Professional Documents

Culture Documents

PC200-6 MAIN PUMP TEST (94999 Up) SEBH537361 - 10678

Uploaded by

PHÁT NGUYỄN THẾ100%(7)100% found this document useful (7 votes)

738 views14 pagesKOMATSU main pump

Original Title

PC200-6 MAIN PUMP TEST (94999 up) SEBH537361_10678

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentKOMATSU main pump

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(7)100% found this document useful (7 votes)

738 views14 pagesPC200-6 MAIN PUMP TEST (94999 Up) SEBH537361 - 10678

Uploaded by

PHÁT NGUYỄN THẾKOMATSU main pump

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 14

‘SEBH537361

10f 14

TESTING METHODS

FOR REBUILT UNITS

DRAFT No. KIPFP97-002

(Tokyo internal use only}

PROCEDURE

oo

APPLICATION

es

KIND OF PPM ‘MAINPUMP |

There are many cases where the PPM units of above Model are

mounted on other Machine Models and the applicable STANDARD

VALUE varies depending on the case but note that the TESTING

PROCEDURE and DIMENSIONS OF TEST PIECE are applicable in

common to most of the cases as above.

Therefore, the applicable Machine Model and Part No. described in

the table below become effective only at the time when the table is

prepared and may often be subject to change without notice.

MACHINE MODEL PART No.

PC200-6 #94999 and up

PC210-6 #30916 and up

PC220-6 #52741 and up

PC230-6 #10169 and up 708-2L-00422

708-21-00412

PC228UU-1 #10022 and up 708-21-00431

Note: The Machine Models in the LIST OF FORM No.s are applicable even if not described in

this procedure.

_FILING INSTRUCTIONS:

+ FILE THIS SEQUENTLY BY FORM No. in the separator 3

KOMATSU eo

PROCEDURE Bacay sense

MAIN PUMP Dot at

1. INTRODUCTION 2) Test Specification

(1) Oil Pressure (Maximum Pressure)

1) This manual describes mainly the test proce: Standard value test: 34.3 MPa(350 kg/cm?)

dures for which the test stand KHT75 or its Converted value test : 34.3 MPa(350 kg/cm?)

equivalent is used. (2) Flow Rate (Maximum)

2) This manual is common to PC200-6 Series Standard value test: 212 &/min, approx.

(m/c) and PC220-6 Series (m/c) as well. Converted value test : 159 L/min. approx.

‘ Theoretical delivery Maximum :105cc/rev.

2. SCOPE Minimum : 13cc/rev.

(3) Revolution per minute

This manual applies to quality confirmation test of, Standard value test: 2000rpm

reproduced ones of hydraulic piston pump Converted value test : 1500rpm

HPV95+95 (corresponding to 105+108cc/rev.) as~

sembly for CLSS mounted on the following ma-

chines (PC200-6 Series and PC220-6 Series)

1) Sample Specification

See Table 2-1

Table 2-1. Sample Specifications

Samples HPV95+95 (Corresponding to 105+105cc/rev.)

Machines on which

samples are mounted | PC200-6 Seri

(mic) | PC220-6 Series (m/c) Pc228UU-1

Item Nos, 708-21-00412 708-21-00422 708-2L-00431

C2006: #94999 and up| PC220-6: #52741 and up | PC228UU-1 =#10022 and up

‘Applicable Serial Nos. | PC200L.C-6: #94999 and up| PC220LC-6: #52741 and up

PC210-8: #30196 and up| PC220-8: #10169 and up

| Pc210LC-6: #30196 and up| PC230LC-6: #10169 and up

3. TEST ITEMS

Table 3-1. List of Test Items

Test items Performance test of piston pump

LS contol eh

furning:in | Flow measurement | PC contro characteristic test |S Conte cha

~ || Fine

taximum|Minimum| H mode mote mode | Normal | control

Test classification Maxiemar Hmode | Smote | Lmode | "moge. | contr

5 7 a Jo

Standord value test ° ° o | o | *o | o

Converted valve test ° o[ of] of] o] a

. “tached | Attached] Attached | Atached | Atached | tached | Atached | Atached

Applicable crcut diagram | Growing t_|Orawing i[Drawing 1) Drawing 1] Drawing 1 [Drawing 1 Drawing 2 Drawing 2

x @ Test items marked with A are partly omitted due to the capacity of the hydraulic test stand

