbookDocument15 pagesPlastic Properties HandbookguilloteARGNo ratings yet

- Smartfind E5 g5 User ManualDocument49 pagesSmartfind E5 g5 User ManualdrewlioNo ratings yet

- 2500 Valve BrochureDocument12 pages2500 Valve BrochureJurie_sk3608No ratings yet

- LP32HS User Manual v1Document52 pagesLP32HS User Manual v1tonizx7rrNo ratings yet

- DIR-819 A1 Manual v1.02WW PDFDocument172 pagesDIR-819 A1 Manual v1.02WW PDFSerginho Jaafa ReggaeNo ratings yet

- Wealth and Poverty in The Book of Proverbs PDFDocument133 pagesWealth and Poverty in The Book of Proverbs PDFMaahes Cultural Library100% (1)

- Work Breakdown StructureDocument8 pagesWork Breakdown StructurerenshagullNo ratings yet

- D25KS Sanvick PDFDocument4 pagesD25KS Sanvick PDFJiménez Manuel100% (1)

- J.K. Brimacombe - Design of Continuous Casting MachinesDocument13 pagesJ.K. Brimacombe - Design of Continuous Casting MachinesJavier GómezNo ratings yet

- 4.2.4.5 Packet Tracer - Connecting A Wired and Wireless LAN InstructionsDocument5 pages4.2.4.5 Packet Tracer - Connecting A Wired and Wireless LAN InstructionsAhmadHijaziNo ratings yet

- ISA InTech Journal - April 2021Document50 pagesISA InTech Journal - April 2021Ike EdmondNo ratings yet

- SW OSDocument11 pagesSW OSErnest OfosuNo ratings yet

- Traditional Perceptions and Treatment of Mental Illness in EthiopiaDocument7 pagesTraditional Perceptions and Treatment of Mental Illness in EthiopiaifriqiyahNo ratings yet

- 2nd Term Project 4º Eso Beauty Canons 2015-16 DefinitivoDocument2 pages2nd Term Project 4º Eso Beauty Canons 2015-16 DefinitivopasferacosNo ratings yet

- Origin ManualDocument186 pagesOrigin ManualmariaNo ratings yet

- Is 2 - 2000 Rules For Rounded Off For Numericals PDFDocument18 pagesIs 2 - 2000 Rules For Rounded Off For Numericals PDFbala subramanyamNo ratings yet

- Hanwha Q Cells Data Sheet Qpeak L-g4.2 360-370 2017-10 Rev02 NaDocument2 pagesHanwha Q Cells Data Sheet Qpeak L-g4.2 360-370 2017-10 Rev02 NazulfikarNo ratings yet