KHT75,

© For the test item marked with *, check if the filter is clogged. (The converted value test is not

possible and this check is omitted.) So, be sure to clean or replace the filter after the end of the

test.

4. FUNCTIONS AND CONDITIONS OF SAMPLES

See Attached Table 1.

PROCEDURE

IP ‘SEBHS37361

MAIN PUMP: 3of 14

5. EQUIPMENT, DEVICES AND JIGS FOR TEST

1) Applicable Bench

(1) Converted Value Test

Komatsu General Purpose Hydraulic Test Stand KHT7S or its equivalent

(2) Standard Value Test

Hydraulic test stand with the same capacity as a test stand in production factory or its equivalent

+ Applicable oil shall be Komatsu genuine engine oil SAE10W-CD or its equivalent, and oil contamina-

tion level shall be controlled to NAS Class 10 during the test.

2) Applicable Devices

Prepare devices listed in Table 5-1.

Table 5-1. List of Devices

aves] tem Nos Measuring positions, Uses

Pvc tem NeS 4) | temmames | ay | Specication ng positios

yes 0vs120 | Gauge = | 0-302 Pato kgiems) | Pom outlet (PAL, LS pressure

sre PLSl. Conol pressure

_ Gatection see tl

798-101-5130 Gauge 1 | 0-5.9 MPa(60 kgiem*) EPC source pressure pick-up

e bree (CEP) Pump suction area

3 Drainores

& = Gauge 2 | 0-0 waa Kaiemm

3 | veeaorzr00 | Oilerntiat | + ser| 098.0 Po 00 salon [Power source (or allover

é pressure gauge ° prea ge eatecn ume

Eccput (pal and US prosoure

799-401.2000 | Transformer unit Input power source oueou

1OOVAC, (Pcsh

utp power sourc

‘zvoc

‘G700-823060 | convo 2 | iter signal aon For PC valve ond 8 vaWve

Wodie “so mApp | solenoid signala

o700582.0800 2. | input curent 0014

FSC780 Flowmeter Working presaure mean Scen Tae

2ORM-100, Flow indicator Shea sokgFem

| Measured tow

Iproduced by Flow 3 to 100 hin

| Thine!

3 Pants crea ~

2 (Thread: | Stop valve 1 | Working pressure For generating LS differential

PT se") 34.3MPa (350kg/cm’) min, | pressure ($1)

Ihirose Vatve Maximum flow : 20min

Indust

Set pressure 4 3Pa

reopte-140%60 | Relieve 2 ajataMee [torte vave

[Uchida Oil Hydrau: | canane |

Ties Industry) 760 flmins min

@ The controller marked with © is used to operate PC and LS valves.

®

@

Prepared two sets of them

Other devices are the same as those for the test of pump HPV95495.

For installation of pressure gauges and devices, see the hydraulic circuit diagrams (Attached

Drawings 1 and 2)

For devices marked with %, the maker types are shown and the maker names are in[ ]. These

devices are not supplied. (Item numbers are not registered.) So, select any maker's equivalents

satisfying the specifications

You might also like

- Technical Manual: ExcavatorDocument129 pagesTechnical Manual: ExcavatorPHÁT NGUYỄN THẾ100% (1)

- 390F UENR64560001 Hydraulic Circuit REVDocument11 pages390F UENR64560001 Hydraulic Circuit REVPHÁT NGUYỄN THẾNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document35 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Eduardo SantanaNo ratings yet

- MARK 8 X-Mode New Starting ModeDocument1 pageMARK 8 X-Mode New Starting ModePHÁT NGUYỄN THẾNo ratings yet

- Press Sensor ChangeDocument1 pagePress Sensor ChangePHÁT NGUYỄN THẾNo ratings yet

- Manitou 180 ATJ (EURO 3) Electric CircuitDocument11 pagesManitou 180 ATJ (EURO 3) Electric CircuitPHÁT NGUYỄN THẾNo ratings yet

- Komatsu Construction ICT 163-E-02Document6 pagesKomatsu Construction ICT 163-E-02edotecNo ratings yet

- Sk115 Sk235sr-1e - sk170 Sk480-6e Auto Idle Stop Time AdjustDocument2 pagesSk115 Sk235sr-1e - sk170 Sk480-6e Auto Idle Stop Time AdjustPHÁT NGUYỄN THẾ0% (1)

- KOMTRAX BrochureDocument8 pagesKOMTRAX BrochurePHÁT NGUYỄN THẾNo ratings yet

- PC240 PC290 Apr2011Document1 pagePC240 PC290 Apr2011PHÁT NGUYỄN THẾNo ratings yet

- Sk210-8 Engine Starter Do Not WorkDocument1 pageSk210-8 Engine Starter Do Not WorkPHÁT NGUYỄN THẾNo ratings yet

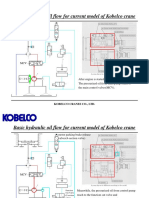

- Basic Hydraulic Oil Flow For Curent Model of Kobelco CraneDocument79 pagesBasic Hydraulic Oil Flow For Curent Model of Kobelco CranePHÁT NGUYỄN THẾ100% (2)

- Subject: Page 1 of 17Document17 pagesSubject: Page 1 of 17PHÁT NGUYỄN THẾ100% (1)

- Subject: Page 1 of 17Document17 pagesSubject: Page 1 of 17PHÁT NGUYỄN THẾ100% (1)

- BM800HD 2F BrochureDocument8 pagesBM800HD 2F BrochurePHÁT NGUYỄN THẾNo ratings yet

- KOMATSU Excavator Detail ExplainingDocument8 pagesKOMATSU Excavator Detail ExplainingPHÁT NGUYỄN THẾNo ratings yet

- Principle of Synchcronous MotorDocument3 pagesPrinciple of Synchcronous MotorPHÁT NGUYỄN THẾNo ratings yet

- E Service InstructionsDocument17 pagesE Service InstructionsPHÁT NGUYỄN THẾ0% (1)

- KOMATSU Excavator Detail ExplainingDocument6 pagesKOMATSU Excavator Detail ExplainingPHÁT NGUYỄN THẾNo ratings yet

- E3170015BDocument44 pagesE3170015BPHÁT NGUYỄN THẾ100% (1)

- Subject: Page 1 of 8Document8 pagesSubject: Page 1 of 8PHÁT NGUYỄN THẾ100% (1)

- Subject: Page 1 of 57Document57 pagesSubject: Page 1 of 57PHÁT NGUYỄN THẾNo ratings yet

- Subject: Page 1 of 7Document7 pagesSubject: Page 1 of 7PHÁT NGUYỄN THẾNo ratings yet

- EskavatorDocument6 pagesEskavatorYasri AcciNo ratings yet

- Torque Conveter TA22-42E Training TextDocument8 pagesTorque Conveter TA22-42E Training TextPHÁT NGUYỄN THẾNo ratings yet

- EskavatorDocument6 pagesEskavatorYasri AcciNo ratings yet

- KOMATSU Excavator Detail ExplainingDocument6 pagesKOMATSU Excavator Detail ExplainingPHÁT NGUYỄN THẾNo ratings yet

- EskavatorDocument6 pagesEskavatorYasri AcciNo ratings yet

- 151-09 - E KomatsuDocument6 pages151-09 - E Komatsuthierrylindo100% (8)

- EskavatorDocument6 pagesEskavatorYasri AcciNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)